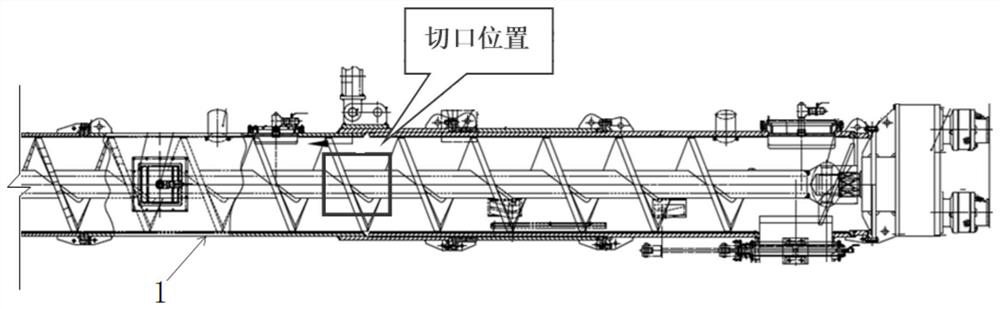

Quick treatment method for jam of shield screw conveyer and pile casing

A technology of shield spiral and processing method, which is applied in the direction of earth cube drilling, mining equipment, mining equipment, etc., can solve problems such as difficulty in ensuring the safety of construction personnel, affecting the design of shield intervals, and taking a long time, so as to improve shield tunneling. The construction efficiency of the structure, the plugging method is simple and easy, and the effect of reducing the operation risk

Active Publication Date: 2020-11-13

CHINA UNIV OF MINING & TECH (BEIJING) +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the existing technology, it is time-consuming and labor-intensive to clean the debris by manually entering the soil bin or the exit of the screw machine, and it is difficult to ensure the safety of the construction personnel. Or adding a sleeve to separate the gravel, clay, etc. It also takes a long time. Once the shutdown time is long, it will not only affect the construction period, but also cause the shield machine to sink when the geological conditions are relatively bad, which will affect the original line design of the shield section, and the cost will be even greater.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific example

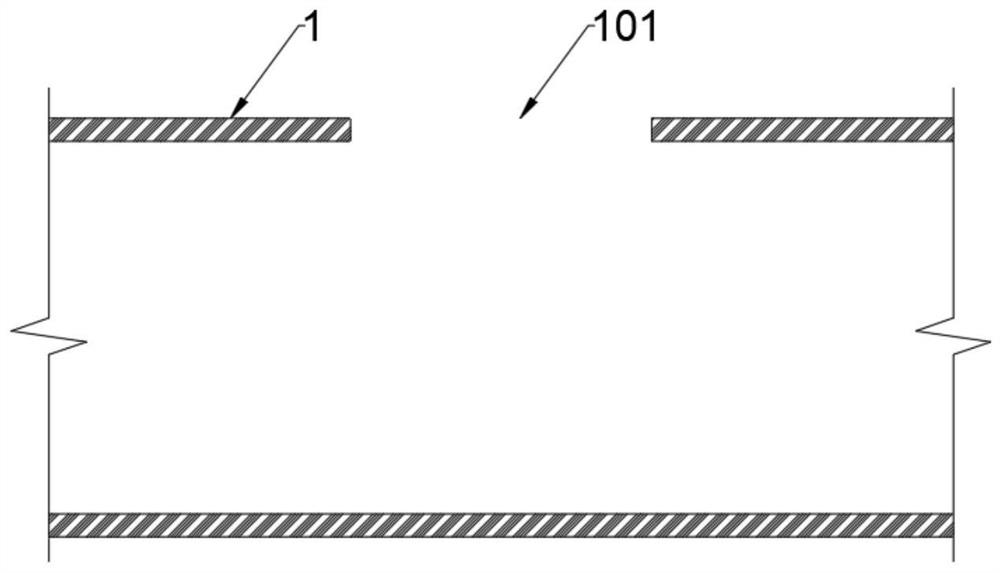

[0096] As a specific example, the thickness of the gasket is 5-10 mm, and the thickness of each wear-resistant composite steel plate is 12-15 mm.

[0097] As a specific example, the second bolt hole 207 has a through hole and a countersunk hole, and the countersunk hole can accommodate the nut of the bolt 205, so that the top surface of the bolt 205 is flush with the top surface of the connecting plate 204 after installation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

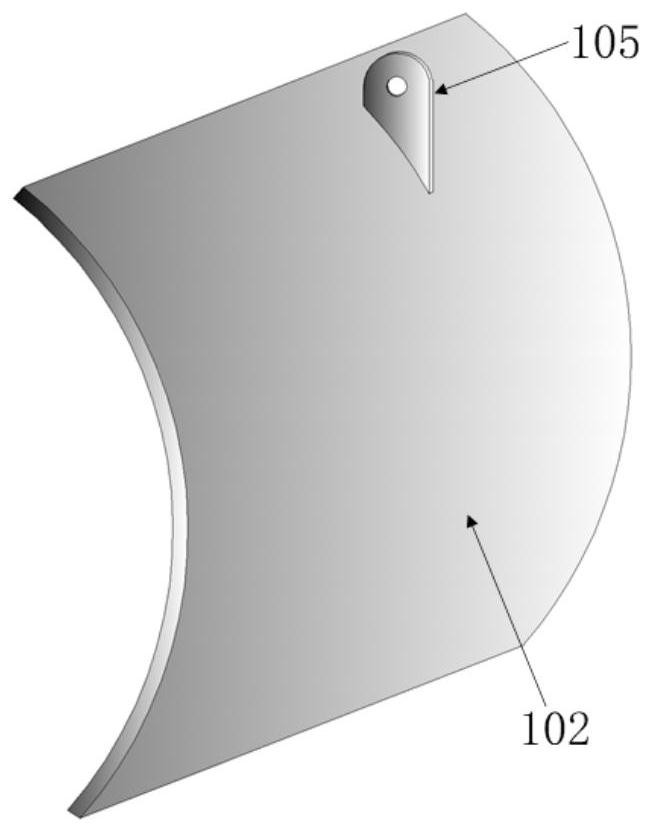

The invention provides a quick treatment method for jam of a shield screw conveyer. The method comprises the following steps of S10, determining a jam area; S20, determining a cut dimension in the jamarea and cutting the pile casing to form an overhaul cut, and cleaning a jam foreign matter in the screw conveyer through the cut; S30, finishing cleaning; and S40, closing the cut again by using a cut plate. According to the quick treatment method for jam of the shield screw conveyer, based on original inspection, an opening of a certain specification is cut in a proper position in a side surface of the pile casing of the screw conveyor, gravels and lonestones inside are cleaned, and finally, the cut is welded and closed again. The quick treatment method prevents a worker from cleaning the inside directly, so that the operation risk of constructors is reduced greatly, the treatment efficiency is high, and the problem of project delay caused by jam is solved well. The plugging method is simple and feasible, can solve emergencies ruly, efficiently and safely in coping with a contingency plan, is of certain guiding significance to existing shield construction, and is worth being popularized.

Description

Technical field [0001] The invention relates to the technical field of shield construction of underground tunnels, in particular to a quick processing method and a protecting tube of a shield screw conveyor. technical background [0002] Shield machine, as the pioneer of urban subway construction, has become the primary construction method of underground tunnel construction in China because of its high degree of mechanization, fast tunneling speed and little disturbance to stratum. The composition of shield machine is complex. As an integral part of shield machine, screw conveyor can discharge the muck in the silo on the one hand, so that the shield can move forward continuously in the stratum. On the other hand, it can control the pressure at the bottom of the conveyor, maintain the earth pressure balance on the shield excavation face, and ensure the normal tunneling of shield machine. It plays an important role. At the same time, our country has a vast territory. When shield tu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21D9/12E21D9/06E21F17/00

CPCE21D9/06E21D9/124E21F17/00

Inventor 江华王春河王太平熊云超郑尧夫尹清锋韩维畴

Owner CHINA UNIV OF MINING & TECH (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com