Preparation method of novel thermochromic printing ink

A thermochromic ink technology, applied in inks, household utensils, applications, etc., can solve the problems of thermochromic inks that do not meet environmental protection requirements, poor adhesion and friction resistance, and need to improve discoloration sensitivity, so as to achieve easy implementation , good hiding power and high sensitivity to discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

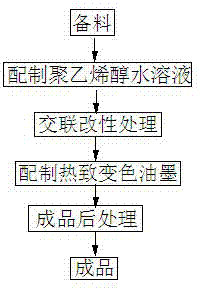

Image

Examples

Embodiment 1

[0016] The specific preparation method of the novel thermochromic ink mentioned here is as follows:

[0017] a) Preparation of materials, the main components of the ink and their parts ratio are: 53 parts of linking material, 1.5 parts of crosslinking agent, 40 parts of heat-absorbing and reversible discoloration pigment, 5.5 parts of defoaming agent; polyvinyl alcohol is selected as linking material Resin powder, its polymerization degree is 1700, alcoholysis degree is 88%; Cross-linking agent selects boric acid solution; 7um;

[0018] b) Prepare polyvinyl alcohol aqueous solution, the preparation process is as follows: First, add polyvinyl alcohol resin powder and deionized water to the mixing tank according to the mass percentage of 1:10, seal it and place it for 48 hours to fully swell the polyvinyl alcohol particles Then, heat the mixing tank to 90°C, control the speed at 200r / min, and stir evenly for 2 hours to obtain a uniform sol-like material; finally, slowly cool th...

Embodiment 2

[0023] The specific preparation method of the novel thermochromic ink mentioned here is as follows:

[0024] a) Preparation of materials, the main components of the ink and their parts ratio are: 52 parts of linking material, 2 parts of crosslinking agent, 41 parts of thermal achromatic reversible color pigment, 5 parts of defoaming agent; the linking material is polyvinyl alcohol Resin powder, its polymerization degree is 1700, alcoholysis degree is 88%; Cross-linking agent selects boric acid solution; 7um;

[0025] b) Prepare polyvinyl alcohol aqueous solution, the preparation process is as follows: First, add polyvinyl alcohol resin powder and deionized water to the mixing tank according to the mass percentage of 1:10, seal it and place it for 50 hours to fully swell the polyvinyl alcohol particles Then, heat the mixing tank to 85°C, control the speed at 220r / min, and stir evenly for 1.5 hours to obtain a uniform sol-like material; finally, slowly cool the material in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com