Manufacturing method of panel of microwave oven chamber

A manufacturing method and technology of a microwave oven, applied in the field of food machinery, can solve the problems of increasing the preparation cost of the oven chamber, high preparation cost, and poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

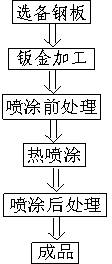

[0017] The specific preparation process of the manufacturing method of the microwave oven cavity panel mentioned in the present invention is as follows:

[0018] a) Select the steel plate. The material of the steel plate is 45 steel. The preparation process includes casting, forging and rolling. The thickness of the selected steel plate is about 1.2mm; the above steel plate has good strength, plasticity and microwave reflection performance, and its price is lower than that of stainless steel. , which can effectively control the preparation cost;

[0019] b) Sheet metal processing, this process includes cutting, punching, folding, trimming, bending, deburring, etc. of steel plates; among them, the left and right panels in the furnace cavity and the corresponding parts of the upper panel need to punch out the cooling hole structure ;The left, right and lower panels are designed as an integrated structure, and the "concave" structure is made through the bending process; each stee...

Embodiment 2

[0024] The specific preparation process of the manufacturing method of the microwave oven cavity panel mentioned in the present invention is as follows:

[0025] a) Select the steel plate, the steel plate material is 20Cr, its preparation process includes casting, forging and rolling, the thickness of the selected steel plate is about 1.4mm; the above steel plate has good strength, plasticity and microwave reflection performance, and its price is lower than stainless steel, Can effectively control the preparation cost;

[0026] b) Sheet metal processing, this process includes cutting, stamping, folding, trimming, bending, deburring, etc. of steel plates; among them, the left and right panels in the furnace cavity and the corresponding parts of the upper panel need to punch out the cooling hole structure ;The left, right and lower panels are designed as an integrated structure, and the "concave" structure is made through the bending process; each steel plate needs to be folded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com