Preparation method of anti-wrinkling and antibacterial compound yarn strip

A technology of composite yarn and antibacterial yarn, applied in the field of textile fabrics, can solve the problems of unsatisfactory air permeability and sweat absorption of fabrics, human discomfort, and low service life of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

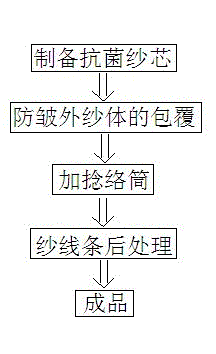

[0019] Concrete preparation process is as follows:

[0020] a) Preparation of antibacterial yarn core, the base material of antibacterial yarn core is natural cotton sliver, and its silk diameter is about 0.12mm; the main preparation process of antibacterial yarn core includes: preparation of antibacterial mother liquor, impregnation treatment of natural cotton sliver and antibacterial yarn core washing, drying, drying, etc.;

[0021] In the preparation process of antibacterial mother liquor, the main components and percentage ratio of antibacterial mother liquor are: nano-silver particles 5%, nano-bamboo charcoal particles 8%, additives 5%, and the rest are solvents; among them, the particles of nano-silver particles The particle size of nano-bamboo charcoal particles is 400-450 mesh, the auxiliary agent is composed of water-soluble silicone oil, dispersant, defoamer and cationic softener, and the solvent is 75% ethanol solution; antibacterial mother liquor The preparation o...

Embodiment 2

[0027] Concrete preparation process is as follows:

[0028] a) Preparation of antibacterial yarn core, the base material of antibacterial yarn core is natural cotton sliver, and its silk diameter is about 0.13mm; the main preparation process of antibacterial yarn core includes: preparation of antibacterial mother liquor, impregnation treatment of natural cotton sliver and antibacterial yarn core washing, drying, drying, etc.;

[0029] In the preparation process of antibacterial mother liquor, the main components and percentage ratio of antibacterial mother liquor are: 6% of nano-silver particles, 10% of nano-bamboo charcoal particles, 6% of additives, and the rest is solvent; among them, the particles of nano-silver particles The particle size of nano-bamboo charcoal particles is 400-450 mesh, the auxiliary agent is composed of water-soluble silicone oil, dispersant, defoamer and cationic softener, and the solvent is 75% ethanol solution; antibacterial mother liquor The prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com