Thin-walled part machining method

A processing method and technology of thin-walled parts, applied in the field of parts processing and thin-walled parts processing, to achieve the effects of improving processing accuracy and surface quality, reasonable process arrangement, and solving the problem of processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

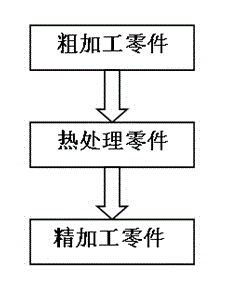

[0020] The specific processing method is as follows:

[0021] a) Rough machining parts, first use the traditional vise clamping device to position and clamp the parts, and then use high-speed cutting processing technology for rough machining to remove excess material from the parts and leave enough margin for finishing. Among them, compared with ordinary cutting, high-speed cutting has fast cutting speed, fast material deformation speed, large strain rate, and is not easy to produce built-up edge and phosphorus thorns, thus ensuring the surface quality of parts; at the same time, due to the fast cutting speed, Most of the cutting heat is taken away by the chips, and the cutting surface has no time to produce plastic deformation, and the milling process has been completed, so that the stress generated during the processing is controlled in a small range, and the dimensional accuracy of the part processing is better guaranteed.

[0022] b) Heat treatment parts, the specific trea...

Embodiment 2

[0025] The specific processing method is as follows:

[0026] a) Rough machining parts, first use the traditional vise clamping device to position and clamp the parts, and then use high-speed cutting processing technology for rough machining to remove excess material from the parts and leave enough margin for finishing. Among them, compared with ordinary cutting, high-speed cutting has fast cutting speed, fast material deformation speed, large strain rate, and is not easy to produce built-up edge and phosphorus thorns, thus ensuring the surface quality of parts; at the same time, due to the fast cutting speed, Most of the cutting heat is taken away by the chips, and the cutting surface has no time to produce plastic deformation, and the milling process has been completed, so that the stress generated during the processing is controlled in a small range, and the dimensional accuracy of the part processing is better guaranteed.

[0027] b) Heat treatment parts, the specific trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com