Insect-repelling antibacterial fabric manufacture process

A production process and antibacterial fabric technology, applied in biochemical fiber treatment, textile, yarn, etc., can solve the problems of skin being easily bitten by various insects, inconvenient use, cost, troublesome life, etc., to achieve reasonable process arrangement, The effect of long service life and broad application market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

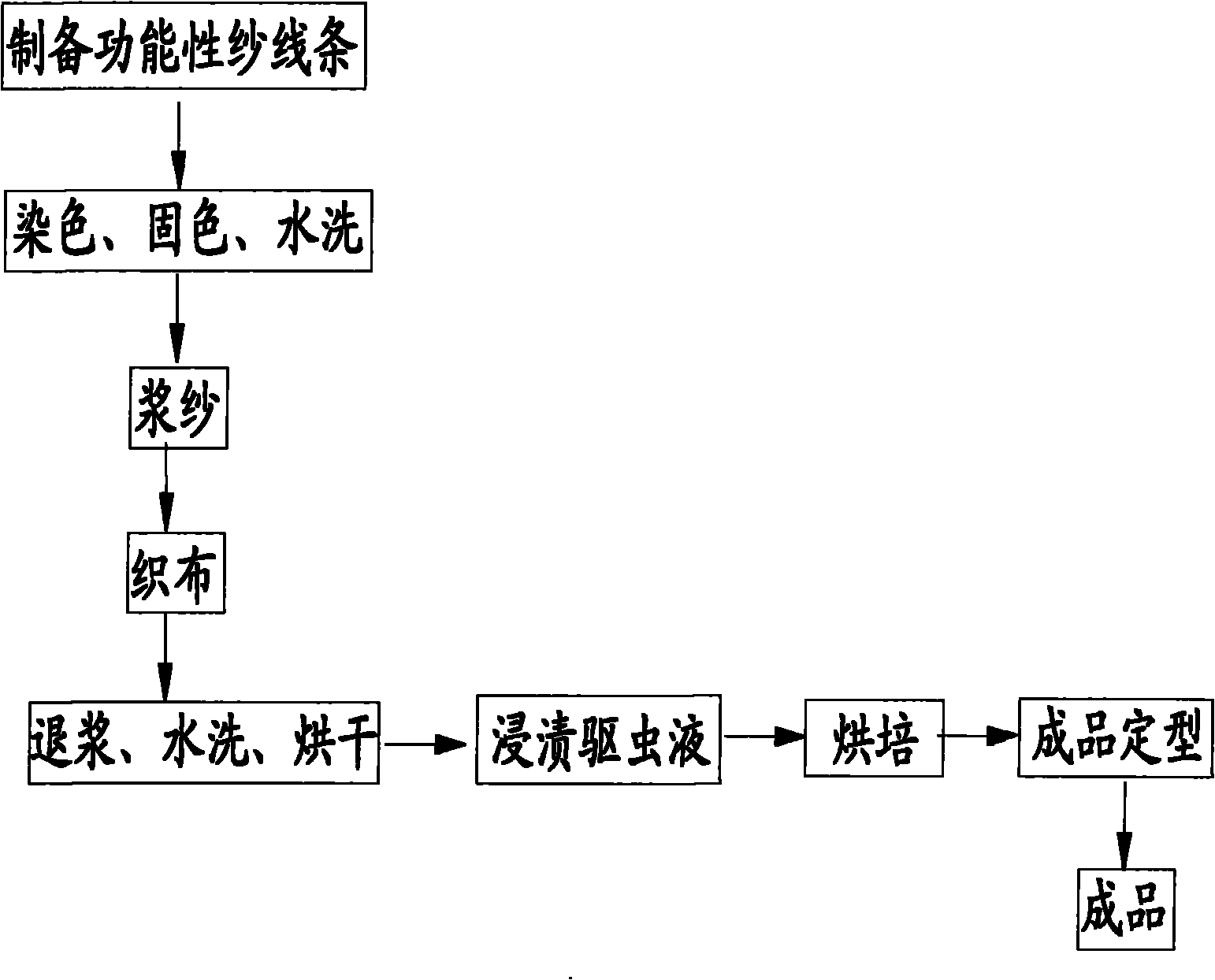

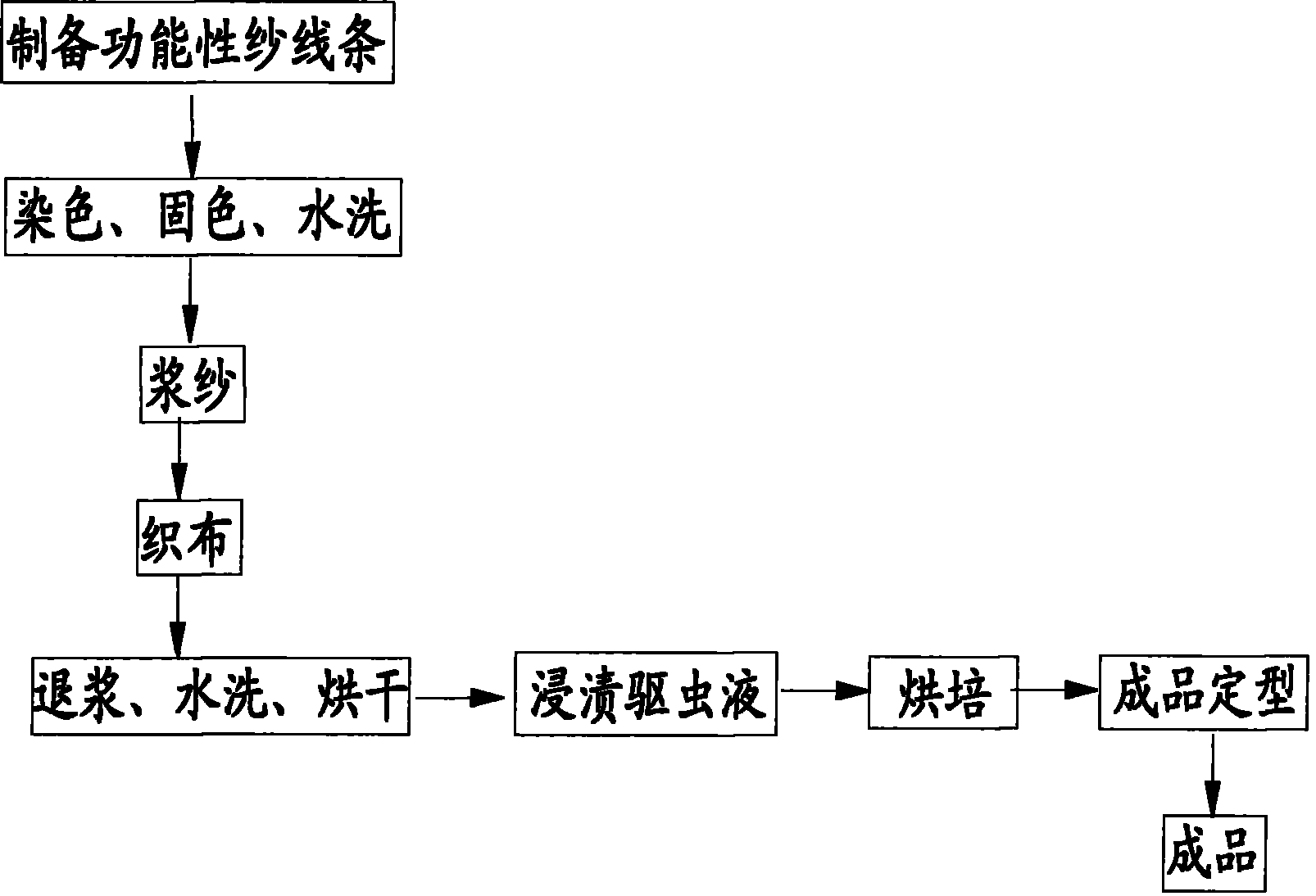

Method used

Image

Examples

Embodiment 1

[0019] The specific implementation process is as follows:

[0020] a) To prepare functional yarns, first select the components and percentages of functional yarns: 15% nano-bamboo carbon fiber, 5% nano-silver fiber, 80% polyester cotton fiber, and then through cleaning, cotton opening, and Sliver, roving, spun yarn, winding and twisting processes to complete the preparation of functional yarns;

[0021] b) Dyeing, color fixing and washing, first use reactive dye blue KD5B for coloring, then use reactive dye color fixing agent KD for color fixing treatment, and finally use neutral cleaning solution to clean, the temperature of the whole process should not exceed 90°C;

[0022] c) sizing, the sizing adopts the processing mode of warp beam sizing;

[0023] d) weaving, using the weaving process to weave the treated functional yarn into cloth;

[0024] e) Desizing, washing, and drying. First, put the cloth in 0.9G / L desizing enzyme BF-7658 for 30 minutes. The temperature is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com