Fire-proof wheel and production technology thereof

A technology of rollers and wheel cores, used in elevators, shafts and bearings, transportation and packaging, etc., can solve the problems of nylon material with high friction coefficient, no fireproof function, and easy noise generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

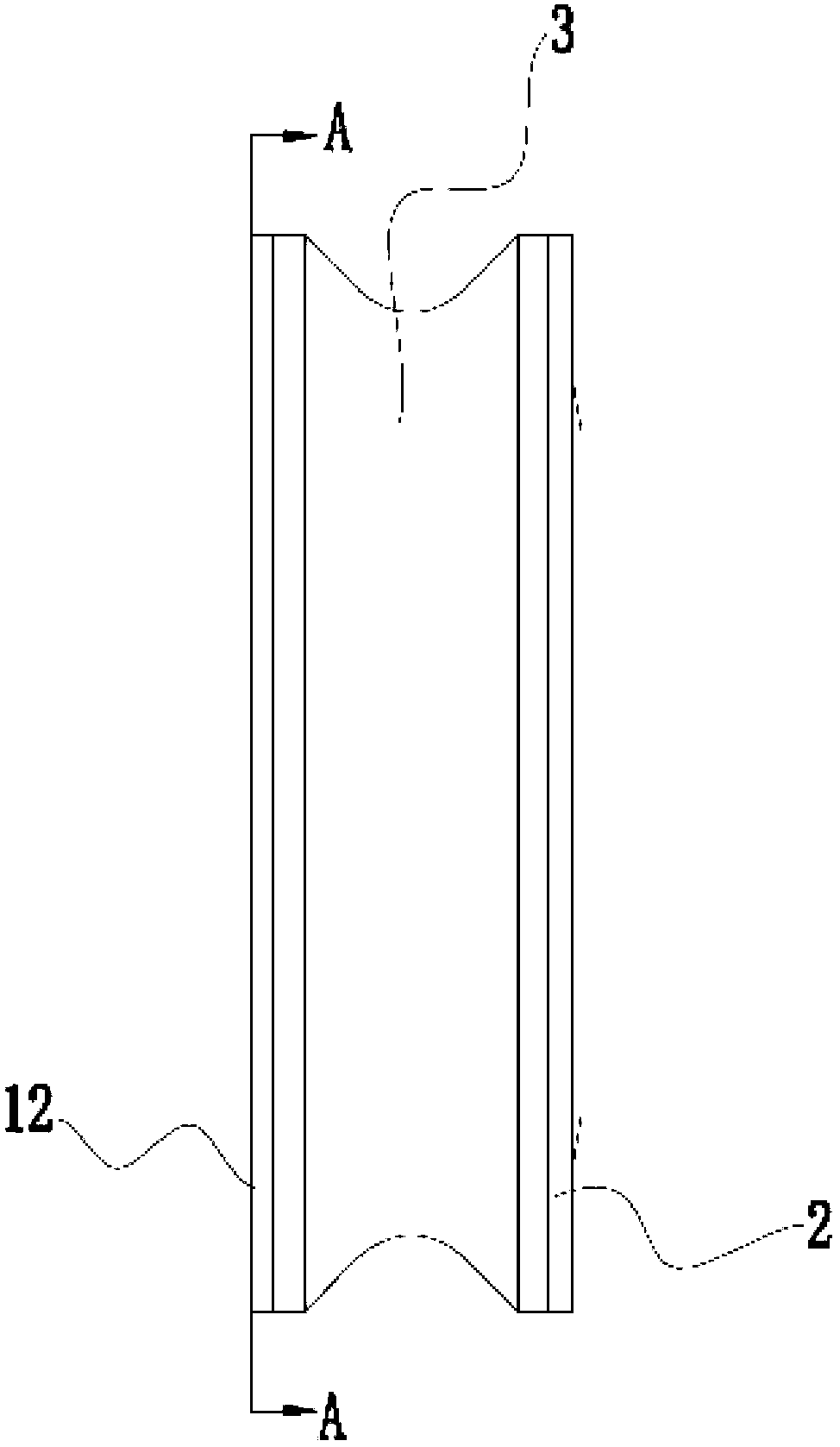

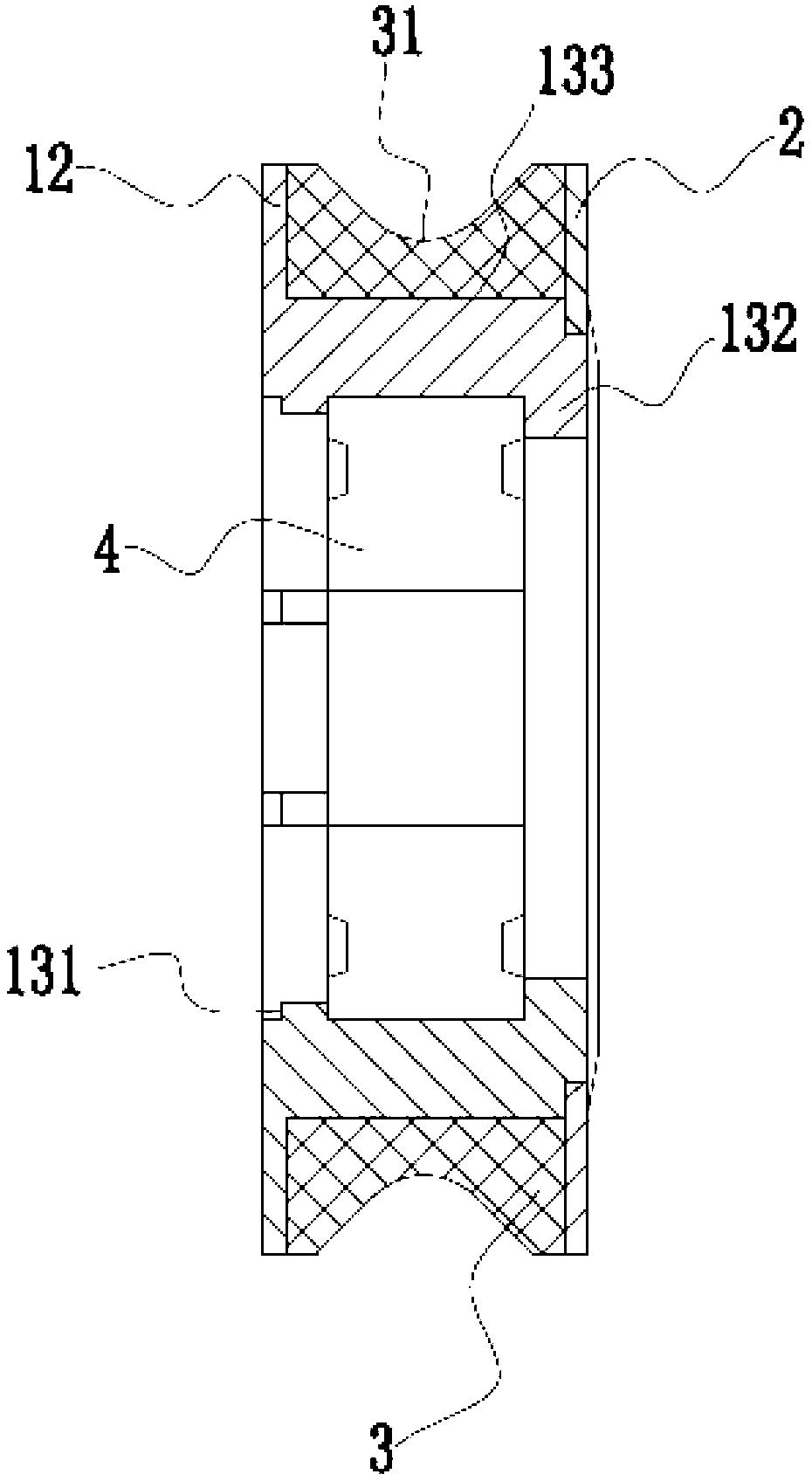

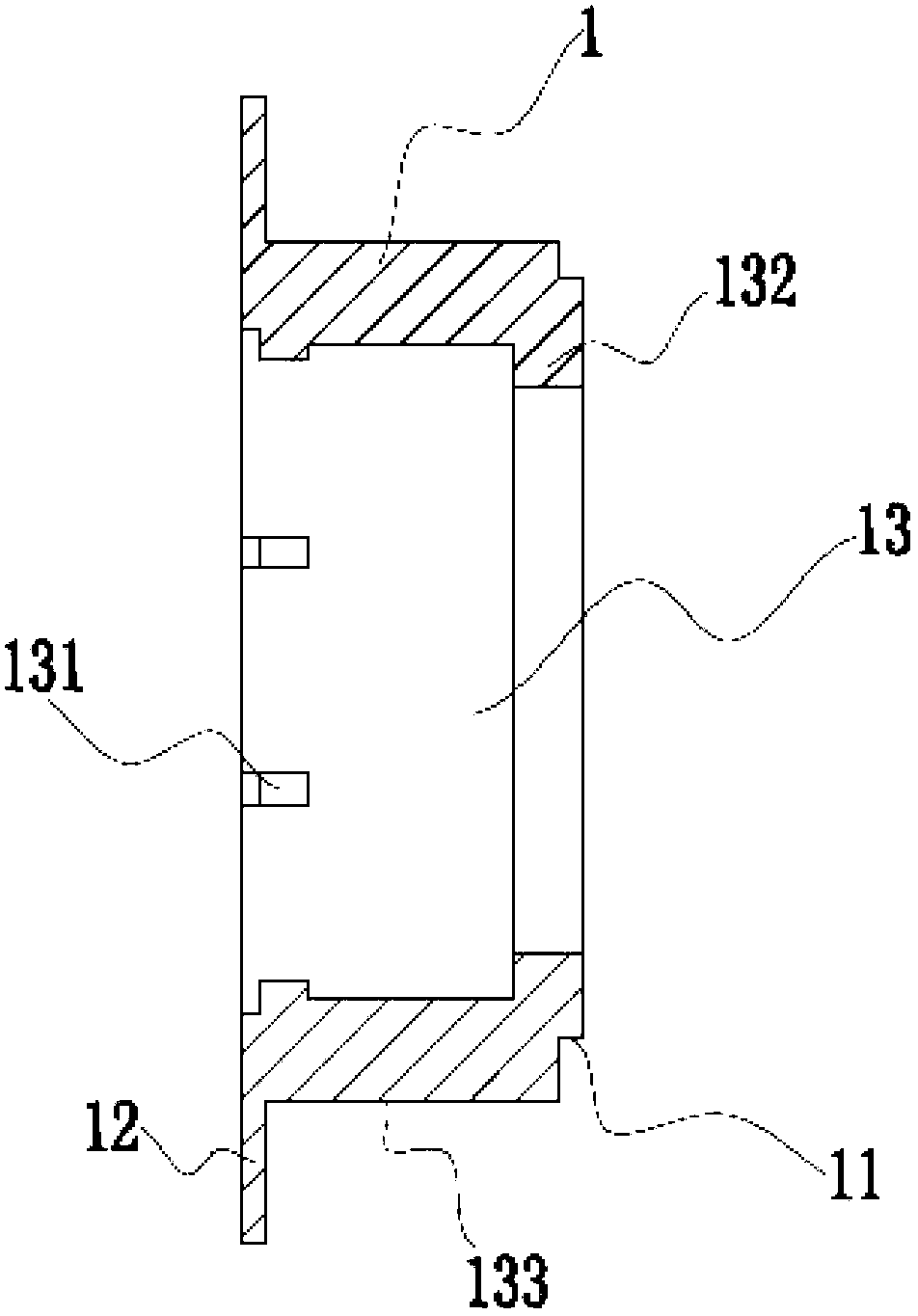

[0016] Such as figure 1 , figure 2 with image 3 As shown, the fireproof roller provided in this embodiment includes a metal roller body and a bearing 4, and is characterized in that the roller body includes a retaining ring 2 and a wheel core 1 with a through hole 13, and one end of the wheel core 1 has a There is a folded edge 12, and the other end is provided with a first limit step 11. The retaining ring 2 is riveted on the first limit step 11. The riveting method can be preferably screw riveting. The riveted structure can lift the retaining ring 2 and the wheel core. 1, a second limiting step 132 is provided at one end of the inner wall of the through hole 13 of the wheel core 1, and six riveting points 131 are arranged in a ring at the other end, and the bearing 4 is fixedly placed between the riveting points 131 and the second limiting step. Between the steps 132, the outer surface of the wheel core 1 is sleeved with a Teflon ring 4, the Teflon ring 3 is located betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com