Process and system for automatically cleaning tobacco boxes

An automatic cleaning and cleaning system technology, applied in the field of technology and systems, can solve the problems of too simple cleaning tool functions, difficult to reliably ensure the cleanness of boxes, and high labor intensity, so as to optimize the cleaning process, save equipment investment costs, and achieve automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

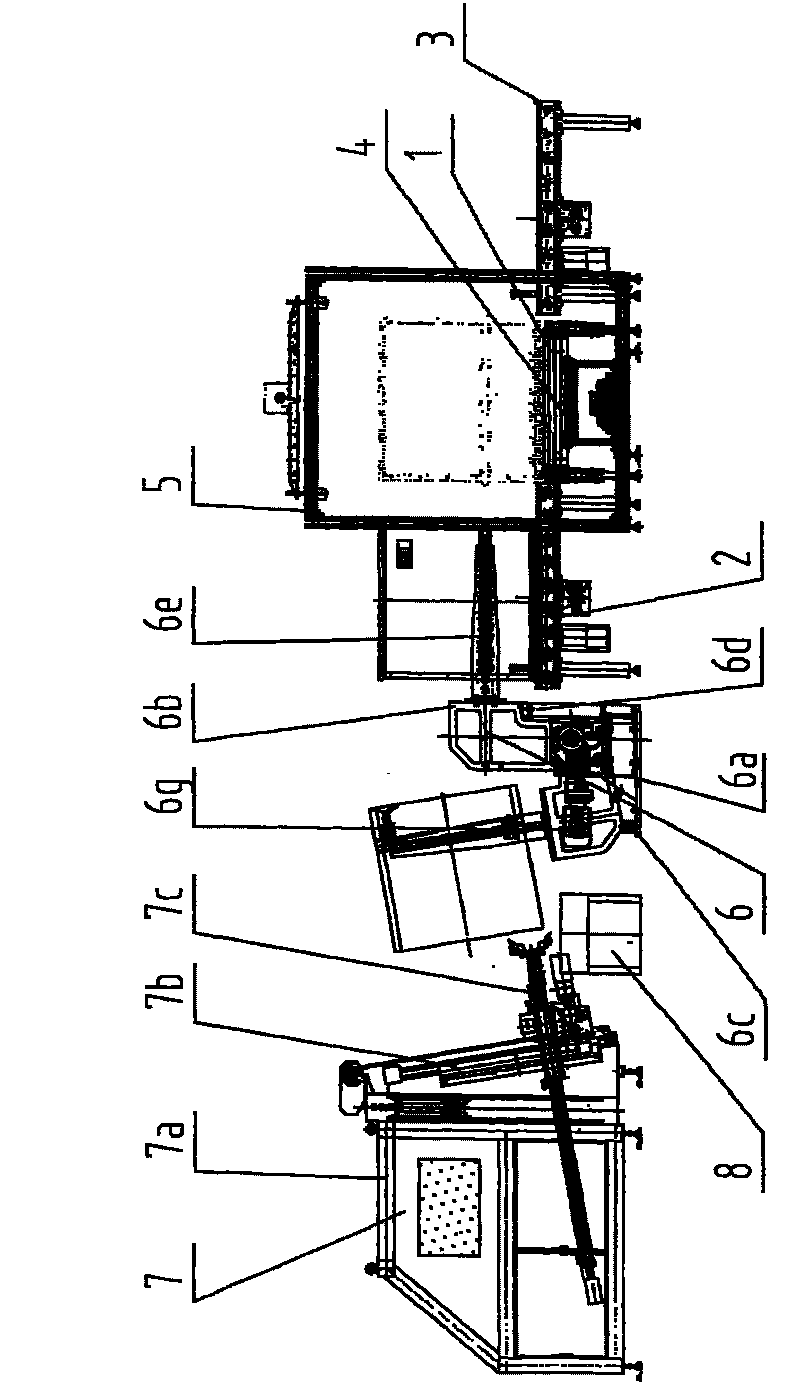

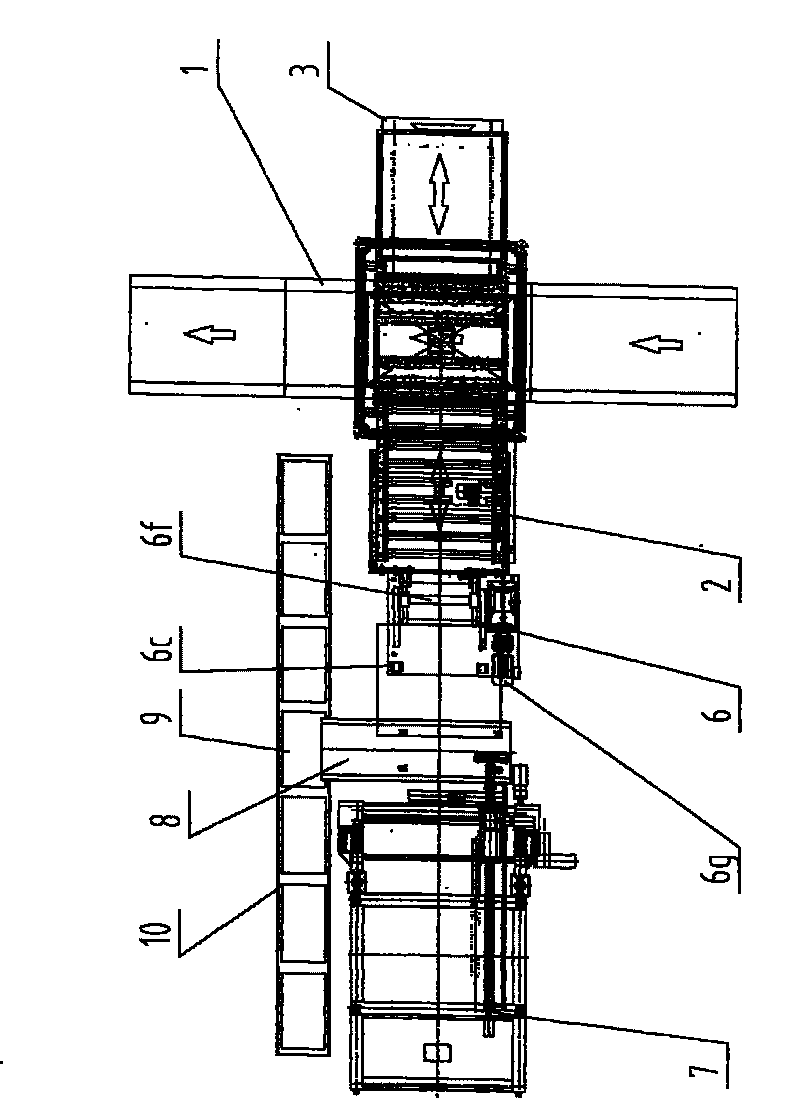

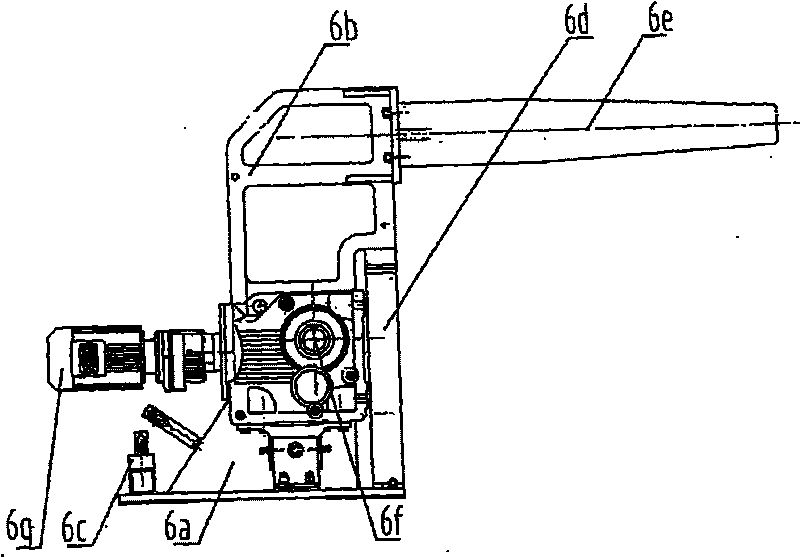

[0028] like figure 1 , figure 2 As shown, the smoke box automatic cleaning system of the present invention includes a smoke box conveyor 1, a two-way conveyor 2 located on one side of the smoke box conveyor and vertically arranged with the smoke box conveyor, and a lifting mechanism nested in the smoke box conveyor. Conveyor 4, visual detection device 5 installed above the lifting conveyor, turning machine 6 located at the rear end of the two-way conveyor, cleaning robot 7 located at the rear end of the turning machine, and residual material conveying belt between the turning machine 6 and cleaning robot 7 Machine 8 is provided with recovery box 9 at the outlet end of residual material conveying belt machine. An auxiliary conveyor 3 is arranged opposite to the two-way conveyor 2 on the other side of the cigarette case conveyor 1 . The auxiliary conveyor 3 can convey in one direction or in two directions, and this embodiment is a conveying mechanism that can convey in two di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com