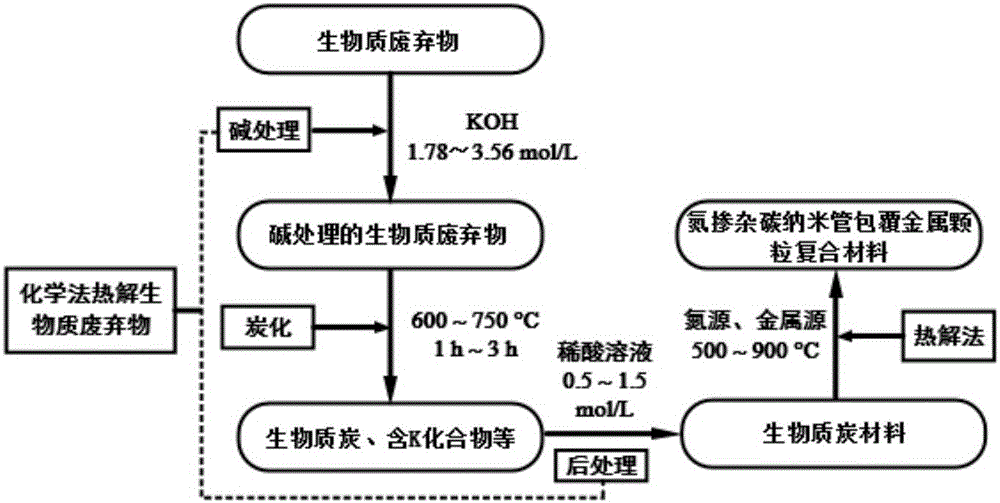

Method for using biomass waste for preparing nitrogen-doped carbon nanotube coated metal particle composite material

A biomass waste, metal particle technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of high preparation cost, cumbersome steps, low yield and purity, and achieve high application value and technology. Simple, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Carbonized distiller's grain waste: Weigh 10.0g (0.1782mol) KOH and 10.0g distiller's grain waste, mix them in a beaker containing 80mL deionized water, keep stirring at 25°C for 8h, dry and grind, Obtain heterogeneous mixture A; place this heterogeneous mixture A in a quartz boat, and move the quartz boat to the constant temperature zone of a tubular resistance furnace with nitrogen protection gas, and heat up to 750°C, then carbonized at constant temperature for 2 hours, the product was washed with dilute hydrochloric acid solution with a concentration of 0.5mol / L and distilled water, and dried to obtain distiller's grain charcoal.

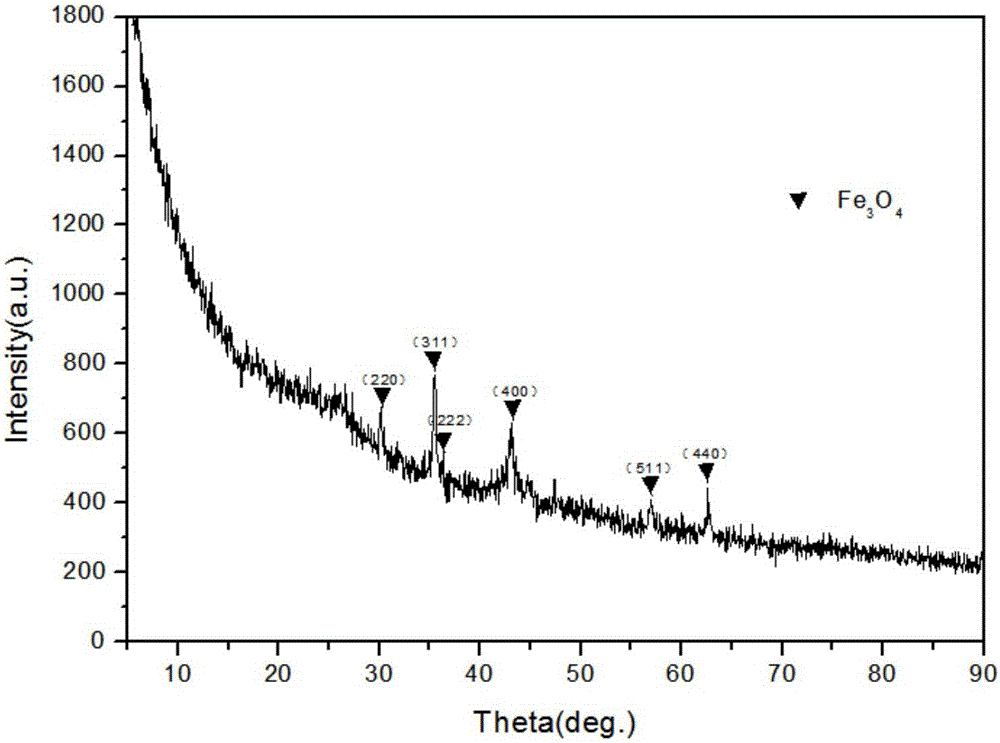

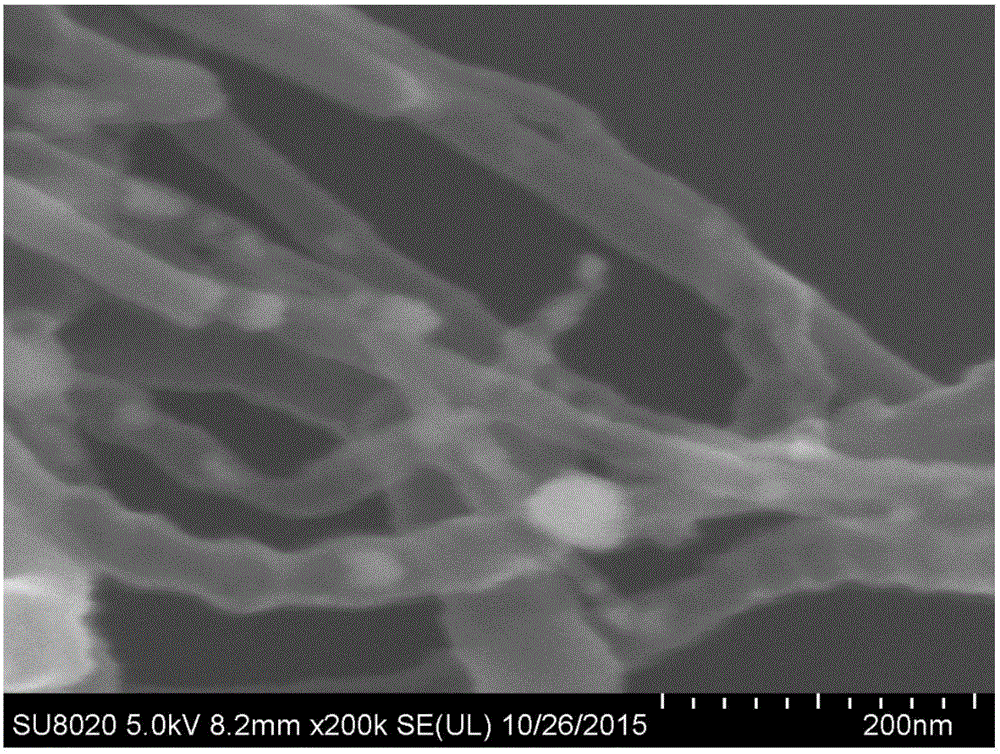

[0029] (2) Preparation of nitrogen-doped carbon nanotube-coated metal particle composites by pyrolysis

[0030] Weigh 0.2g distillers charcoal, 80.0mg (0.2878mmol) FeSO 4 ·7H 2 O and 4.0g (0.0317mol) melamine; Mix the three heterogeneously in a beaker containing 100mL of methanol, magnetically stir for 5h to mix the three evenly, th...

Embodiment 2

[0035] (1) Carbonized corn stalk waste: Weigh 10.0g (0.1782mol) KOH and 10.0g corn stalk waste, mix them in a beaker containing 80mL deionized water, keep stirring at 25°C for 8h, dry, Grind to obtain the heterogeneous mixture A; place the heterogeneous mixture A in a quartz boat, and move the quartz boat to the constant temperature zone of the tubular resistance furnace with nitrogen protection gas, at a heating rate of 10°C / min The temperature was raised to 750° C., and then carbonized at a constant temperature for 2 hours. The product was washed with a dilute hydrochloric acid solution with a concentration of 0.5 mol / L and distilled water, and dried to obtain corn stalk charcoal.

[0036] (2) Preparation of nitrogen-doped carbon nanotube-coated metal particle composites by pyrolysis

[0037] Weigh 0.2g corn stalk charcoal, 80.0mg (0.2878mmol) FeSO 4 ·7H 2 O and 4.0g (0.0317mol) melamine; Mix the three heterogeneously in a beaker containing 100mL of methanol, magnetically ...

Embodiment 3

[0040] (1) Carbonized rice husk waste: Weigh 10.0g (0.1782mol) KOH and 10.0g rice husk waste, mix them in a beaker containing 80mL deionized water, keep stirring at 25°C for 8h, dry, Grind to obtain the heterogeneous mixture A; place the heterogeneous mixture A in a quartz boat, and move the quartz boat to the constant temperature zone of the tubular resistance furnace with nitrogen protection gas, at a heating rate of 10°C / min Raise the temperature to 750°C, then carbonize at a constant temperature for 2 hours, wash the product with a dilute hydrochloric acid solution with a concentration of 0.5mol / L and distilled water, and obtain rice husk charcoal after drying.

[0041] (2) Preparation of nitrogen-doped carbon nanotube-coated metal particle composites by pyrolysis

[0042] Weigh 0.2g rice husk charcoal, 80.0mg (0.2878mmol) FeSO 4 ·7H 2 O and 4.0g (0.0317mol) melamine; Mix the three heterogeneously in a beaker containing 100mL of methanol, magnetically stir for 5h to mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com