Automatic IC testing and sorting device

A sorting and equipment technology, applied in the field of IC test sorting equipment, can solve the problems affecting the speed of test sorting, IC chips cannot slide out, waste of human resources, etc., to achieve a short replacement cycle, meet the collection rate, save cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

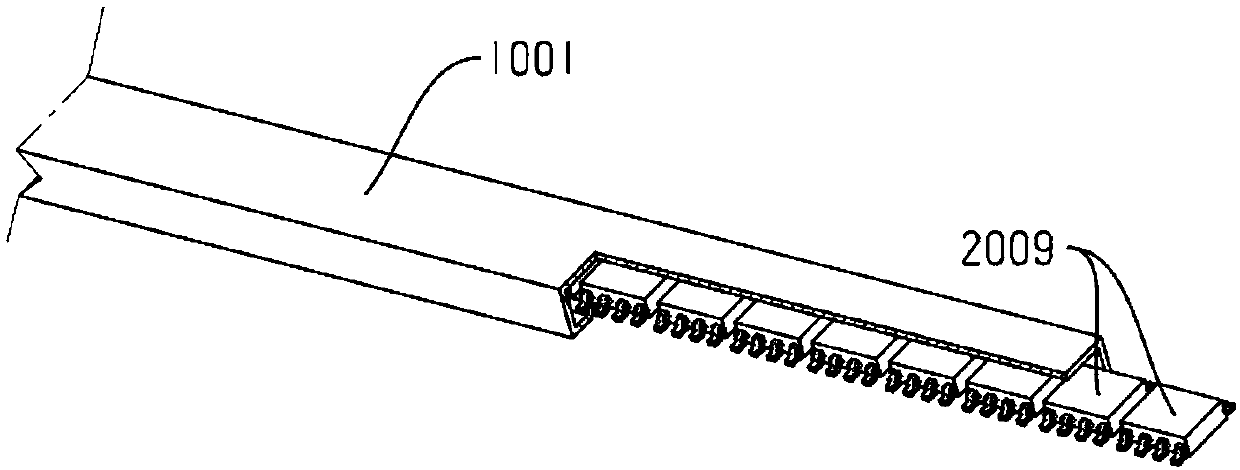

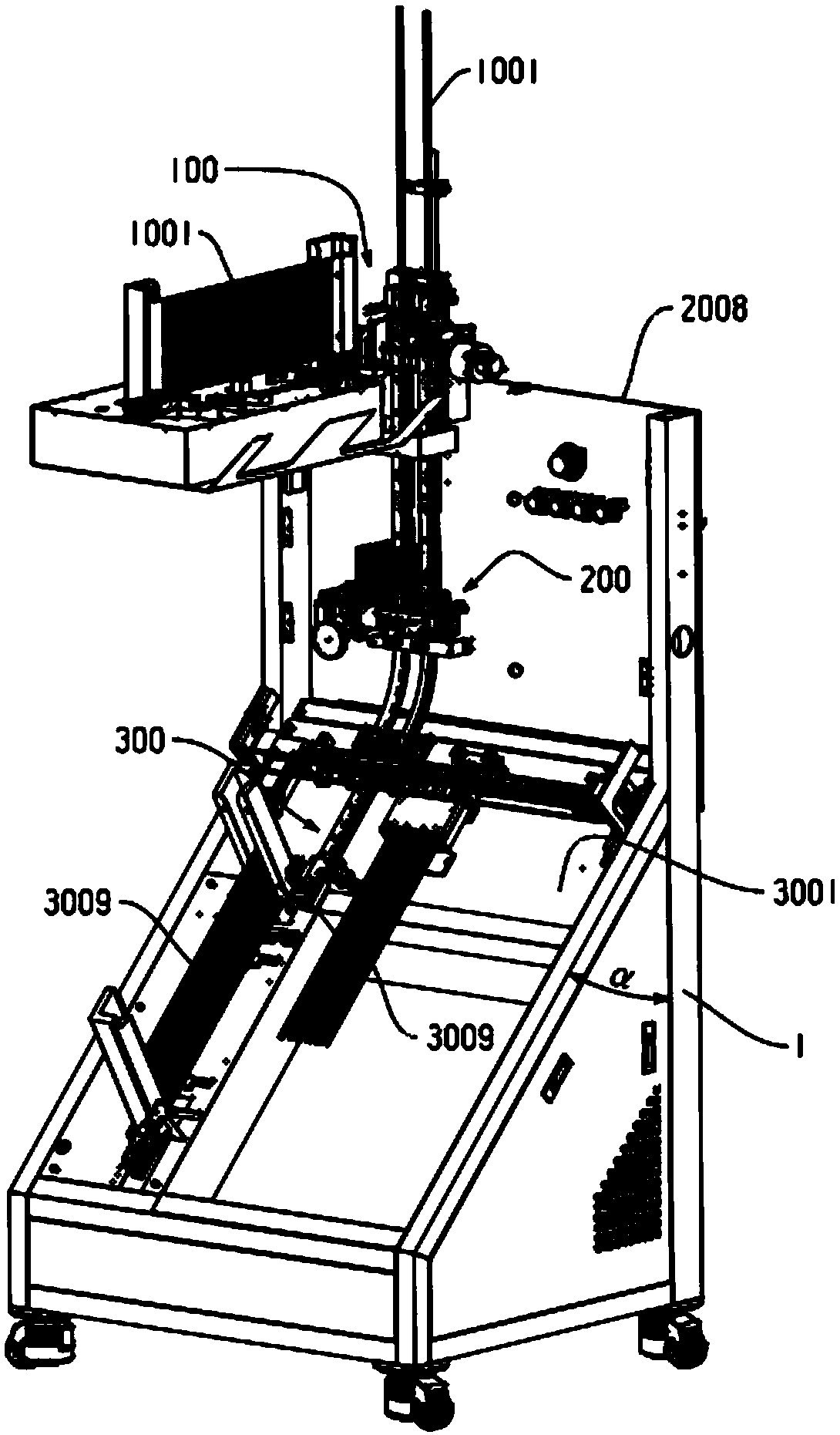

[0061] Embodiment: a kind of automated IC test sorting equipment, such as Figure 1 to Figure 22 Shown: including the feeding device 100, the testing device 200 and the sorting and receiving device 300 installed on the frame 1 and arranged in sequence from top to bottom, the frame includes a vertically arranged first mounting plate 2008 and is connected with the The bottom of the first mounting plate is connected to the second mounting plate 3001 which is arranged obliquely. The IC material tube 1001 is clamped on the feeding device, and the untested IC chip 2009 in the IC material tube is supplied to the device through the feeding device. After the test is completed, it is sorted by the sorting and receiving device and stored in a plurality of empty material tubes 3009.

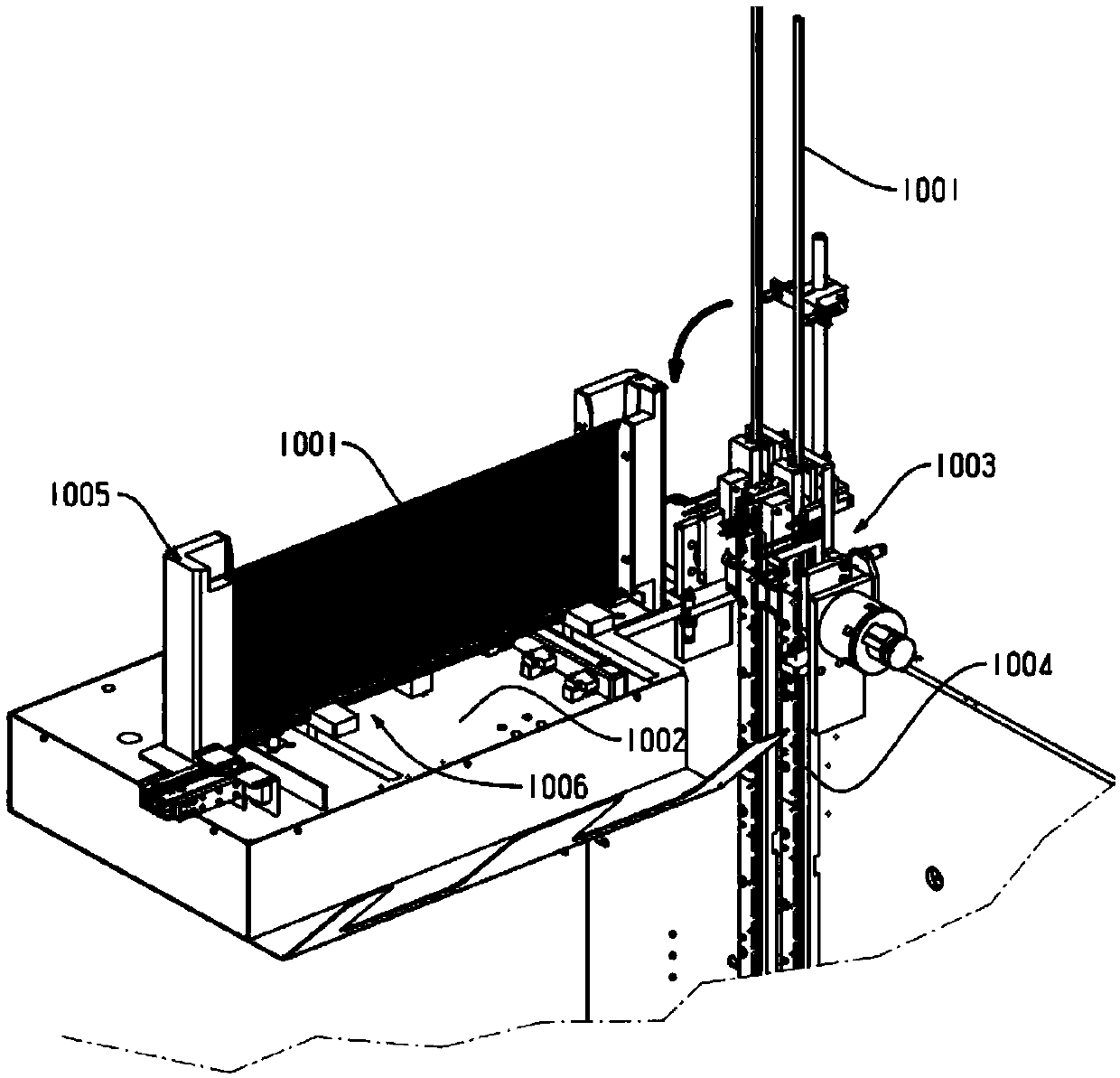

[0062] The feeding device such as Figure 3 to Figure 9As shown: it includes a horizontally arranged loading table 1002, a feeding mechanism 1003 for taking out the IC chips in the IC material tube, and a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com