Variable inclination angle energy-saving feeder easy to assemble and change

A feeder and variable inclination technology, which is used in port feeding equipment, metallurgy, and mining fields, can solve problems such as large time consumption, material leakage, and low working efficiency of production systems, so as to reduce power consumption and wear and prolong use. Longevity, easy and quick maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

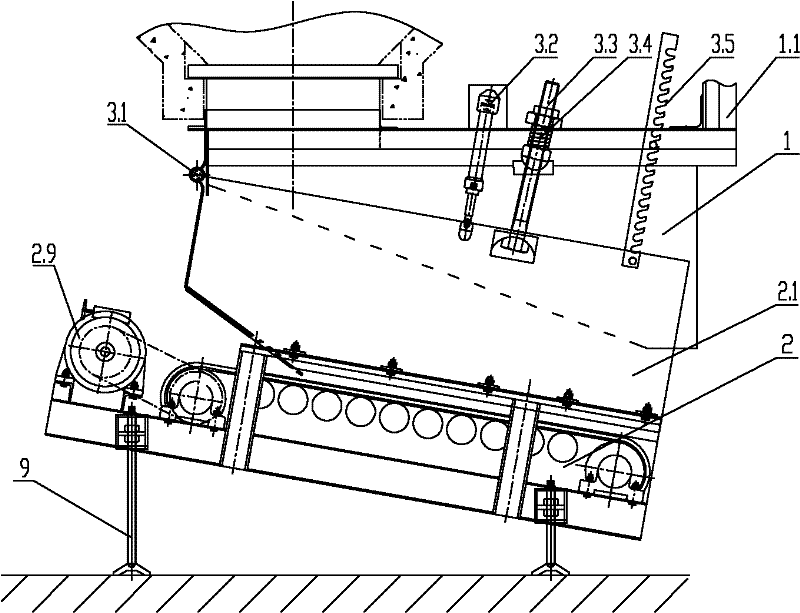

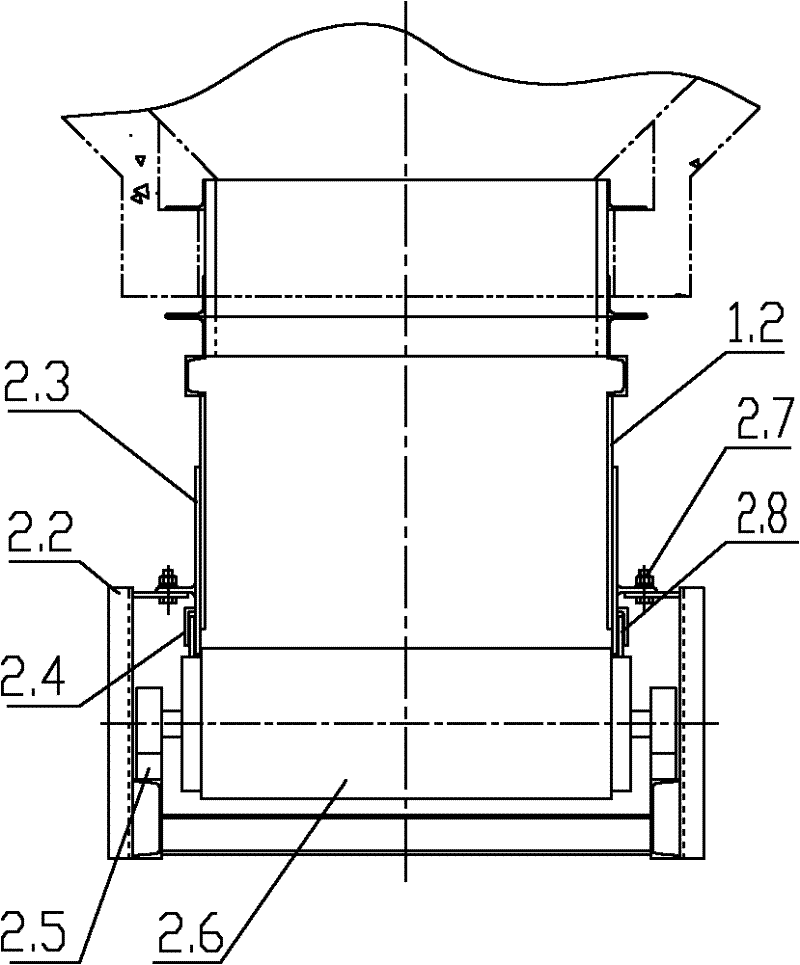

[0028] figure 1 with figure 2 It is the variable inclination angle easy to assemble and replace the energy-saving feeder described in embodiment 1. The feeder includes a material guide chute 1 and a conveying chassis 2, and the conveying chassis 2 is arranged below the material guide trough 1. A hanging mechanism 1.1 is provided on the material guide trough 1, and a support device 9 is provided at the bottom of the conveying chassis 2. The conveying chassis 2 includes a feeding trough 2.1 and a chassis 2.2. The feeding trough 2.1 is arranged on the chassis 2.2. The feeding trough 2.1 can be integrated with the chassis 2.2, or can be fixedly connected to the chassis 2.2 through bolts and other components. . The feeding chute 2.1 is located below the feed chute 1 . The feed chute 1 is provided with an angle adjustment mechanism, and the angle adjustment mechanism includes an angle adjustment oil cylinder 1 3.2, an angle adjustment screw rod 3.3 and a sliding hanging tooth 3...

Embodiment 2

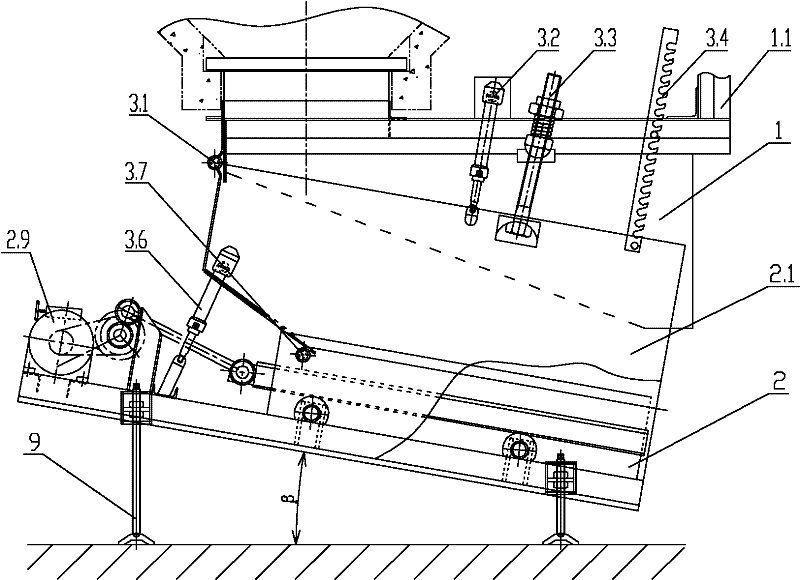

[0036] image 3 It is easy to assemble and replace the energy-saving feeder with variable inclination described in embodiment 2. Different from Embodiment 1, an angle adjustment mechanism, that is, an angle adjustment oil cylinder II 3.6, is also provided on the conveying chassis 2, and a rotating mechanism II 3.7 is set on the conveying chassis 2 at the same time, that is, the conveying chassis 2 can simultaneously move along the rotating mechanism I 3.1 and the rotating mechanism. II 3.7 implements rotation. The feeder in this embodiment is a reciprocating feeder, and the feeder can also be a scraper feeder, a trough feeder, a crawler feeder, or an apron feeder.

[0037] Others are with embodiment 1.

Embodiment 3

[0039] Figure 4 It is easy to assemble and replace the energy-saving feeder with variable inclination described in embodiment 3. The feeder includes a material guide trough 1 and a conveying chassis, the conveying chassis includes a material guide hopper 4, the material guide hopper 4 is located below the material guide trough 1, an angle adjustment mechanism is arranged on the material guide trough 1, and the angle adjustment mechanism can also be arranged on the material guide hopper 4 on. The side plate 4.1 of the hopper and the bottom plate of the conveying chassis can be in an integrated structure, or can be connected in a sealed manner. The guide trough baffle plate and the side plate 4.1 of the hopper are fitted and slidably connected, and an elastic seal is provided at the joint, and the elastic seal can be made of polymer material, polyester material, rubber material and / or plastic ester materials etc. The bottom of the guide hopper 4 is provided with a supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com