Large dry dense medium fluidized bed separation machine and separation system

A fluidized bed, heavy medium technology, used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc. Get effective sorting and other issues to achieve the effects of improving sorting stability, improving sorting effect, and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

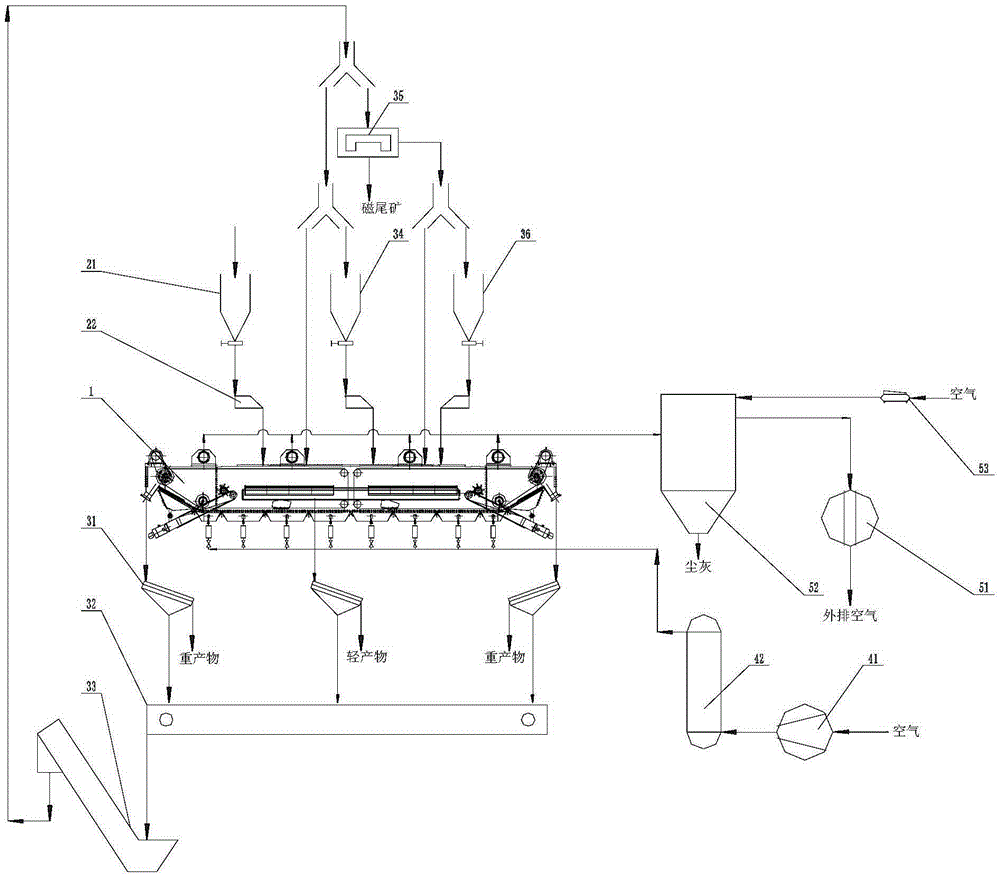

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

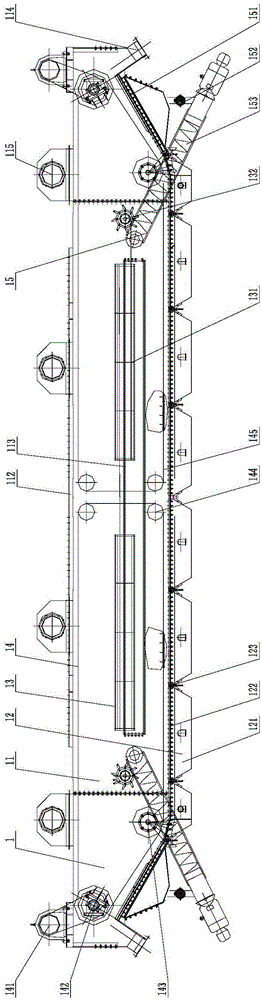

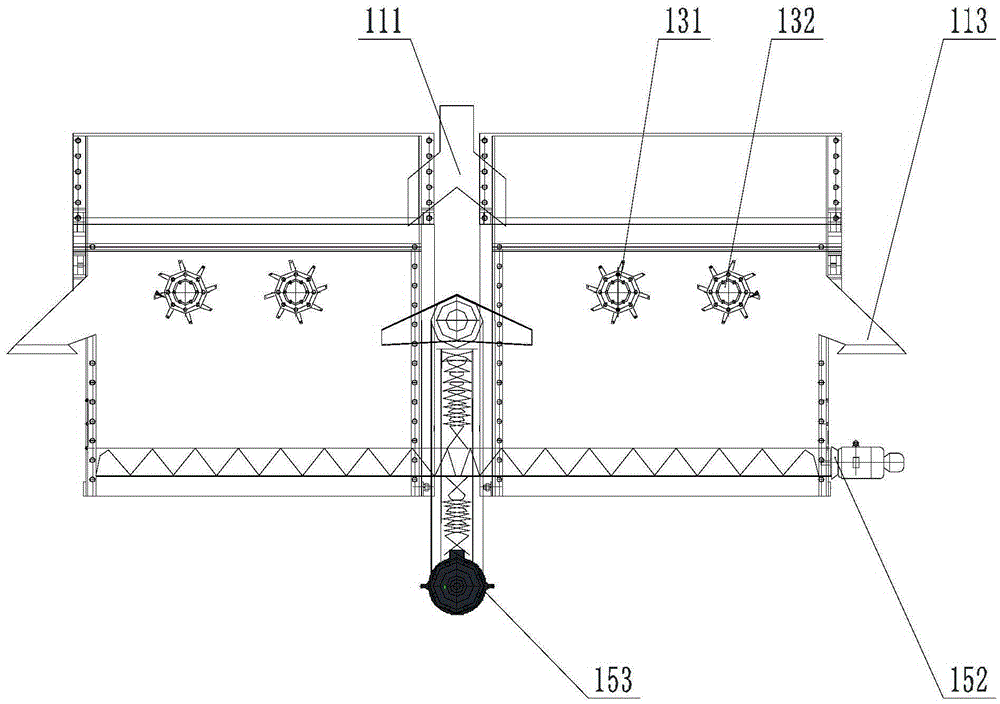

[0027] Such as figure 1 , figure 2 Shown is a large-scale dry-process heavy-medium fluidized bed sorter, including a sorting machine body 11 , an air distribution device 12 , a floating object discharge device 13 , a sinking object discharge device 14 and a weighted mass rapid circulation device 15 .

[0028] The sorting machine body 11 is provided with a sorting material inlet 111, an aggravated material inlet 112, a floating material discharge port 113, a sinking material discharge port 114, and an air-induced dust removal port 115; the sorting machine body 11 is an air-heavy medium The formation of the fluidized bed, the sorting of the material, the discharge of the floating substance and the discharge of the sinking substance provide space.

[0029]The air distribution device 12 includes several air distribution units, and the air distribution units are detachab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com