Same-cavity integrated vertical walnut shell high-speed multi-stage superfine grinding device and method

A technology of ultra-fine grinding and crushing device, which is applied in the direction of grain processing, etc. It can solve the problems of long and complicated crushing process, uncontrollable particle size, uneven particle size distribution, etc., and achieve compact structure, improved crushing quality, and uniform particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

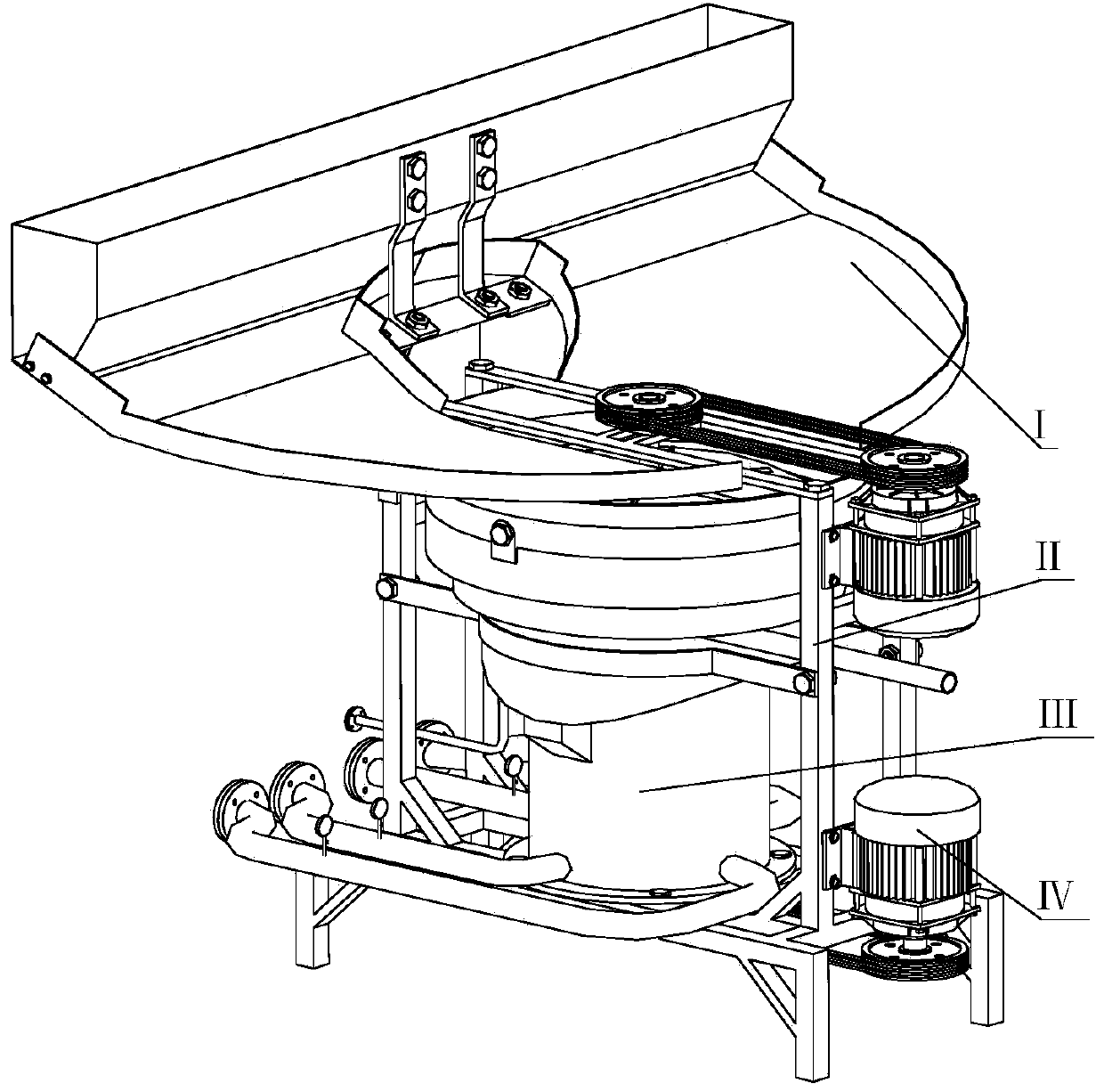

[0097] See attached figure 1 As shown, this embodiment discloses a vertical walnut shell high-speed multi-stage superfine grinding device integrated in the same cavity. The device integrates mechanical energy and pneumatic impact energy to cooperate with the vertical cavity. , Integrate the vertical crushing device III in the same cavity, and the power source IV is composed of four parts. The dual-channel slide-down feeding device I is located on the top of the frame II, the same-cavity integrated vertical crushing device III is located at the bottom of the dual-channel slide-down feeding device I, and the power source IV is located on the side of the frame II.

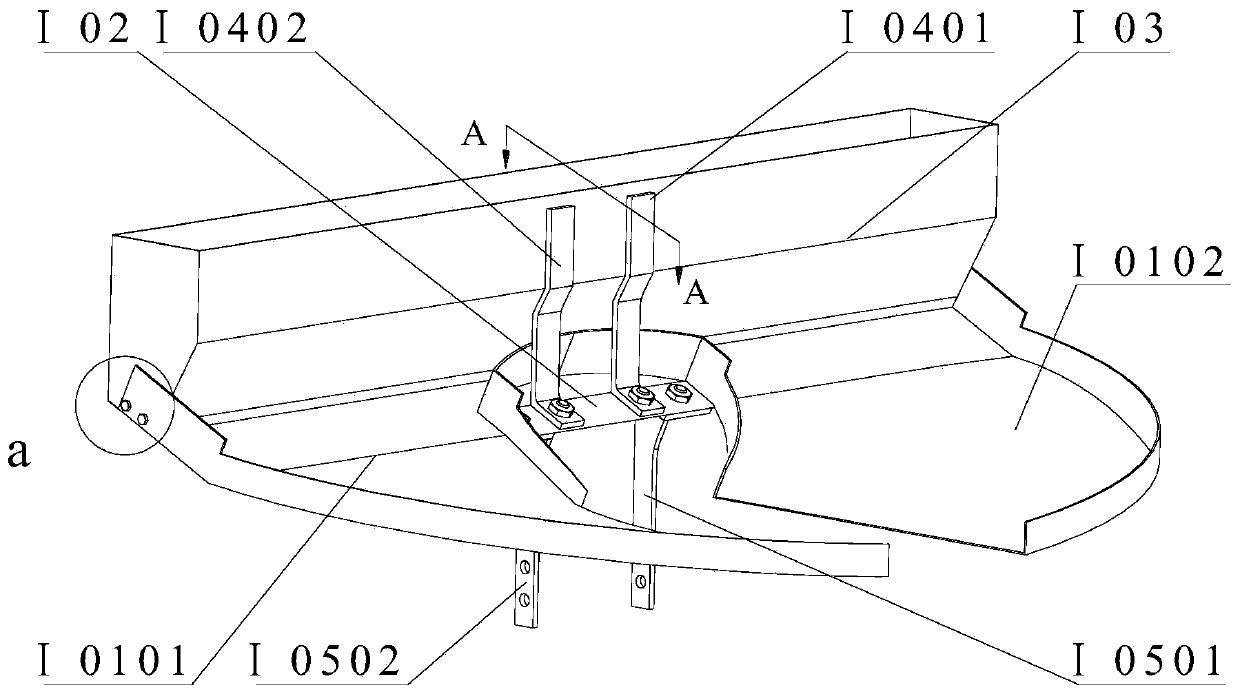

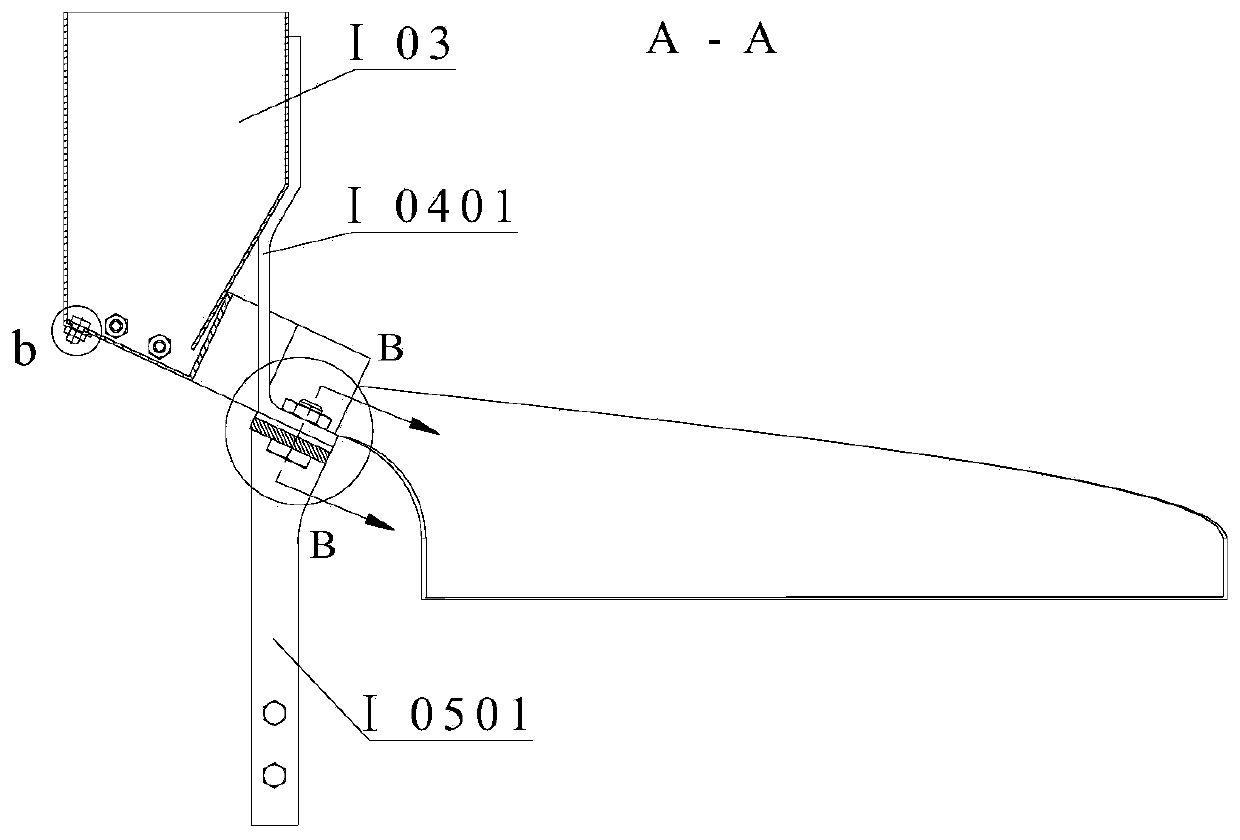

[0098] Such as figure 2 As shown, the first helical inclined slideway I0101 and the second helical inclined slideway I0102 of the dual-channel slide-down feeding device I are placed oppositely, welded on the connecting plate I02, and form a whole. The first bent connecting plate I0401 and the second bent connecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com