Coal slime spiral buffer feeding method and coal slime spiral buffer feeding machine

A feeder and coal slime technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of inability to complete the conveying operation requirements, materials are easily broken, and power consumption is high, so as to prevent material blockage and reduce maintenance rates. , the effect of low running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through embodiment.

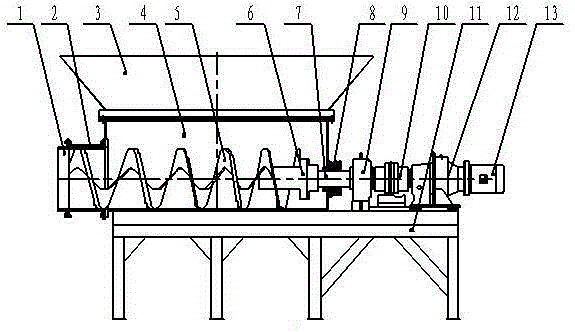

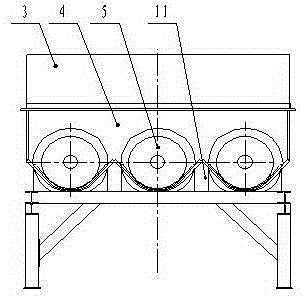

[0017] A coal slime spiral buffer feeder, comprising a discharge port 1, a support sleeve 2, a silo 3, a feeder housing 4, a shaftless variable pitch screw conveying system 5, a slider coupling 6, a main shaft 7, Sealing device 8, bearing seat 9, plum blossom coupling 10, frame 11, reducer 12 and motor 13, feeder housing 4 is arranged on frame 11, and feed bin 3 is arranged above feeder housing 4 , the inner wall of the silo 3 is lined with ultra-high molecular polyethylene lining board or stainless steel plate, the shaftless variable pitch screw conveying system 5 is installed in the feeder housing 4, and the wear-resistant lining board is provided at the bottom, and the feeder housing 4 The front part is equipped with a discharge port 1, and the discharge port of the silo 3 is matched with the shaftless variable pitch screw conveying system 5; The place is called the head; the tail of the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com