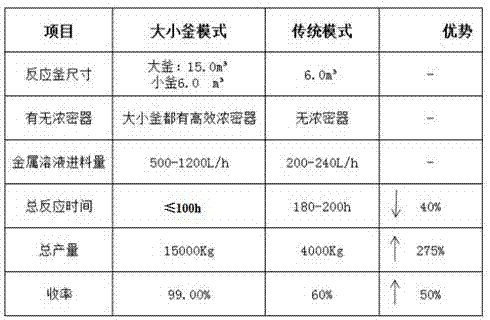

Method of quickly synthesizing ternary lithium battery cathode material precursor with double kettles

A ternary lithium battery and positive electrode material technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as poor yield and long reaction time, and achieve the effects of accelerating reaction speed, increasing yield, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

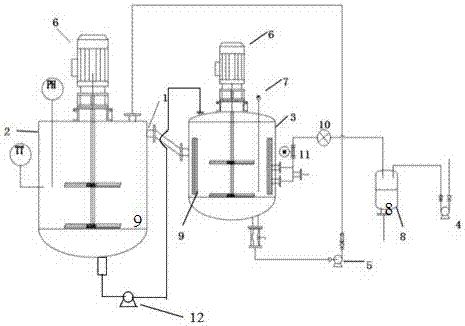

[0021] Such as figure 1 As shown, the inventive method uses two sets of synthetic devices with the same structure and different volumes, each set of devices includes a reactor and a thickener, and an overflow port is arranged on the reactor, and the overflow port is communicated with the thickener, and the thickener The bottom is connected to the reaction kettle through a circulation pump, and there is a filter rod in the thickener, and the mother liquor collected by the filter rod is connected to a vacuum buffer tank through a flow meter and a pneumatic valve. As a preference, the bottom of the reactor is flange-connected to the top of the thickener through a centrifugal pump. If the vacuum negative pressure system fails, the mother liquor can be discharged through positive pressure filtration through the centrifugal pump connected to the lower part of the reactor and the pipeline to the top of the thickener.

[0022] The synthesis process is as follows:

[0023] 1. A new t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com