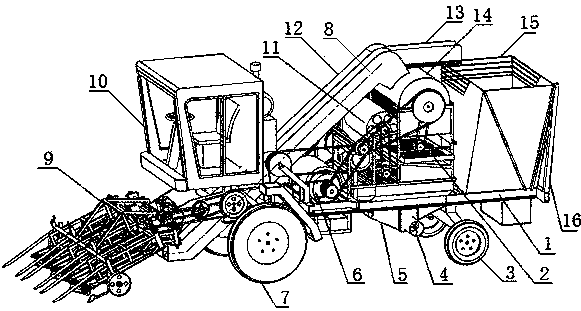

Three-ridge six-row peanut seedling and fruit integrated combined harvesting machine

A combined harvester and peanut seedling technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of single function, low operation efficiency, inability to pick, etc., and achieves good fruit picking performance and high work efficiency. , the effect of low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

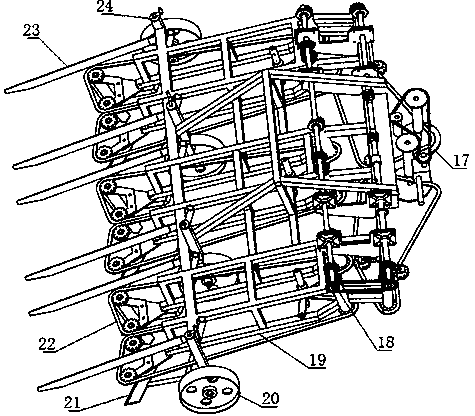

[0012] as attached figure 1 , 2 A three-ridge and six-row peanut seedling and fruit combined harvester is shown, which is composed of a walking system, a fruit pulling system, and a fruit picking system. The walking system includes a frame 1, and the front sides of the frame 1 are provided with Drive wheel 7 is arranged, and the rear end both sides is provided with traveling wheel 3, and the front end top of frame 1 is provided with cab 10, and engine 6 is installed in the middle; Described fruit pulling system 9, is arranged on the front end of frame 1, comprises support 19 , the front end of described support 19 is provided with three groups of six seedling tendril righting rods 23, is used for peanut seedling tendril righting, and the following of seedling tendril straightening rod 23 is provided with three groups of clamping sprockets 22 side by side, and the following of clamping sprocket 22 is provided with three Group six spade blades 21, each group of two spade blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com