Rotary three-station bidirectional building material pressing machine

A two-way pressing, three-station technology, applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problems of high equipment investment, low production efficiency, and low economic benefits, and achieve the goal of improving production economic benefits and productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

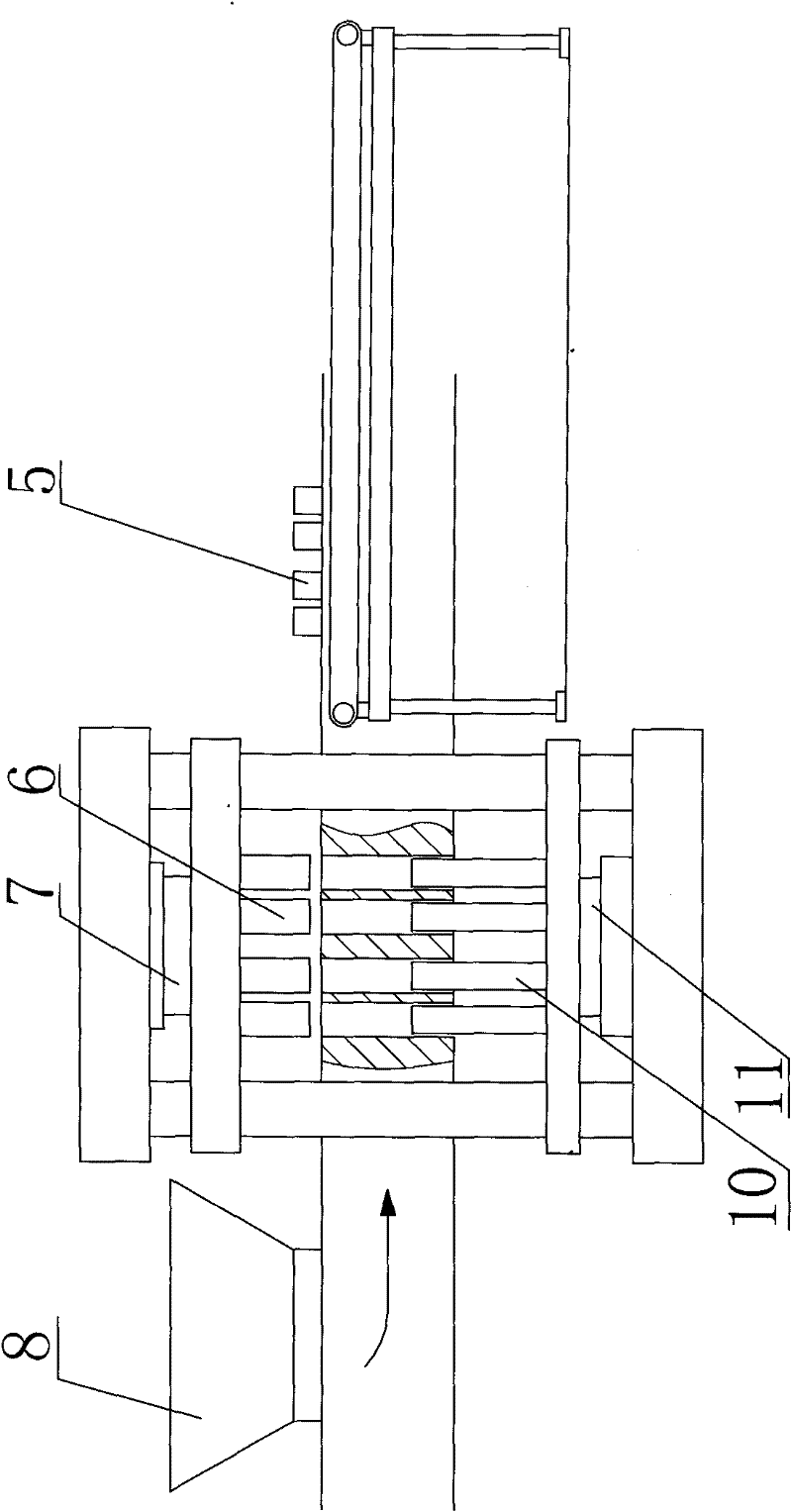

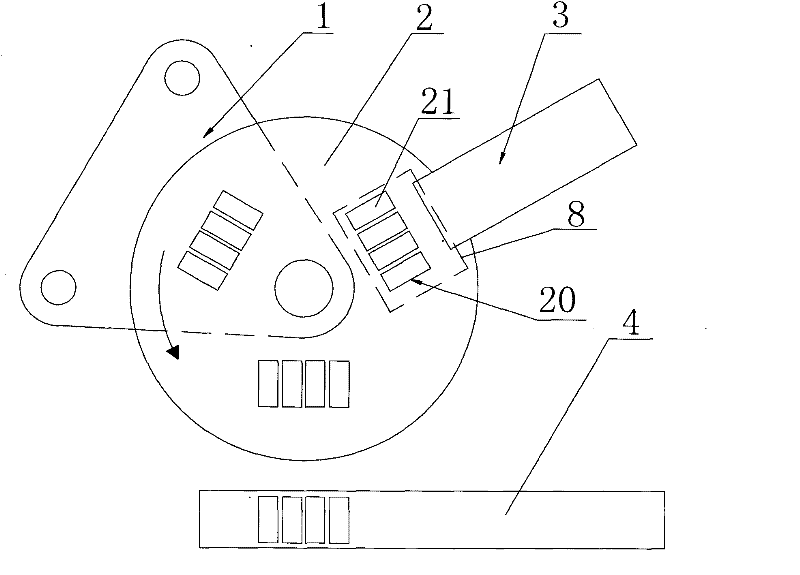

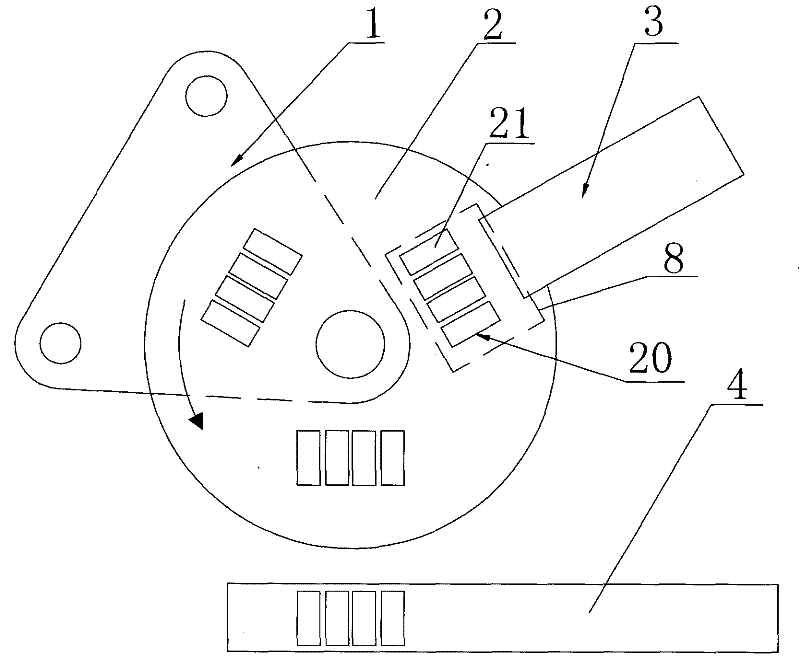

[0017] Embodiment: A rotary three-station two-way building material press machine, including a two-way press machine 1, a three-station turntable 2, a feeder 3 and a demoulding and palletizing system, the three-station turntable 2 is arranged horizontally, and the three-station turntable 2 The station turntable 2 can rotate around its center of circle, and three groups of mold frames 20 are evenly distributed on the circumference area at the same distance from its center of circle in the three-station turntable 2 (i.e. form three stations). There are at least two mold cavities 21, and the lower ends of each set of mold frames 20 are correspondingly positioned with a lower mold 10, which can be longitudinally positioned and moved in the mold frame 20 (that is, move up and down). 1. The positions of the feeder 3 and the demoulding and palletizing system are fixed, and the demoulding and palletizing system includes a demoulding and palletizing device and a brick conveyor 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com