Gasified fly ash dehydration treatment technique

A treatment process and fly ash technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of frequent replacement of filter cloth, difficult gasification fly ash treatment, low dehydration efficiency, etc., to facilitate post-processing and transportation, avoiding waste of water resources, and reducing the moisture content of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

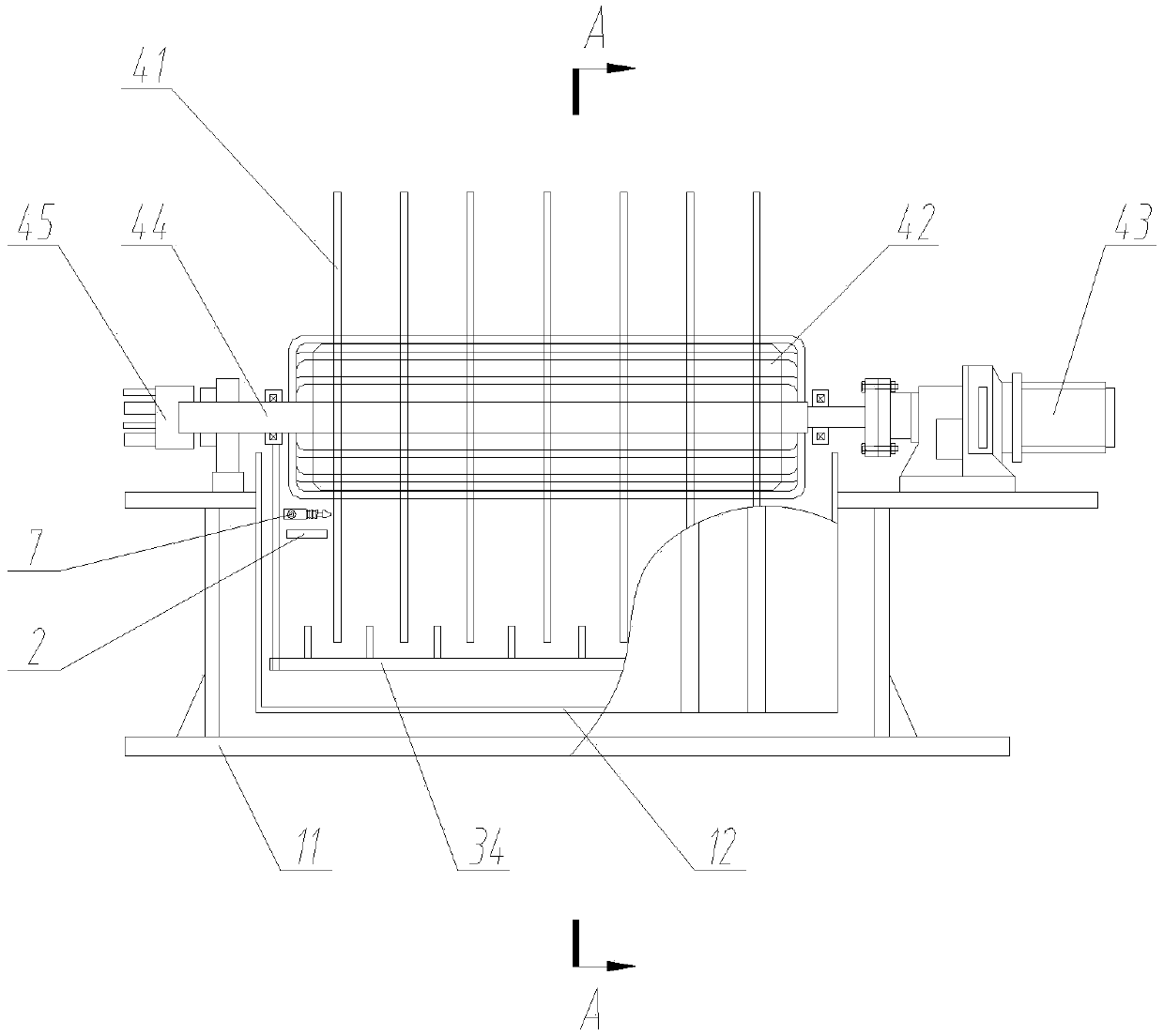

[0042] The gasification fly ash dehydration treatment process implemented by the above-mentioned equipment includes the following steps:

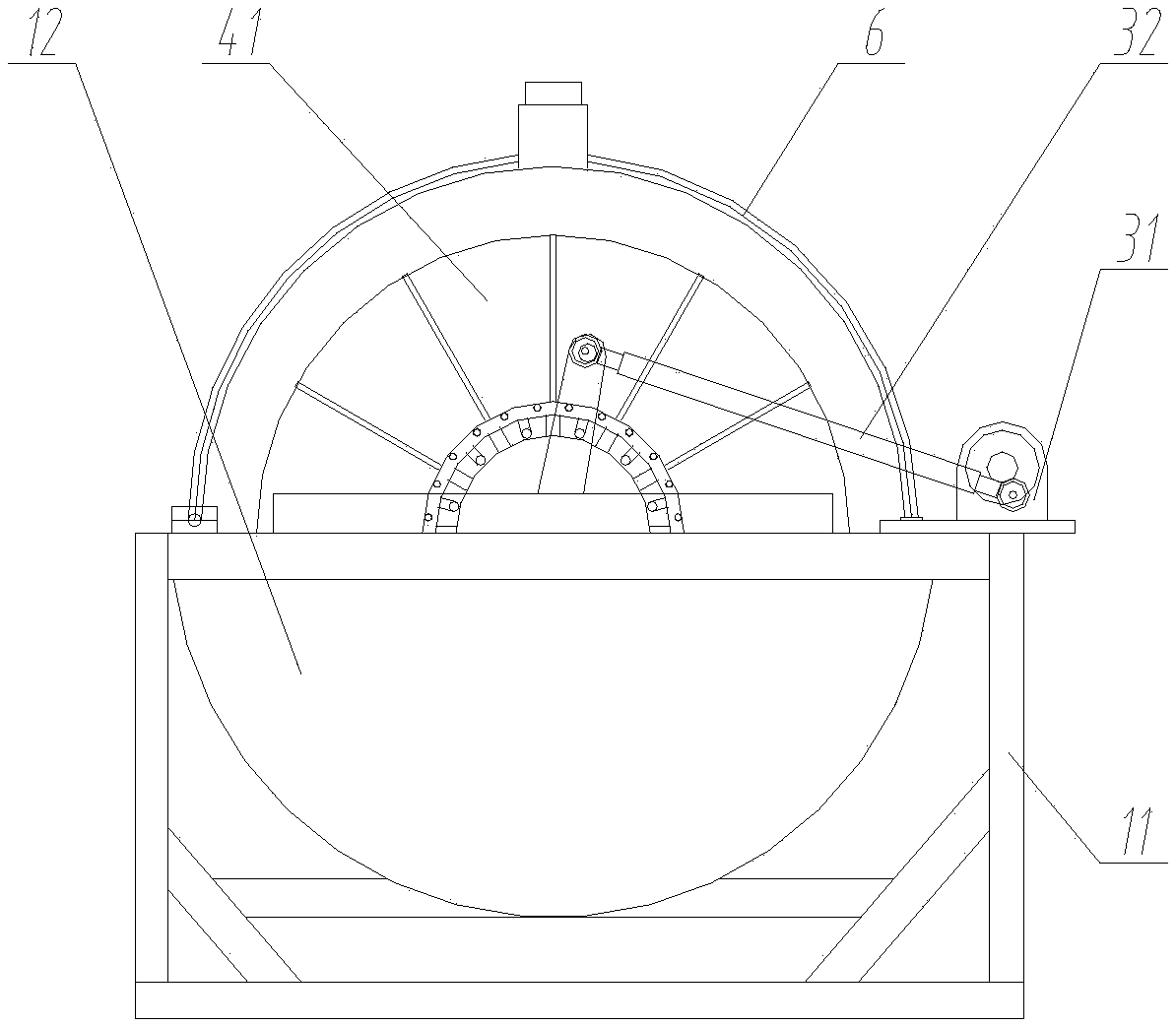

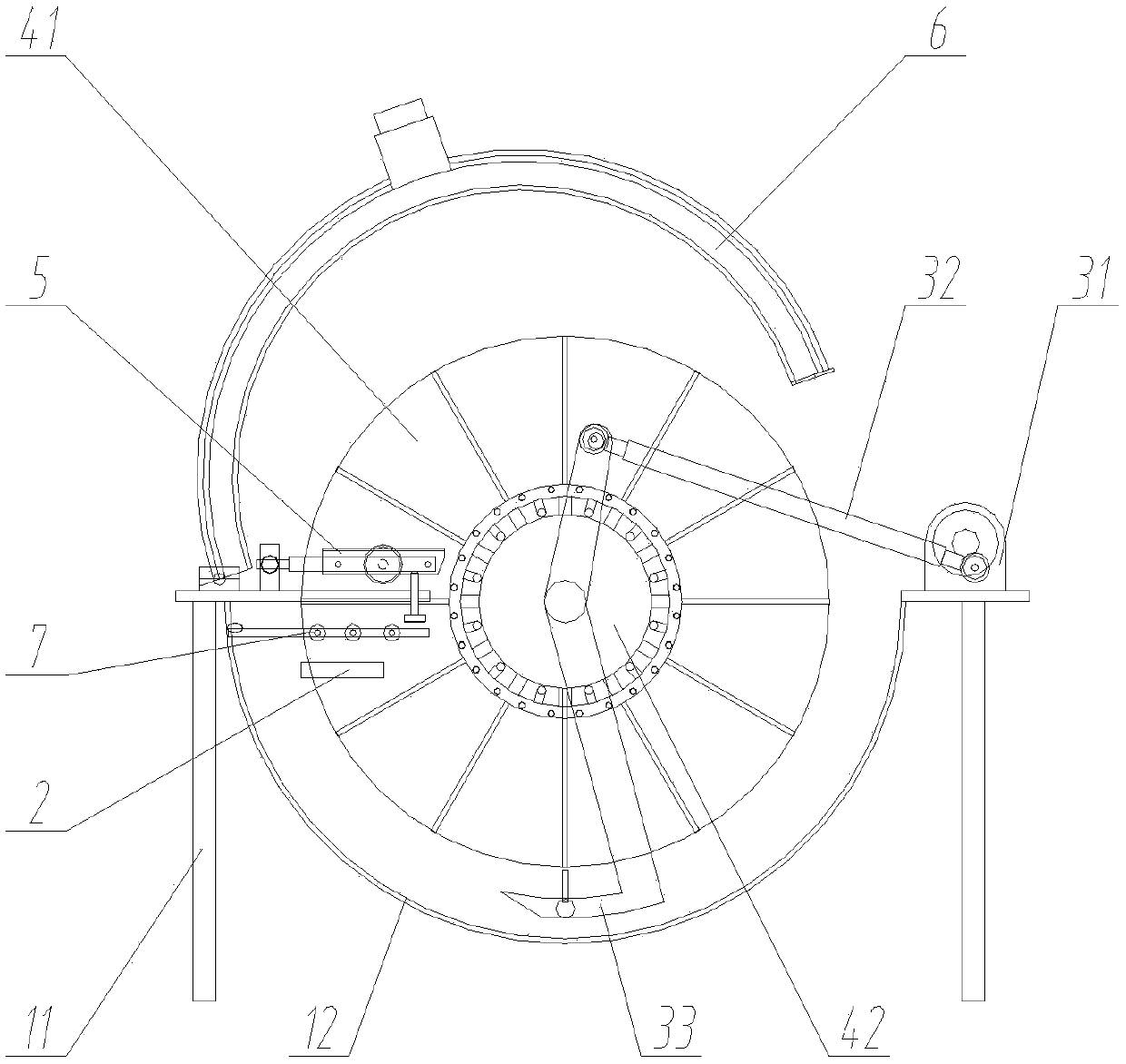

[0043] Step 1: Add flocculant to the gasified fly ash suspension, pass the gasified fly ash suspension with a temperature of 30°C and a concentration of 20% into the filter tank 12, and immerse the ceramic filter disc 41 in the gasified fly ash suspension In the liquid, start the second motor 43, the second motor 43 drives the main shaft 44 and the ceramic filter disc 41 to rotate at a speed of 2-5r / min, and start the vacuum pump to evacuate the ceramic filter disc 41 through the distribution valve 45 to make the inside and the outside The pressure difference is in a negative pressure state;

[0044] Step 2: start the first motor 31 again, and the first motor 31 drives the main plate and the stirring connecting rod 32 to realize the structural movement of the crank rocker, so that the stirring rocker 33 swings around the middle, and the swi...

Embodiment 2

[0051] The gasification fly ash dehydration treatment process implemented by the above-mentioned equipment includes the following steps:

[0052] Step 1: Add flocculant to the gasified fly ash suspension, pass the gasified fly ash suspension with a temperature of 80°C and a concentration of 20% into the filter tank 12, and immerse the ceramic filter disc 41 in the gasified fly ash suspension In the liquid, start the second motor 43, the second motor 43 drives the main shaft 44 and the ceramic filter disc 41 to rotate at a speed of 2-5r / min, and start the vacuum pump to evacuate the ceramic filter disc 41 through the distribution valve 45 to make the inside and the outside The pressure difference is in a negative pressure state;

[0053] Step 2: start the first motor 31 again, and the first motor 31 drives the main plate and the stirring connecting rod 32 to realize the structural movement of the crank rocker, so that the stirring rocker 33 swings around the middle, and the swi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com