Wire bonding apparatus

a technology of wire bonding and wire, which is applied in the direction of non-electric welding apparatus, welding apparatus, manufacturing tools, etc., can solve the problems of long short service life of wire, and inability to protrude from wire for forming a tail, etc., and achieves the effect of convenient protruding, smooth protruding, and extended usage period of capillary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

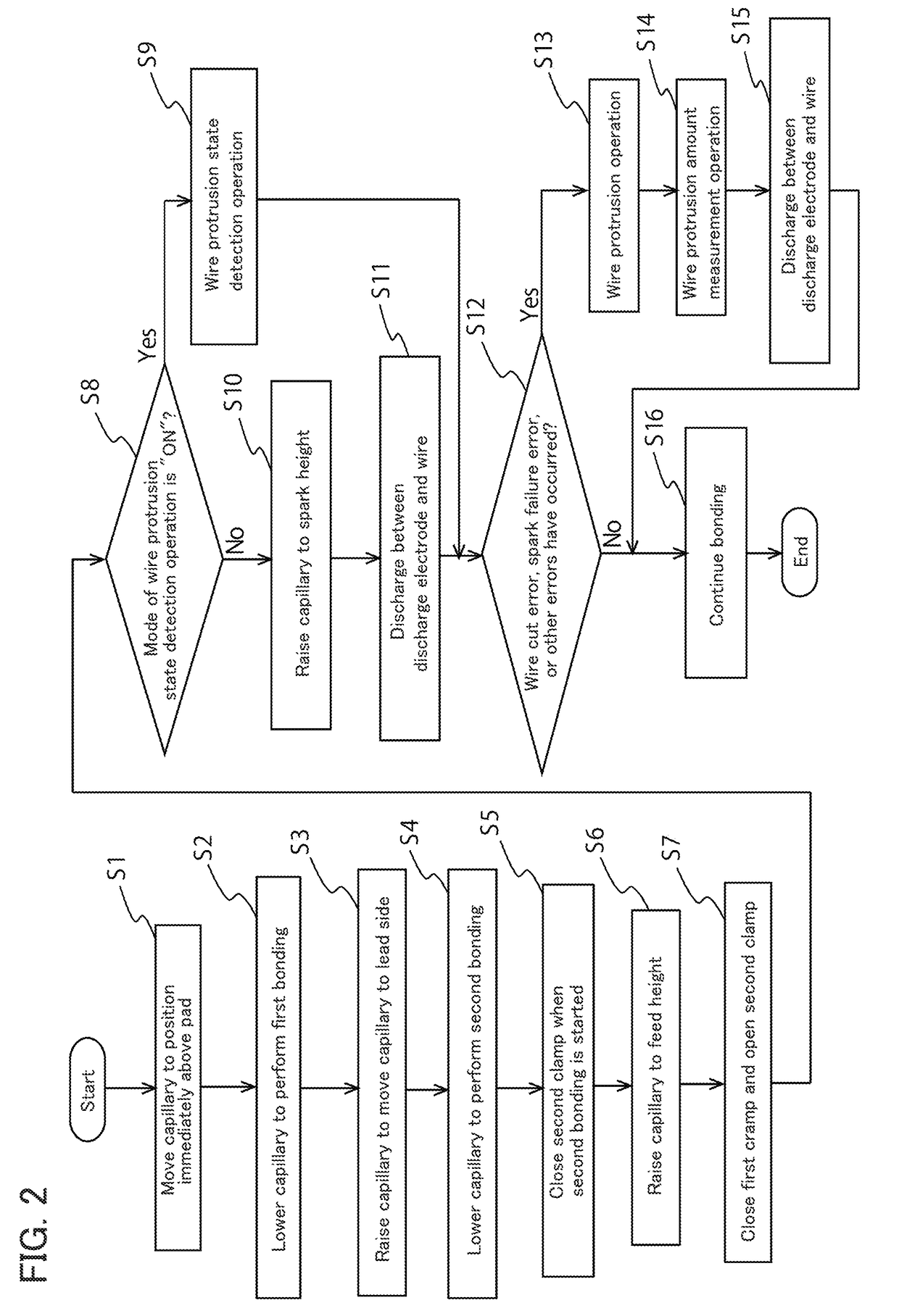

[0049]Now, with reference to the drawings, a wire bonding apparatus according to an embodiment of the present invention is described. According to the present invention, a wire can be automatically protruded from a leading end of a capillary without being affected by a bonding state at a second bonding point or members such as the capillary and the wire. Further, cleaning of removing dirt on the capillary during bonding and protrusion of the wire after the capillary is cleaned can be reliably performed. Thus, an operating rate of the wire bonding apparatus is significantly improved.

[0050][Configuration of Wire Bonding Apparatus]

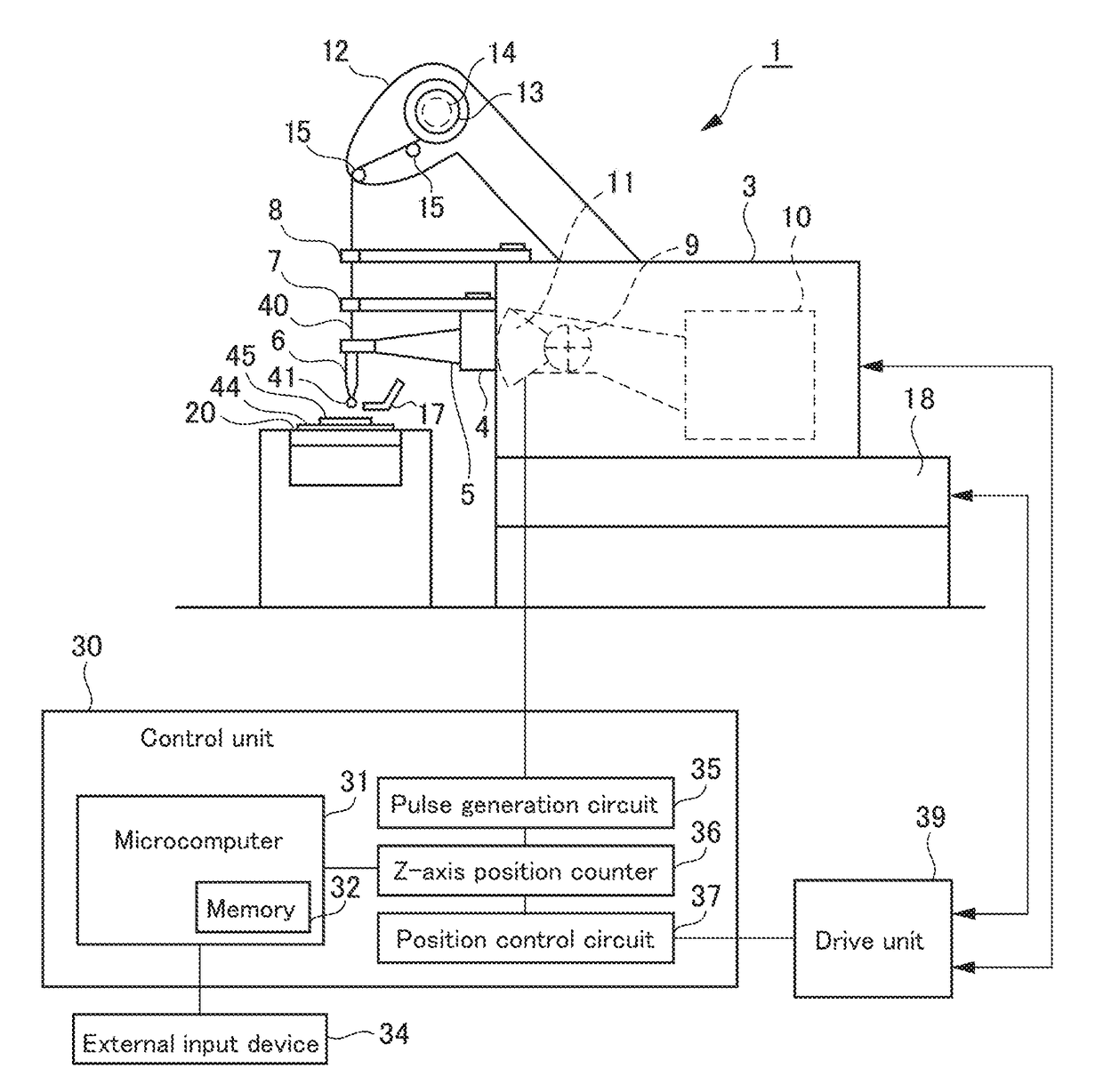

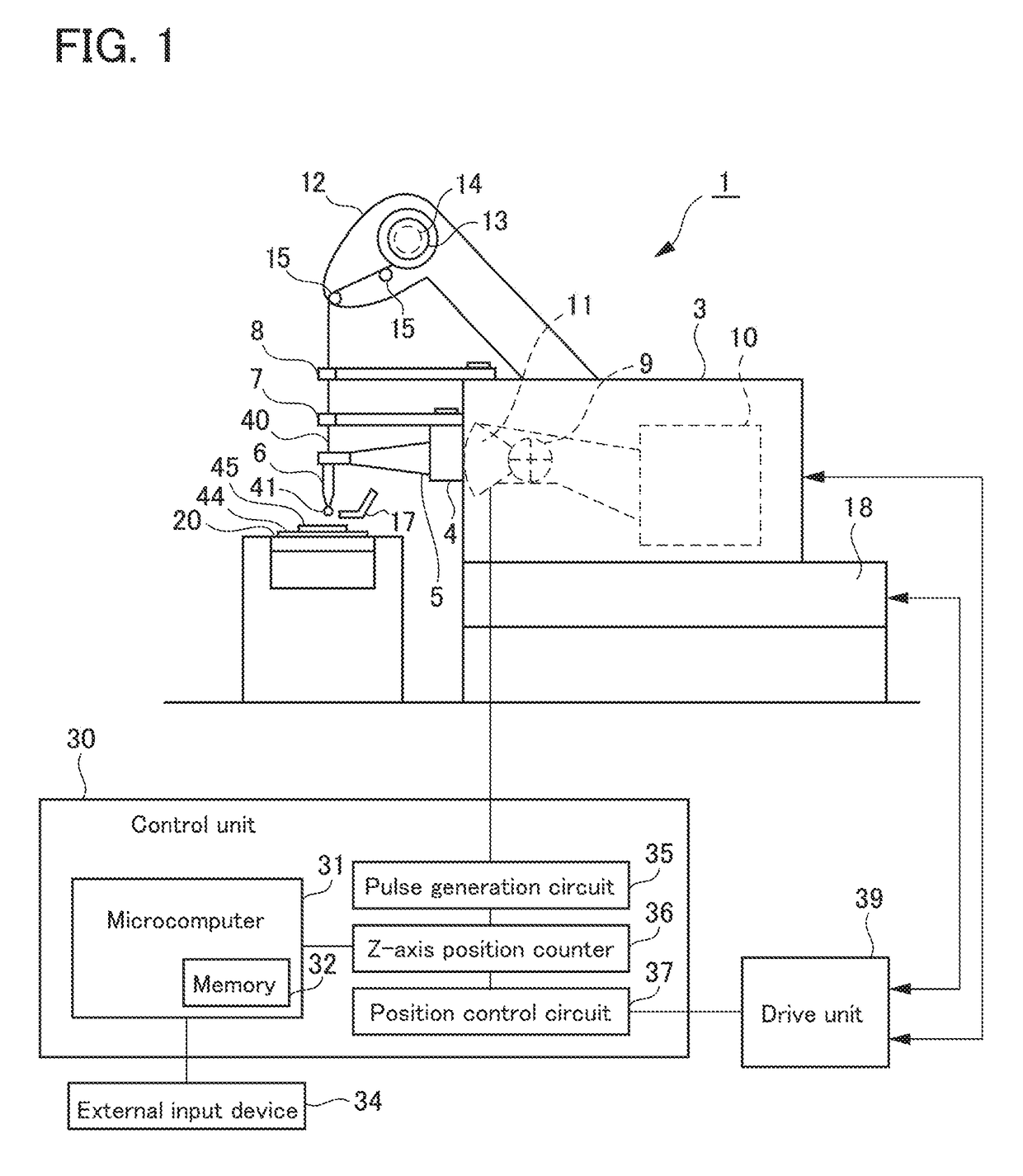

[0051]FIG. 1 is a diagram for illustrating a configuration of the wire bonding apparatus of the present invention. As illustrated in FIG. 1, a wire bonding apparatus 1 includes a bonding head 3, an XY stage 18 serving as positioning means, on which the bonding head 3 is mounted, for positioning the bonding head 3 by two-dimensionally moving the bonding head 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| ultrasonic vibration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com