Tobacco production line equipment inspection method based on wireless technology

A wireless technology and assembly line technology, applied in the direction of registering/indicating machine work, instruments, registering/indicating, etc., can solve problems such as difficult maintenance and repair plans, low efficiency of inspection results, easy missing items or errors, etc., to achieve saving The effect of maintenance costs, improving the effective utilization rate of equipment, and reducing the failure rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

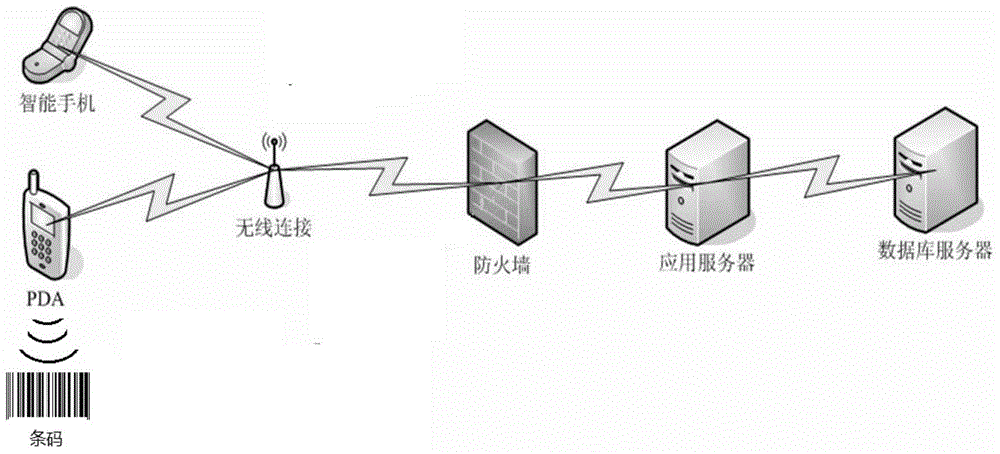

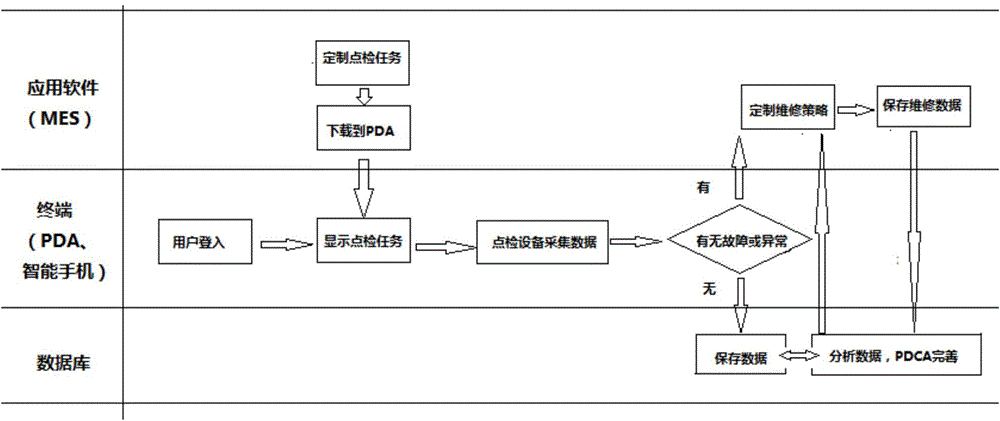

[0023] like figure 1 Shown is a tobacco assembly line equipment inspection system based on wireless technology. The system includes terminal equipment, barcodes, wireless routers, firewalls, application servers, and database servers. The terminal equipment adopts a PDA or smart phone with wireless WIFI function, and the bar code is unique for each part of each equipment. The terminal equipment is connected to the application server and the database server through a wireless router to transmit data.

[0024] The terminal mentioned above is represented by PDA, which is equipped with special inspection software (EqucCheck), and users can see their own inspection tasks after logging in. Inspection tasks include inspection routes and equipment operating parameter requirements. The maintenance personnel scan the barcode on the equipment during the inspection, record and report the current equipment operating parameters, the location of the inspection personnel, the inspection time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com