Combination system for treating landfill leachate and method for treating landfill leachate by using combination system

A landfill leachate and combined system technology, which is applied to the combined system for treating landfill leachate and the field of landfill leachate treatment, can solve problems such as increasing cleaning difficulty and cleaning frequency, shortening continuous operation time, and hindering the smooth progress of evaporation, etc., to achieve The effect of extending the continuous operation time, shortening the processing cycle, and improving the continuous operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

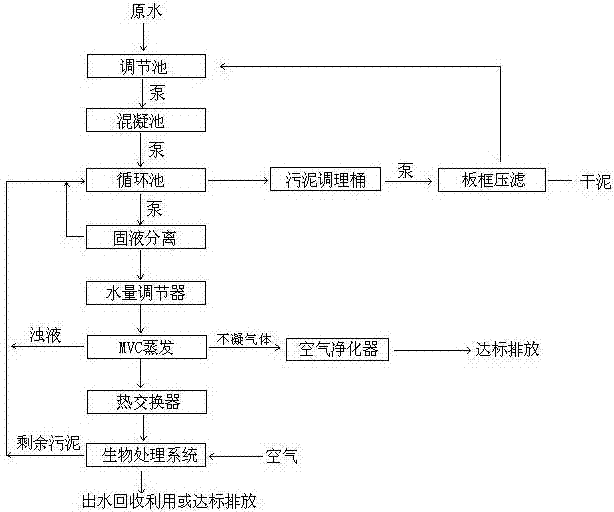

Image

Examples

Embodiment 1

[0029] A garbage transfer station in Shanghai produces about 200 tons of landfill leachate per day. The original COD of the filtrate is about 15,000 mg / L, the SS is about 9,000 mg / L, the ammonia nitrogen is about 40 mg / L, and the chroma is about 500 times.

[0030] Proceed as follows:

[0031] (1) After the landfill leachate is coagulated, it is pumped into the UF system of the leachate combined system through a water pump with a lift of 30 meters. The UF filter membrane has a pore size of 0.1 μm and is made of polypropylene nitrile. The liquid COD after ultrafiltration is reduced to 5600mg / L, SS is reduced to 40mg / L, and the separated sludge is dehydrated and then incinerated;

[0032] (2) Use a water pump to pump the supernatant into the water volume regulator to adjust the water volume and then enter the MVC system for evaporation. No foam is generated during the evaporation process. The COD of the evaporated liquid is determined to be 600 mg / L, and the water and supernatan...

Embodiment 2

[0037] A garbage transfer station in Nanjing produces about 400 tons of landfill leachate per day. The original COD of the filtrate is about 20,000 mg / L, the SS is about 11,000 mg / L, the ammonia nitrogen is about 60 mg / L, and the chroma is about 500 times.

[0038] Proceed as follows:

[0039] (1) After coagulation, the landfill leachate is pumped into the coagulation and sedimentation system of the leachate combined system through a water pump with a lift of 35 meters. The coagulation and sedimentation condition is to add a polymer coagulant aid. After coagulation and sedimentation, the COD of the liquid is reduced to 5000mg / L, and the SS is reduced to 36mg / L, and the separated sludge is directly recharged;

[0040] (2) Use a water pump to pump the supernatant into the water volume regulator to adjust the water volume and then enter the MVC system for evaporation. No foam is generated during the evaporation process. The COD of the evaporated liquid is determined to be 500 mg / ...

Embodiment 3

[0045] A garbage transfer station in Wuxi produces about 250 tons of landfill leachate per day, the original COD of the filtrate is about 12000mg / L, the SS is about 8000mg / L, the ammonia nitrogen is about 40mg / L, and the chroma is about 400 times.

[0046] Proceed as follows:

[0047] (1) After coagulation, the landfill leachate is pumped into the UF system of the leachate combined system through a water pump with a lift of 25 meters. The UF filter membrane has a pore size of 0.04 μm and is made of polypropylene nitrile, and is carried out by cross-flow ultrafiltration. Ultrafiltration. After coagulation and sedimentation, the measured COD drops to 4600mg / L, SS drops to 28mg / L, and the separated sludge is directly refilled;

[0048] (2) Use a water pump to pump the supernatant into the water volume regulator to adjust the water volume and then enter the MVC system for evaporation. No foam is generated during the evaporation process. The COD of the evaporated liquid is determi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com