Continuous operation production process for synthesizing hydrogen chloride to prepare hydrochloric acid

A technology of hydrogen chloride and hydrogen chloride gas, applied in the direction of chlorine/hydrogen chloride, etc., can solve the problems of demanding circulating water production process, failure, equipment blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

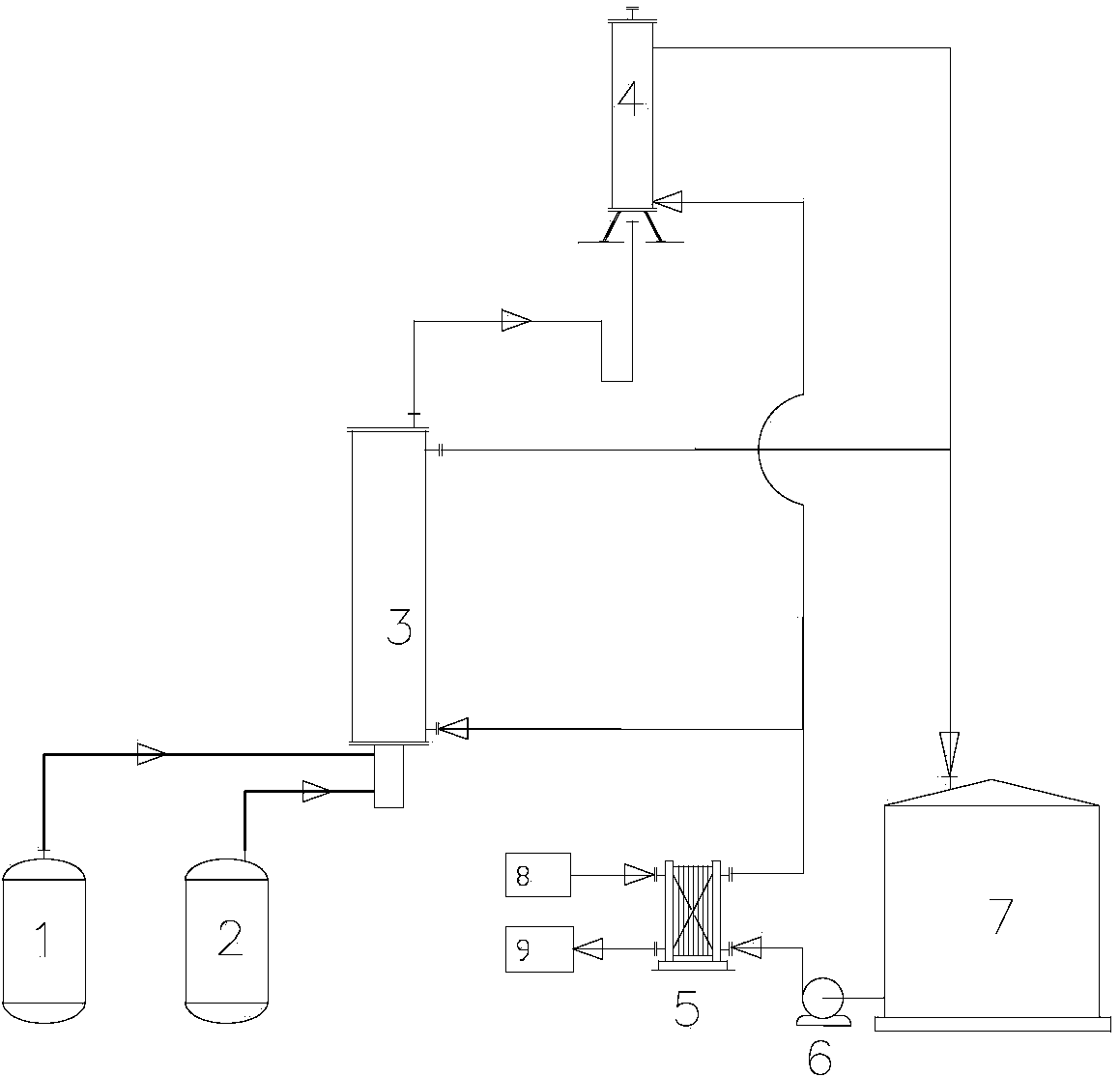

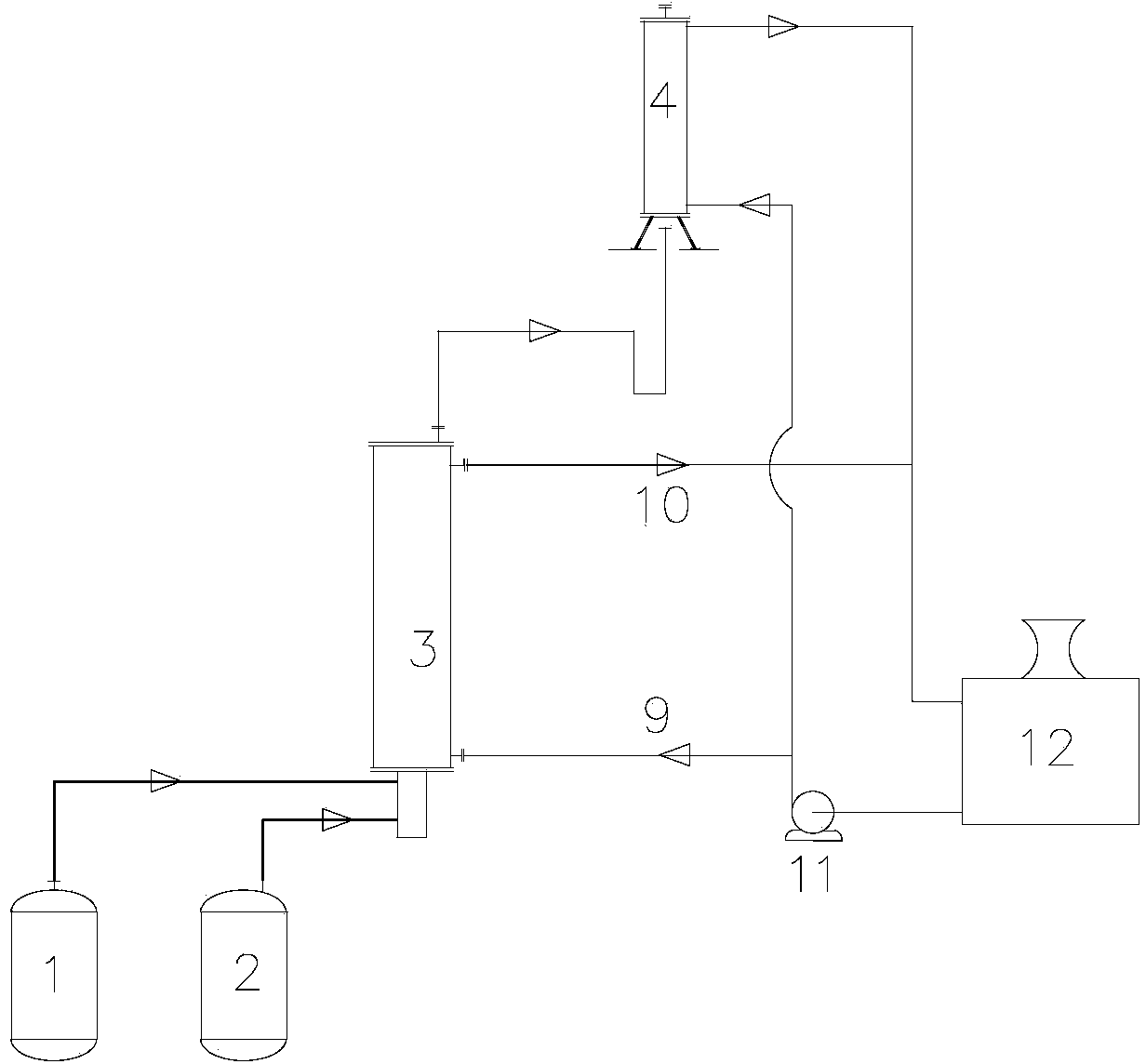

[0019] Embodiment 1: the schematic flow chart is as figure 1 shown.

[0020] A continuous operation production process for synthesizing hydrogen chloride and producing hydrochloric acid. Hydrogen and chlorine are respectively adjusted in the hydrogen buffer tank 1 and chlorine buffer tank 2 to adjust the pressure to 0.1 MPa, adjust the flow rate, and pass into the synthesis furnace 3 according to the molar ratio of hydrogen and chlorine at 1:1.05. , the combustion reaction in the synthesis furnace 3 produces hydrogen chloride gas at about 1800 ° C; the hydrogen chloride gas is cooled to about 40 ° C in the furnace body, enters the absorber 4 and is absorbed by pure water to become hydrochloric acid, and the excess gas enters the tail gas device for absorption. Among them, the heat generated during the synthesis and absorption of hydrogen chloride is removed in the following ways:

[0021] First use circulating cooling water to cool the desalted water in the heat exchanger 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com