Novel composite mute floor and manufacturing method thereof

A composite, silent technology, used in building structures, other home appliances, floors, etc., can solve the problems of affecting the quality of the board, the wear resistance is not high enough, and the surface of the workpiece is easily scratched, so as to reduce waste of resources and prevent The effect of low cooling temperature and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

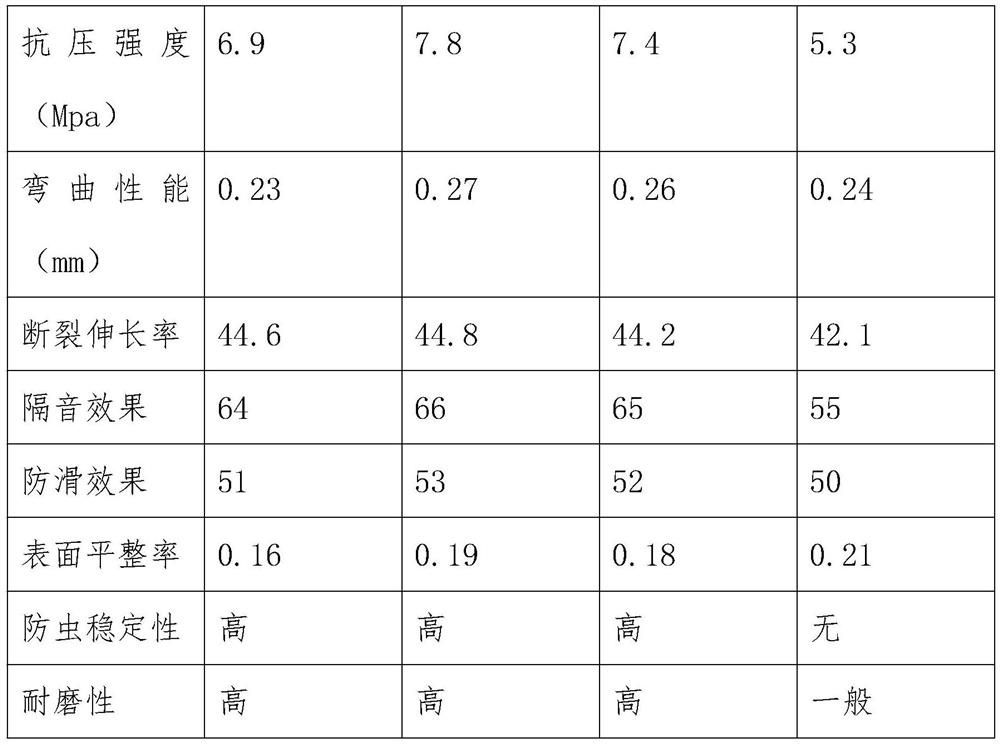

Embodiment 1

[0022] A new composite silent floor proposed by the present invention includes the following preparation materials: inner core layer: 50 parts of sawdust, 42 parts of polyvinyl chloride resin, 28 parts of glue, 10 parts of chemical fiber, 10 parts of foaming agent and 5 parts of insect repellent PVC sound-absorbing layer: 10 parts of PVC resin, 3 parts of foaming agent and 6 parts of stabilizer; wear-resistant layer: 8 parts of polystyrene resin, 5 parts of wear-resistant agent, 1 part of antioxidant and 6 parts of toughening agent.

[0023] A method for manufacturing a novel composite silent floor, comprising the following preparation steps:

[0024] S1. Put the prepared wood chips and polyvinyl chloride resin into a mixer by weight and heat and stir for 1 hour. The rotation speed of the mixer is 45r / s, and the temperature is controlled at 85°C to obtain the first mixture of substrates;

[0025] S2. Then add glue, chemical fiber and insect repellent to the stirring in S1 and ...

Embodiment 2

[0032] A new composite silent floor proposed by the present invention includes the following preparation materials: inner core layer: 55 parts of sawdust, 47 parts of polyvinyl chloride resin, 33 parts of glue, 13 parts of chemical fiber, 13 parts of foaming agent and 6 parts of insect repellent PVC sound-absorbing layer: 15 parts of PVC resin, 4 parts of foaming agent and 7 parts of stabilizer; wear-resistant layer: 13 parts of polystyrene resin, 10 parts of wear-resistant agent, 2 parts of antioxidant and 8 parts of toughening agent.

[0033] A method for manufacturing a novel composite silent floor, comprising the following preparation steps:

[0034] S1. Put the prepared wood chips and polyvinyl chloride resin into a mixer by weight and heat and stir for 2 hours. The rotation speed of the mixer is 45r / s, and the temperature is controlled at 90°C to obtain the first mixture of substrates;

[0035] S2. Then add glue, chemical fiber and insect repellant to the stirring in S1 ...

Embodiment 3

[0042] A new composite silent floor proposed by the present invention includes the following preparation materials: inner core layer: 60 parts of sawdust, 52 parts of polyvinyl chloride resin, 38 parts of glue, 15 parts of chemical fiber, 15 parts of foaming agent and 7 parts of insect repellent PVC sound-absorbing layer: 20 parts of PVC resin, 5 parts of foaming agent and 8 parts of stabilizer; wear-resistant layer: 18 parts of polystyrene resin, 15 parts of wear-resistant agent, 3 parts of antioxidant and 10 parts of toughening agent.

[0043] A method for manufacturing a novel composite silent floor, comprising the following preparation steps:

[0044] S1. Put the prepared wood chips and polyvinyl chloride resin into a mixer by weight and heat and stir for 3 hours. The rotation speed of the mixer is 45r / s, and the temperature is controlled at 95°C to obtain the first mixture of substrates;

[0045] S2. Then add glue, chemical fiber and insect repellant to the stirring in S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com