Cooling crystallization desalting system for high-salinity waste water

A technology of cooling crystallization and high salt content, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as equipment corrosion and scaling, high energy consumption, etc., and achieve reduction Corrosion, improve utilization efficiency, solve the effect of heat exchange deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

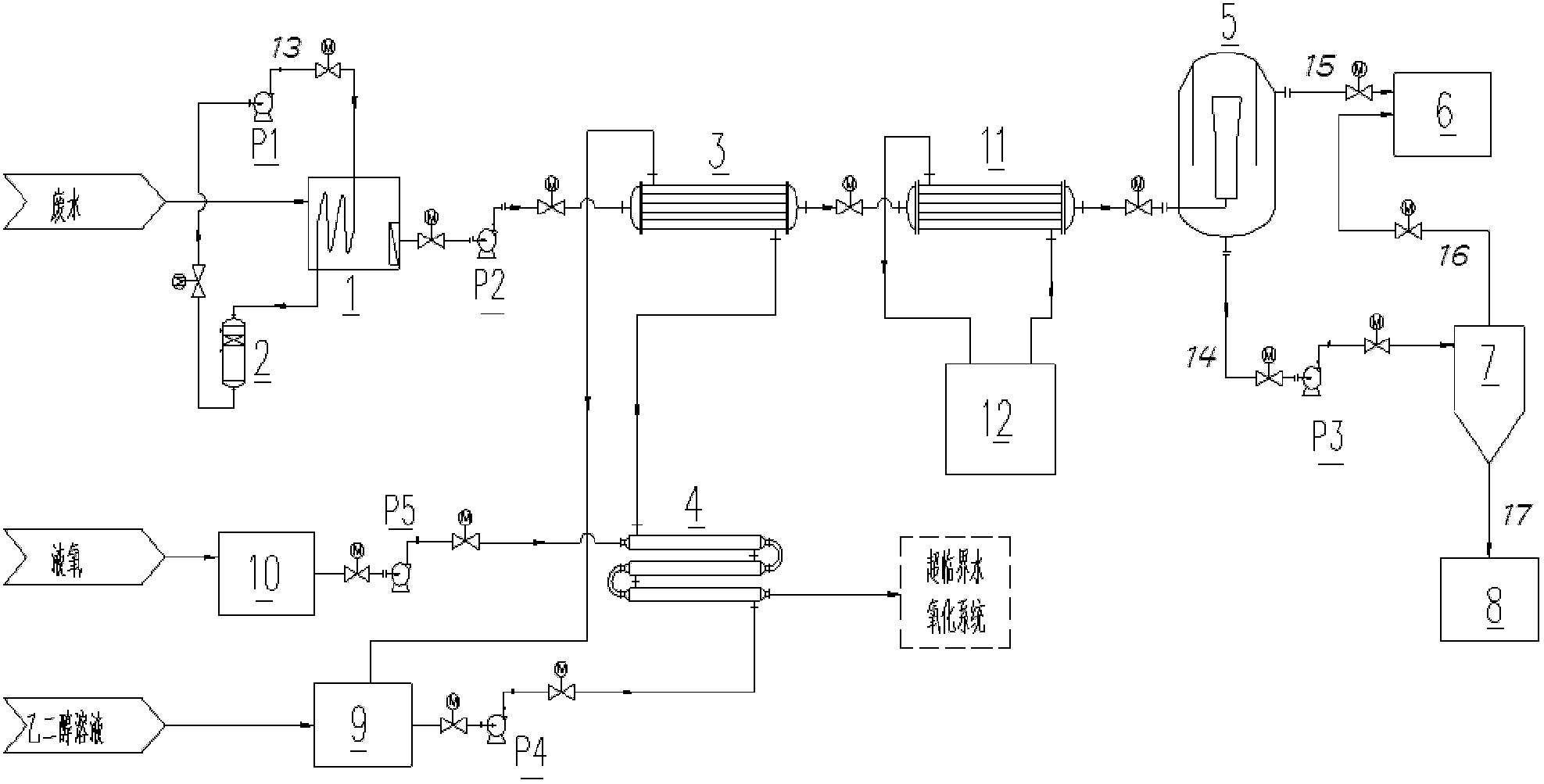

[0018] refer to figure 1 , the high-salt wastewater is stored in the wastewater storage tank 1, the outlet of the wastewater storage tank 1 is connected to the wastewater pump P2, the outlet of the wastewater pump is connected to the inlet of the wastewater heat exchanger 3 tube side, and the outlet of the wastewater heat exchanger 3 tube side is connected to The inlet of the tube side of the heat exchanger 11 of the refrigerating unit is connected, and the outlet of the tube side of the heat exchanger 11 of the refrigerating unit is connected with the inlet of the cooling crystallizer 5 . The shell-side outlet and inlet of the heat exchanger 11 of the refrigerating unit are respectively connected with the inlet and the outlet of the refrigerating unit 12 . The outlet of the mother liquor on the upper part of the cooling crystallizer 5 is connected to the inlet of the comprehensive waste water tank 6, the outlet of the crystal slurry on the lower part of the cooling crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com