Air treatment system and method for cooling resin slices

An air handling system and resin slicing technology, applied in the field of resin processing, can solve the problem that the cooling capacity of the air inlet cooling unit cannot meet the needs of high-load production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

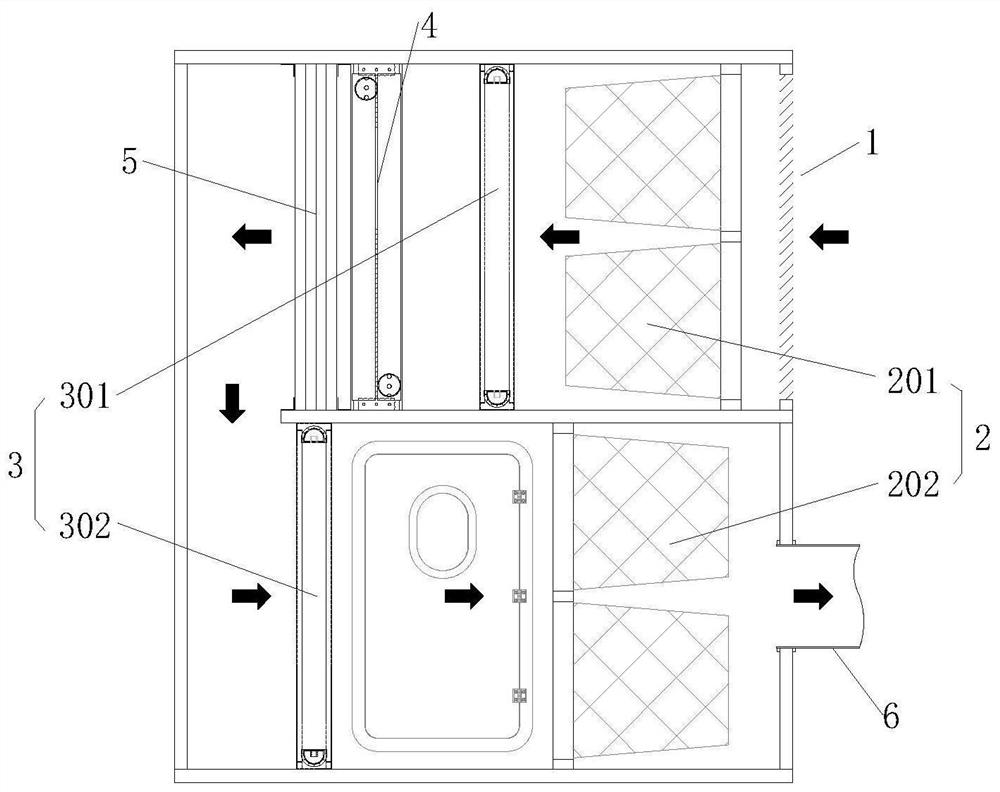

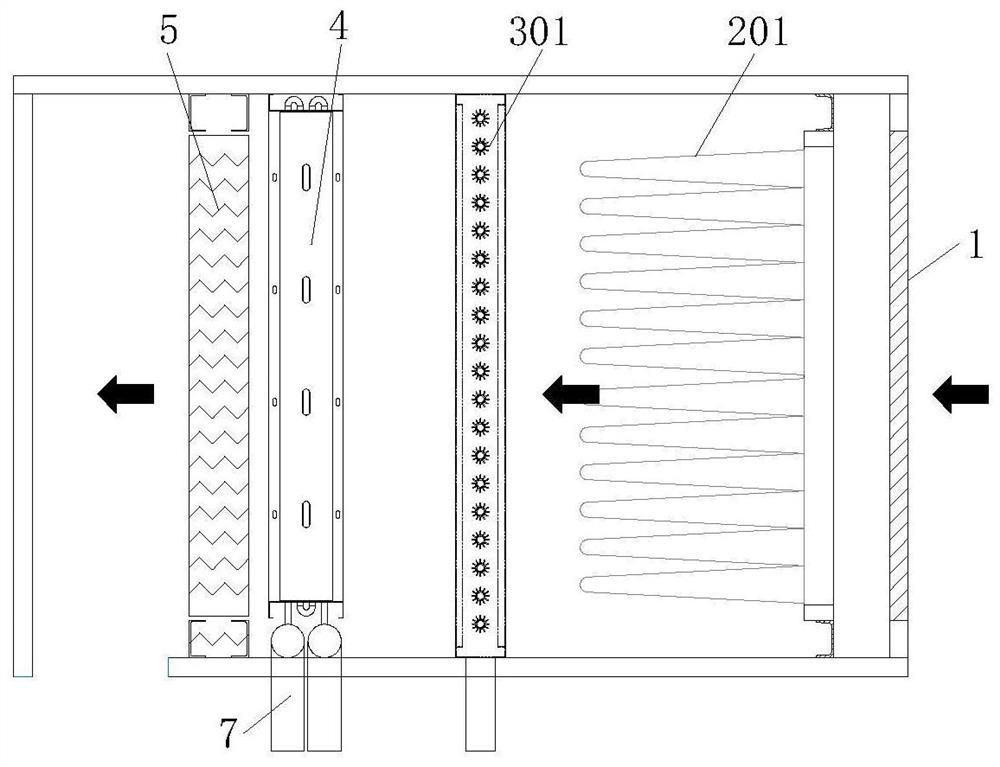

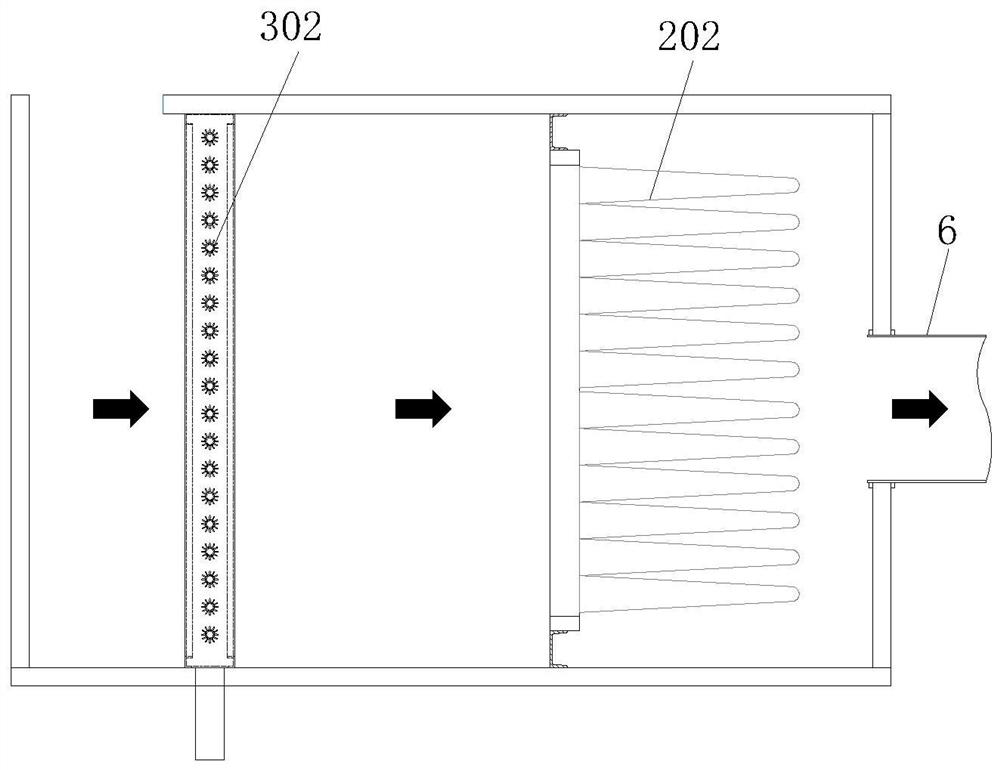

[0032] Please refer to the attached Figure 1-3 , with figure 1 It shows the front view of the air handling system for cooling the resin chips provided by the embodiment of the present application, and the attached figure 2 Shows the embodiment provided by the application figure 1 Top view of the middle and upper floors, with image 3 Shows the embodiment provided by the application figure 1 A top view of the middle and lower floors. attached by Figure 1-3 It can be seen that the air treatment system for cooling resin chips provided by the embodiment of the present application includes a louver section 1 , a filter section 2 , a steam heating section 3 , a cooling section 4 and a dehumidification section 5 . The air treatment system provided by the embodiment of the present application will be described in detail below with reference to the accompanying drawings.

[0033] Specifically, the louver section 1 is a component for coarsely filtering air. The main part of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com