Automatic controlled stainless steel inner tube electrolytic polishing device

An electrolytic polishing and stainless steel tube technology, applied in the field of stainless steel surface treatment, can solve the problems of small current flow area, small electric field current, and more gas, and achieve the effects of reducing heat loss, consistent effect, and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

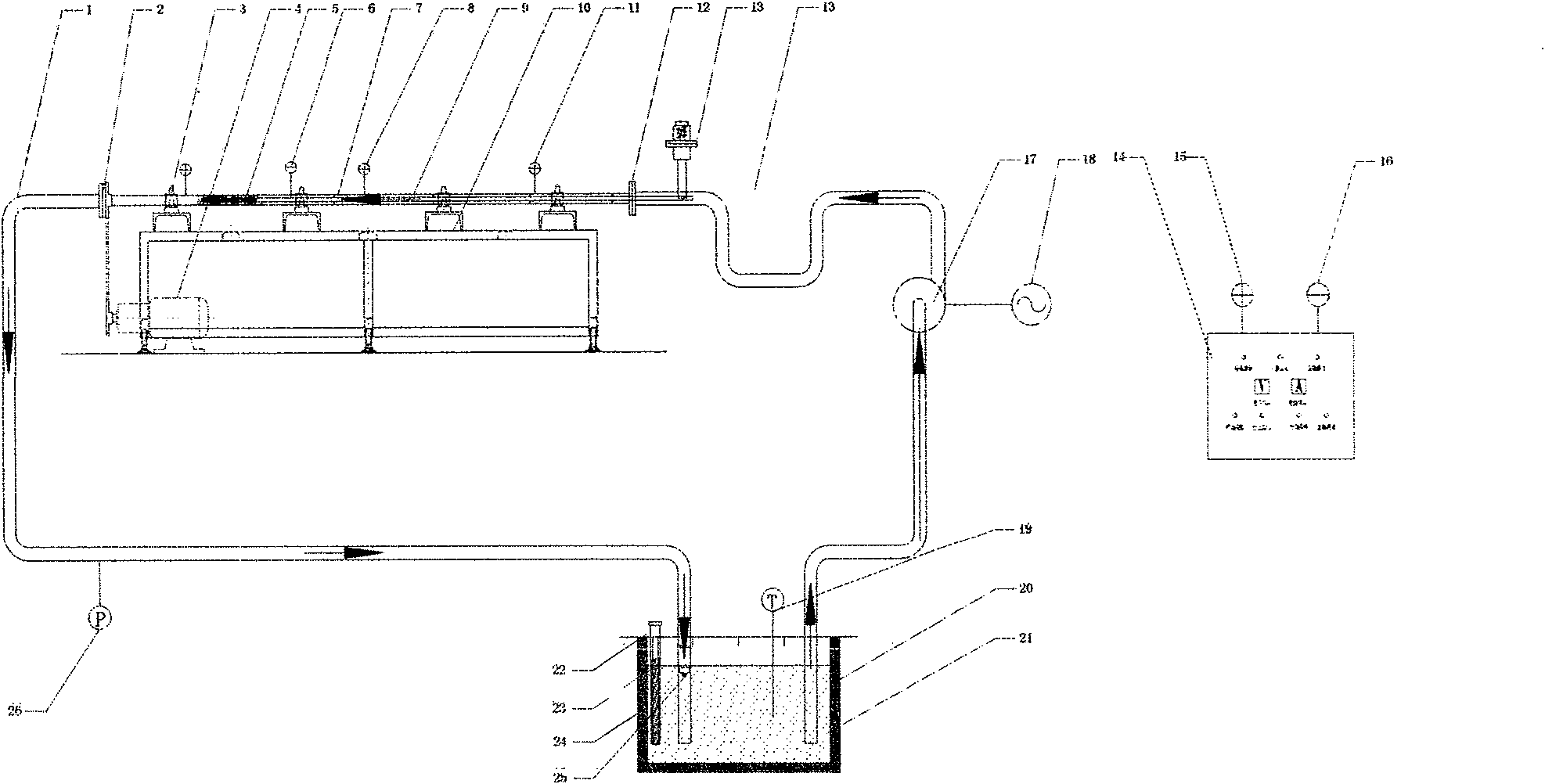

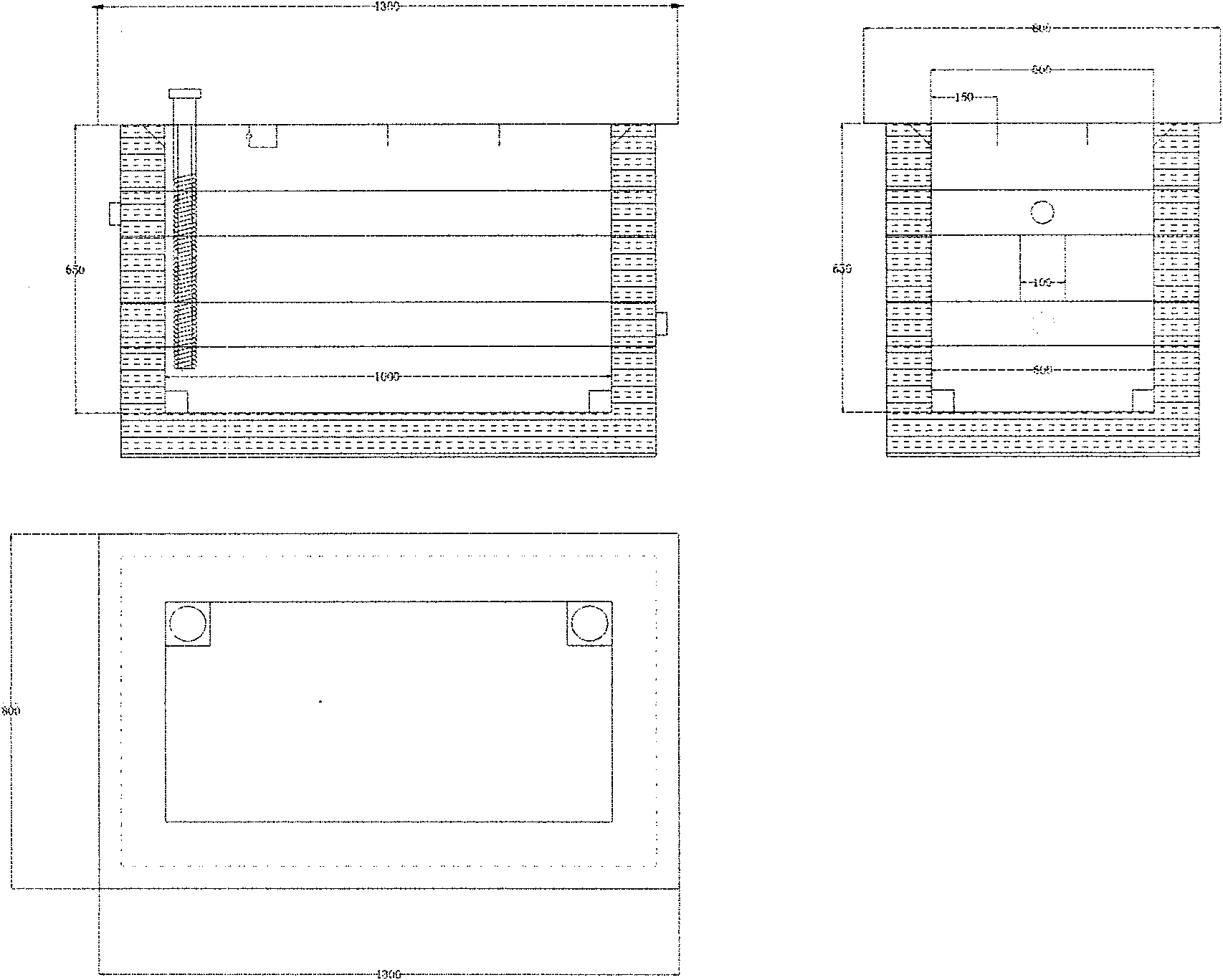

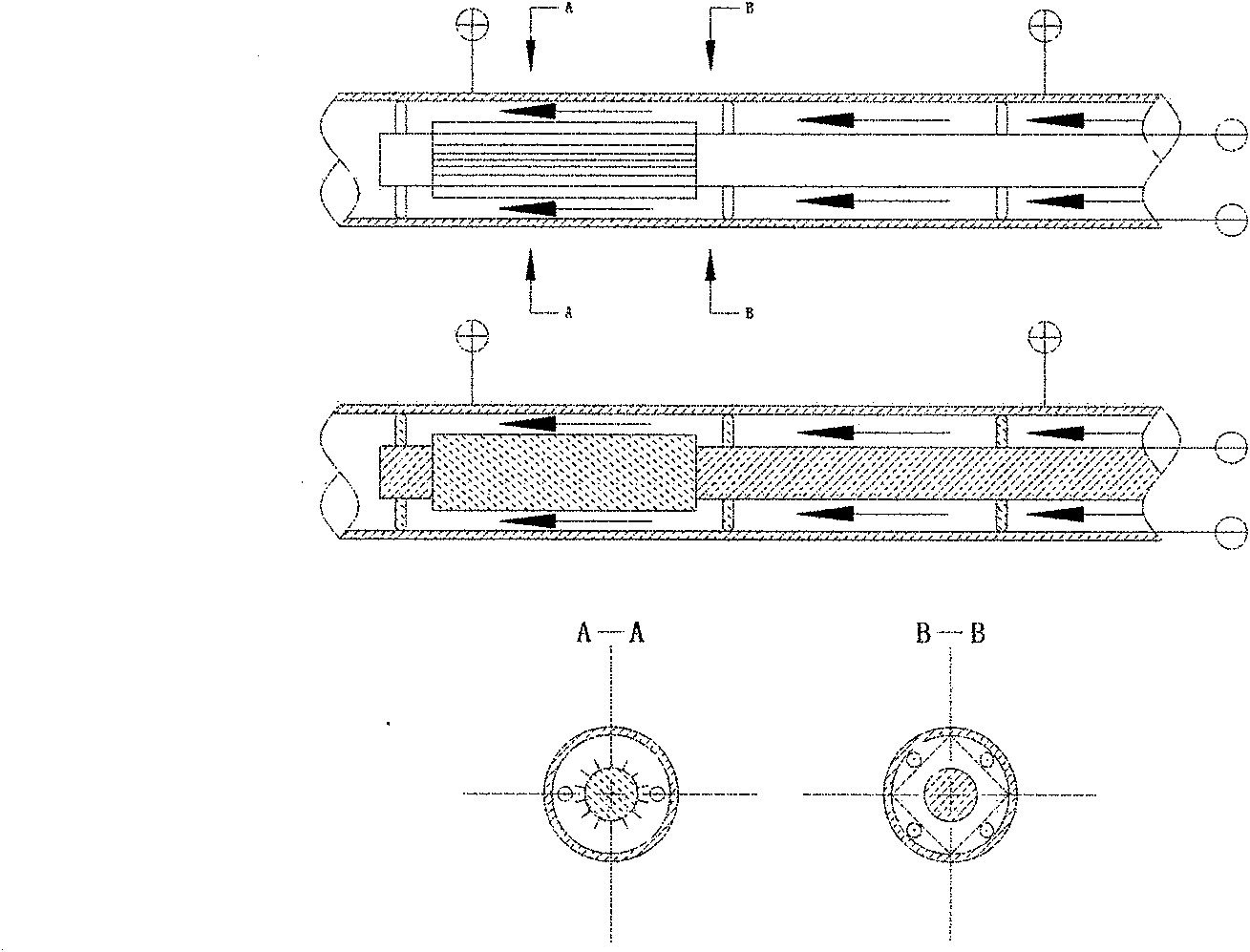

[0036] see Figure 1 to Figure 6 As shown, the automatically controlled stainless steel inner tube electrolytic polishing equipment of the present invention includes a reversible pulse power supply host 13, an electrolytic polishing liquid circulation system 1, an adjustable stainless steel tube rolling device 7, an electrolyte turnover tank 20, a movable electric ( Cathode) electrode preparation tool 5 and environment-friendly electrolytic polishing liquid 21; The main frame 14 of described reversible pulse power supply includes pulse power supply, constant current and voltage stabilizing device, time controller, automatic current regulating and voltage regulating device, overload and overcurrent protection device, An undervoltage and phase loss protection device, an adjustable duty ratio device; the electrolytic polishing liquid turnover ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com