Electrolysis system with ion membrane electrolyzer and pressure regulating method thereof

An ionic membrane electrolysis cell and electrolysis system technology, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of control valve erosion, greater air pressure fluctuation, and decreased control valve sensitivity, so as to reduce production costs and reduce pressure fluctuations. , the effect of reducing the replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

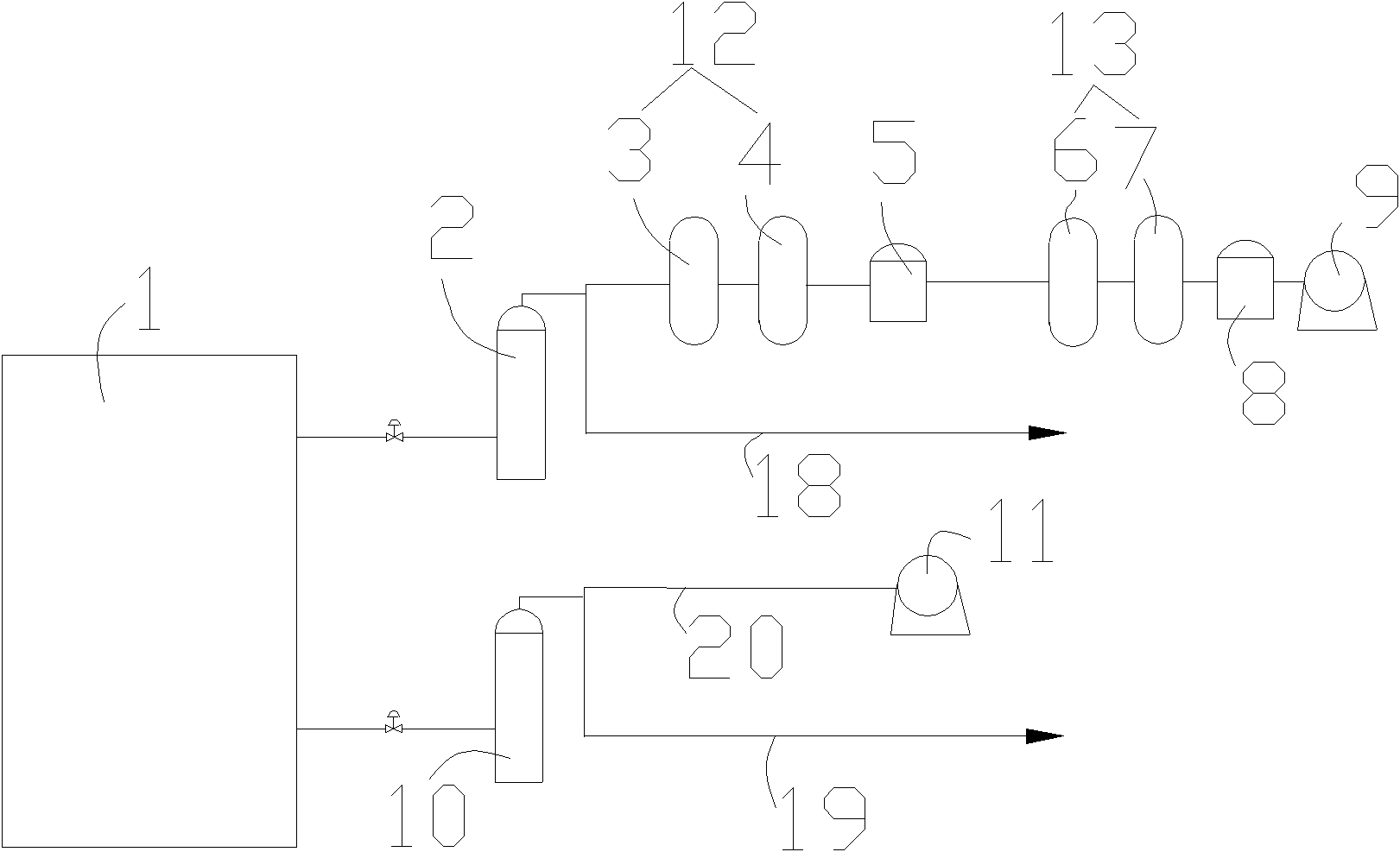

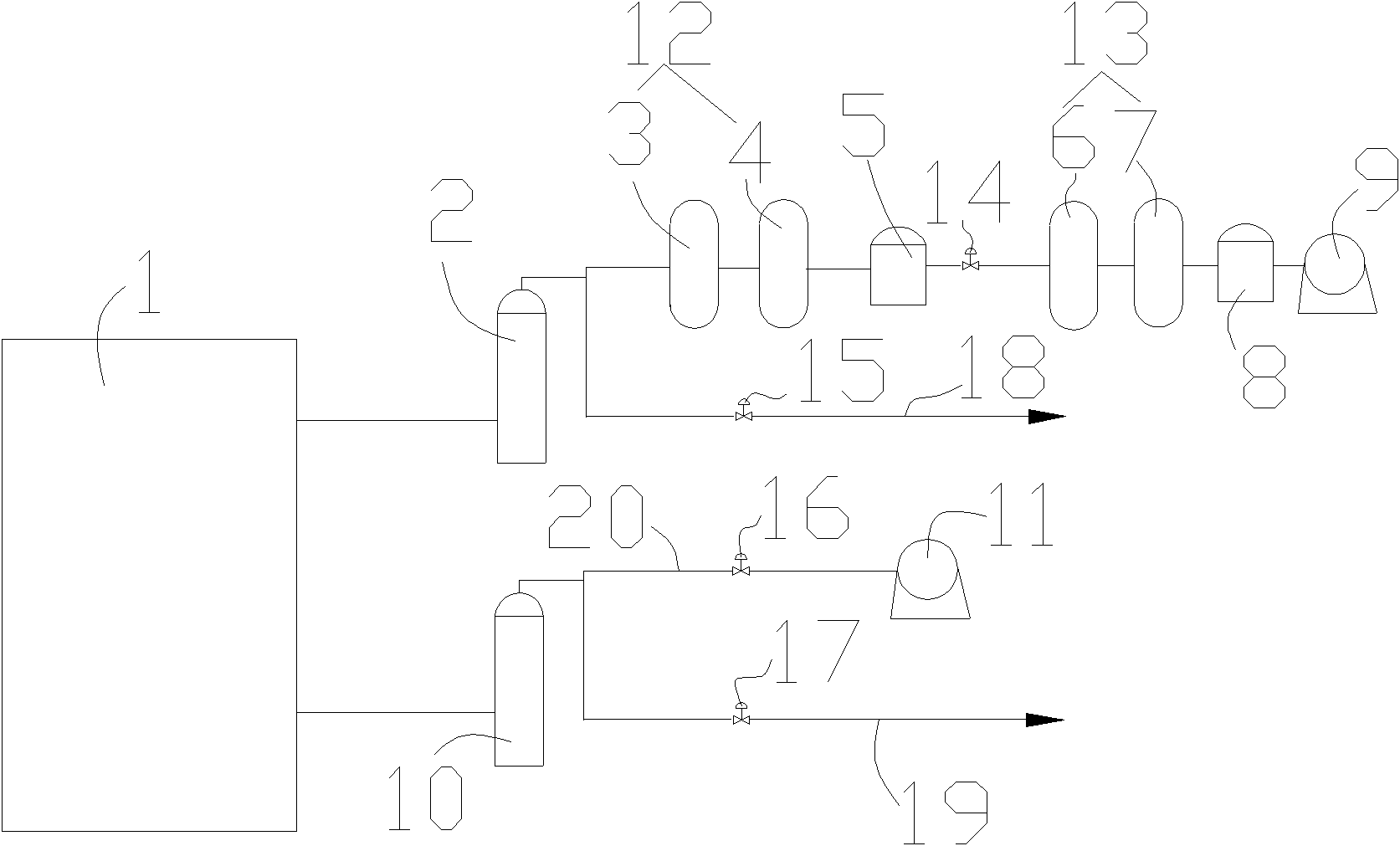

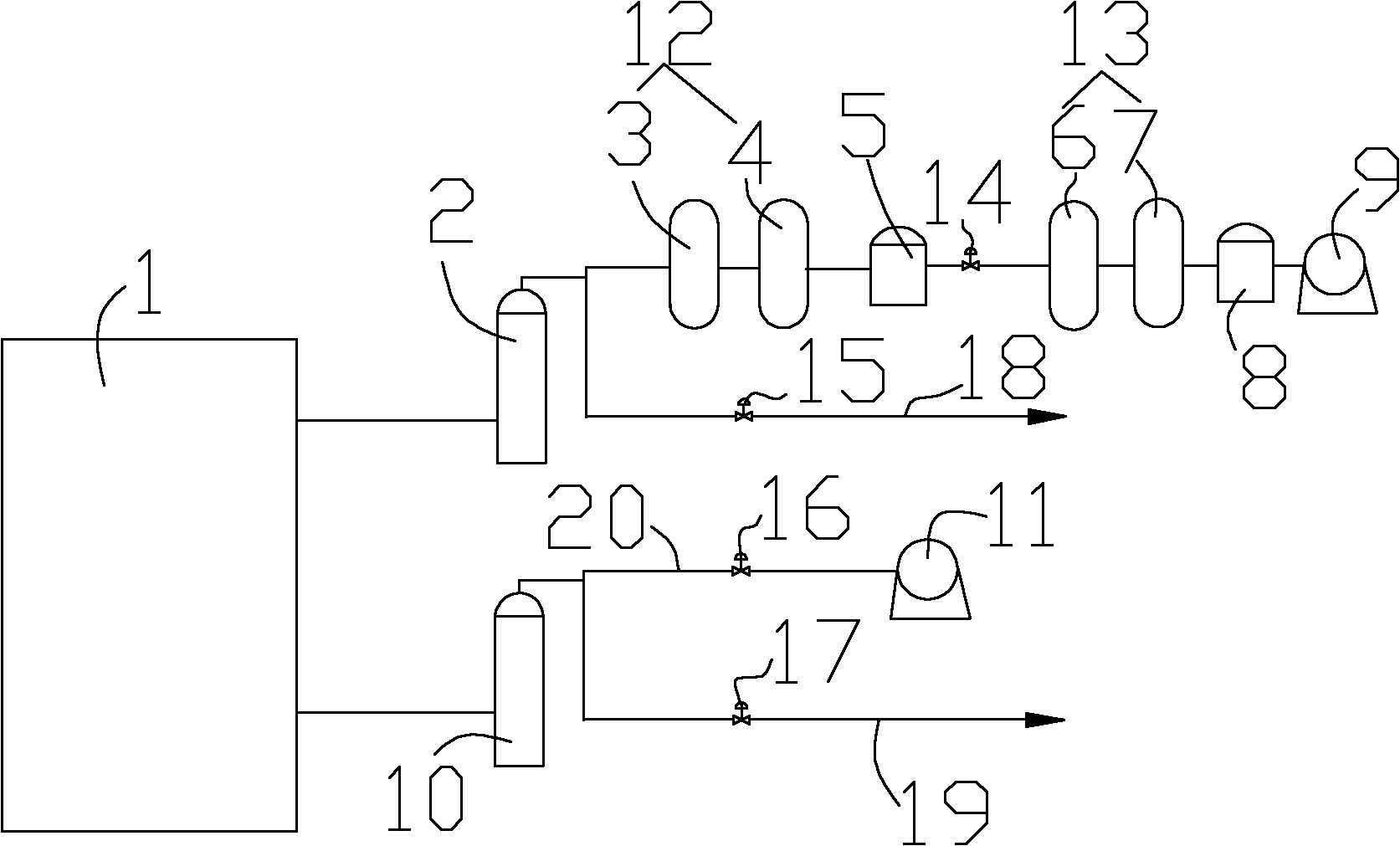

[0016] Such as figure 2 As shown, the electrolysis system containing ion-exchange membrane electrolyzer comprises ion-exchange membrane electrolyzer 1, and described ion-exchange membrane electrolyzer 1 is connected with chlorine gas recovery system and hydrogen recovery system, and described chlorine gas recovery system comprises the chlorine scrubbing that is connected successively by pipeline Tower 2, cooling device 12, water trap 5, drying device 13, acid trap 8 and chlorine gas compressor 9, said cooling device 12 comprises a first titanium cooler 3 and a second titanium cooler 4 connected, Described drying device 13 comprises the first drying tower 6 and the second drying tower 7 that are connected, and the pipeline between described chlorine scrubber 2 and cooling device 12 is connected with waste gas recovery branch pipe 18, and described chlorine gas recovery system also includes chlorine gas Air pressure regulating device, said chlorine gas pressure regulating devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com