Pneumatic rice metering device with integrated disc chamber

A pneumatic, seed metering technology, applied in sowing, seeder parts, seeder, etc., can solve the problems of complex rotating structure, large air pressure fluctuation and instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with specific embodiments.

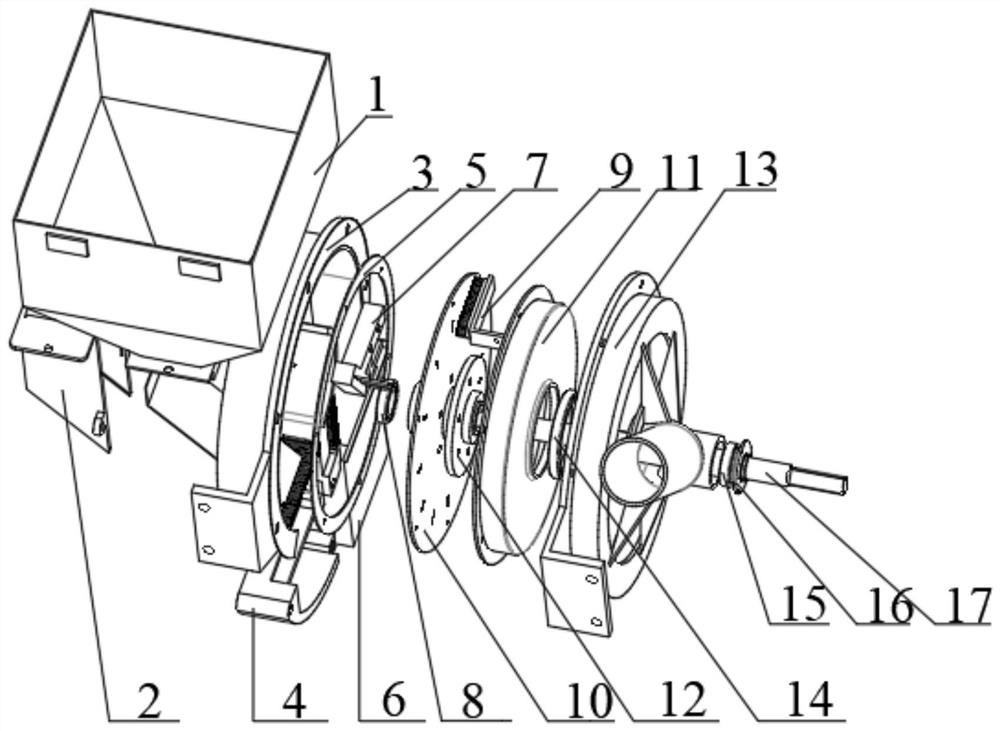

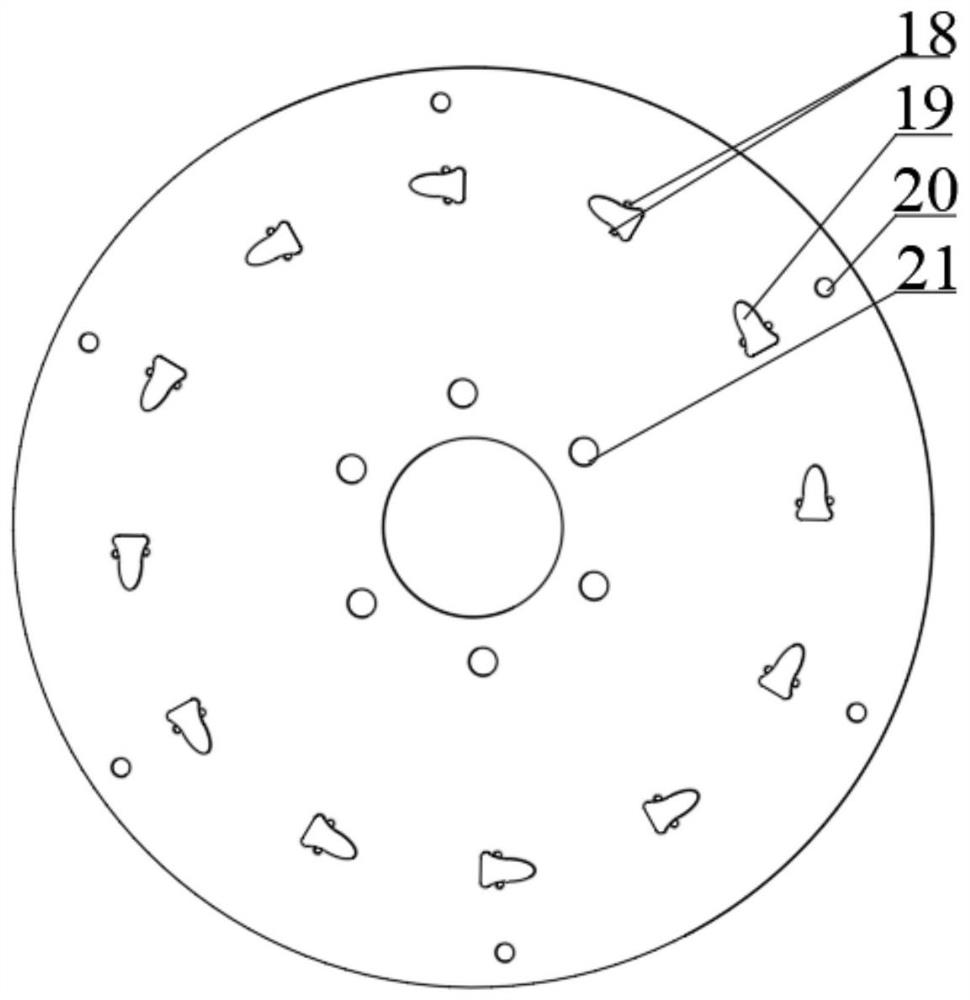

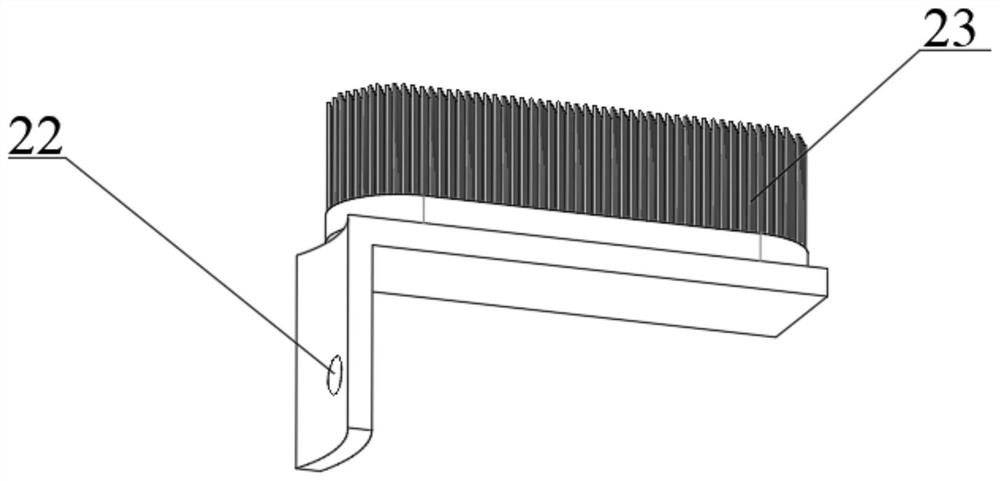

[0037] A pneumatic rice metering device with an integrated disc chamber, including a seed box 1, a connecting piece 2, a seed metering housing 3, a seed unloading device 4, a seed metering pipe 6, a seed metering disc 10, a flange 12, and a sealing ring 5. Brush 9, air chamber 11, negative pressure pipe housing 13 and seeding shaft 17.

[0038] The seed box 1 is connected with the seed discharge housing 3 through the connector 2, the seed unloading device 4 is arranged on one side of the bottom of the seed discharge housing 3, and the seed discharge pipe 6 is arranged on the other side of the bottom of the seed discharge housing 3. The seed pipe is connected with the seed discharge port, and a seed wall is arranged between the seed inlet and the seed discharge port. Seed-clearing device 7 is provided on the seed-discharging housing 3, and the seed-clearing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com