Internally tangent double-barrel rolling type pump

A rolling, double-barrel technology, applied in the direction of rotary piston pumps, pumps, machines/engines, etc., can solve problems such as poor sealing effect, limited types, and small flow rate of conveying medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

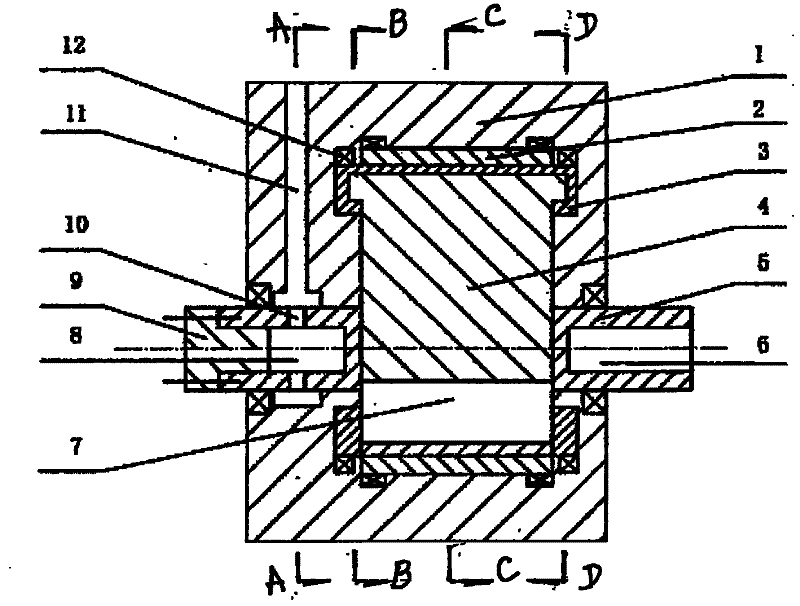

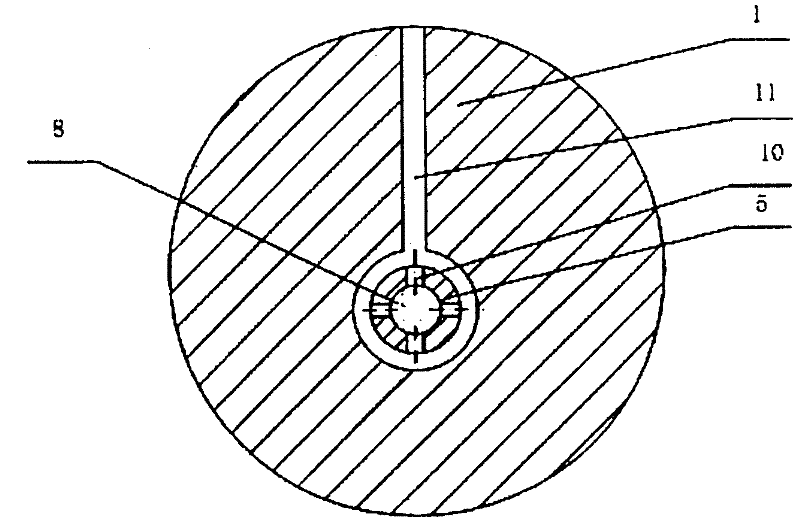

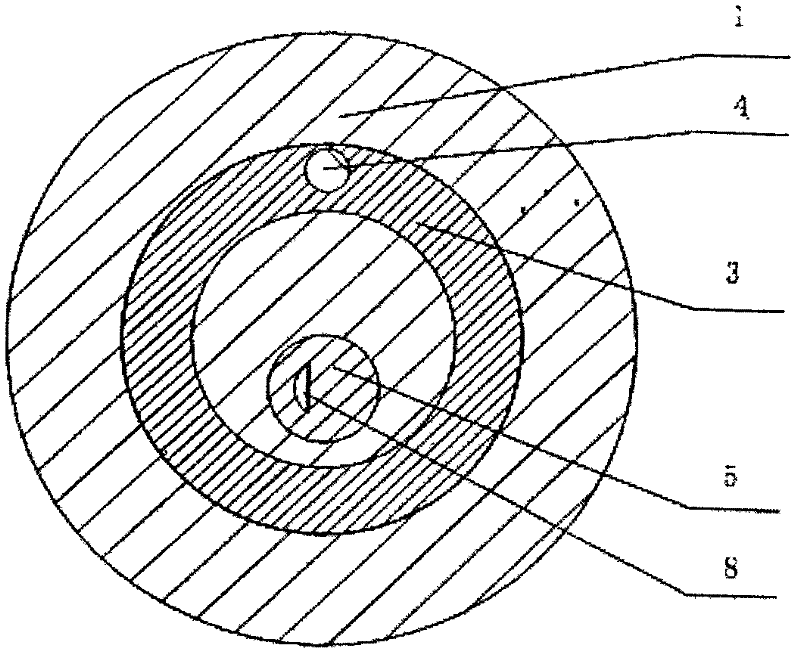

[0022] Figure 1 to Figure 9 Among them, the outer rotor 2, which is arranged in the pump casing 1 and connected with its bearing, is concentric with the pump casing 1. An inner rotor is arranged inside the outer rotor 2, which is composed of a main shaft 5 that is connected to the pump casing 1 bearing and connected to the power motor, a double-ring single-beam bracket 3 that is sleeved on the main shaft 5 and connected with the pump casing 1 bearing, and one end is movably connected to the In the groove on the double-ring single-beam support 3, the other end is plugged into the partition plate 4 in the slot of the main shaft 5 to form, and there is a gap between the end of the partition plate 4 inserted in the slot of the main shaft 5 and the slot of the main shaft 5 The cavity constitutes the diaphragm movement chamber 7. The inner rotor separates the inner cavity of the outer rotor 2 into two parts, the sealed left working chamber 14 and the right working chamber 13 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com