Electrolytic polishing solution circulating device used for electrolytic polishing of stainless steel inner tube

A technology of electrolytic polishing and stainless steel tubes, which is applied in the electrolytic process and electrolytic components, etc. It can solve the problems of difficult control of electrolytic polishing processing parameters, inability to discharge gas and garbage, and rise in temperature, so as to achieve good polishing quality and final Effect, the effect of controlling the polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

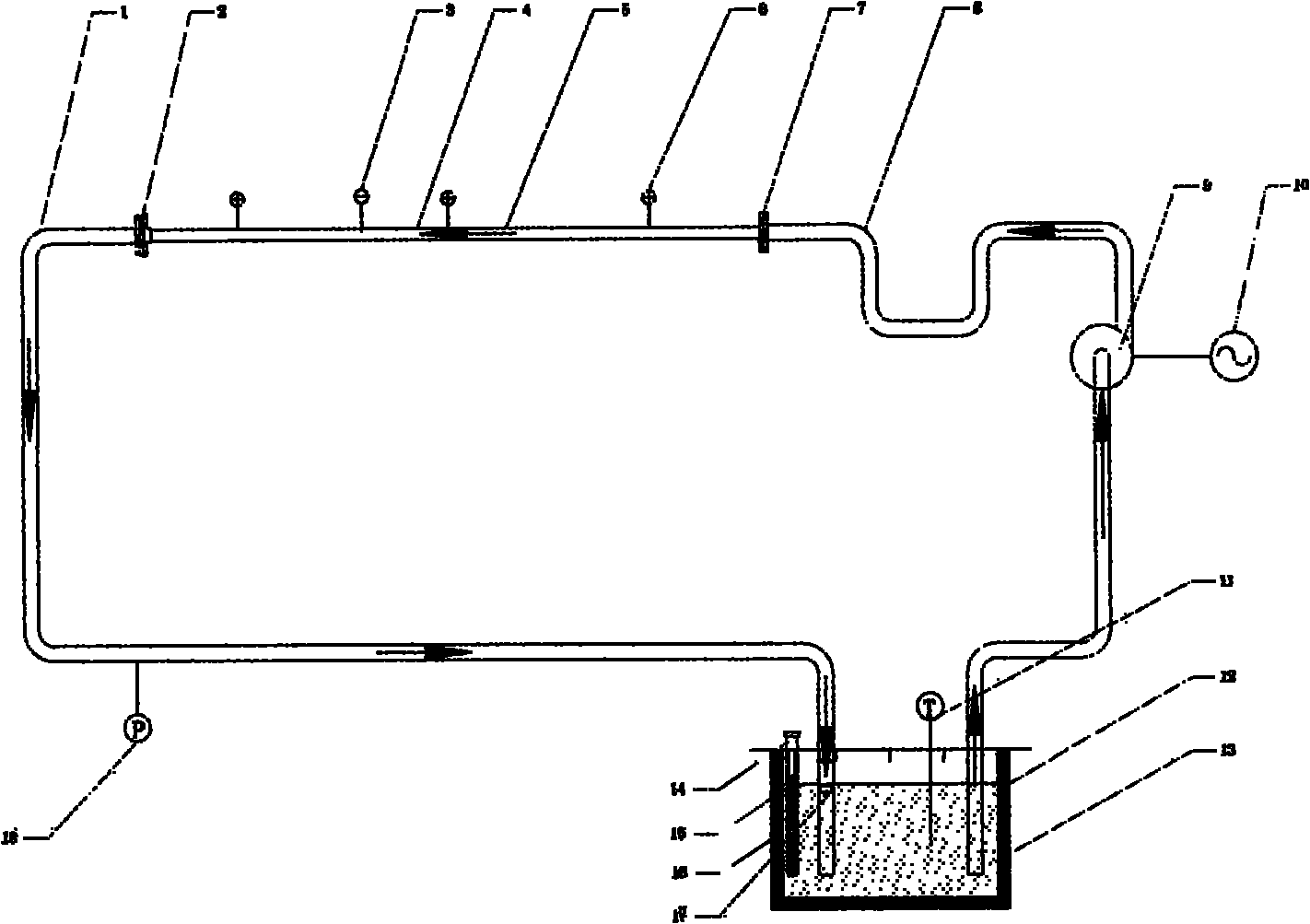

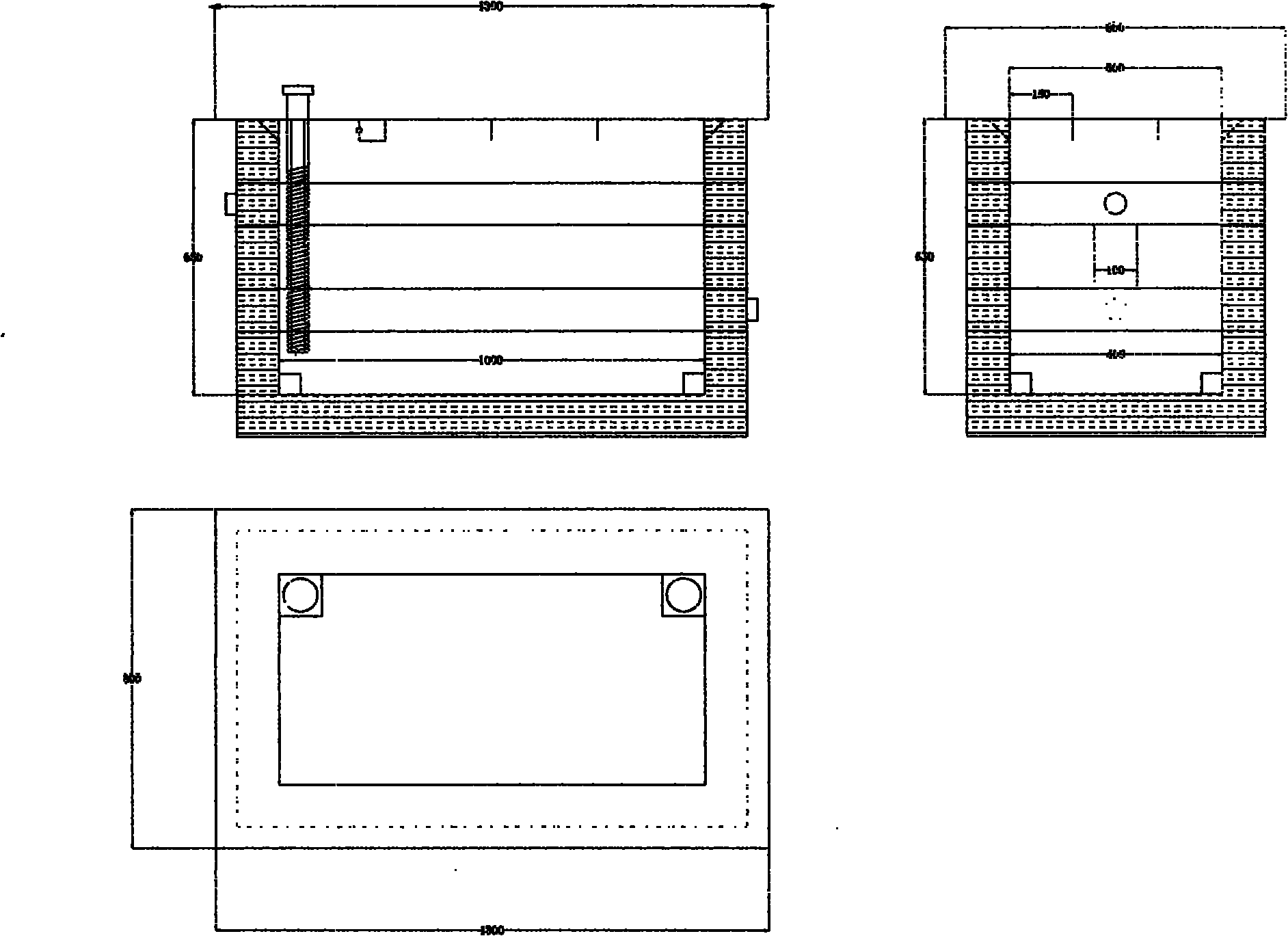

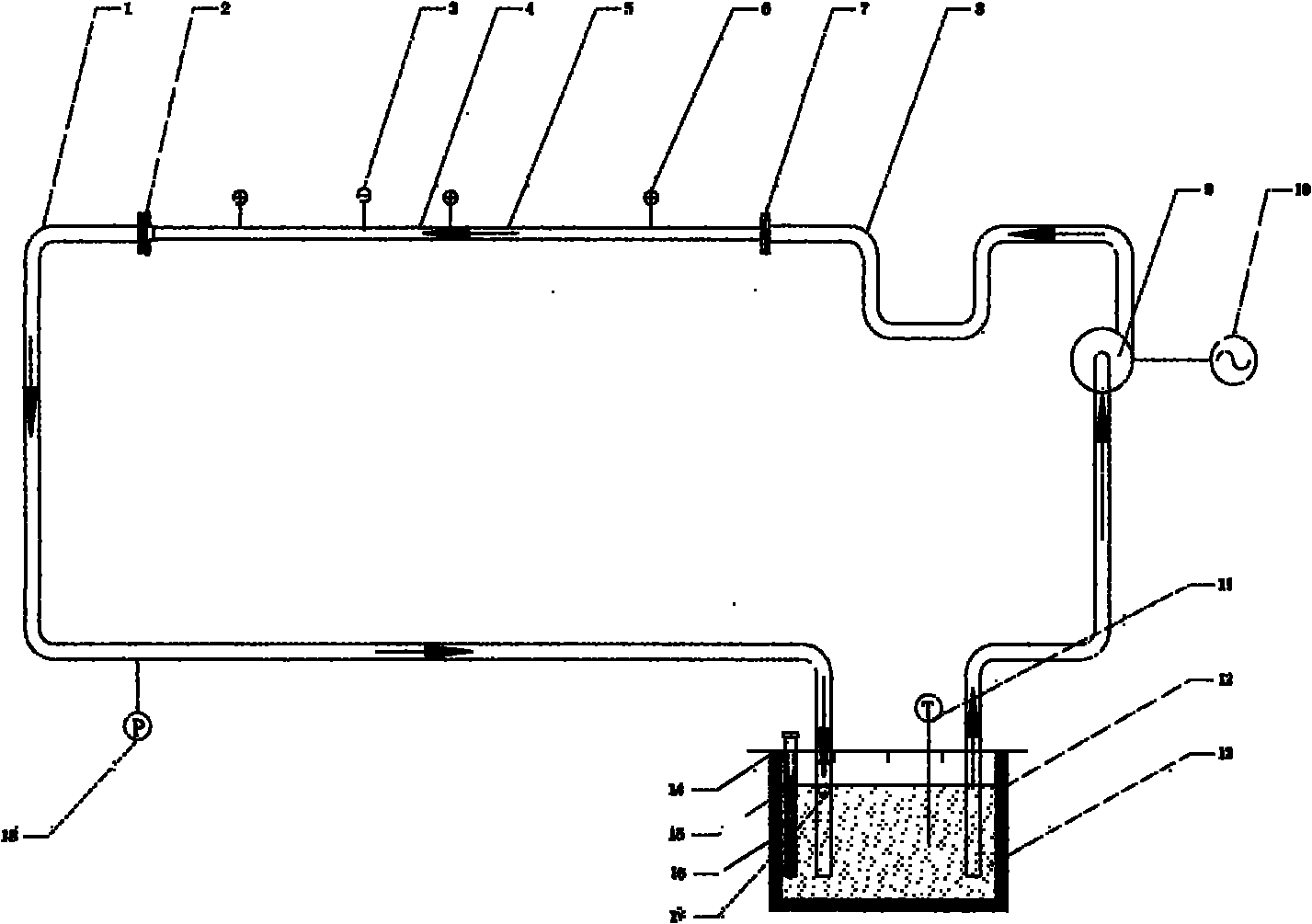

[0031] Please refer to Figures 1 to 3, the electropolishing liquid circulation device 1 of the present invention includes an electropolishing liquid circulation system 4 and an electropolishing liquid turnover tank 12; the electropolishing liquid circulation system 4 includes an acid-resistant, high-temperature, and high-pressure circulating pump 9. Frequency conversion speed regulator 10, pressure gauge 18, stainless steel pipe to be processed 5, stainless steel nozzle sealing device 7; the electrolytic polishing solution turnover tank 2 has an electrothermal cooling device 14, a temperature controller 11, an insulating layer 16, and a filtering device 17. Air suction recovery device; the electrolyte turnover tank 12 is located at the bottom of the electropolishing liquid circulation system 4; the electrolytic polishing liquid circulation sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com