Hydraulic-plate-free quenching device and method for continuous quenching of steel strip

A technology of quenching device and hydraulic plate, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of inconsistency, uneven liquid flow, large temperature difference in the heating part of the quenching steel strip, etc., and achieve rapid temperature circulation and uniform temperature exchange , Increase the effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

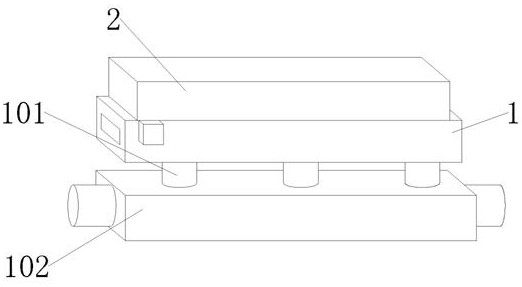

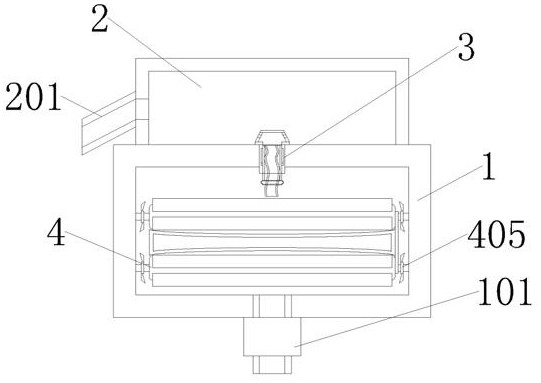

[0035] Embodiment 1: A non-hydraulic plate quenching device and method for continuous quenching of steel strips, including an outer box 1 and a drainage box 2, the top of the outer box 1 is fixedly connected with the drainage box 2, and the top of the outer box 1 is fixedly connected with a The water guide assembly 3 for discharging the cold liquid is rotatably connected to the inside of the outer box 1 with a rotatable assembly 4 capable of rotating water flow for heat exchange.

[0036] The inside of the water guide assembly 3 is movably connected with an inner pipe 301, the two sides of the inner pipe 301 are fixedly connected with sliders 302, the bottom of the inner pipe 301 is fixedly connected with a floating pipe 304, and the top of the inner pipe 301 is fixedly connected with a drain cover 303, The inside of the inner tube 301 is fixedly connected with a limiting ring 307 , the top of the limiting ring 307 is movably connected with a cover piece 305 , and the bottom of...

Embodiment 2

[0043] Embodiment 2: The difference between Embodiment 2 and Embodiment 1 is that the rotating assembly 4 is driven by a motor connected to the outer surface of the outer box 1;

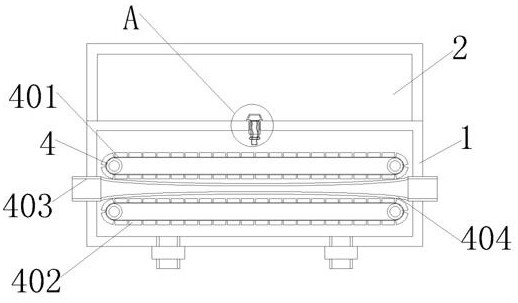

[0044] The outer surfaces of the two rotating assemblies 4 are movably connected with crawler belts 401 , the outer surfaces of the crawler belts 401 are fixedly connected with heat conduction fins 402 , and the two rotating assemblies 4 are movably connected with heat conduction plates 404 , and both sides of the heat conduction plate 404 are fixedly connected with extending To the feeding pipe 403 on both sides of the outer box 1 , the outer surface of the rotating assembly 4 is fixedly connected with a fixed pipe 405 , and the outer surface of the fixed pipe 405 is fixedly connected with a water guide piece 406 .

[0045] The track 401 is made of zinc alloy, the heat conducting sheet 402 is made of copper, and the heat conducting plate 404 is made of graphite cold iron.

[0046] There are multiple...

Embodiment 3

[0050] Embodiment 3: The difference between embodiment 3 and embodiment 2 is that a water pump 101 is fixedly connected to the bottom of the outer box 1, and the water outlet end of the water pump 101 extends to the inner bottom of the outer box 1, and the water inlet end of the water pump 101 is fixedly connected with a cooling The liquid tank 102 and the back of the drainage tank 2 are fixedly connected with an outlet pipe 201 .

[0051] Wherein, three water pumps 101 are provided, and the three water pumps 101 are equidistantly distributed on the bottom of the outer box 1 .

[0052] Wherein, one end of the water outlet pipe 201 is inclined downward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com