an ozone generator

An ozone generator and refrigerant technology, which can be used in ozone preparation, ozone preparation by discharge method, oxygen/ozone/oxide/hydroxide, etc., and can solve problems such as poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

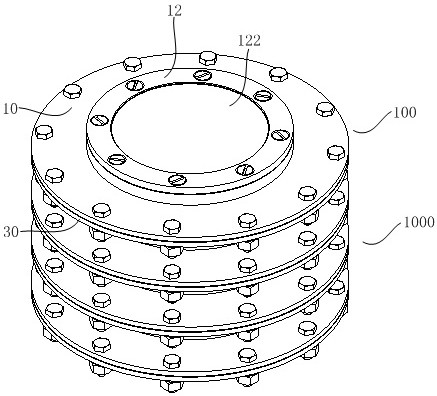

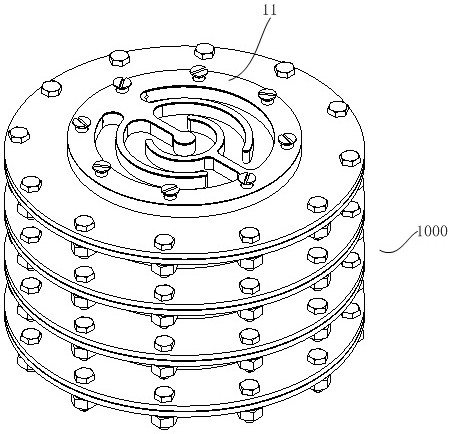

[0029] Such as figure 1 , figure 2 As shown, this embodiment proposes an ozone generating device 1000, which includes four groups of plate-type discharge cells 100.

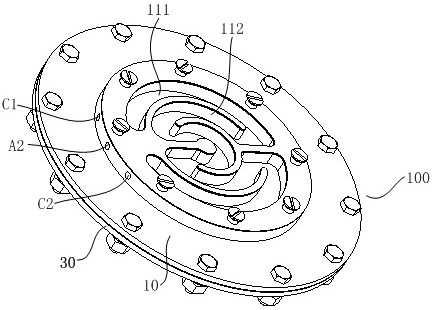

[0030] Such as Figure 3 to Figure 8 As shown, each discharge cell 100 includes a dielectric layer (not shown in the drawings), a ground electrode plate 10, and a high voltage electrode substrate 30 formed with a high voltage electrode plate 20 and a high voltage cable interface E. In order to improve the service cycle, the ground electrode plate 10 and the high-voltage electrode substrate 30 can be made of corrosion-resistant metal materials, and the existing mature technology can be used to form a dielectric made of ceramic material with uniform thickness and excellent performance on the high-voltage electrode plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com