Patents

Literature

35results about How to "Improve oil and gas separation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

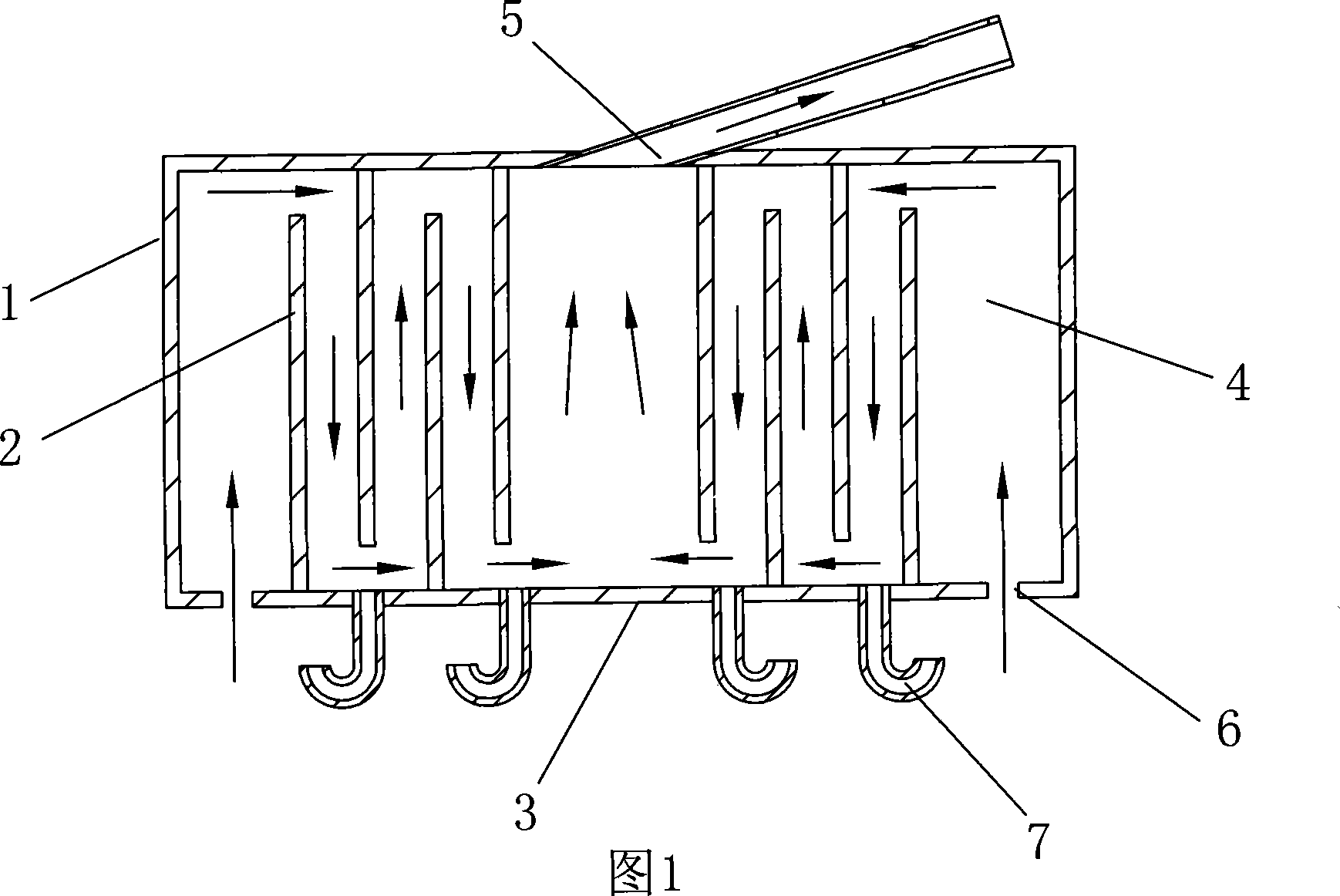

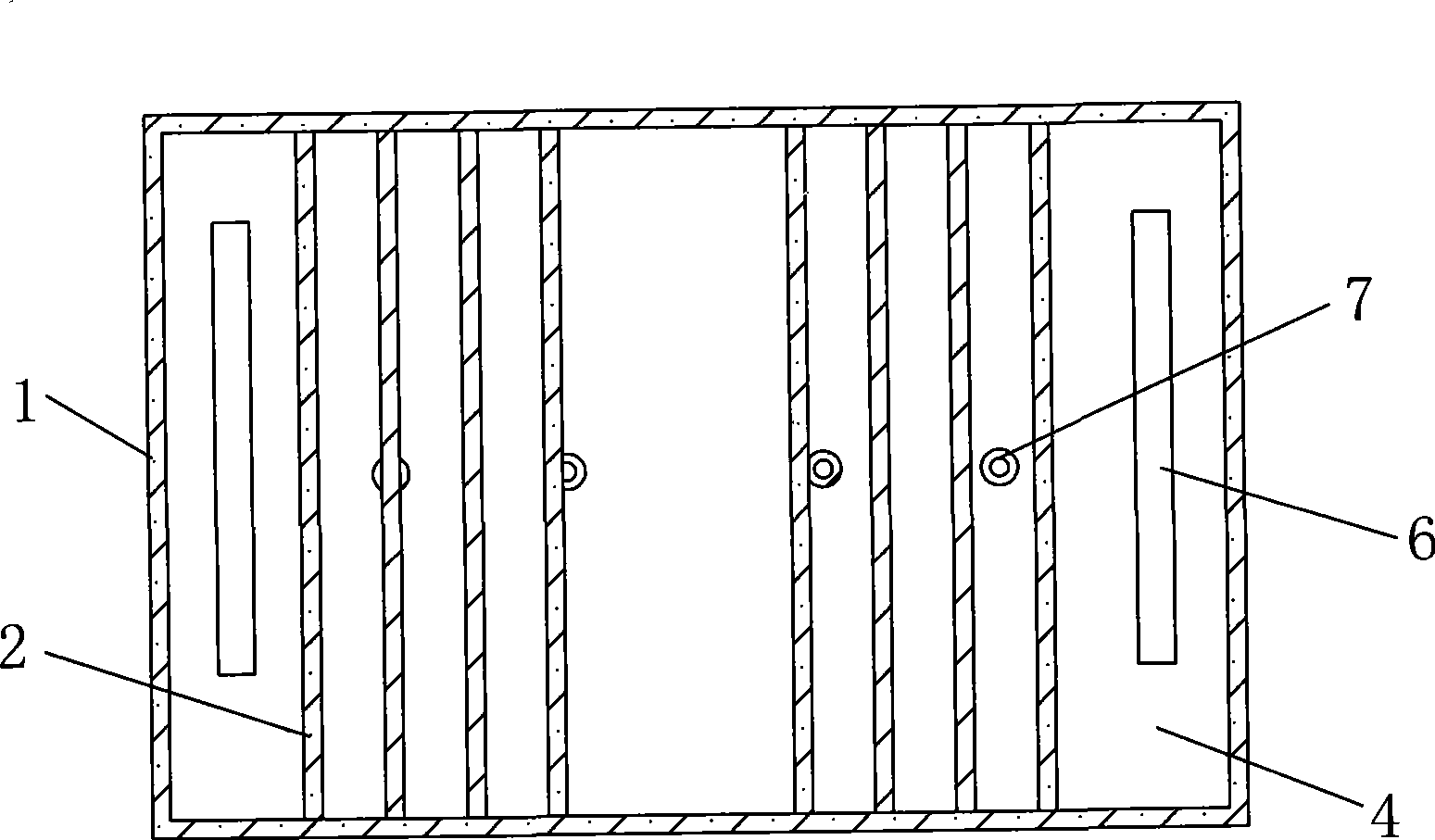

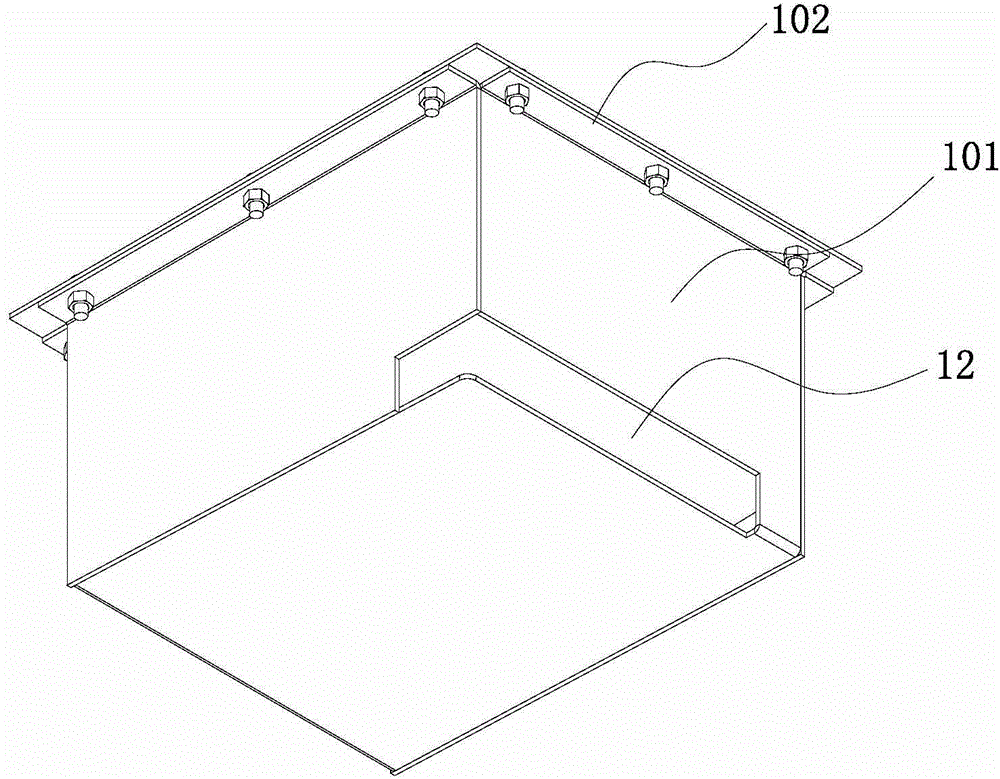

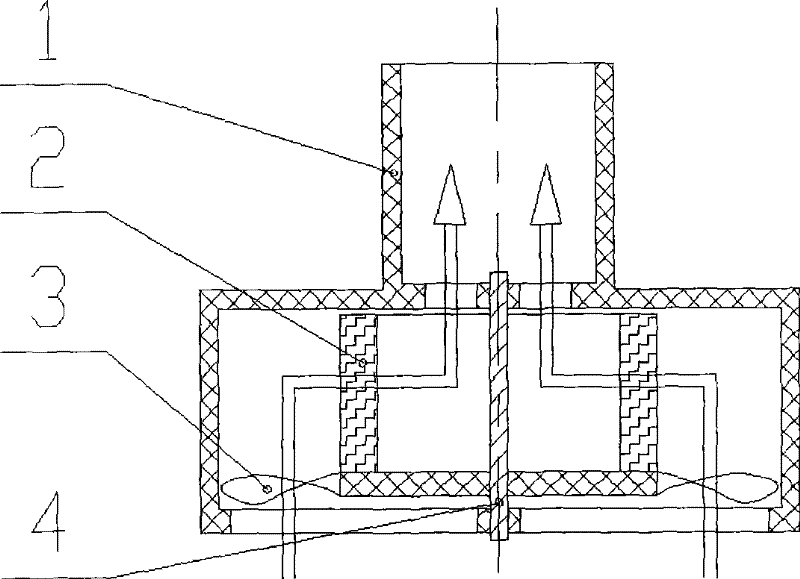

Labyrinth type oil-gas separating structure in cover of engine spiracular atrium

InactiveCN101363345ASimple ventilation systemEffective ventilation systemMachines/enginesCrankcase ventillationEngine valveLabyrinth structure

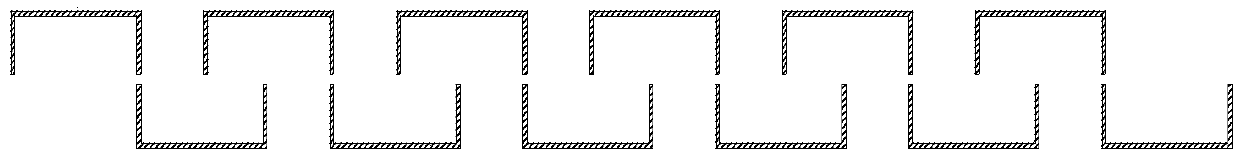

The invention relates to a labyrinth gas-oil separating structure in a valve cover of an engine and is characterized in that: a gas-oil separating chamber, which is jointly composed by an oil baffle base plate and the valve cover and is provided with a gas mixture inlet and an outlet of a ventilating pipe, is internally provided with a labyrinth structure which can prolong the detention time of the gas mixture in the gas-oil separating chamber and enlarge the contact area between the gas mixture and the inner wall of the separating chamber. The labyrinth gas-oil separating structure aims at simplifying the arrangement of a ventilating system and optimizing and modifying the structures of the valve cover and the oil baffle plate, thus forming an effective oil separating labyrinth and achieving the effect of independent arrangement of a gas-oil separating device; and the whole ventilating system of the engine becomes simpler and more effective.

Owner:CHERY AUTOMOBILE CO LTD

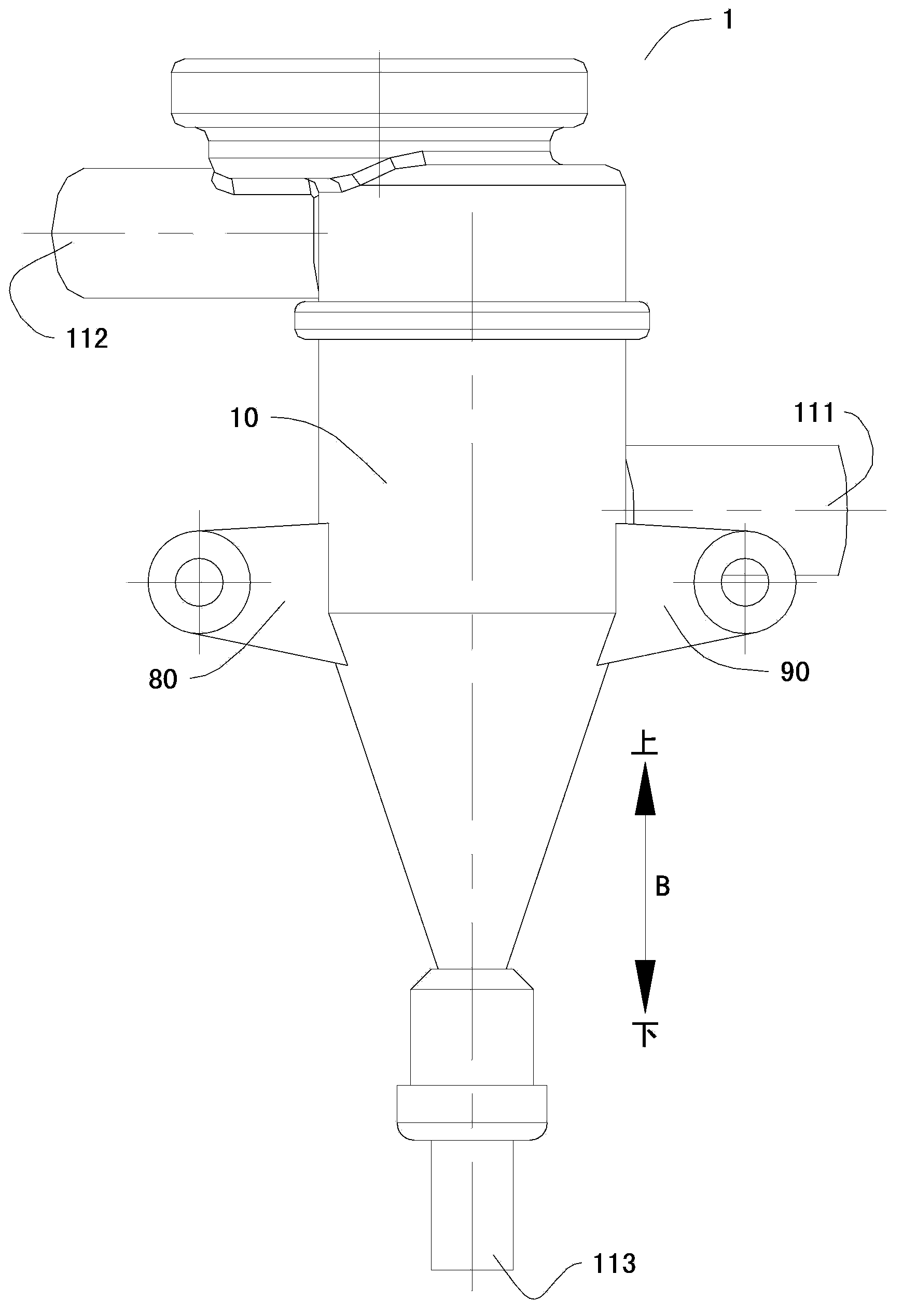

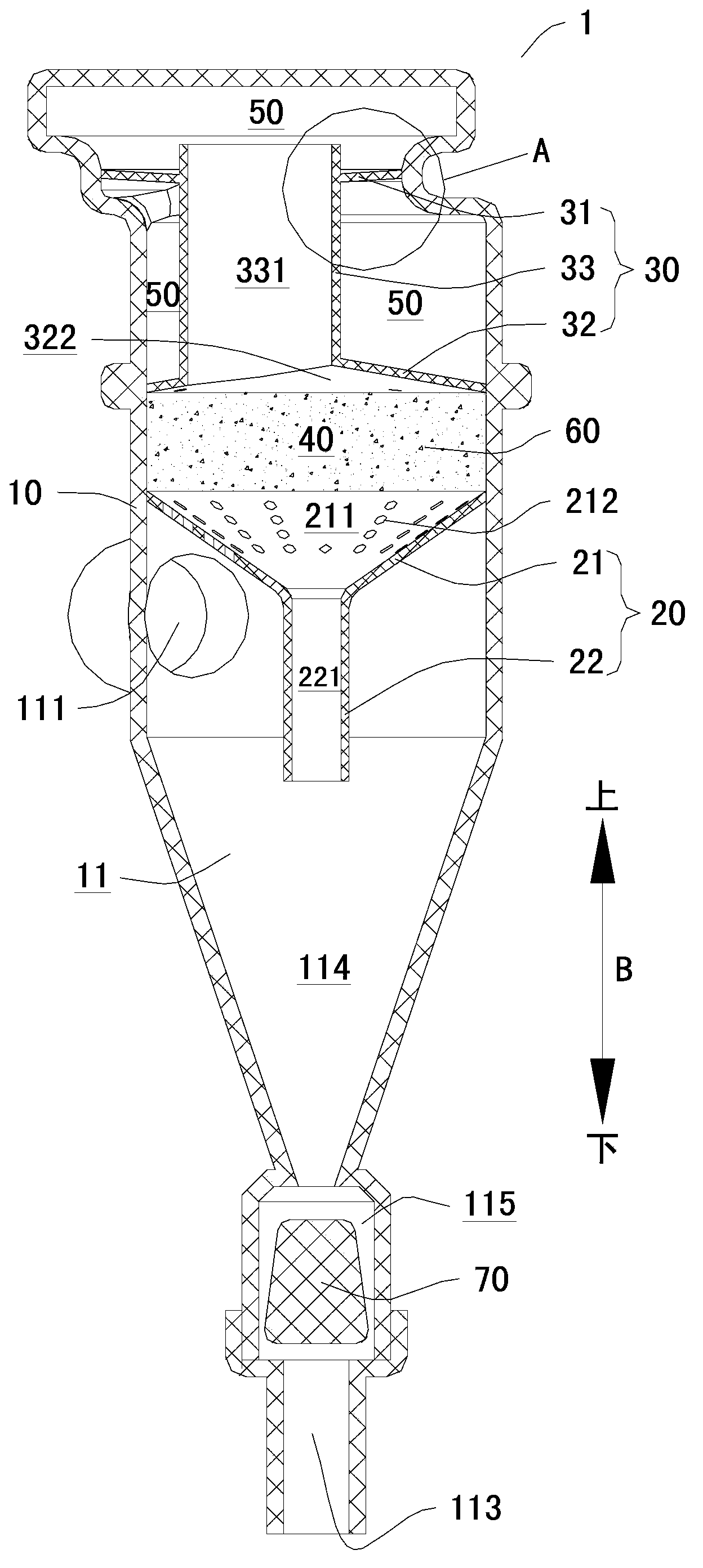

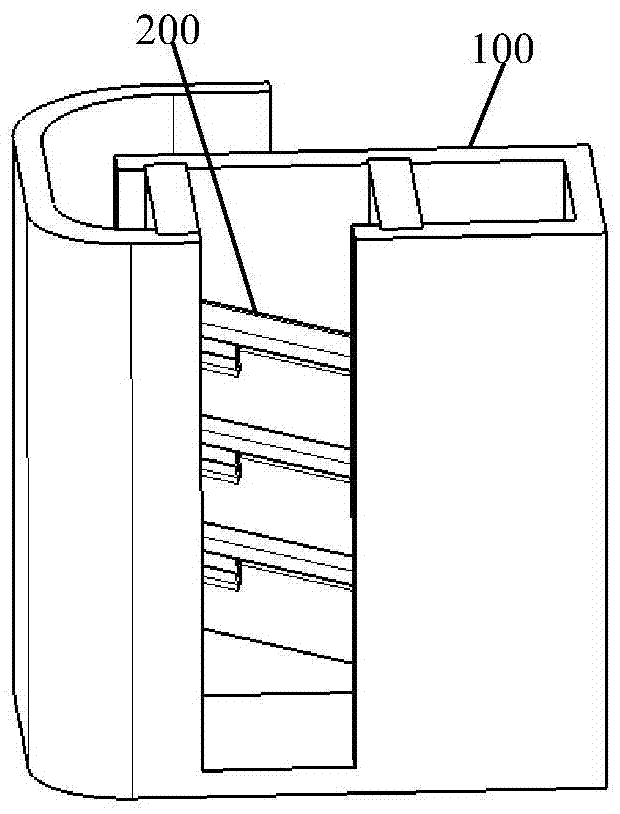

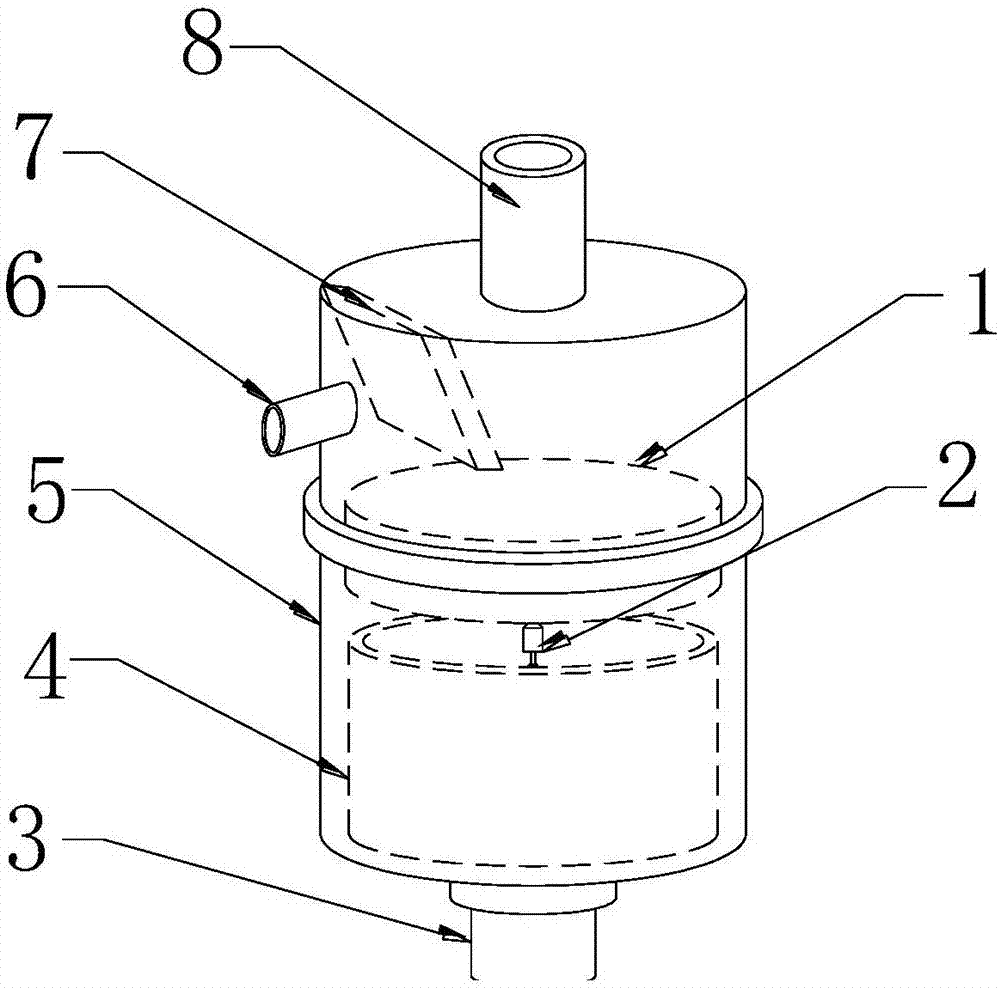

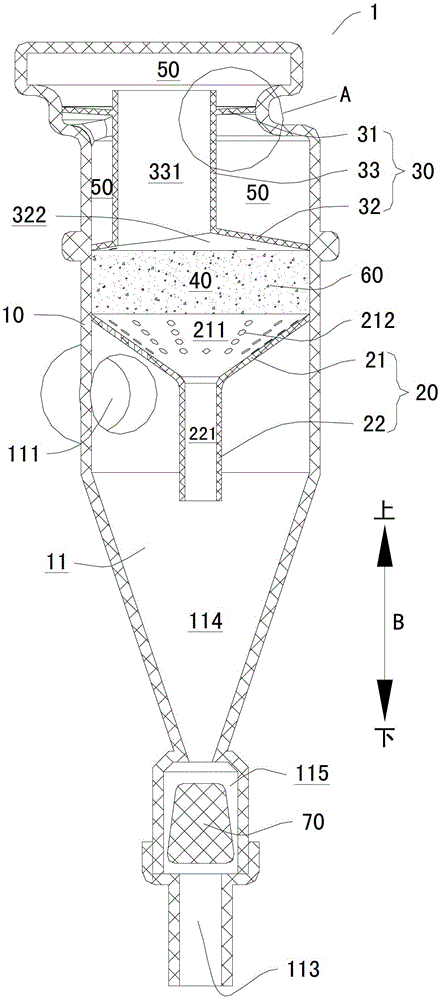

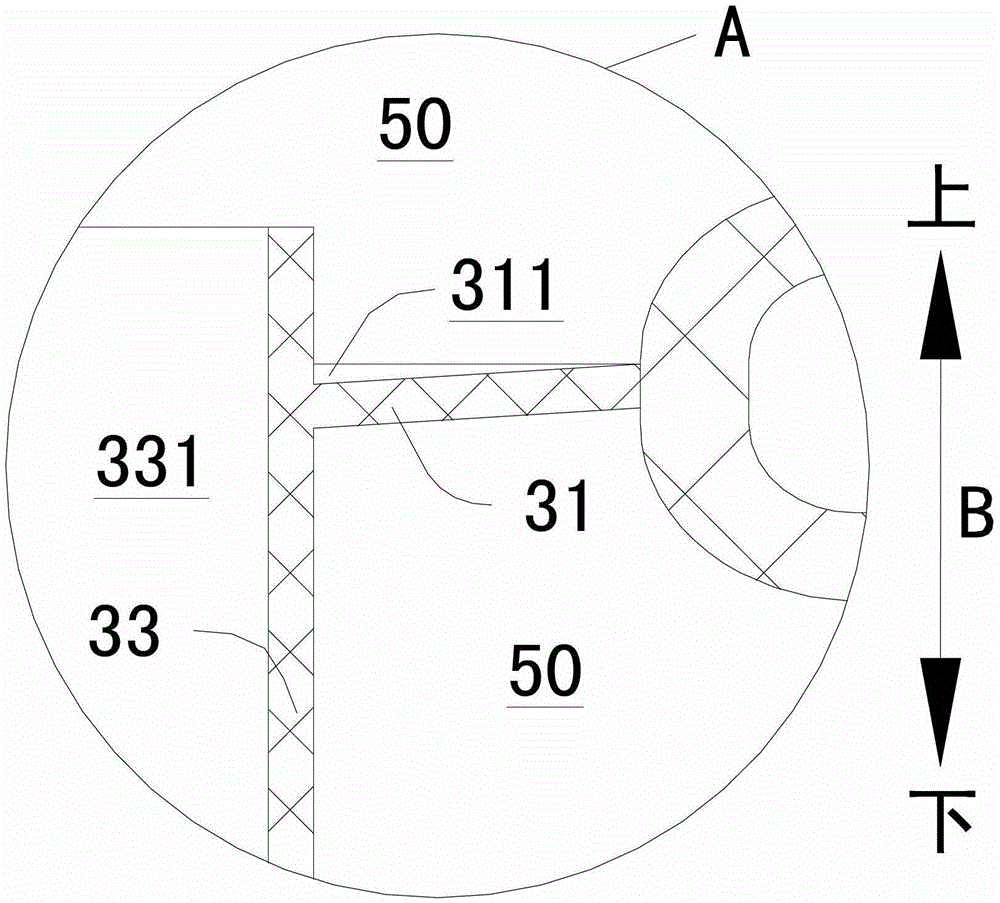

Engine oil-gas separation device and engine and vehicle comprising same

ActiveCN103790673AImprove separation efficiencyHigh recovery rateMachines/enginesCrankcase ventillationWaste managementGas separation

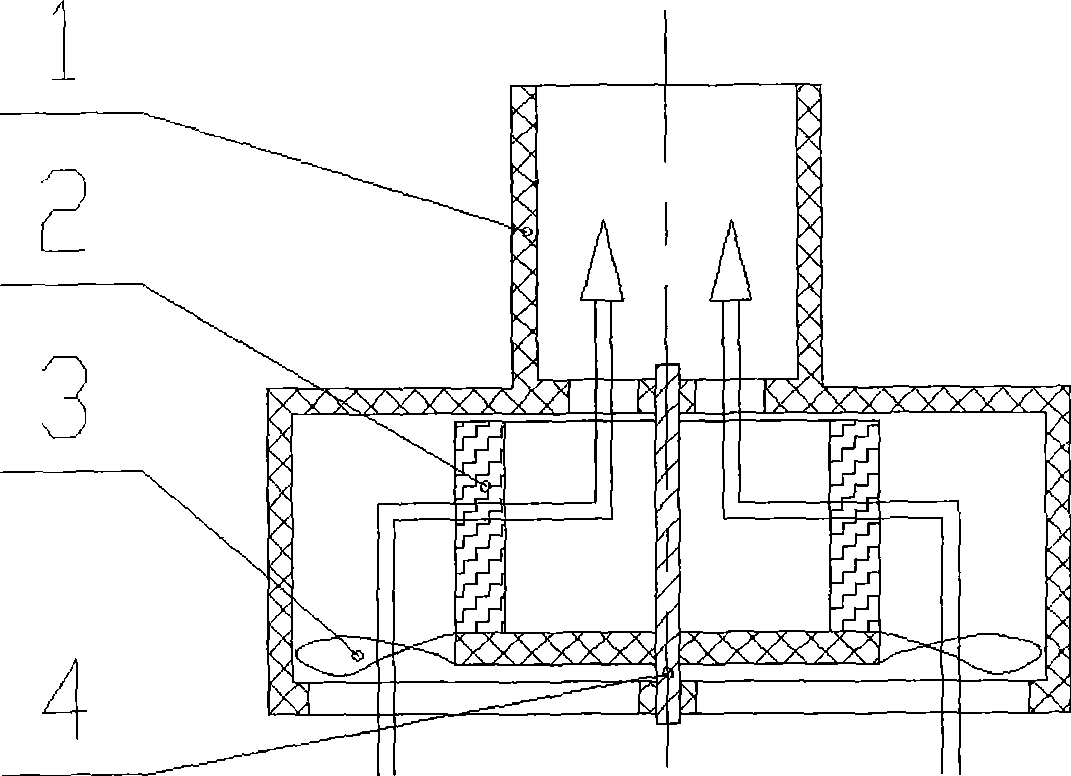

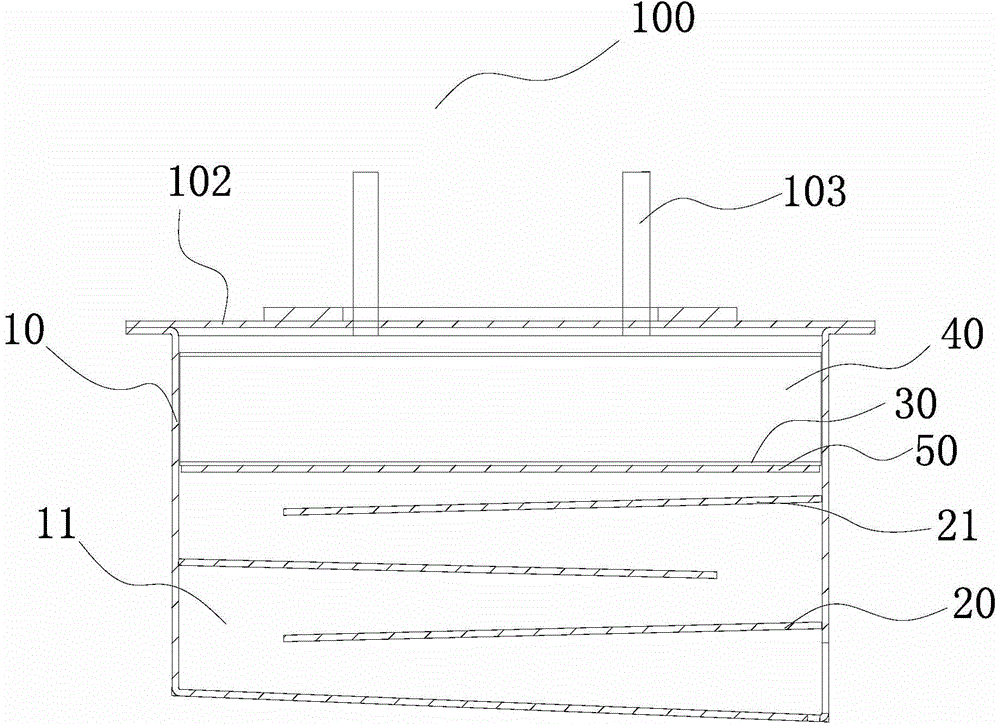

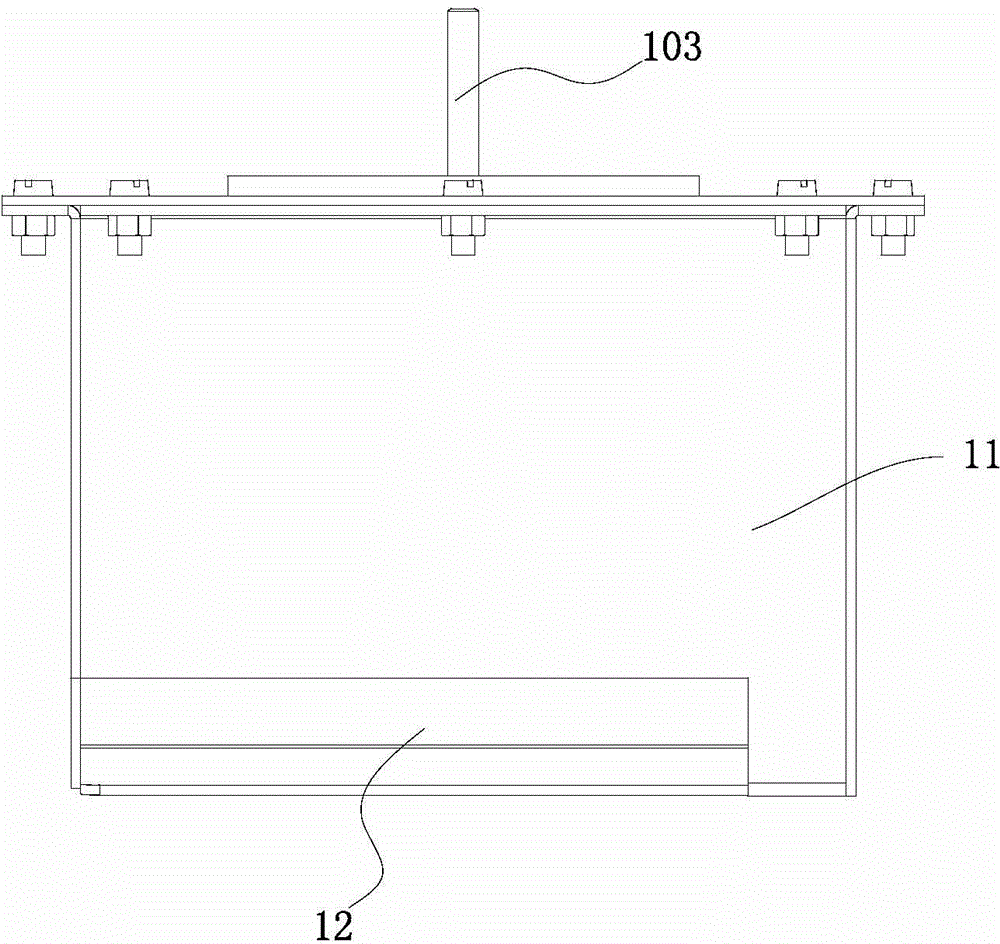

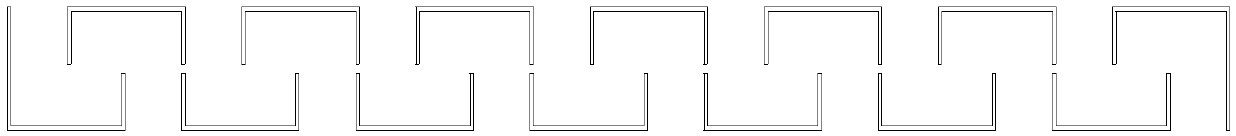

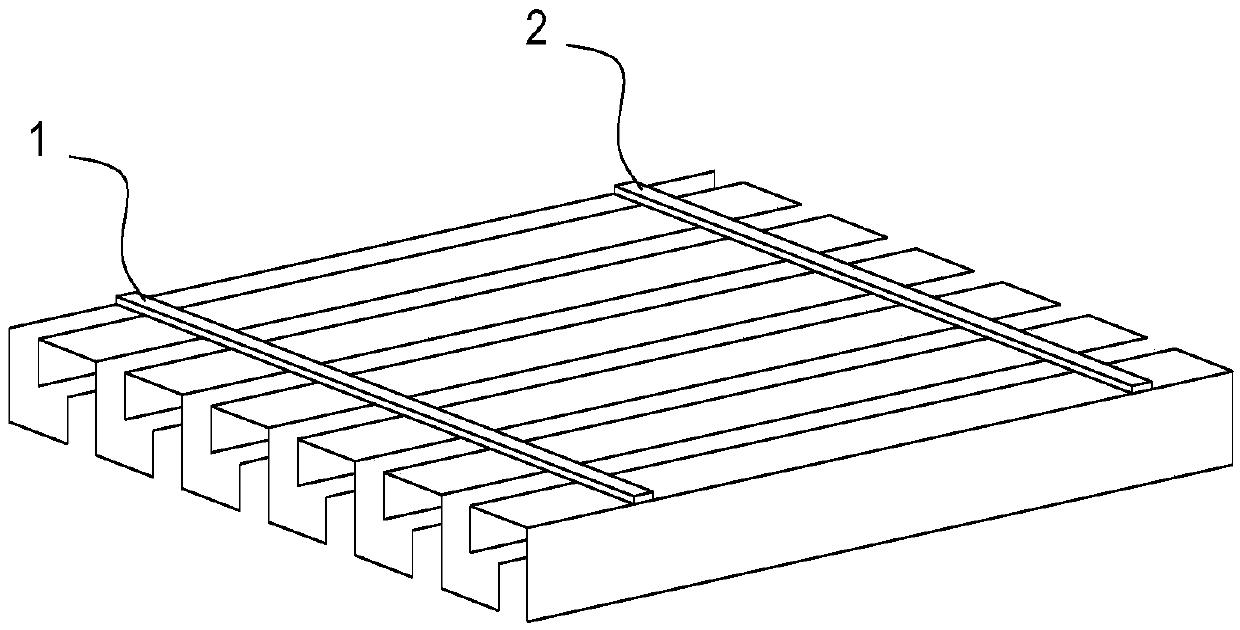

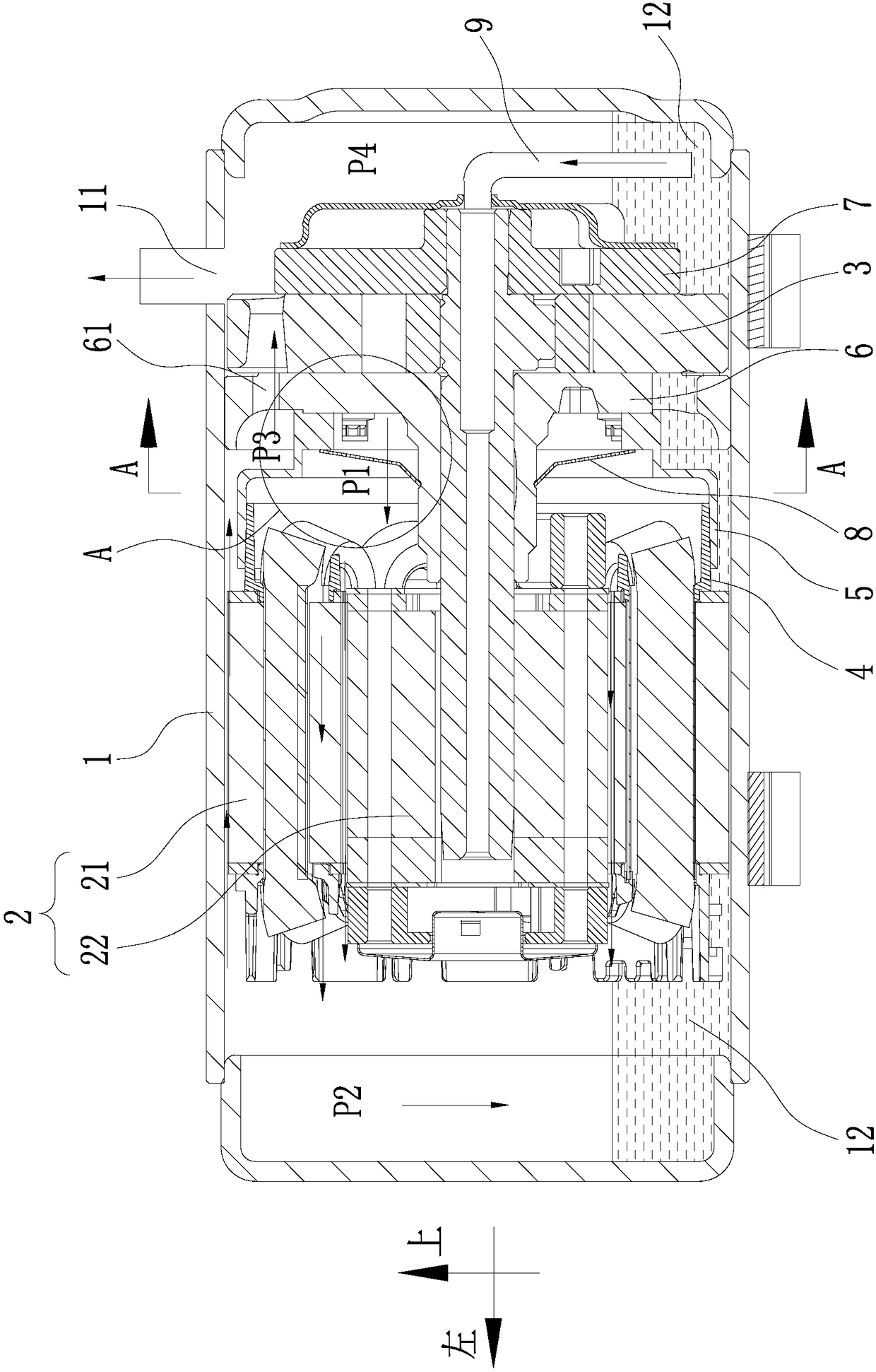

The invention discloses an engine oil-gas separation device and an engine comprising the same and a vehicle comprising the same. The engine oil-gas separation device comprises a body, a lower separating part, an upper separating part and a filtering part; an accommodating chamber is formed in the body and comprises a gas inlet, a gas outlet and an oil return opening; the lower separating part is arranged in the accommodating chamber and connected with the wall of the accommodating chamber; the upper separating part is arranged in the accommodating chamber and connected with the wall of the accommodating chamber; a first separating chamber which is communicated with the gas inlet is limited out between the lower separating part, the upper separating part and the wall of the accommodating chamber; a plurality of second separating chambers are limited out between the upper separating part and the wall of the accommodating chamber; the plurality of second separating chambers are communicated with each other and are communicated with the first separating chamber and the gas outlet; the filtering part is arranged in the first separating chamber. The engine oil-gas separation device has the advantages of being good in oil-gas separation effect, high in oil recovery rate and the like.

Owner:BEIQI FOTON MOTOR CO LTD

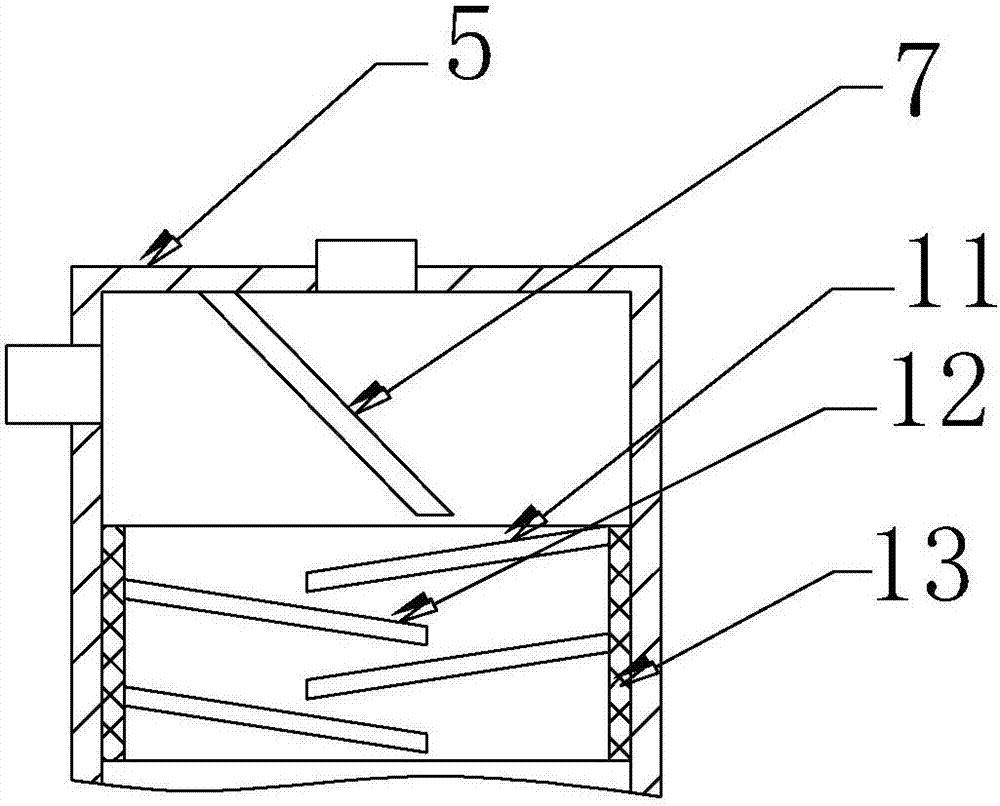

Oil-gas separating device for engine

ActiveCN101363344AReduce resistanceGood oil and gas separation effectMachines/enginesCrankcase ventillationProduct gasProcess engineering

The invention relates to a gas-oil separator of an engine with high gas-oil separating efficiency and low resistance. The technical proposal is as follows: the gas-oil separator of the engine is characterized in that vanes, a filter element and a rotation shaft are arranged, wherein, the vanes and the filter element are fixed on the rotation shaft which is arranged on a shell. The gas-oil separator combines the structural features of a filter element type gas-oil separator and a cyclone type gas-oil separator, the gas from a crank case is separated by the vanes for the first time and by the filter element once again, meanwhile, as the filter element can rotate, oil drops attached to the filter element can be separated from the filter element under the action of centrifugal force, thus effectively reducing the resistance of the filter element, achieving the optimal gas-oil separating effect and lowering the resistance of the system.

Owner:CHERY AUTOMOBILE CO LTD

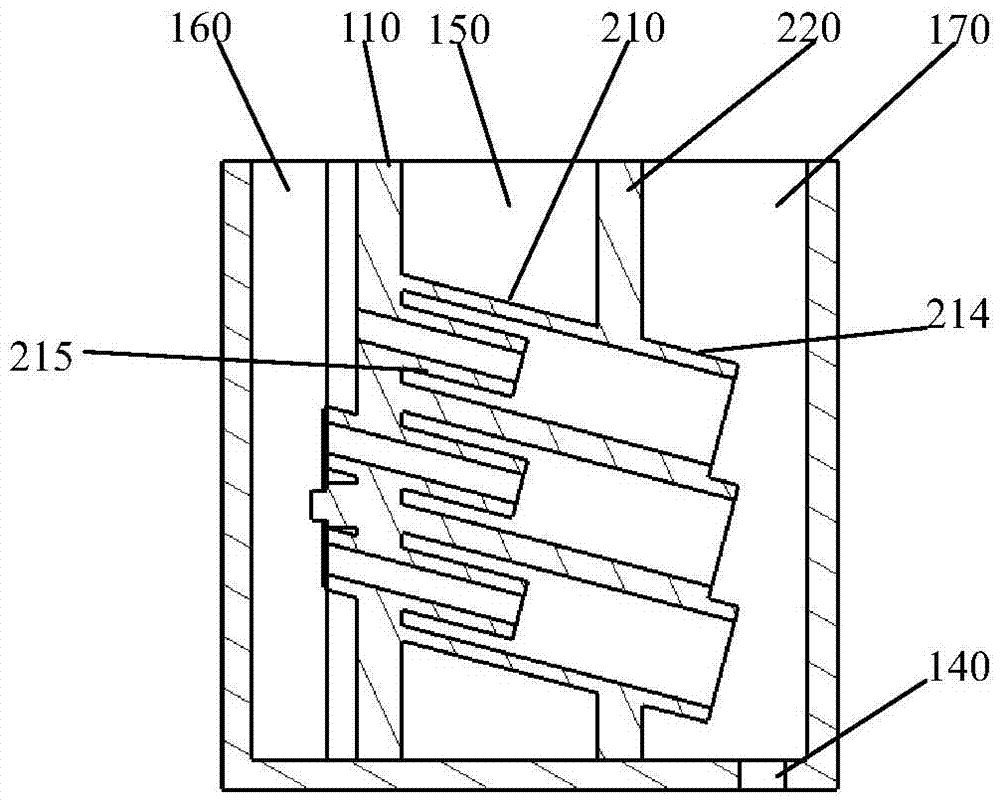

Oil-gas separation device and compressor comprising same

The invention discloses an oil-gas separation device and a compressor comprising the same. The oil-gas separation device comprises a shell, a baffle plate, a first filtering layer and a second filtering layer, wherein a cavity is defined in the shell, an inlet is formed in the lower portion of the shell, and an outlet is formed in the upper portion of the shell; the baffle plate is arranged in the cavity and located above the inlet; the first filtering layer is arranged above the baffle plate; the second filtering layer is arranged above the first filtering layer. According to the oil-gas separation device, the baffle plate is arranged in the shell, coolant gas and oil mist mixed gas entering the shell from the inlet passes through the baffle plate, thus the flow speed of the coolant gas and oil mist mixed gas can be decreased, liquid drops are formed on the wall surface of the baffle plate, the big liquid drops in the mixed gas are separated, the mixed gas is filtered through the first filtering layer and the second filtering layer, complete separation of coolant gas and oil mist is achieved finally, and the separation effect is good. The purity of the coolant gas flowing out of the outlet can be effectively improved.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

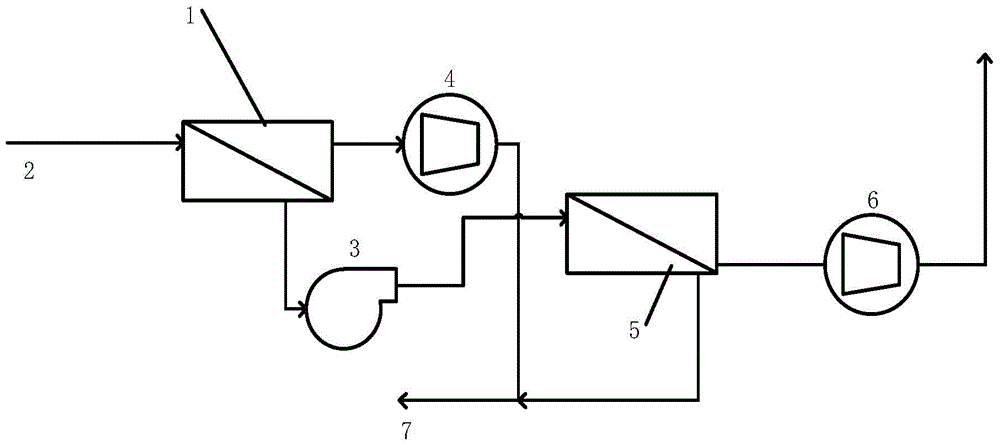

Two-stage membrane method oil-gas recovery apparatus and recovery method thereof

InactiveCN104906922APreferential permeabilityImprove reliabilityDispersed particle separationMembrane methodActivated carbon

The present invention discloses a two-stage membrane method oil-gas recovery apparatus and a recovery method thereof. The two-stage membrane method oil-gas recovery apparatus comprises a rubber state membrane assembly, a glass state membrane assembly, a vacuum pump 1 and a vacuum pump 2, wherein the inlet end of the rubber state membrane assembly is communicated with an oil-gas inlet pipeline, the retentate side outlet end of the rubber state membrane assembly is connected with the inlet end of a fan through a pipeline, the outlet end of the fan is connected with the inlet end of the glass state membrane assembly, the retentate side outlet end of the glass state membrane assembly is connected with the vacuum pump 2, standard discharge is performed after passing through the vacuum pump 2, the retentate side outlet end of the rubber state membrane assembly is connected with the vacuum pump 1, the vacuum pump 1 is connected with an absorption tower or oil tank, and the retentate side of the glass state membrane assembly is connected to the absorption tower or oil tank through a pipeline. Compared with the traditional rubber state membrane separation and active carbon adsorption process scheme, the apparatus and the method of the present invention have the following advantages that: high reliability and high safety are provided, the structure is delicate, the occupation area is small, and no secondary pollution is generated.

Owner:CHINA PETROLEUM & CHEM CORP +1

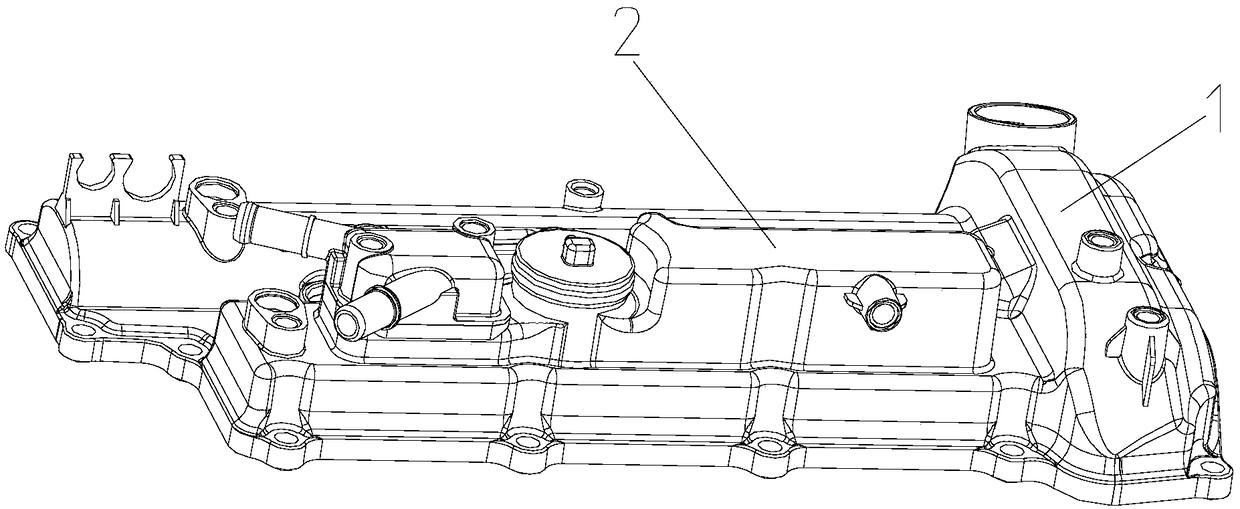

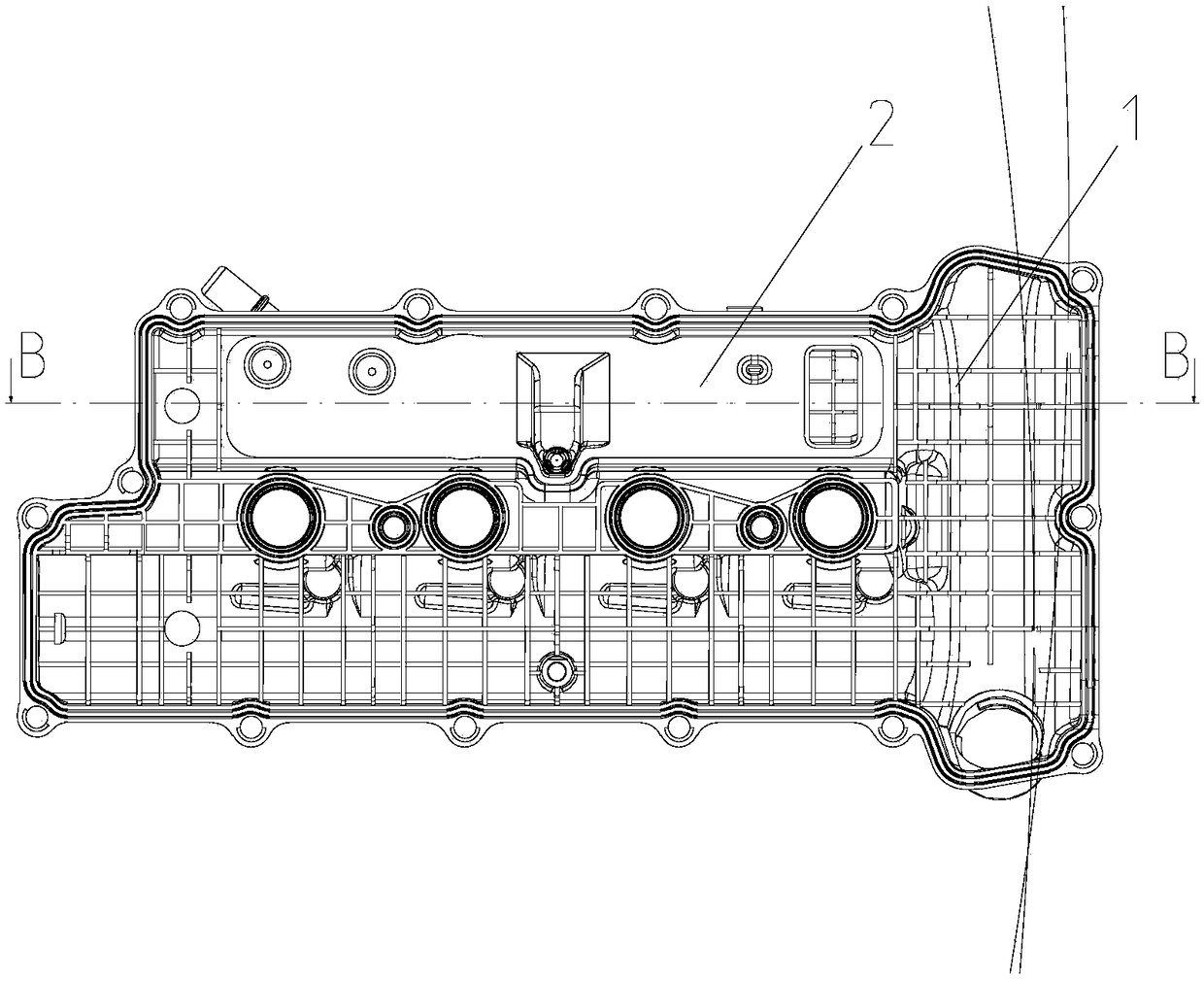

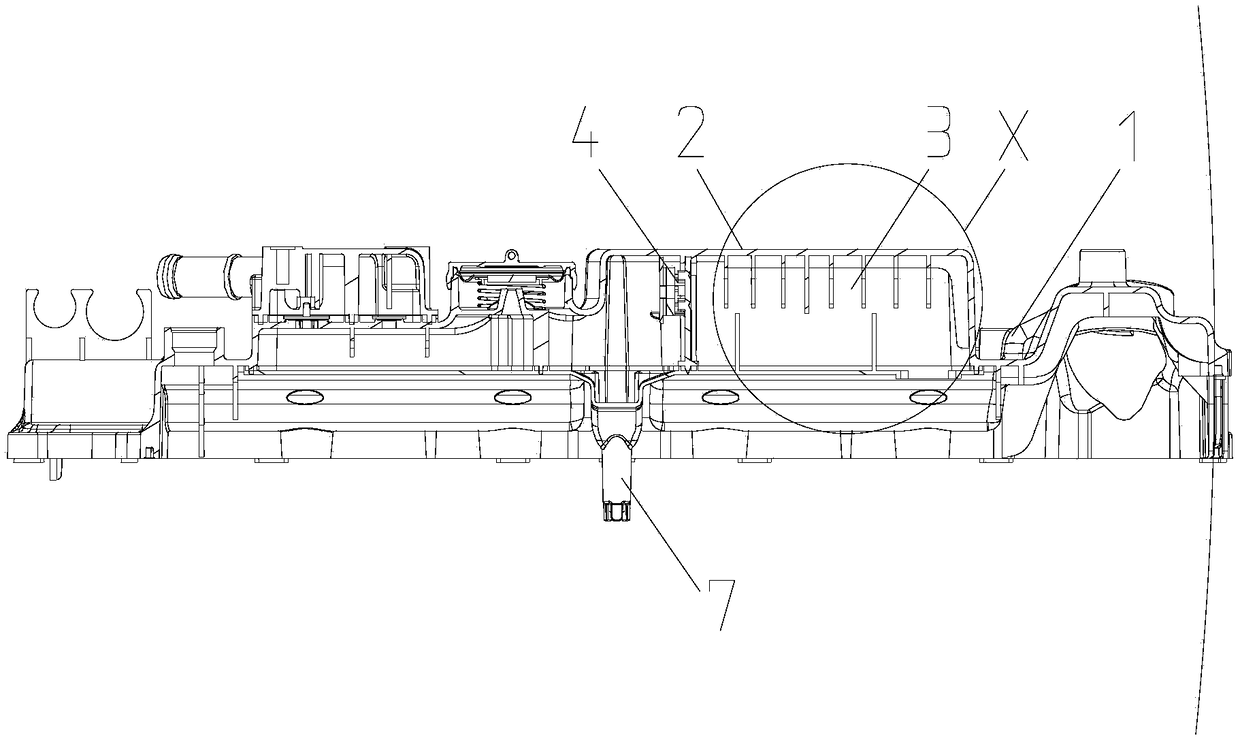

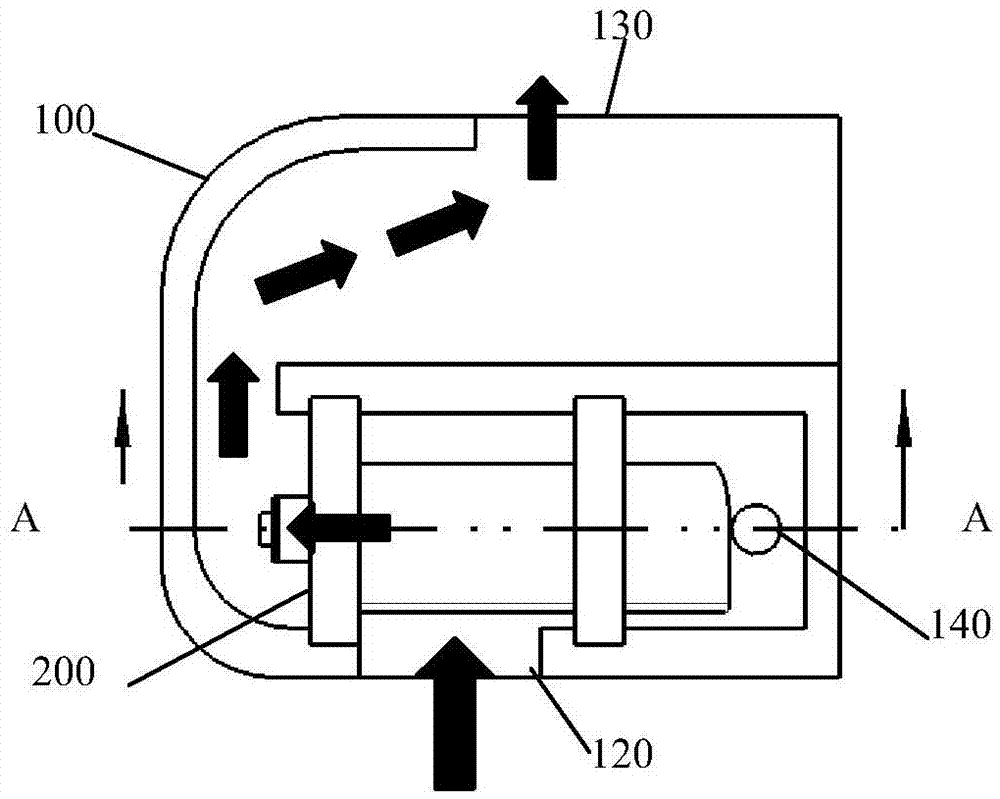

Oil-gas separation system with secondary separation function

InactiveCN109296421AReduce impact pressureReduce distortionMachines/enginesCrankcase ventillationEngineeringSeparation system

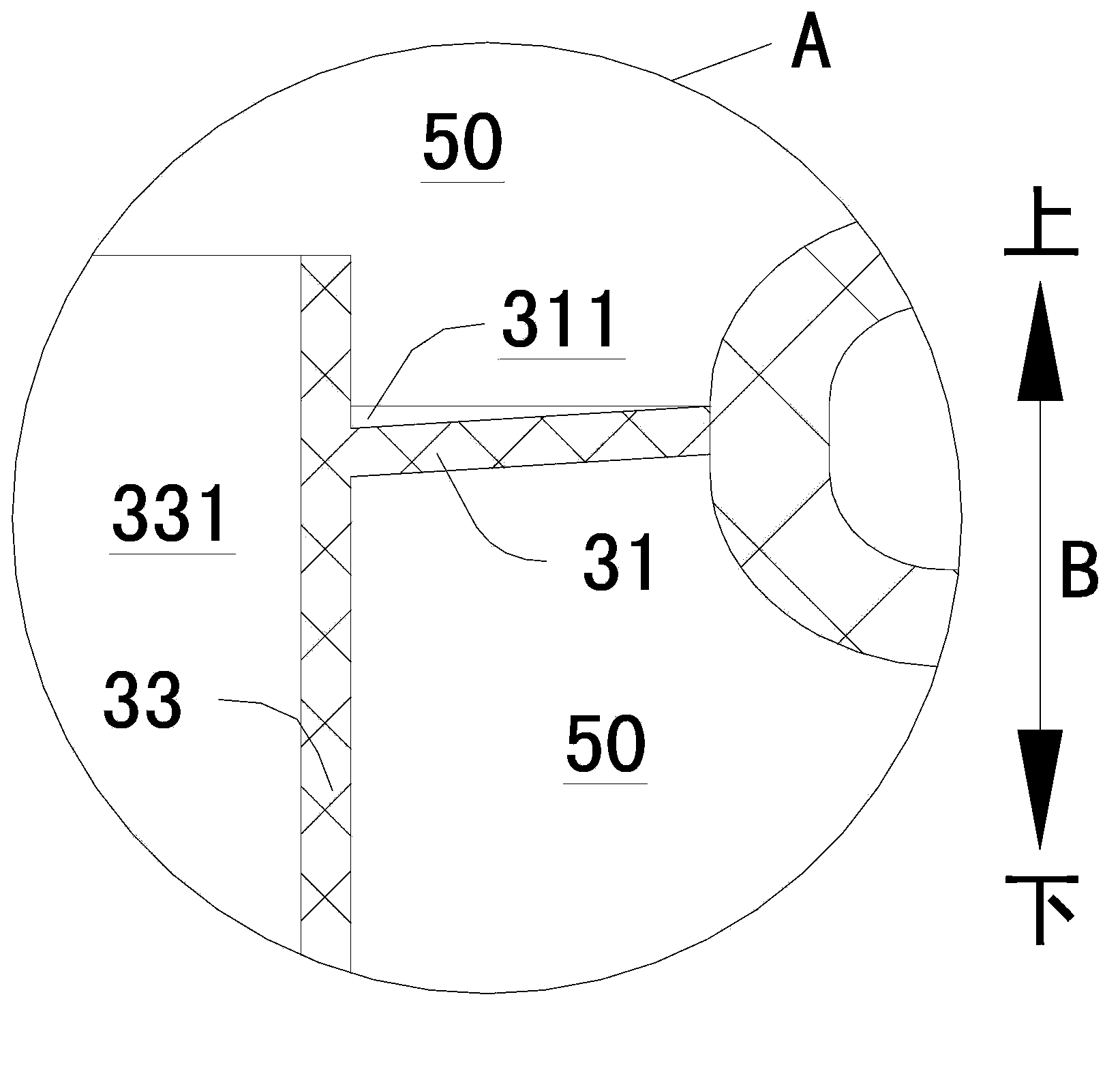

The invention discloses an oil-gas separation system with a secondary separation function. The oil-gas separation system with the secondary separation function comprises an oil-gas loop arranged on acylinder cover hood, the oil-gas loop is provided with a coarse separation structure and a fine separation structure, and the coarse separation structure is located on the upstream side of the fine separation structure. The coarse separation structure comprises a labyrinth air path arranged on the oil-gas loop. The fine separation structure comprises a fine separator shell and filter cotton. The shape of the fine separator is matched with the shape of the section of the oil-gas loop, and the fine separator shell is provided with a mounting structure capable of being fixed to the oil-gas loop.The oil-gas separation system is further provided with a baffle, the baffle is parallel to the mounting side of the filter cotton of the fine separator shell and is relatively fixed to the fine separator shell. The filter cotton is fixed to the baffle side between the baffle and the fine separator shell. A plurality of oil-gas separation holes are formed in the position, corresponding to the filter cotton, of the fine separator shell correspondingly in a penetrating mode. The oil-gas separation system with the secondary separation function has the beneficial effects that the impact pressure ofgas containing oil is sufficiently weakened, the degree of deformation of a filter element is reduced, and the optimal oil-gas separation effect can be ensured.

Owner:SHENTONG TECH GRP CO LTD

Multi-stage oil-gas separator

InactiveCN110822777AImprove oil and gas separation effectRefrigeration componentsEngineeringMechanical engineering

The invention discloses a multi-stage oil-gas separator. The oil-gas separator comprises an outer cylinder body, an intermediate separation cylinder, an inner cylinder body, a gas inlet pipe, an exhaust pipe and an oil guide pipe; a first filter screen is arranged at the inner bottom of the inner cylinder body, the intermediate separation cylinder is arranged in a first cavity, and the inner cylinder body is arranged in a second cavity; and the gas inlet pipe is in communication with the first cavity of the outer cylinder body through a first opening formed in the upper portion of the side part of the outer cylinder body, the exhaust pipe is in communication with a third cavity of the inner cylinder body through a second opening formed in the top of the outer cylinder body, and the oil guide pipe is in communication with the second cavity of the intermediate separation cylinder through a third opening formed in the bottom of the intermediate separation cylinder. The oil-gas separator realizes the effect that the centrifugal separation effect is changed due to the change of the discharge amount in the variable load regulation process of a refrigerating unit, but the good separationeffect can be obtained under different flow rates.

Owner:广东捷邦节能设备制造有限公司

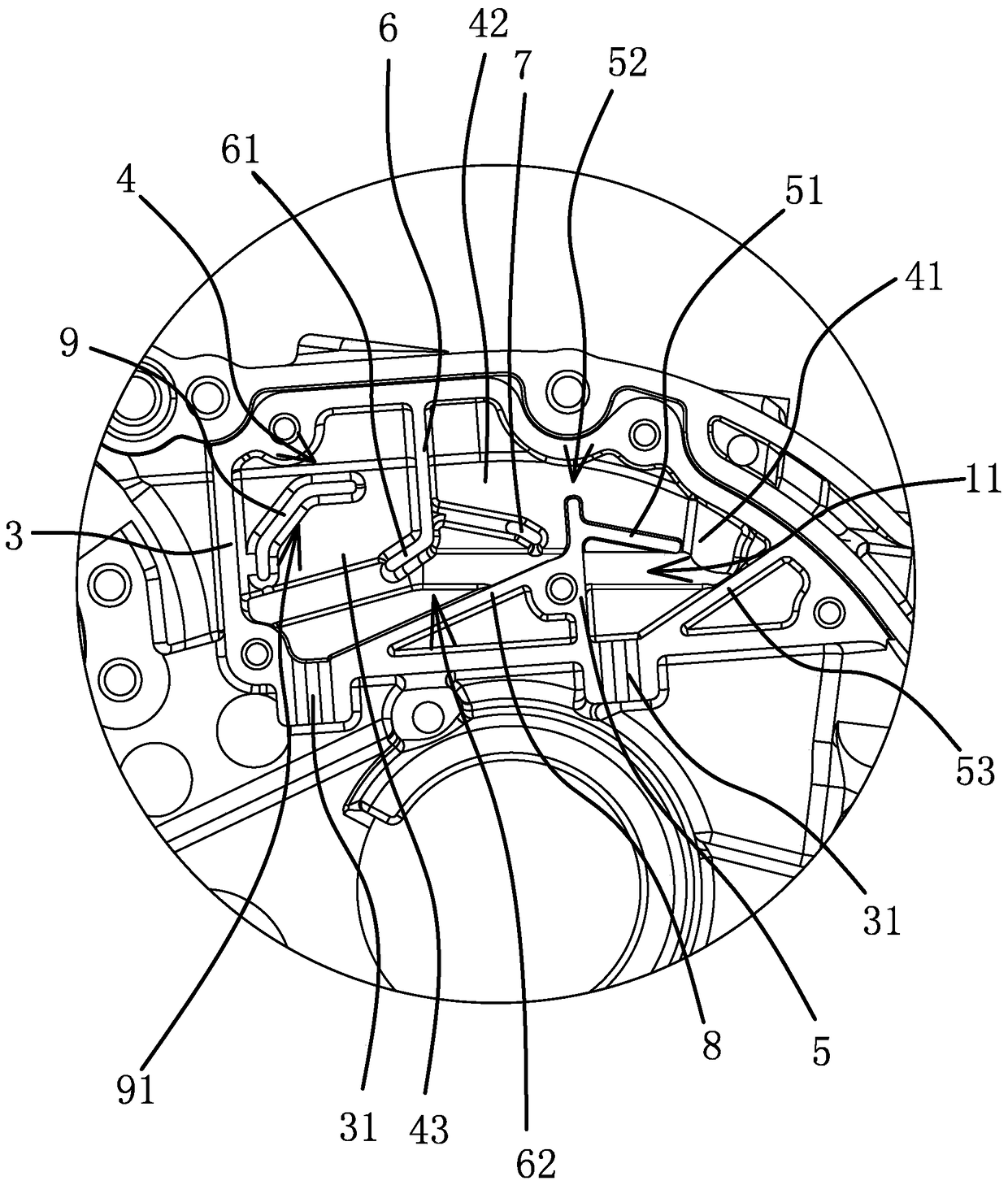

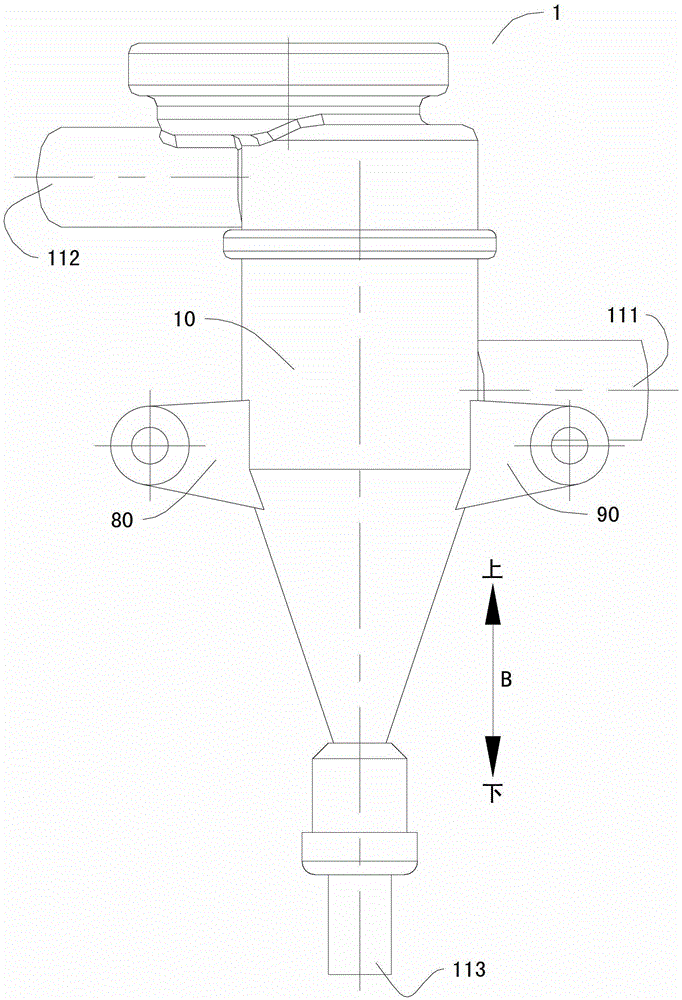

Oil and gas separator, engine and vehicle

ActiveCN106855001AImprove oil and gas separation effectReduce manufacturing costMachines/enginesCrankcase ventillationSeparation systemPetroleum engineering

The embodiment of the invention discloses an oil and gas separator, an engine oil and gas separation system and a vehicle. The oil and gas separator comprises a shell and an oil and gas separation module, wherein the housing is provided with a first connecting part, and the oil and gas separation module includes a cyclone oil and gas separator and a second connecting part, which are fixed to each other; the first connecting part is connected with the second connecting part, and the oil and gas separation module is installed in the shell. According to the oil and gas separator, the engine oil and gas separation system and the vehicle, the oil and gas separation effect is good, the production cost is low, the structure is simple, processing and manufacturing is easily achieved, the occupied space is small and integration is easy to achieve.

Owner:BEIQI FOTON MOTOR CO LTD

Oil-gas separator

PendingCN108049939AReduce working pressure differential changeImprove oil and gas separation effectMachines/enginesCrankcase ventillationEngineeringCrankcase

The invention discloses an oil-gas separator and aims to provide the oil-gas separator which can reduce the operating pressure differential variation of a crankcase and the oil-gas separator to improve the oil-gas separating effect. The oil-gas separator comprises a separator housing, an oil-gas mixing channel arranged in the separator housing and an oil-gas inlet communicating with the oil-gas mixing channel and further comprises a negative pressure adjusting device arranged on the separator housing, wherein the negative pressure adjusting device comprises an air compensation cavity formed inthe separator housing, an air inlet communicating with the air compensation cavity, and an air compensation device arranged on the separator housing and used for compensating air for the oil-gas mixing channel; the air compensation device comprises a compensating through hole and an umbrella-type valve; the compensating through hole is formed in the separator housing and communicates with the oil-gas mixing channel and the air compensation cavity; and the umbrella-type valve is arranged on the inner side face of the oil-gas mixing channel and is used for controlling open-close of the compensating through hole.

Owner:SHENTONG TECH GRP CO LTD

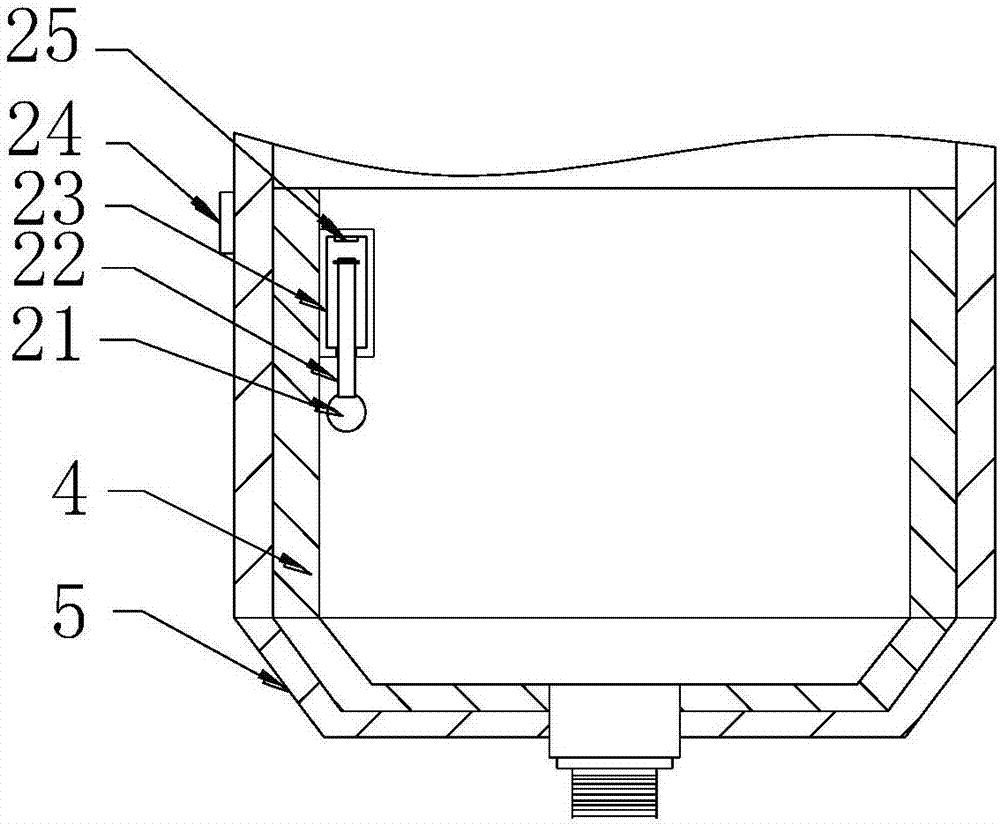

Vehicle air conditioner oil-gas separator

InactiveCN107144058AAchieve recyclingExtended service lifeRefrigeration componentsEngineeringLoudspeaker

The invention provides a vehicle air conditioner oil-gas separator. The vehicle air conditioner oil-gas separator comprises a second guide plate, a shell, a floating ball, a stretchable rod, a guide sleeve, a loudspeaker and a touch switch; the second guide plate is arranged on the left portion of the annular side face in the shell, and the shell is installed at the middle position of the interior of an outer tank; through the design, oil-gas quick separation is achieved, the separation effect is good, and the separation efficiency is high; the floating ball is installed on the lower end face of the stretchable rod, the stretchable rod is assembled in the guide sleeve, the guide sleeve is fixed to the upper position of the annular side face in an oil storage tank, the loudspeaker is arranged on the annular side face of the outer tank and is connected with the touch switch through a connecting line, and the touch switch is arranged at the middle position of the upper end face of the interior of the guide sleeve; and by means of the design, the blockage early warning function is achieved, and the running stability of the vehicle air conditioner oil-gas separator is guaranteed. The vehicle air conditioner oil-gas separator is reasonable in structure, good in oil-gas separation effect, long in service life, good in stability and high in reliability.

Owner:WUJIANG KAILIANDA METAL PROD

A kind of engine oil gas separator

ActiveCN101363344BReduce resistanceImprove oil and gas separation effectMachines/enginesCrankcase ventillationCycloneOil separation

Owner:CHERY AUTOMOBILE CO LTD

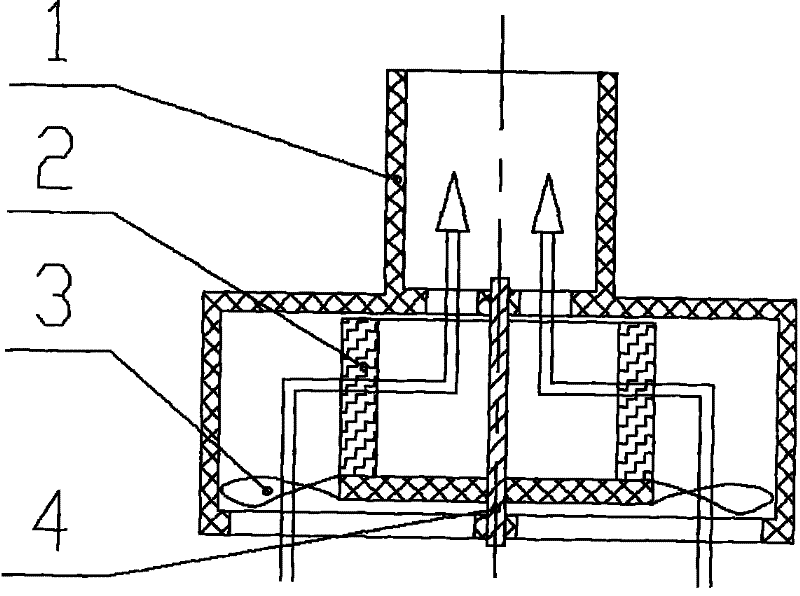

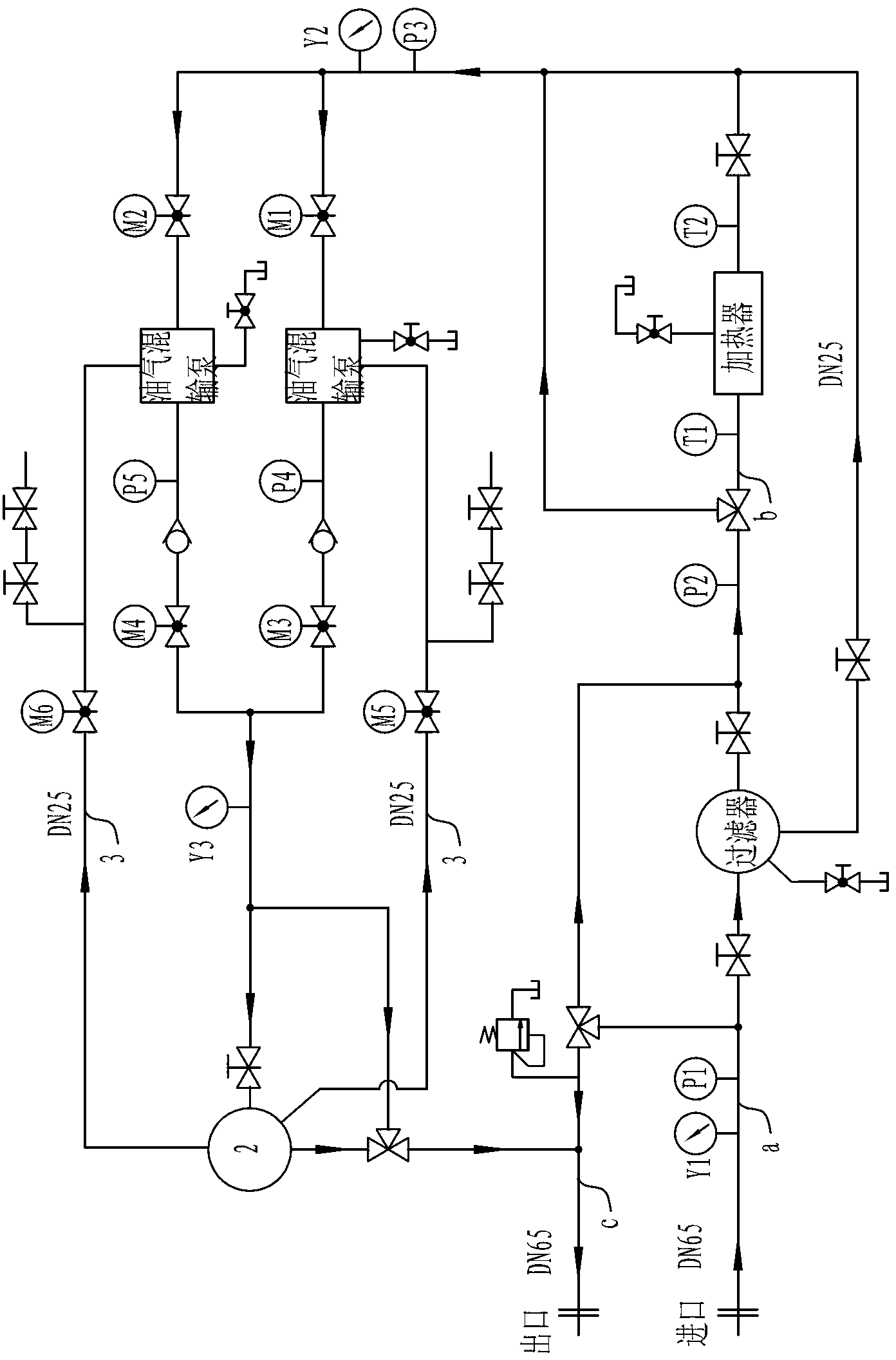

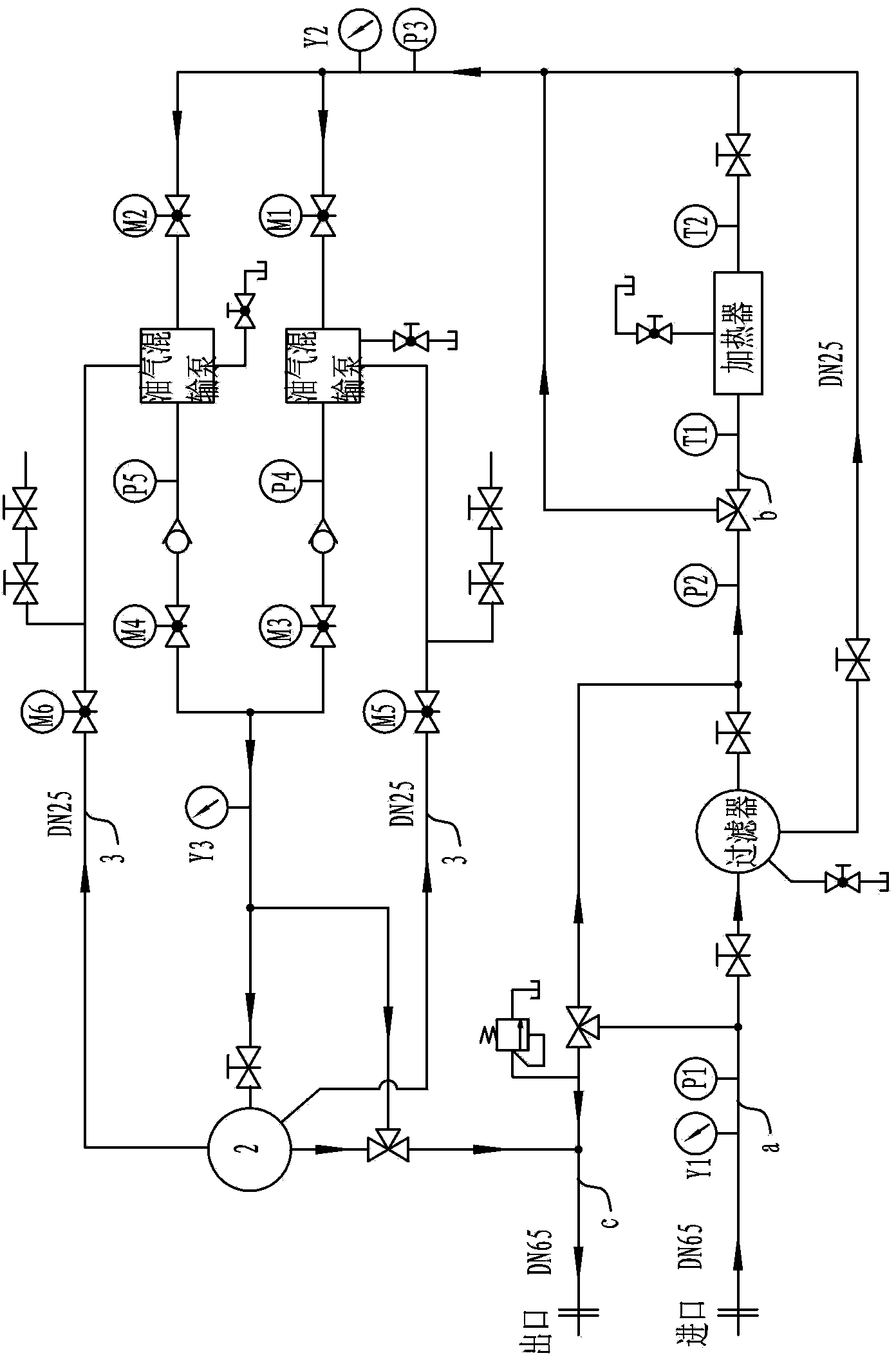

Electric heating type oil gas mixed transmission intelligent integrated system and control method thereof

InactiveCN103256482AExtended service lifeHas a lubricating effectPipeline systemsPumpsTemperature controlAtmospheric pressure

The invention discloses an electric heating type oil gas mixed transmission intelligent integrated system and a control method of the electric heating type oil gas mixed transmission intelligent integrated system. The electric heating type oil gas mixed transmission intelligent integrated system comprises a gas inlet pipeline, an oil gas separating pipe network, a heating pipeline and a gas outlet pipeline. The electric heating type oil gas mixed transmission intelligent integrated system is characterized in that two separating pipelines of the same structure are arranged in the oil gas separating pipe network, each separating pipeline is sequentially provided with an upper electric valve, an oil gas mixed transmission pump, a check valve and a lower electric valve, a separating filtering device is provided with a backflow port, the backflow port is connected with two backflow pipes, each backflow pipe is connected with a pipe connector of the oil gas mixed transmission pump, and adjusting valves are installed on the back flow pipes. The electric heating type oil gas mixed transmission intelligent integrated system has the obvious advantages that high-efficiency separation of oil and gas in the system can be completed, oil and gas temperature control can be realized, gas collecting temperature demands in different environments are satisfied, air pressure of all pipe networks of a whole skid-mounted device can also be monitored, and connection and disconnection of each valve in the networks can be adjusted.

Owner:重庆明珠机电有限公司

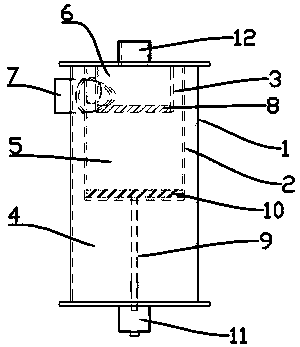

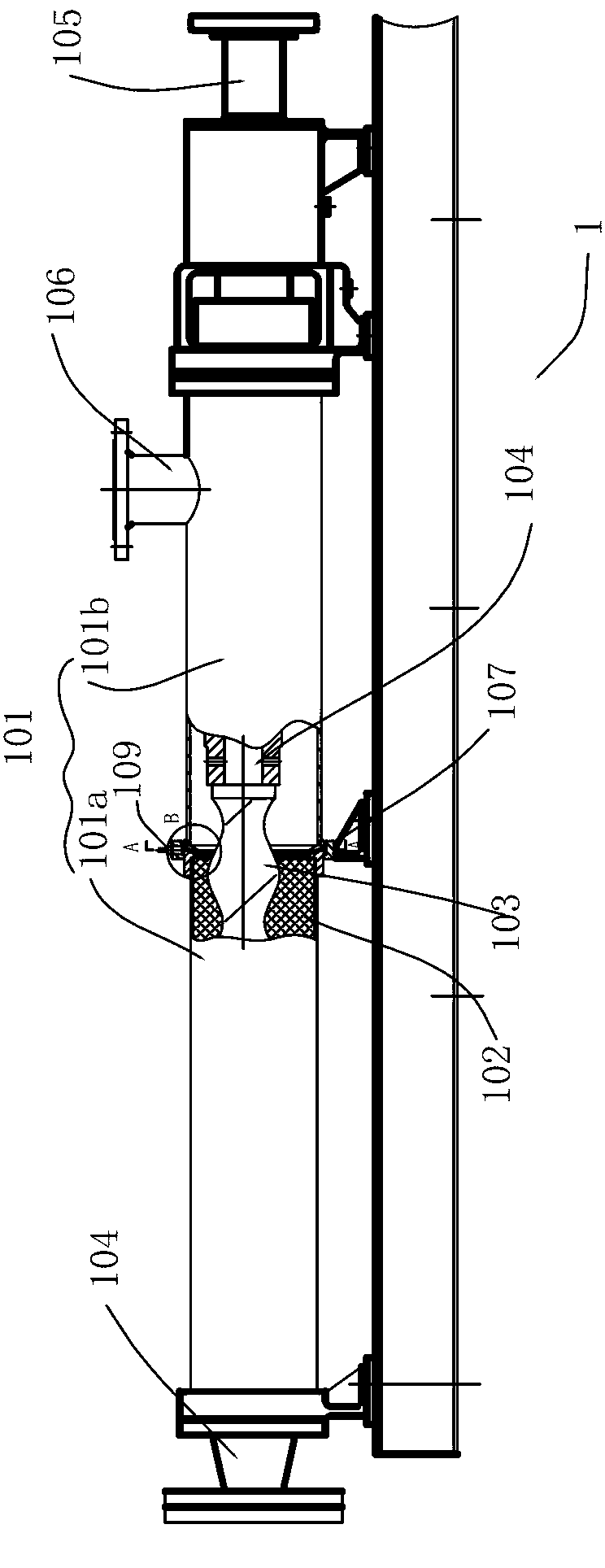

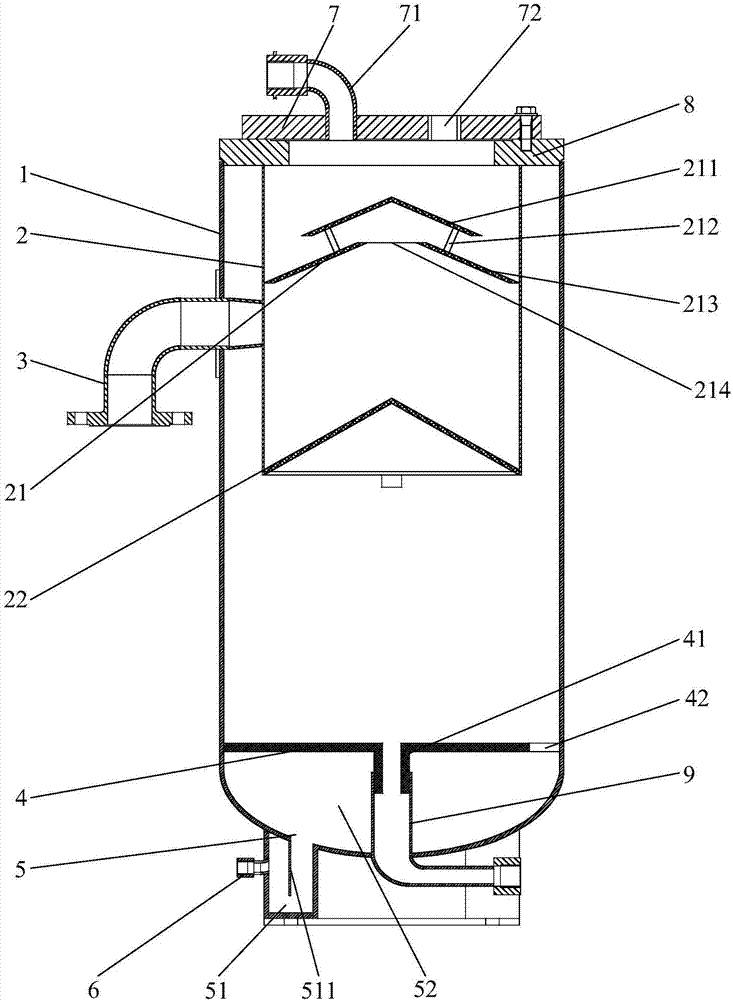

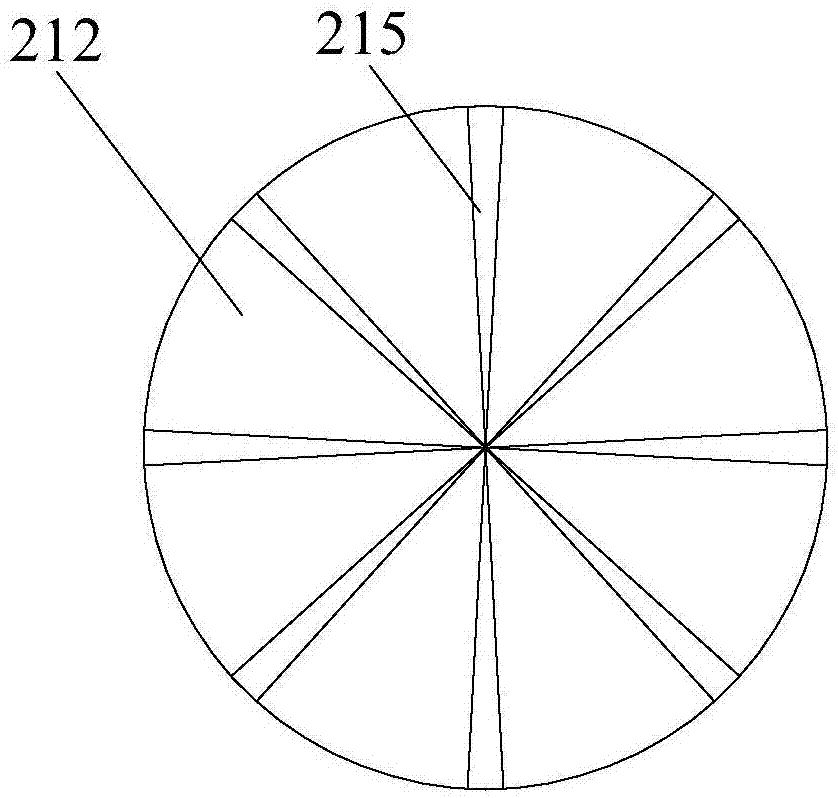

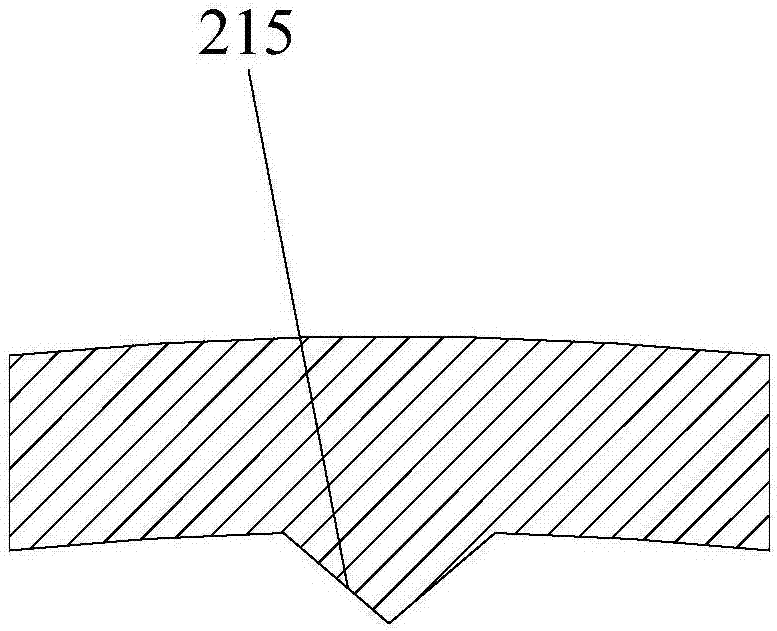

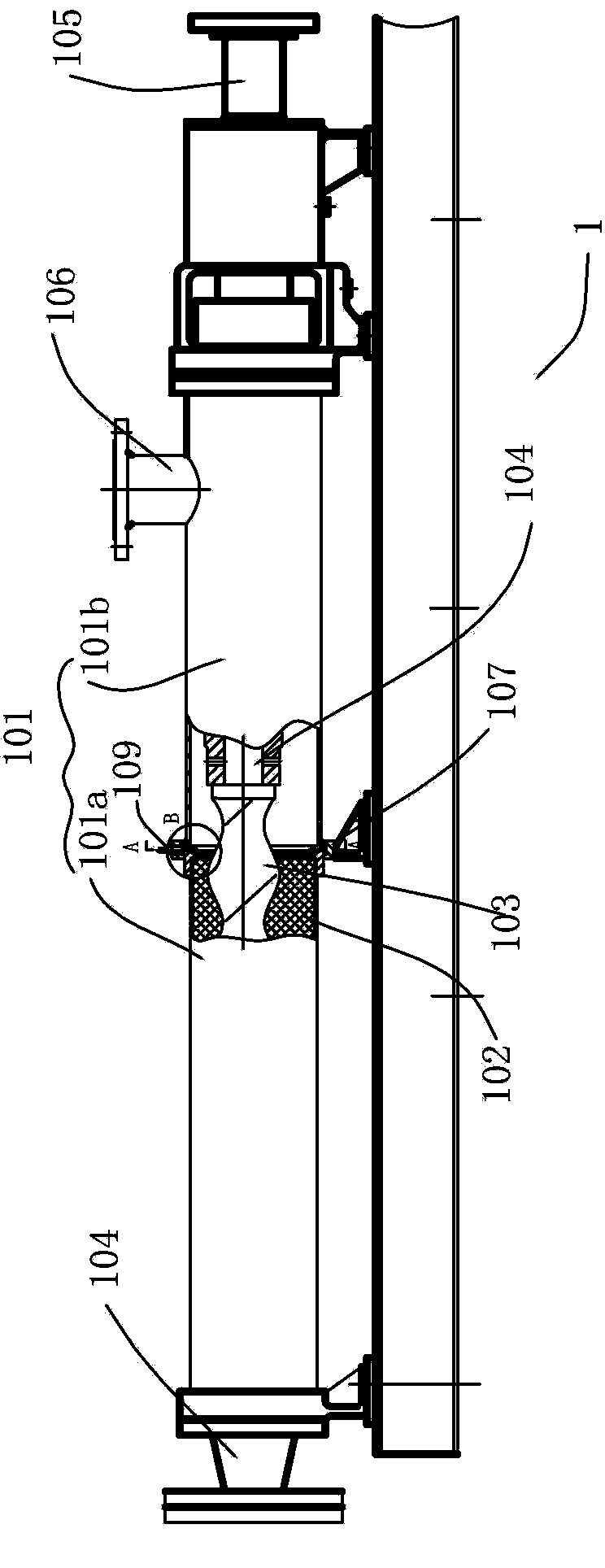

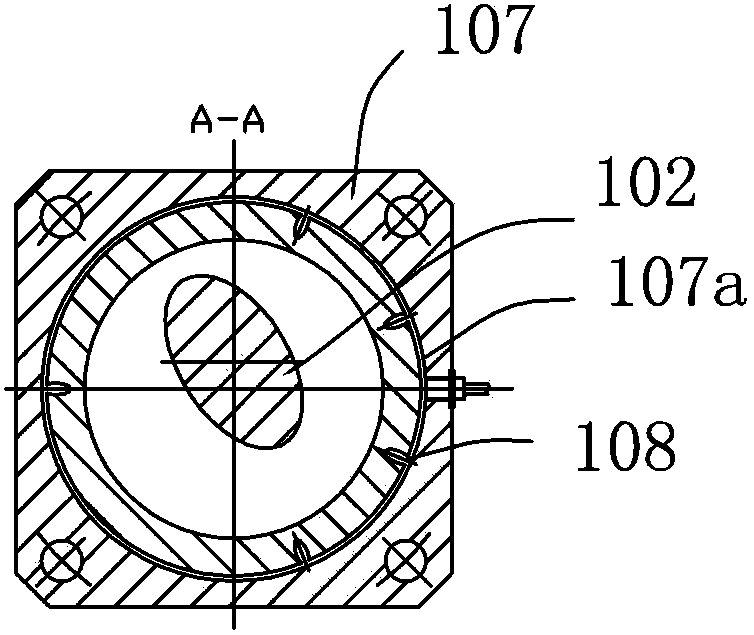

Vertical pressure vessel tank applied to oil-gas separation

InactiveCN107376517AWith secondary separationReasonable structural designSolid waste disposalDispersed particle separationCavity wallPressure vessel

The invention provides a vertical pressure vessel tank applied to oil-gas separation. The vertical pressure vessel tank comprises a tank body, wherein an oil baffling cylinder is arranged in the tank body and is in through connection with a oil-gas inlet tube; a separation umbrella is arranged at the upper part of the inner cavity of the oil baffling cylinder and is composed of two layers of umbrella-shaped separation covers which are arranged at intervals from top to bottom; an oil scattering cap is arranged at the lower part of the separation umbrella and is located at the bottom end part of the oil baffling cylinder; a partition plate is arranged at the lower part of the oil scattering cap; the outer edge of the partition plate is attached on the inner cavity wall of the tank body; a cavity opening is formed in the outer edge of the partition plate; an oil outlet groove is formed in the center of the partition plate; the lower end of the oil outlet groove is correspondingly connected with an oil outlet tube; a water bag area is arranged at the lower part of the partition plate. Through the optimization of design and the combination of the separation umbrella, the secondary separation effect is achieved; the overall oil-gas separation effect is improved; the vertical pressure vessel tank has the characteristics of reasonable structure design and excellent oil-gas separation effect.

Owner:谈辉辉

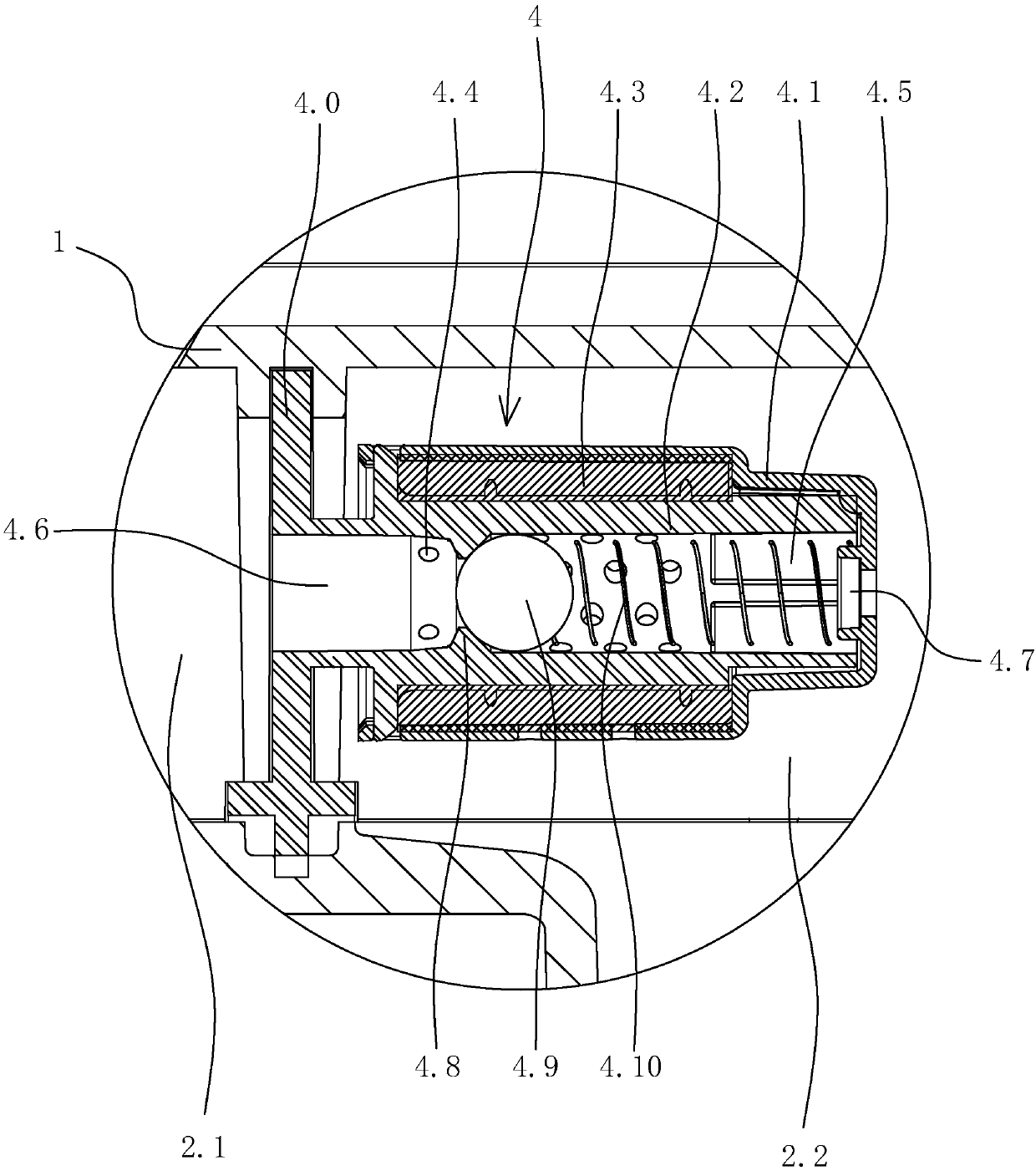

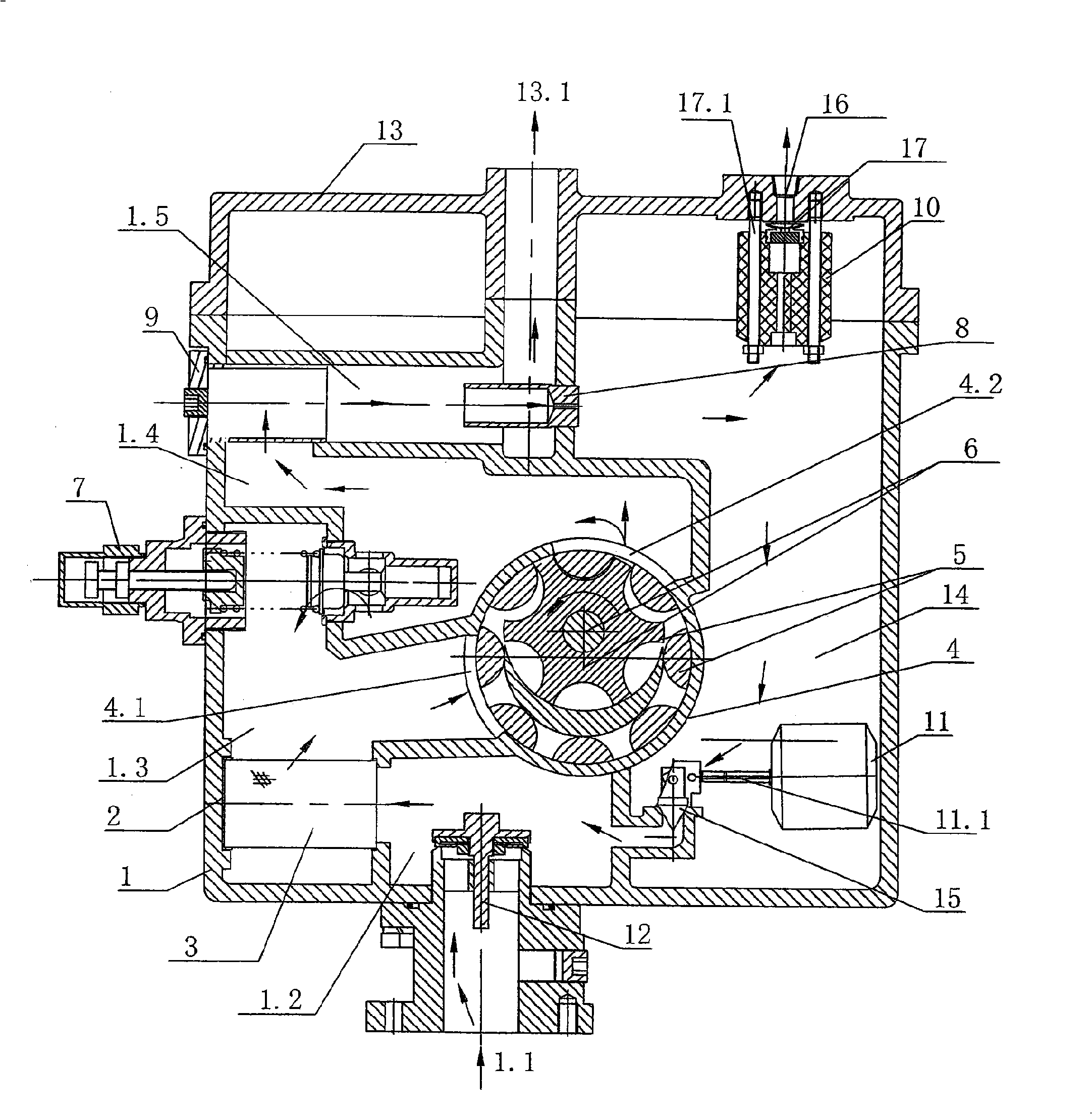

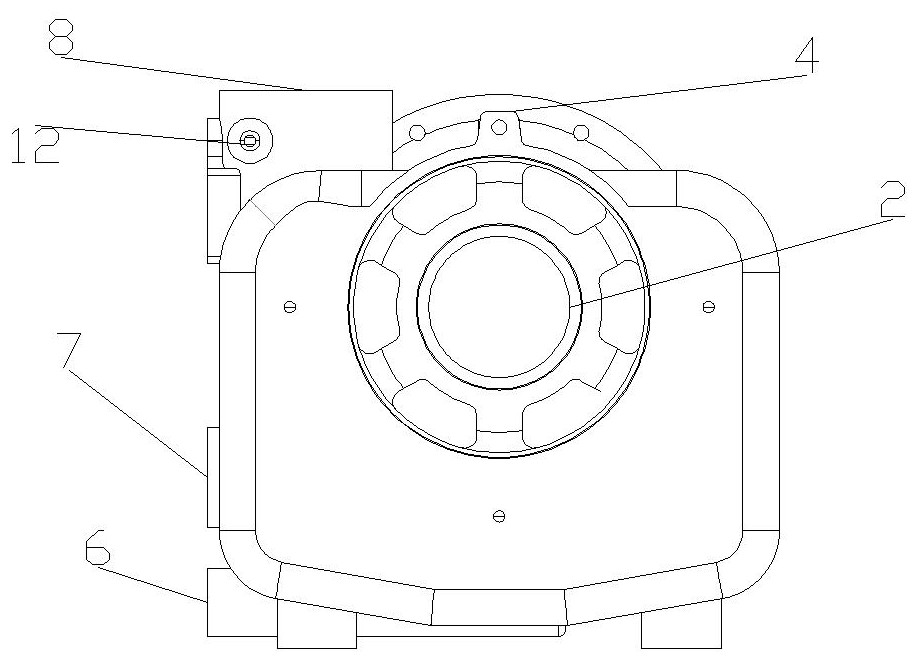

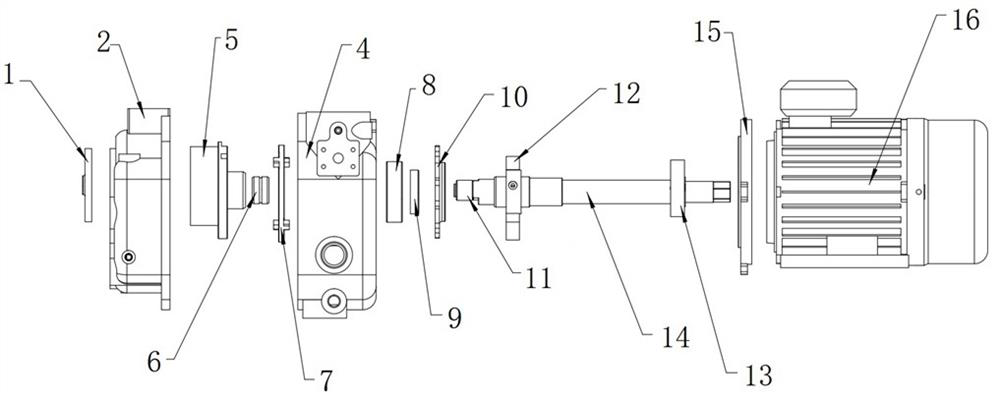

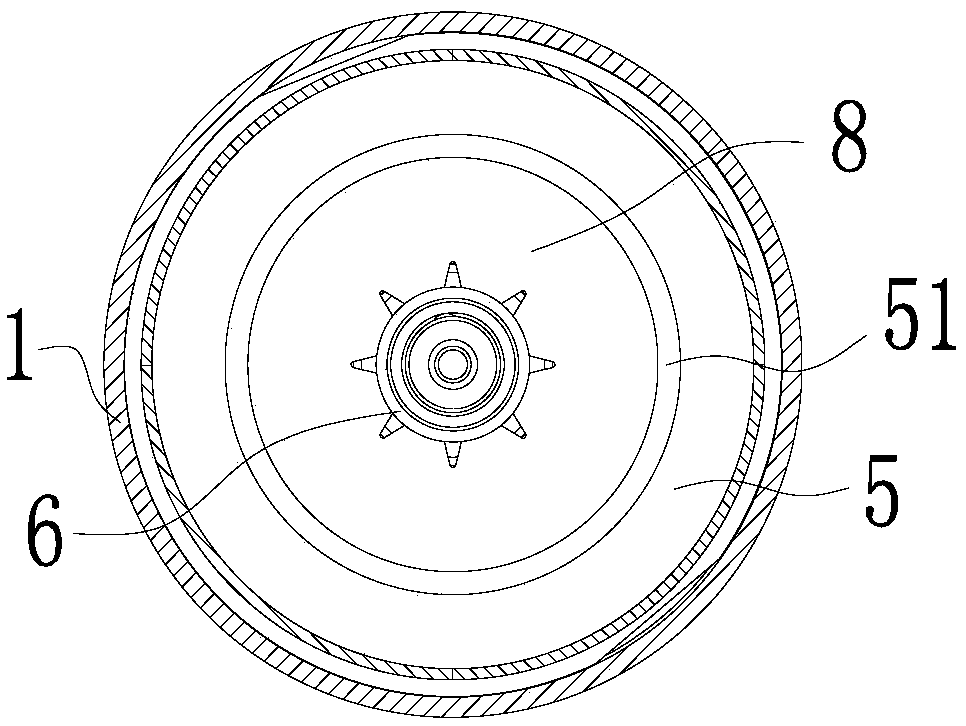

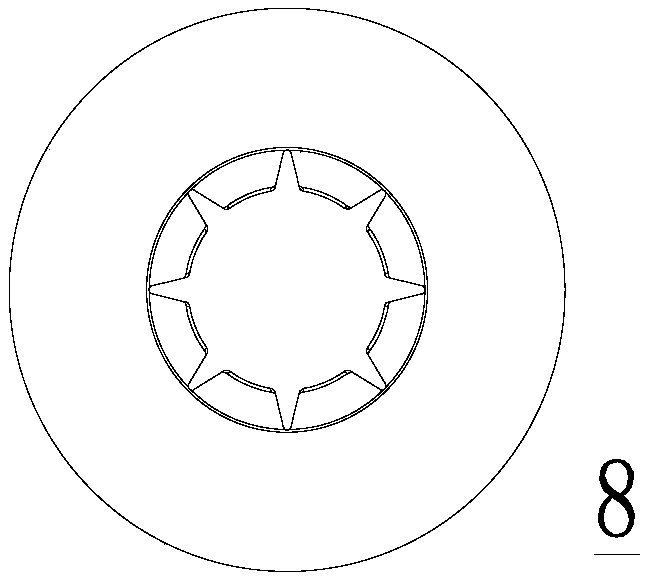

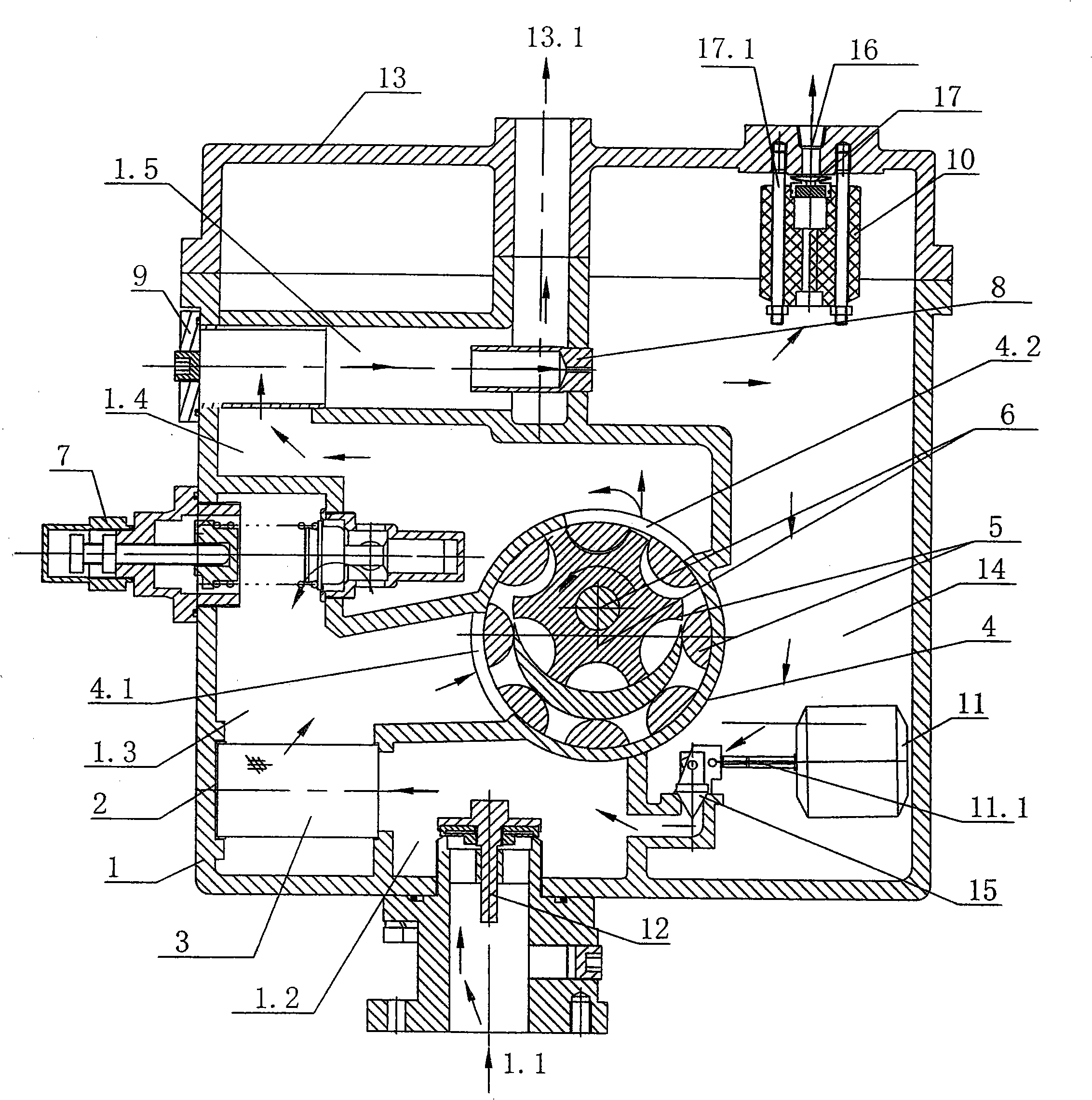

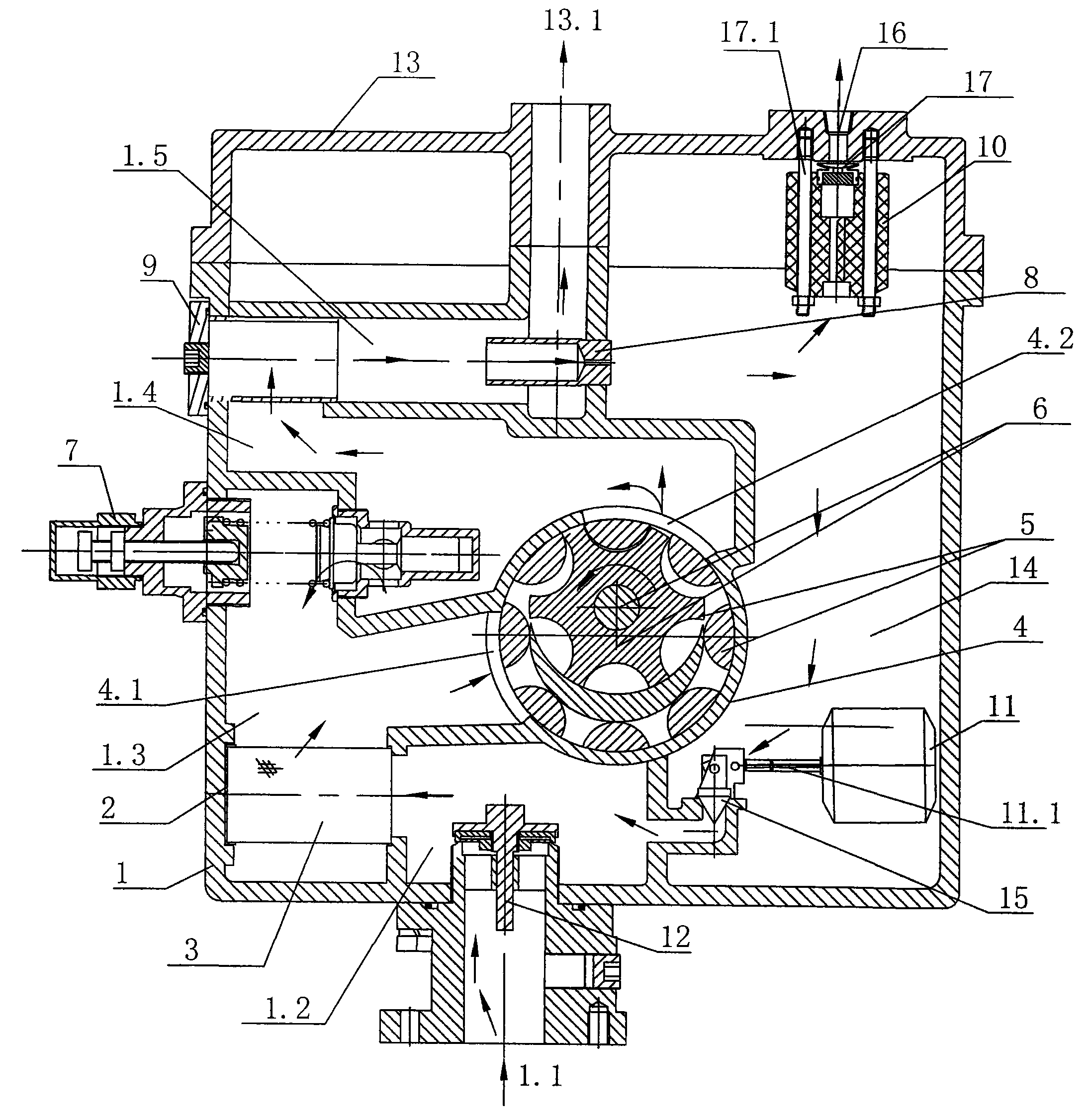

Oil-gas separation circular arc type inside engaged gear combined oil pump

ActiveCN101514699ACompact structureImprove oil and gas separation effectRotary piston pumpsRotary piston liquid enginesBodies oilCheck valve

The invention relates to an oil-gas separation circular arc type inside engaged gear combined oil pump which comprises a pump body (1), the bottom of the pump body (1) is provided with an oil suction hole (1.1) and an oil suction hole check valve (12); the lower part in the pump body (1) is provided with an oil inlet cavity (1.2); the middle in the pump body (1) is provided with an oil inlet chamber (1.3), an eccentric body (4), an oil outlet chamber (1.4) and an oil-gas separation chamber (14), wherein, the eccentric body (4) is internally provided with a combined pump spindle (6) which is provided with a circular arc type inside and outside gear set (5), the wall of a shell of the eccentric body (4) is provided with an eccentric body oil inlet (4.1) and an eccentric body oil outlet (4.2); the upper part in the pump body (1) is provided with an oil outlet channel (1.5); the top of the pump body (1) is provided with a pump cover (13), the top of which is provided with an oil outlet (13.1); the oil outlet channel (1.5) is internally provided with an oil-gas separation pipe (8); the lower part of the oil-gas separation chamber (14) is provided with an oil return float valve (15), and a gas bleeder (16) and a gas bleeding float valve (17) are arranged on the top of the pump cover (13) arranged above the oil-gas separation chamber (14). The combined oil pump has stronger oil-gas separation capability and compacter structure.

Owner:JIANGYIN FUREN HIGH TECH

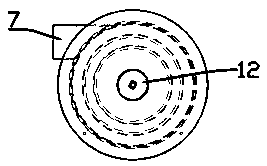

Rotary oil-gas separator

ActiveCN103486042AImprove oil and gas separation effectRotary/oscillating piston pump componentsLiquid fuel engine componentsGas separationEngineering

The present invention discloses a rotary oil-gas separator, which comprises an oil-gas separation barrel, a gas exhaust pipe and an oil-gas separation filtering screen, wherein the oil-gas separation filtering screen is arranged inside the cavity of the oil-gas separation barrel, and the gas exhaust pipe is arranged on the oil-gas separation filtering screen and is provided for communicating both sides of the oil-gas separation filtering screen. The rotary oil-gas separator further comprises a rotary separation device, wherein the rotary separation device is arranged between the oil-gas separation filtering screen and the bottom of the oil-gas separation barrel, and comprises a material inlet, a material outlet and a spiral channel arranged inside the rotary separation device, one end of the material inlet is communicated with the spiral channel, the other end of the material inlet is communicated with one end of the gas exhaust pipe, one end of the material outlet is communicated with the spiral channel, and the other end of the material outlet is toward to the bottom of the oil-gas separation barrel. With the rotary oil-gas separator, an oil-gas separation effect of a compressor can be significantly improved.

Owner:GREE ELECTRIC APPLIANCES INC

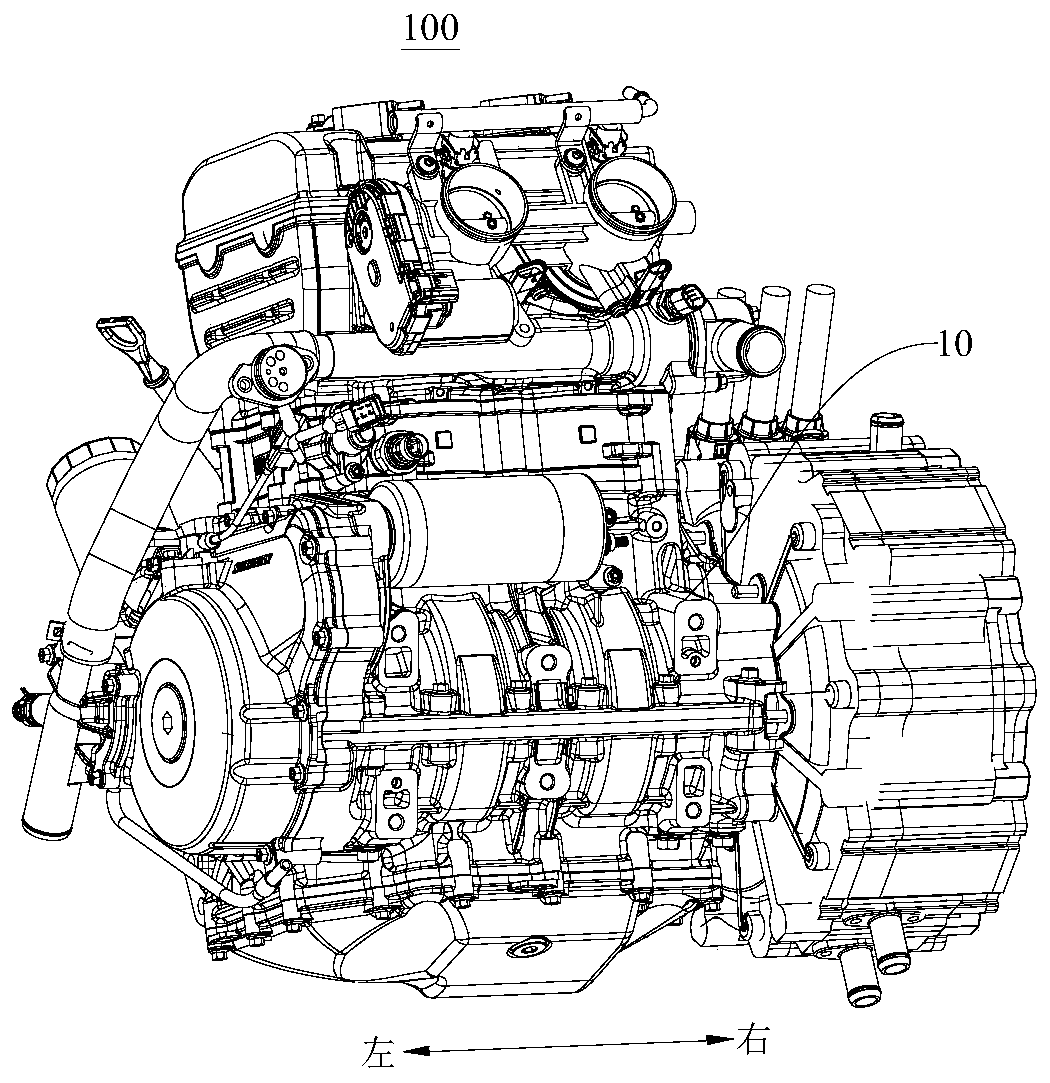

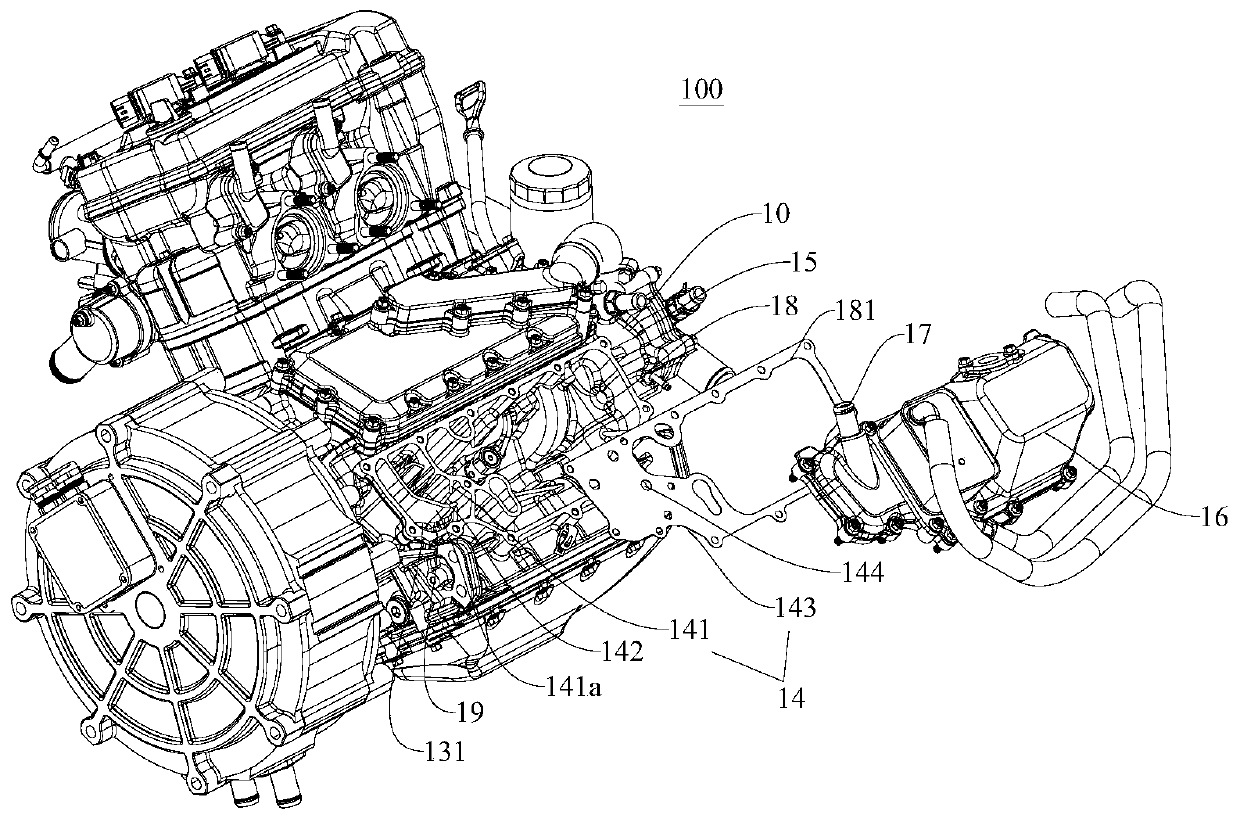

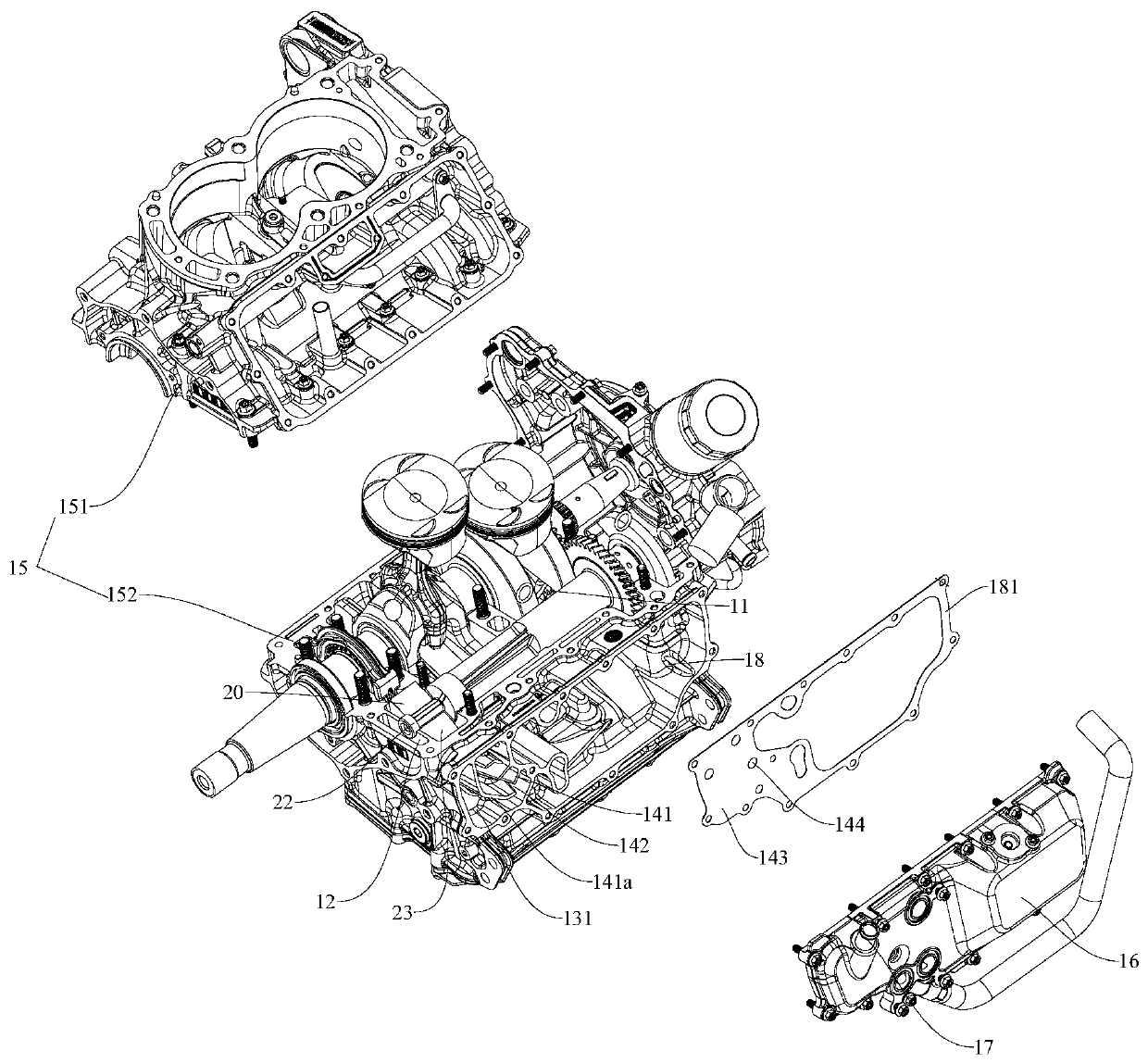

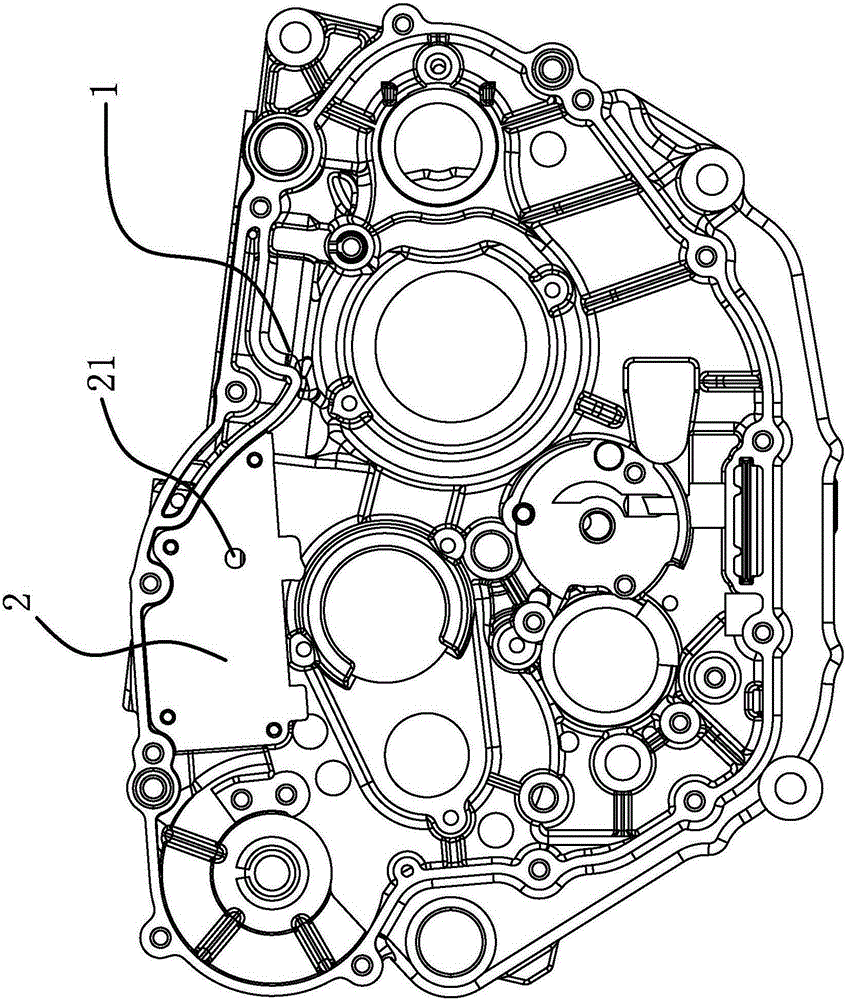

Engine and all-terrain vehicle

The invention discloses an engine and an all-terrain vehicle. The engine comprises a crankcase and a rotating shaft; the crankcase is internally provided with a main cavity, a communication cavity anda separation cavity; the communication cavity is formed in one side of the main cavity; the separation cavity communicates with the communicating cavity and is internally provided with a separation structure; the rotating shaft is rotatably arranged in the main cavity and an axial end of the rotating shaft extends into the communicating cavity; and the rotating shaft is provided with a first communication hole communicating with the main cavity and the communication cavity. Therefore, on the basis of the rotating shaft, by providing the separation chamber, oil and gas separation can be further performed, and the oil and gas separation effect of the engine can be improved; and an oil and gas separation device does not need to be independently arranged, and therefore, the cost of the enginecan be reduced, the layout of the engine is simplified, and the structure is more reliable.

Owner:NINE INTELLIGENT CHANGZHOU TECH CO LTD

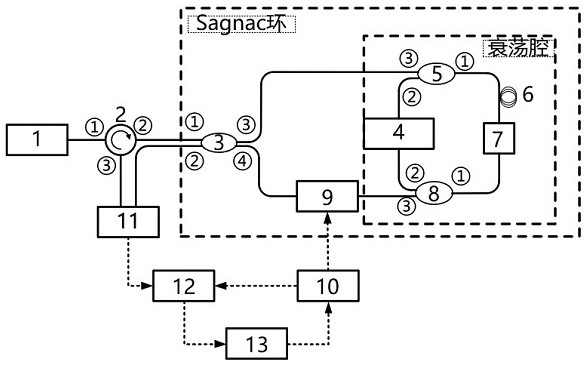

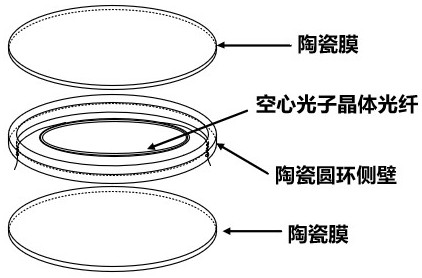

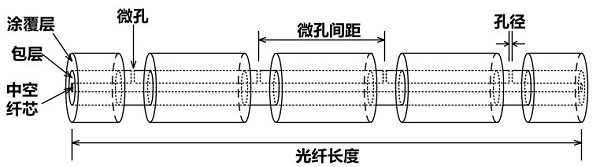

Optical fiber sensing system for dissolved gas in transformer bushing oil

ActiveCN114739955AImprove oil and gas separation effectImprove insulation performancePhase-affecting property measurementsEngineeringLight modulation

The invention provides an optical fiber sensing system for dissolved gas in transformer bushing oil. The optical fiber sensing system comprises a light source, a circulator, a 2 * 2 coupler, an erbium-doped optical fiber amplifier, a first 1 * 2 coupler, a delay optical fiber, a gas sensing module, a second 1 * 2 coupler, an acousto-optic modulator, an acousto-optic modulator driver, a balanced photoelectric detector, a data collector and an upper computer, the gas sensing module is composed of a ceramic membrane and a hollow photonic crystal fiber, the ceramic membrane coated with a high polymer material can achieve efficient oil-gas separation, and the hollow photonic crystal fiber can serve as a gas chamber for interaction of light and gas. And the gas sensing module is arranged in the transformer bushing oil conservator, so that the time of convection diffusion of fault gas to the gas sensing module is shortened. According to the invention, the real-time performance of online monitoring is improved, the performance requirements on the light source and the balance photoelectric detector are reduced while higher sensitivity and lower limit of detection are ensured, and the cost is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

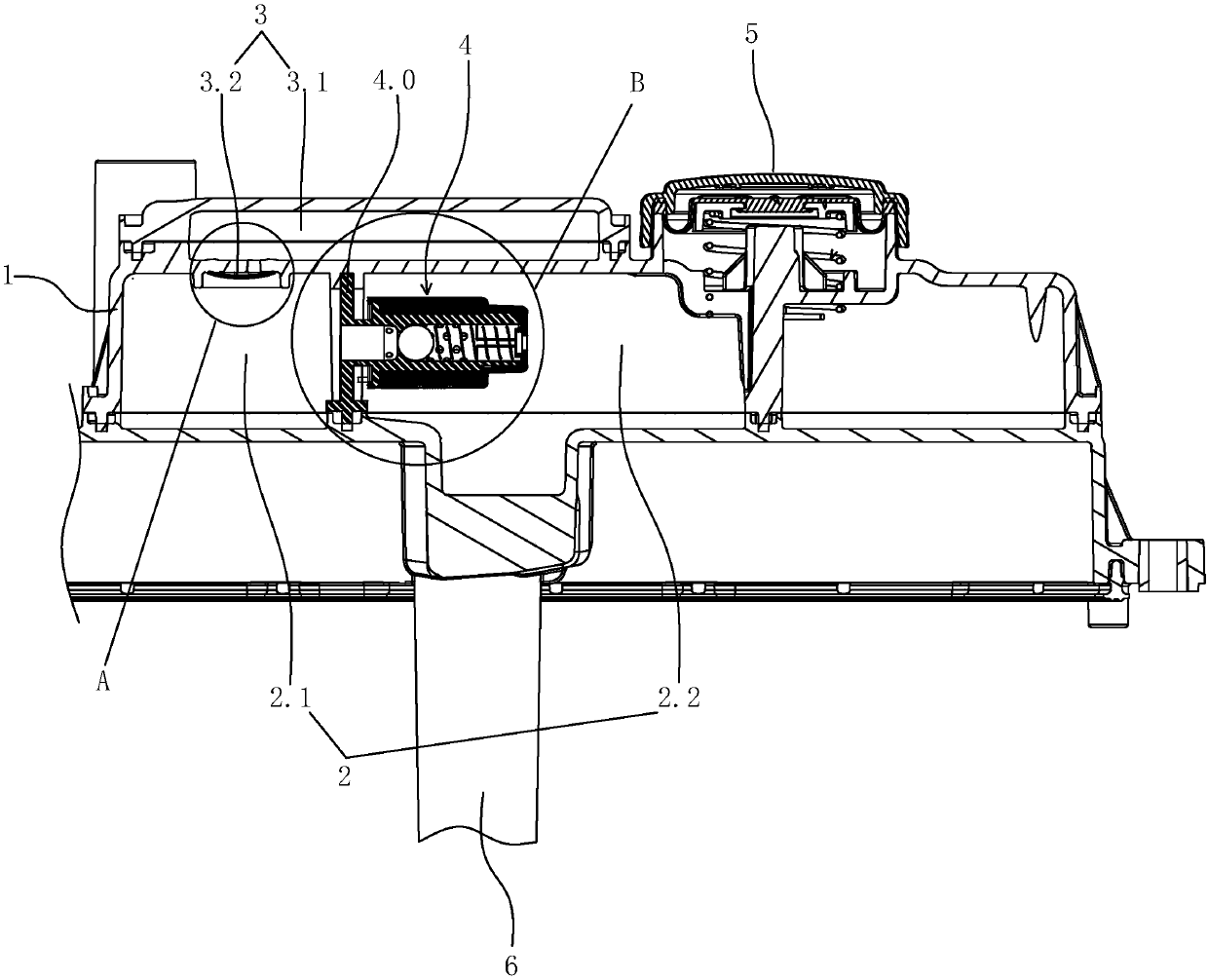

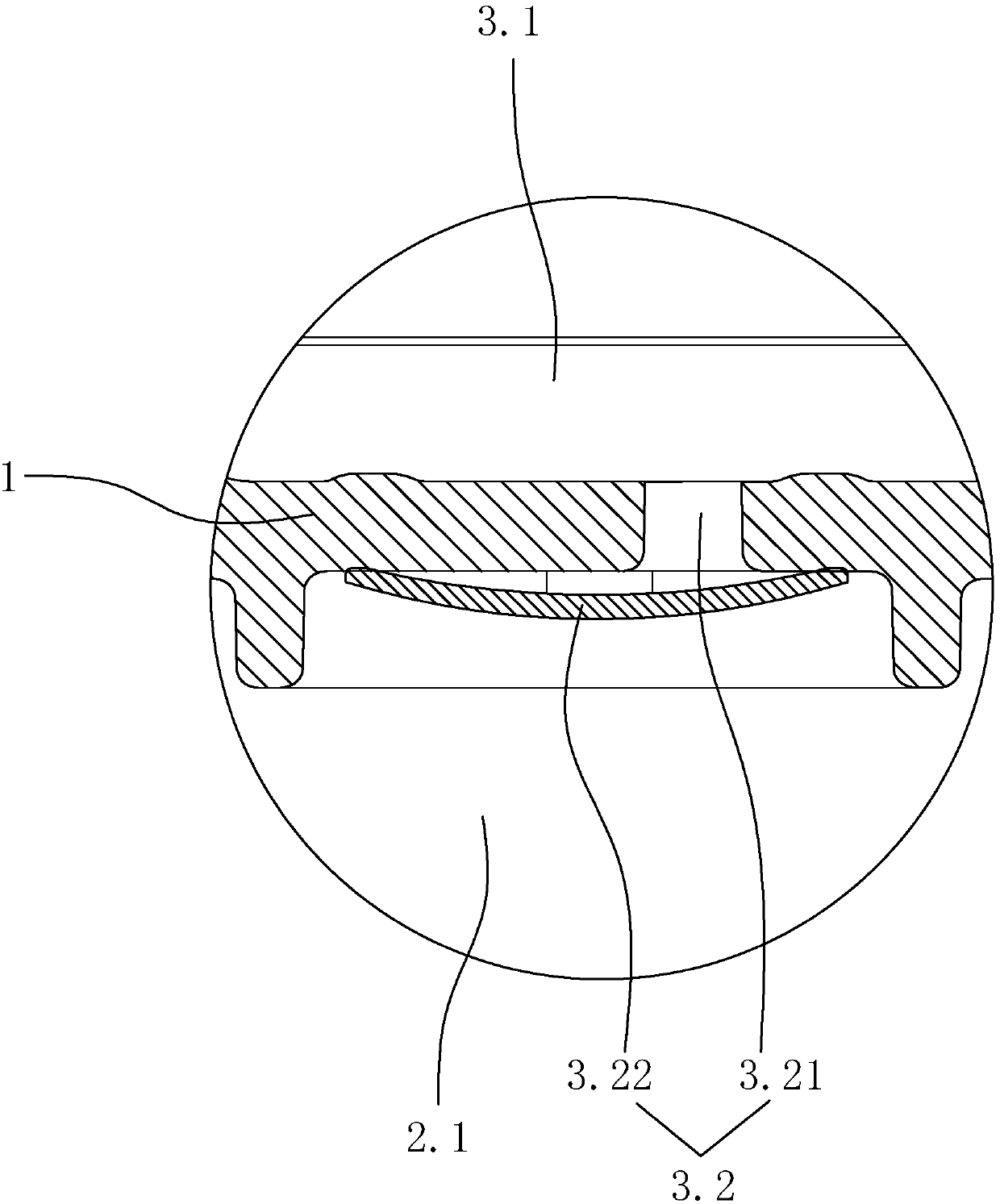

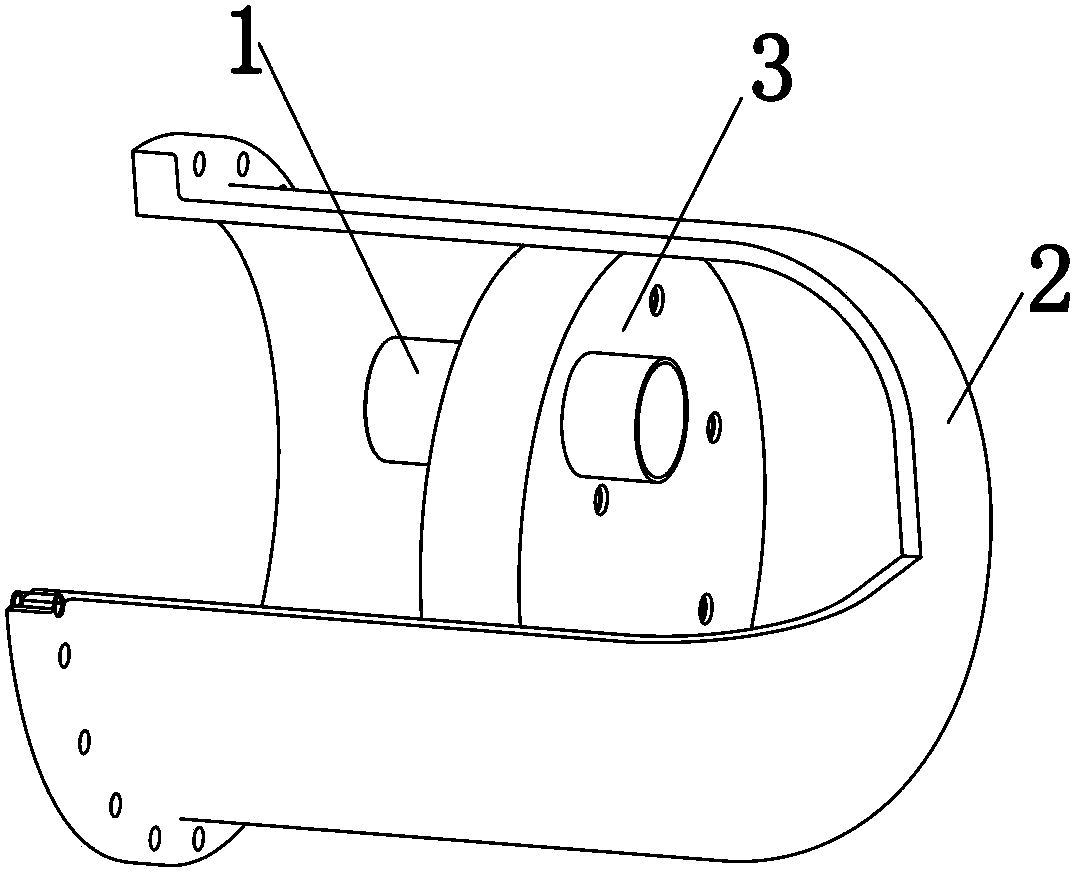

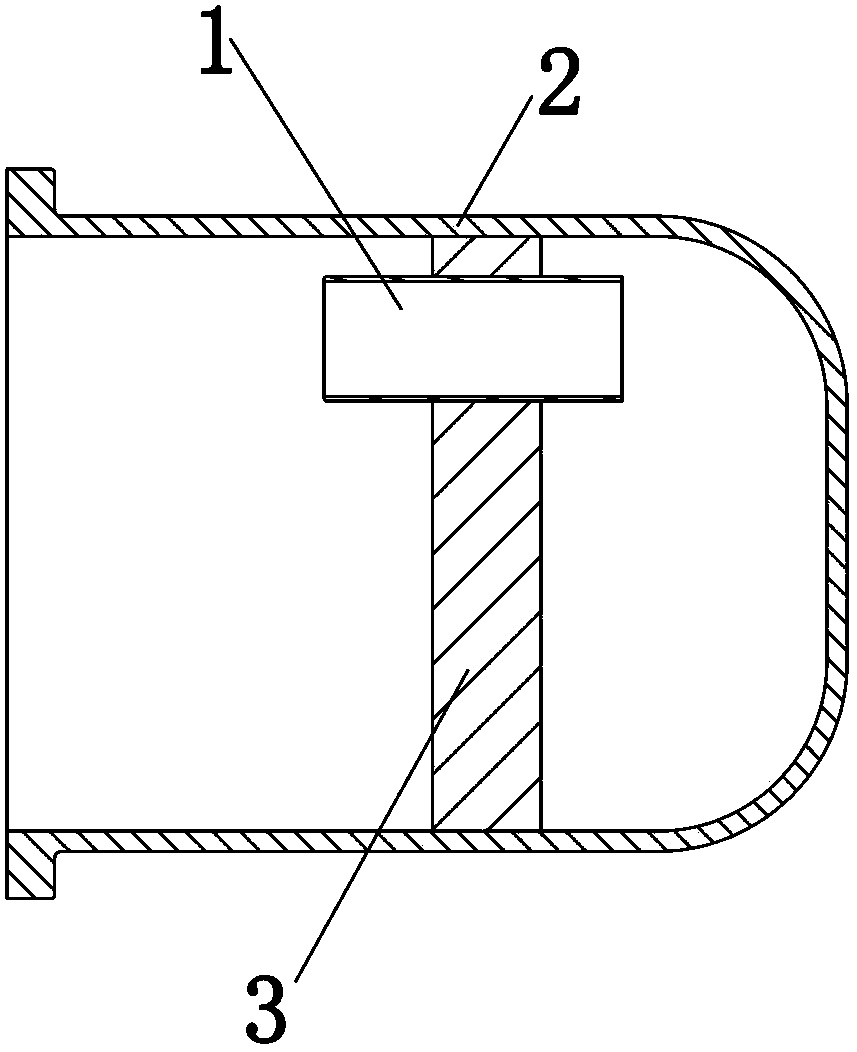

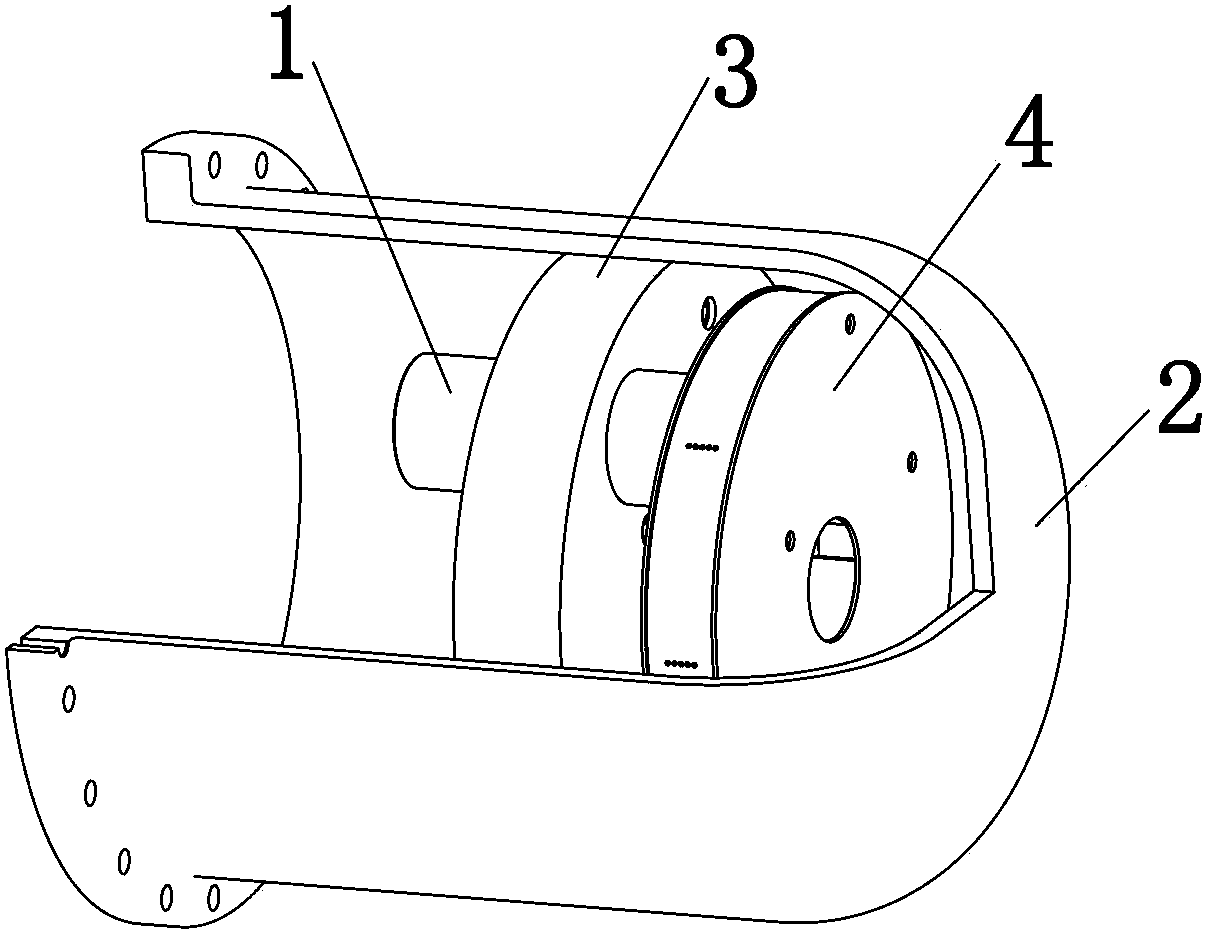

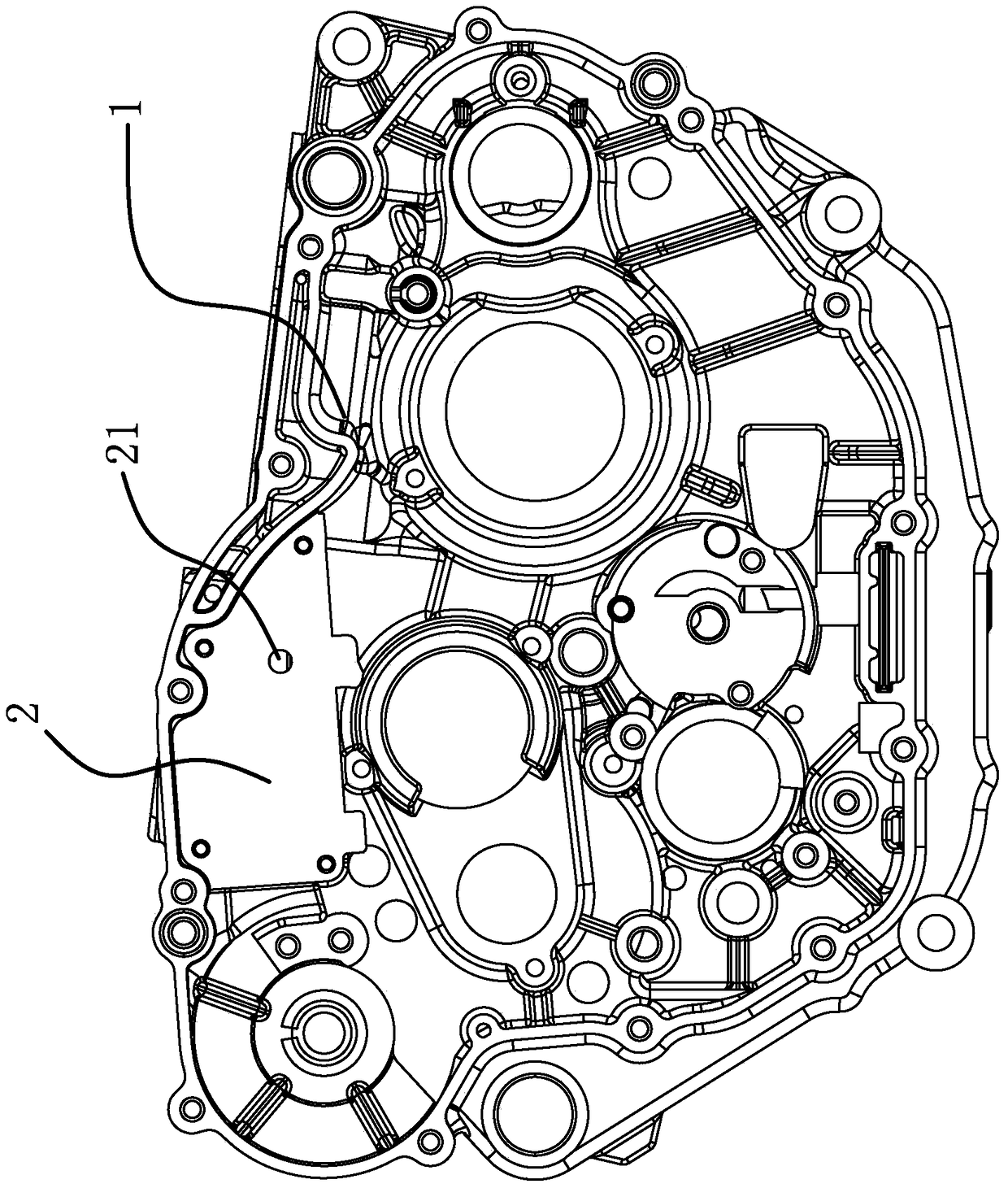

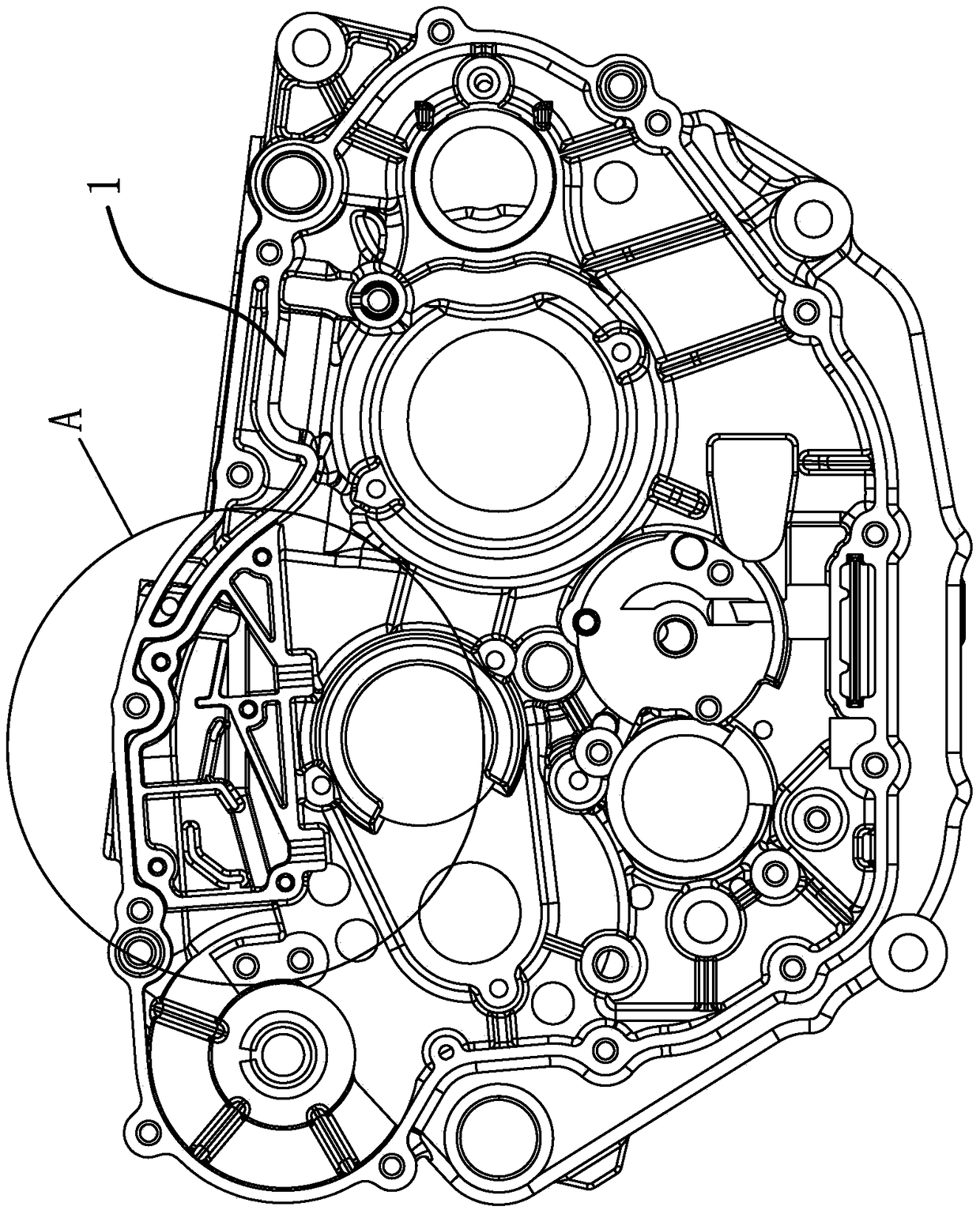

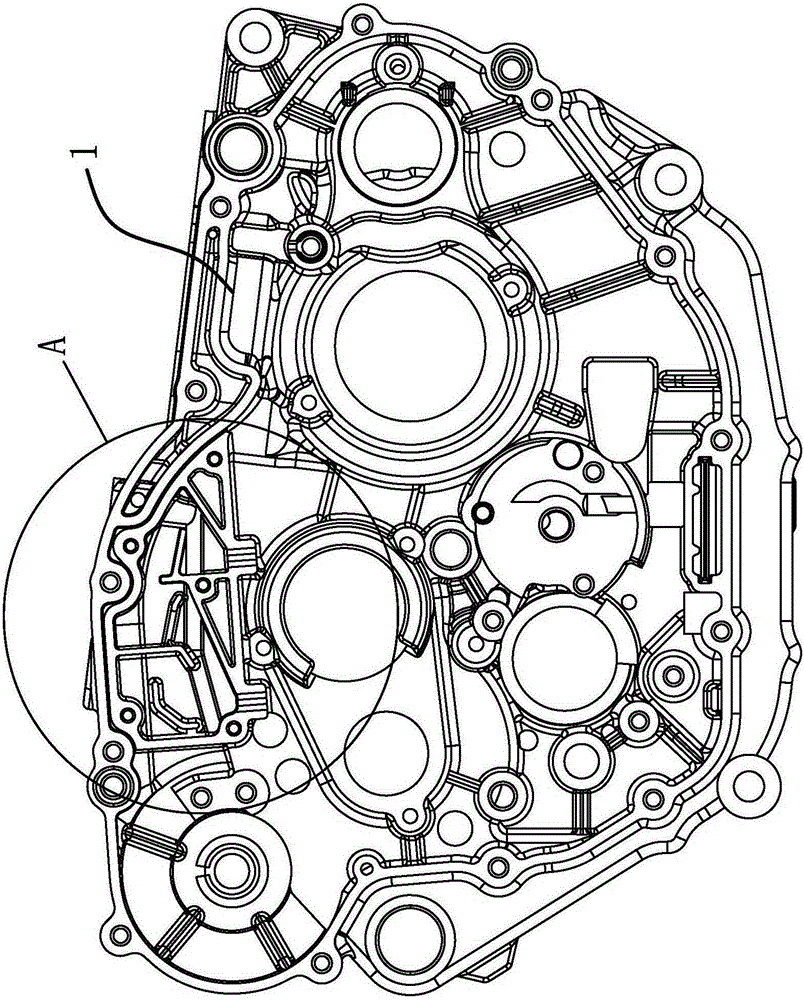

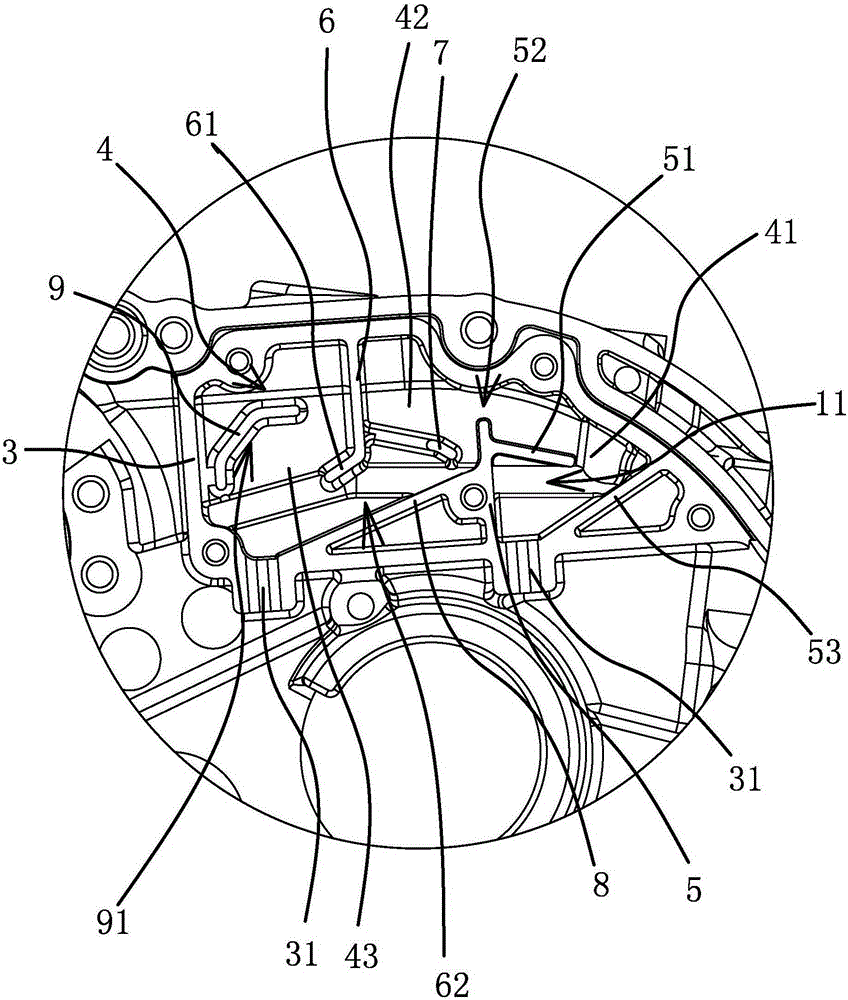

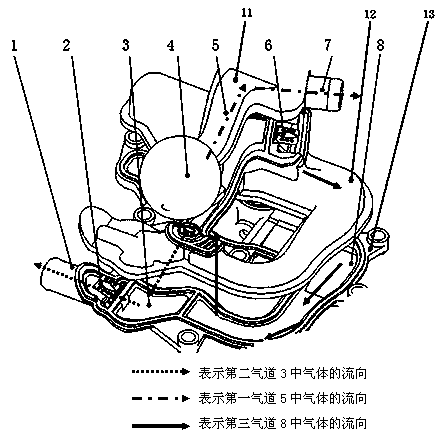

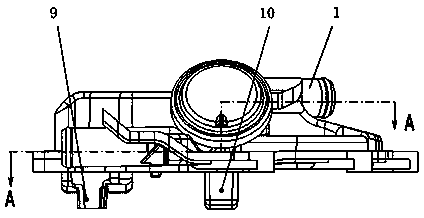

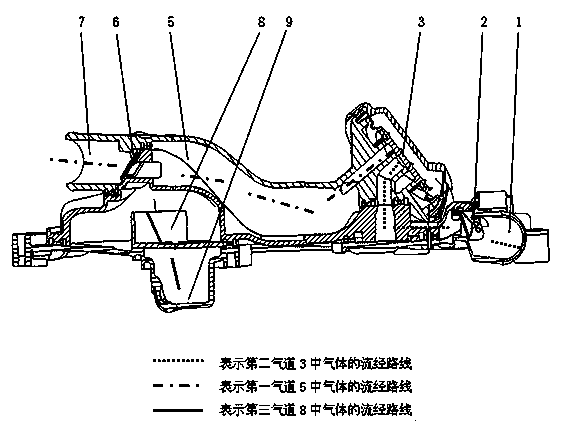

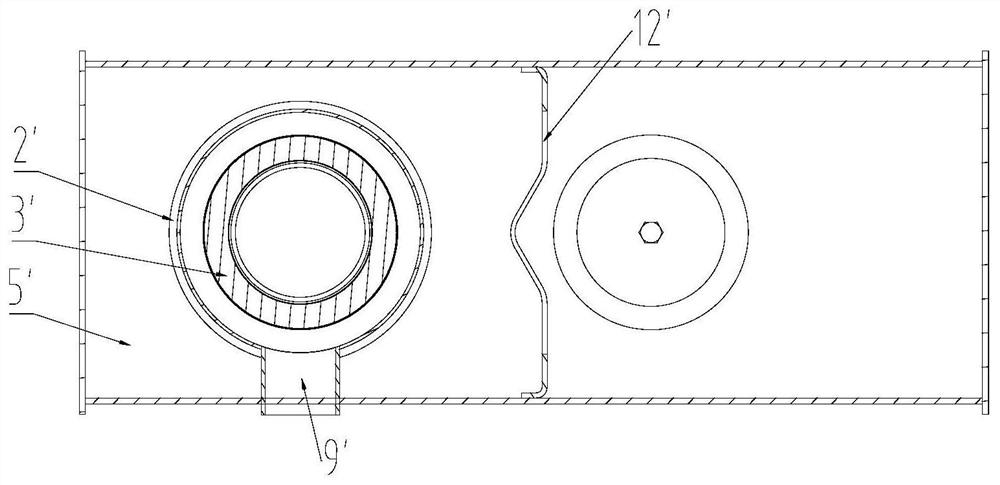

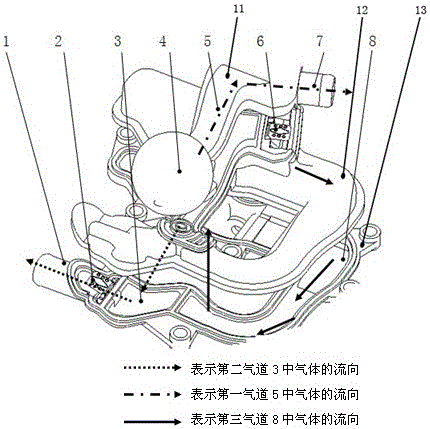

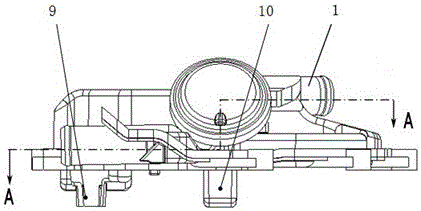

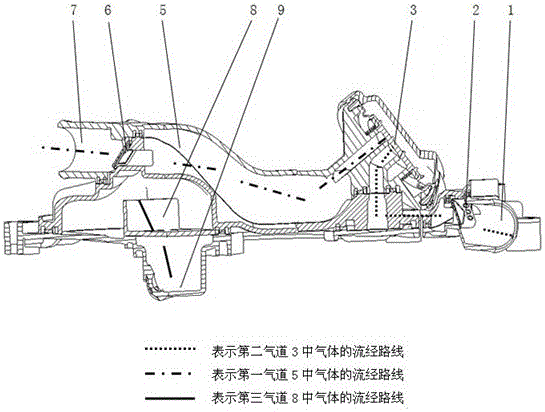

An oil-gas separator on a motorcycle engine case

ActiveCN105221215BEfficient separationImprove oil and gas separation effectMachines/enginesCrankcase ventillationOil separationEngineering

The invention provides an oil-gas separator on a motorcycle engine casing, which belongs to the technical field of motorcycles. The utility model solves the technical problems such as the existing motorcycle needing to fix an independent oil-gas separator on the casing to realize the oil-gas separation, resulting in complex structure and the like. The engine case includes a vertically arranged case cover, and the oil-gas separator is arranged on the inner side of the case cover. The oil-gas separator includes an end cover and a coaming plate, and the coaming plate and the case cover are fixed to form an oil-gas separation chamber; the inside of the coaming plate is fixed with a first The separation plate and the second separation plate, the first separation plate and the second separation plate separate the oil-gas separation chamber to form the first separation chamber, the second separation chamber and the third separation chamber arranged in sequence, and the end cover is provided with Steam inlet hole, when the end cover is fixed to the other end of the coaming plate, the steam inlet hole of the end cover communicates with the first separation chamber, two oil return ports are opened on the lower part of the coaming plate, and two oil return ports are opened on the upper part of the coaming plate Vent. The invention has the advantages of good oil-gas separation effect and simple structure.

Owner:浙江美可达摩托车有限公司

Electric heating type oil gas mixed transmission intelligent integrated system and control method thereof

InactiveCN103256482BImprove delivery efficiencyExtended service lifePipeline systemsPumpsTemperature controlAtmospheric pressure

The invention discloses an electric heating type oil gas mixed transmission intelligent integrated system and a control method of the electric heating type oil gas mixed transmission intelligent integrated system. The electric heating type oil gas mixed transmission intelligent integrated system comprises a gas inlet pipeline, an oil gas separating pipe network, a heating pipeline and a gas outlet pipeline. The electric heating type oil gas mixed transmission intelligent integrated system is characterized in that two separating pipelines of the same structure are arranged in the oil gas separating pipe network, each separating pipeline is sequentially provided with an upper electric valve, an oil gas mixed transmission pump, a check valve and a lower electric valve, a separating filtering device is provided with a backflow port, the backflow port is connected with two backflow pipes, each backflow pipe is connected with a pipe connector of the oil gas mixed transmission pump, and adjusting valves are installed on the back flow pipes. The electric heating type oil gas mixed transmission intelligent integrated system has the obvious advantages that high-efficiency separation of oil and gas in the system can be completed, oil and gas temperature control can be realized, gas collecting temperature demands in different environments are satisfied, air pressure of all pipe networks of a whole skid-mounted device can also be monitored, and connection and disconnection of each valve in the networks can be adjusted.

Owner:重庆明珠机电有限公司

Oil-gas separation device for engine and engine and vehicle having same

ActiveCN103790673BImprove separation efficiencyHigh recovery rateMachines/enginesCrankcase ventillationOil separationWaste management

Owner:BEIQI FOTON MOTOR CO LTD

Oil-gas separator on motorcycle engine tank body

ActiveCN105221215AEfficient separationImprove oil and gas separation effectMachines/enginesCrankcase ventillationEngineeringGas separation

The invention provides an oil-gas separator on a motorcycle engine tank body, and belongs to the technical field of motorcycles. The technical problem that because oil-gas separation can not be achieved until an independent oil-gas separator is fixed to a tank body of an existing motorcycle, the structure is complex is solved. The engine tank body comprises a vertical tank cover. The oil-gas separator is arranged inside the tank cover, and comprises an end cover and a surrounding plate. The surrounding plate and the tank cover are fixed to form an oil-gas separation cavity. A first separation plate and a second separation plate are fixed to the inner side of the surrounding plate and divide the oil-gas separation cavity into a first separation cavity body, a second separation cavity body and a third separation cavity body which are sequentially arrayed. A steam inlet is formed in the end cover. When the end cover is fixed to the other end of the surrounding plate, the steam inlet of the end cover is communicated with the first separation cavity; two oil return openings are formed in the lower portion of the surrounding plate, and a gas outlet is formed in the upper portion of the surrounding plate. The oil-gas separator has the advantages of being good in oil-gas separation effect and simple in structure.

Owner:浙江美可达摩托车有限公司

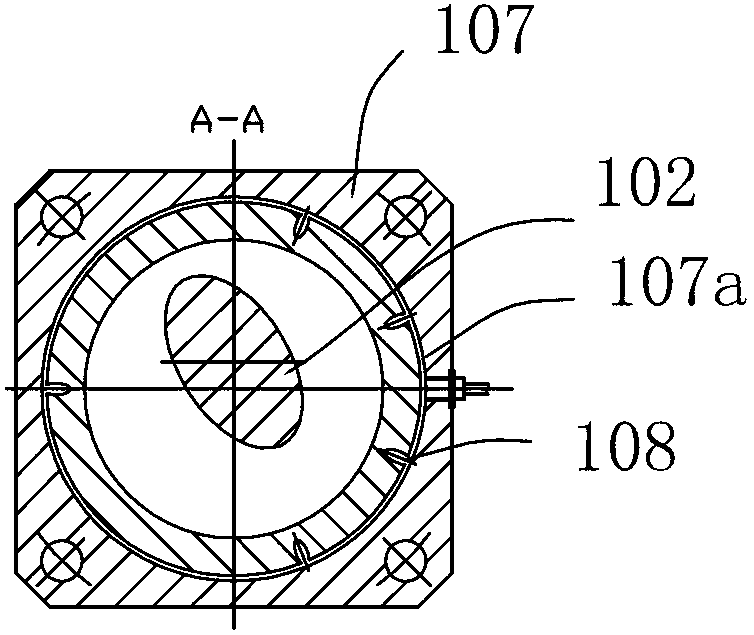

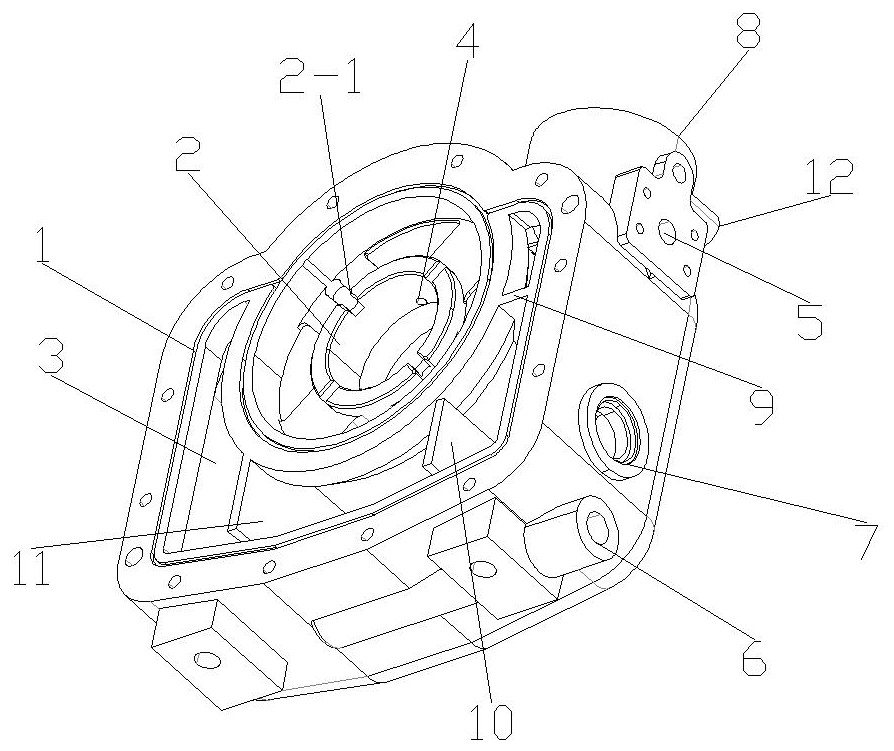

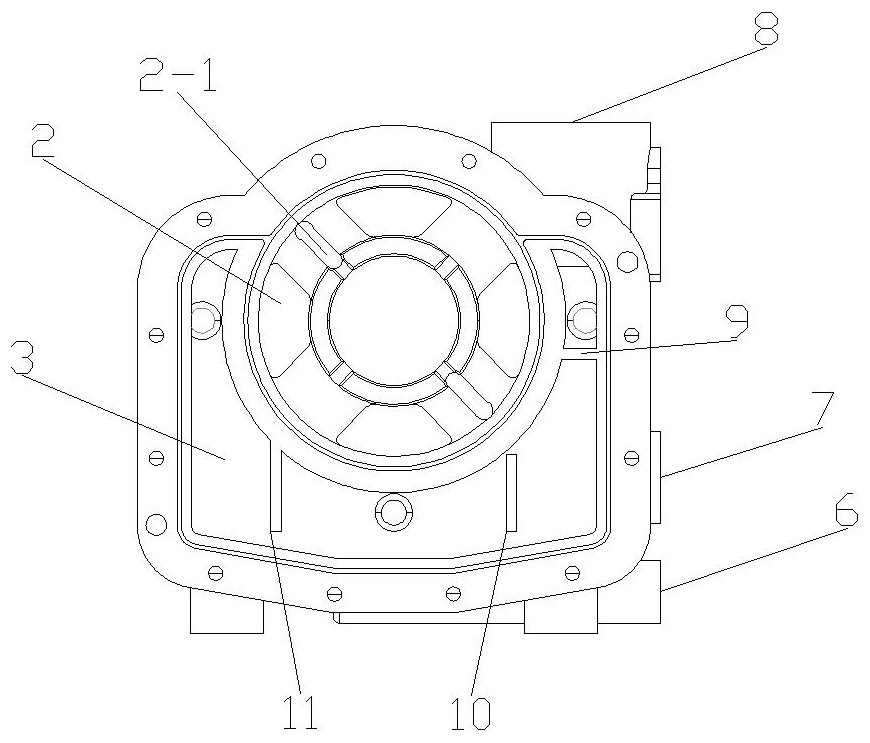

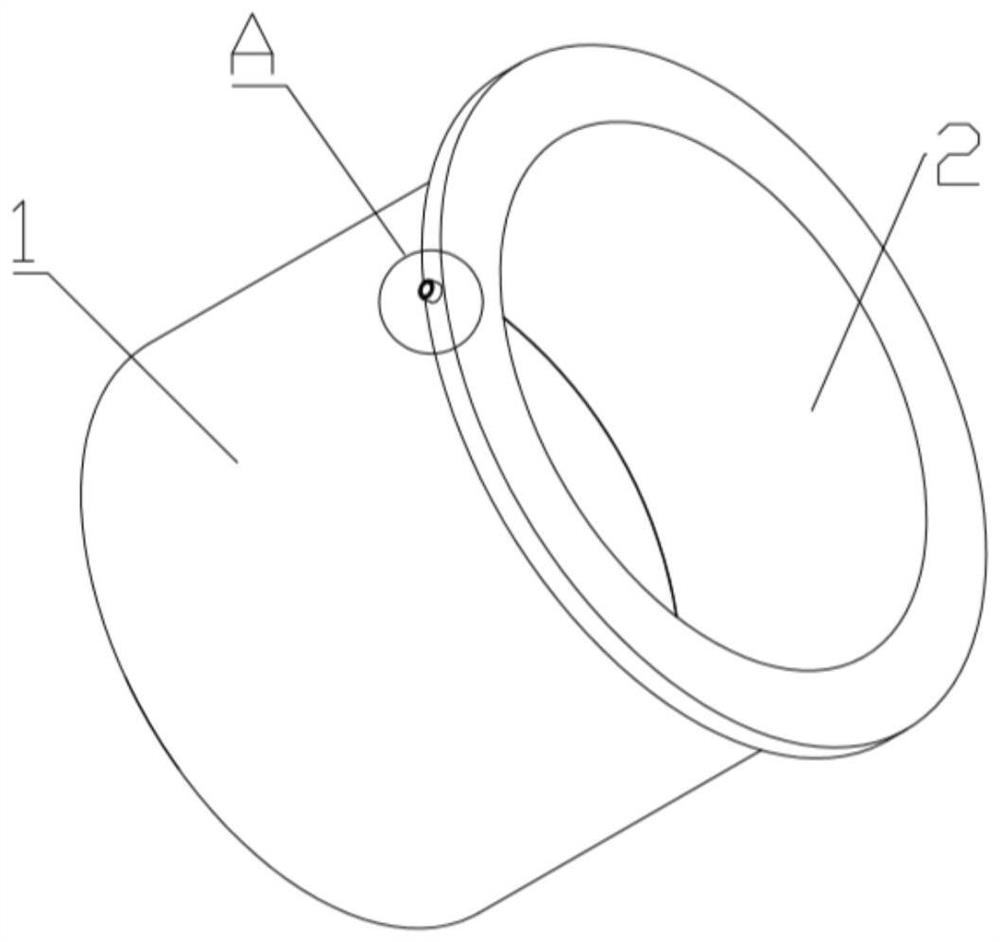

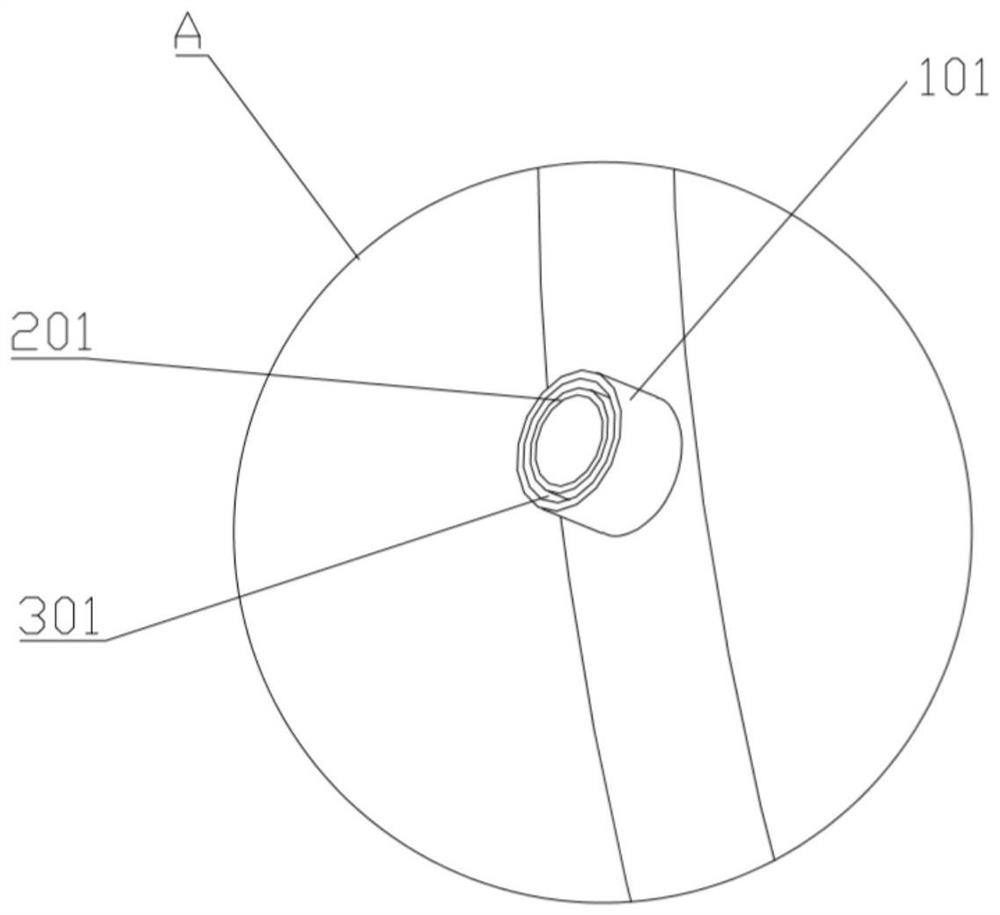

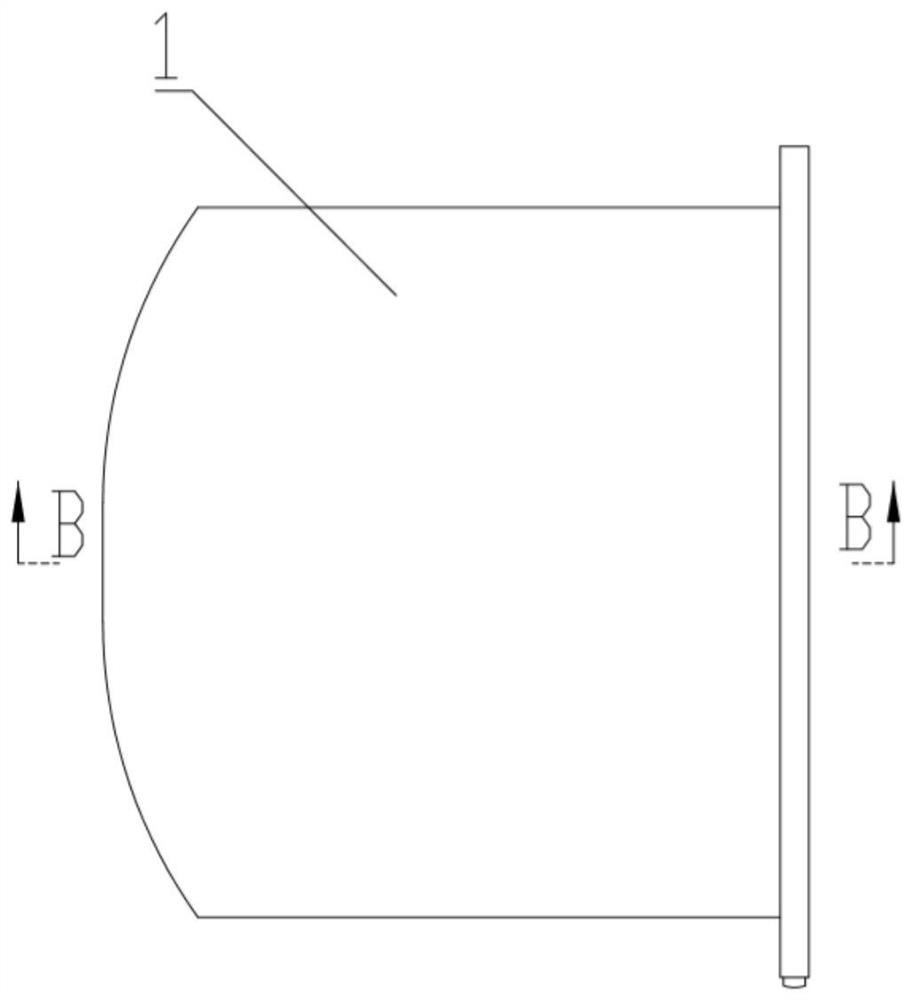

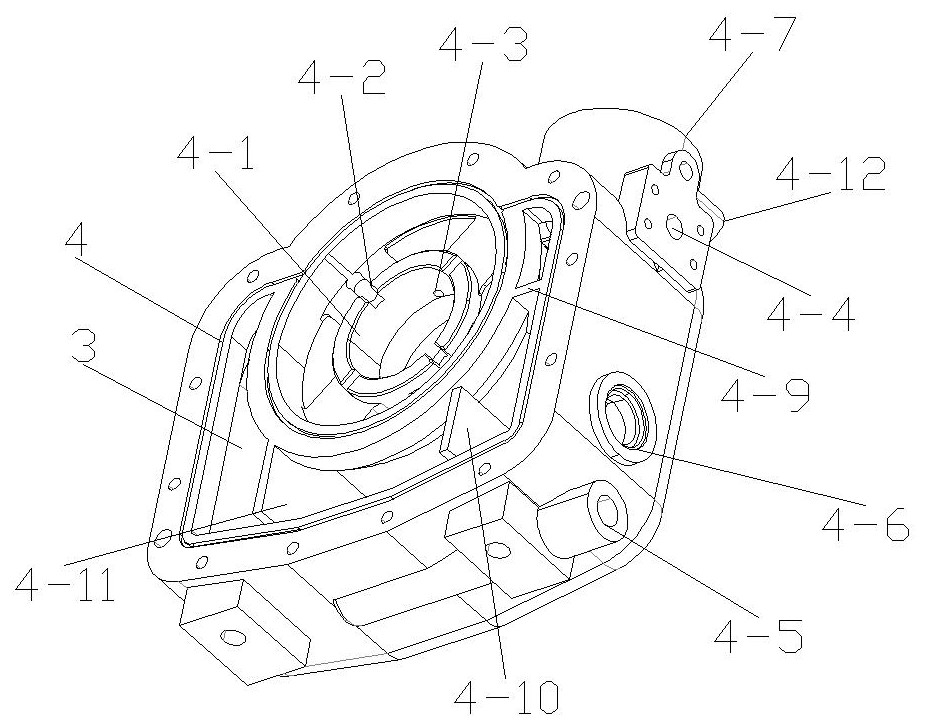

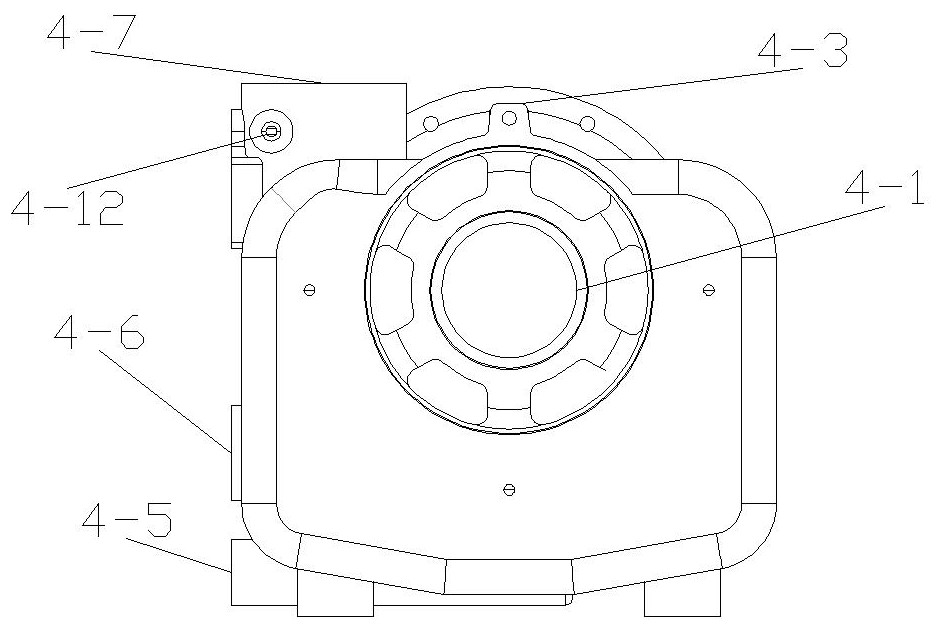

Oil-gas cavity shell of scroll compressor

PendingCN112943617ACompact structureReduce assembly partsRotary piston pumpsRotary piston liquid enginesThermodynamicsMechanical engineering

The invention provides an oil-gas cavity shell of a scroll compressor. The oil-gas cavity shell is provided with an orbiting scroll mounting part, an oil-gas separation cavity, an oil-gas separation core mounting hole, an oil return inlet, an oil return outlet and an exhaust port, the orbiting scroll mounting part is used for mounting an orbiting scroll, and the oil-gas separation core mounting hole is used for mounting an oil-gas separation core and is communicated with the oil-gas separation cavity; the oil return outlet and the exhaust port are both communicated with the oil-gas separation core mounting hole, the oil return outlet is used for guiding out oil separated by the oil-gas separation core, the exhaust port is used for exhausting gas separated by the oil-gas separation core, and the oil return inlet is communicated with the orbiting scroll mounting part; and due to the fact that the orbiting scroll mounting part, the oil-gas separation cavity, the oil-gas separation core mounting hole, the oil return inlet and the oil return outlet are all arranged on the oil-gas cavity shell, an external oil-gas tank, a combination valve, an oil guide pipe and other parts are avoided, a static disc shell of the scroll compressor is small and simple in structure, and assembling parts and connecting pipelines of the whole compressor are greatly reduced.

Owner:NINGBO BAOSI ENERGY EQUIP

Oil-gas separator

ActiveCN103790674APrevent backflowImprove separation efficiencyMachines/enginesCrankcase ventillationEngineeringCrankcase

The invention relates to an oil-gas separator. The oil-gas separator comprises an oil-gas separator body. A first gas discharging tube communicated with a gas feeding manifold, a second gas discharging tube communicated with the front of a supercharger and an oil-gas tube and an oil return port which are communicated with a crank case are arranged on the oil-gas separator body respectively. The first gas discharging tube, the second gas discharging tube and the oil-gas tube are communicated with an oil-gas separation channel in the oil-gas separator body. A first check valve is arranged in the first gas discharging tube, a second check valve is arranged in the second gas discharging tube, and a pressure control valve communicated with the oil-gas separation channel is arranged at the top of the oil-gas separator body. By means of the oil-gas separator, the gas flow in the gas channel can be effectively controlled, the oil-gas separation efficiency is improved, and the crank case pressure is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Medium-high pressure screw compressor

InactiveCN112983826AImprove oil and gas separation effectSmooth exhaustRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsOil separationEngineering

The invention provides a medium-high pressure screw compressor. The medium-high pressure screw compressor comprises a screw rotor, a motor and an oil separation barrel, wherein the oil separation barrel comprises an outer barrel and an inner barrel, the inner barrel is arranged inside the outer barrel in a sleeve mode, a hollow gap layer is arranged between the outer barrel and the inner barrel, a multi-stage filtering device is arranged in the inner barrel, a single-stage filtering device is arranged in the gap layer, an inner exhaust port is formed in the inner barrel, an outer exhaust port is formed in the outer cylinder, the inner exhaust port is arranged in the outer exhaust port in a sleeve mode, a hollow annular cavity is formed between the inner exhaust port and the outer exhaust port, after an oil-gas mixture enters the inner barrel, part of the oil-gas mixture enters the multi-stage filtering device to be filtered and is discharged through the inner exhaust port, and the remaining oil-gas mixture enters the gap layer and is discharged through the annular cavity after being filtered through the single-stage filtering device. The medium-high pressure screw compressor has the advantages that the oil-gas separation effect is good, exhaust is smooth, and the occupied space of the filtering device is small.

Owner:李博志

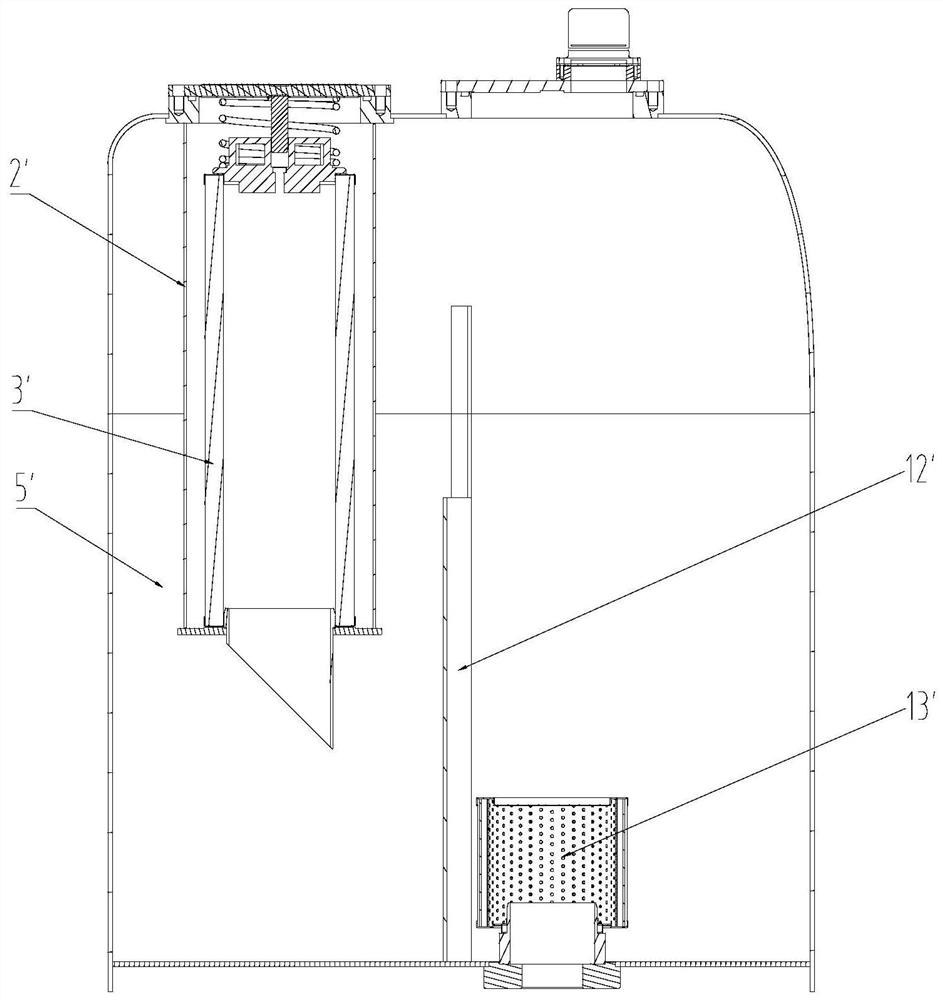

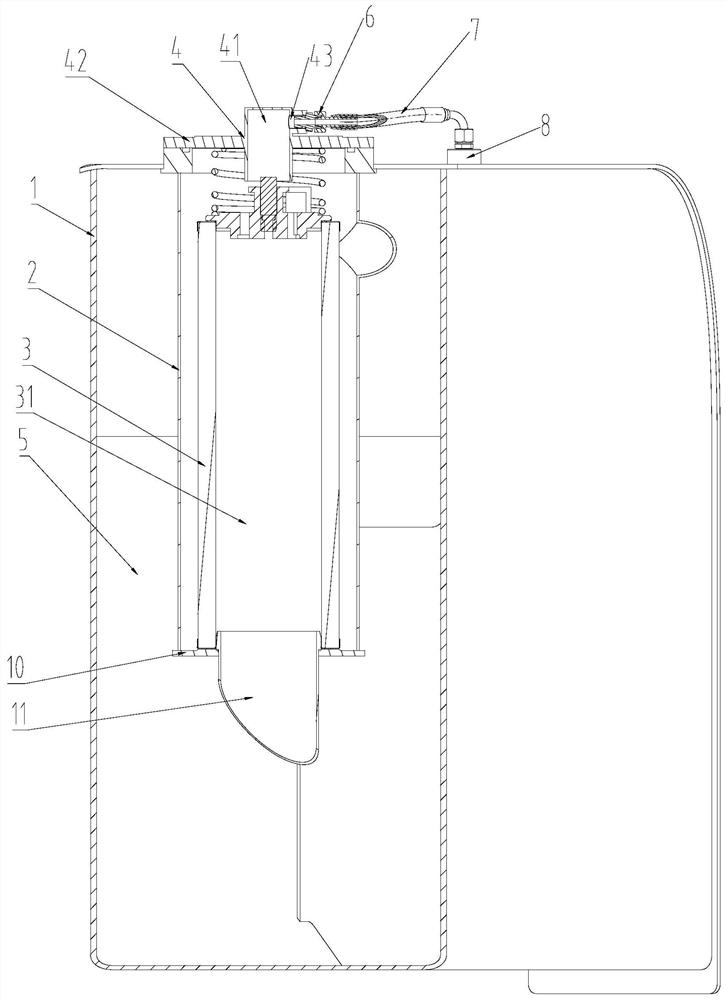

Hydraulic oil box and engineering machine with hydraulic oil box

InactiveCN111795040AImprove oil and gas separation effectReduce adverse effectsPump assembliesSoil-shifting machines/dredgersExhaust pipeFilter element

The invention relates to the field of hydraulic devices, and discloses a hydraulic oil box and an engineering machine. The hydraulic oil box comprises an oil box shell and an oil return case. An oil box cavity is formed in the oil box shell, and an oil return opening is arranged at the top. The oil return case comprises a top cover, an oil return case shell, an oil return filter element and an oilreturn pipe. The top cover is arranged at the oil return opening. The oil return case shell extends into the oil box cavity from the bottom of the top cover. The oil return filter element is mountedin the oil return case shell and is arranged to allow hydraulic oil in the oil return case shell to enter the oil box cavity through the oil return filter element. The top cover is provided with an exhaust pipeline, the gas inlet end of the exhaust pipeline communicates into the oil return case shell, and the gas outlet end of the exhaust pipeline communicates to the outer portion of the oil box shell. The oil return case shell comprises a barrel segment at least located on the upper portion, an oil return port is formed on the side wall of the barrel segment, an outlet of the oil return pipecommunicates with the oil return port, and the oil return pipe tangentially extends relative to the barrel segment from the oil return port.

Owner:ZOOMLION HEAVY IND CO LTD

Scroll compressor main machine and all-in-one machine

PendingCN113187722ACompact structureAvoid externalRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsDrive shaftMechanics

The invention provides a scroll compressor main machine and an all-in-one machine. The scroll compressor main machine comprises a scroll compressor shell, a dynamic scroll plate and a transmission shaft, a static scroll plate and an oil storage cavity are arranged in the scroll compressor shell, the dynamic scroll plate is installed on the scroll compressor shell and engaged with the static scroll plate, the transmission shaft is connected with the dynamic scroll plate and used for driving the dynamic scroll plate to rotate, a circulating cooling oil way and a circulating oil-gas separation oil way are arranged in the scroll compressor shell, the circulating cooling oil way is used for guiding out and cooling oil in the oil storage cavity and then supplying oil to the static scroll plate and / or the dynamic scroll plate, and the circulating oil-gas separation oil way is used for carrying out oil-gas separation on the compressed high-pressure oil gas and then supplying oil to the static scroll plate and / or the dynamic scroll plate. The oil storage cavity, the circulating cooling oil way and the circulating oil-gas separation oil way are all arranged in the scroll compressor shell, so that external connection of other parts such as an oil-gas tank, a combination valve and an oil guide pipe is avoided, and assembly parts and connecting pipelines of the whole compressor are greatly reduced.

Owner:NINGBO BAOSI ENERGY EQUIP

an oil-gas separator

ActiveCN103790674BPrevent backflowImprove separation efficiencyMachines/enginesCrankcase ventillationCrankcaseProcess engineering

The invention relates to an oil-gas separator. The oil-gas separator comprises an oil-gas separator body. A first gas discharging tube communicated with a gas feeding manifold, a second gas discharging tube communicated with the front of a supercharger and an oil-gas tube and an oil return port which are communicated with a crank case are arranged on the oil-gas separator body respectively. The first gas discharging tube, the second gas discharging tube and the oil-gas tube are communicated with an oil-gas separation channel in the oil-gas separator body. A first check valve is arranged in the first gas discharging tube, a second check valve is arranged in the second gas discharging tube, and a pressure control valve communicated with the oil-gas separation channel is arranged at the top of the oil-gas separator body. By means of the oil-gas separator, the gas flow in the gas channel can be effectively controlled, the oil-gas separation efficiency is improved, and the crank case pressure is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Vortex type gas filter

ActiveCN110898537AGood oil and gas separation effectEasy to disassemble and washDispersed particle separationEngineeringMechanical engineering

Owner:四川易轩学锦环保科技有限公司

Horizontal compressor

PendingCN108397390AImprove energy efficiencyImprove reliabilitySealing arrangement for pumpsRotary/oscillating piston pump componentsMotor driveCooling effect

The invention relates to technical field of compressors, and discloses a horizontal compressor. The horizontal compressor comprises a shell body (1), a compressing mechanism (3), a motor (2) and a gasguiding device (5). The compressing mechanism is arranged in the shell body and comprises a main bearing (6). The motor drives the compressing mechanism to work and is provided with an insulating terminal board (4). The gas guiding device comprises a motor connection terminal and a compressing mechanism connection terminal. The motor connection terminal is connected with the insulating terminal board in a sealed way. The compressing mechanism connection terminal is in abut joint with the main bearing, and forms a terminal face seal with the main bearing. An airflow channel is formed between the compressing mechanism and the motor. The airflow channel passes through an inner cavity of the gas guiding device. The design of the horizontal compressor effectively improves the air tightness between the gas guiding device and the compressing mechanism. Thus, a refrigerant is prevented from flowing out from the gap between the gas guiding device and the compressing mechanism. The horizontal compressor can improve the cooling effect of the motor and the oil-gas separating effect of the refrigerant, thereby improving energy efficiency and reliability of the horizontal compressor.

Owner:GUANGDONG WELLING AUTO PARTS CO LTD

Oil-gas separation circular arc type inside engaged gear combined oil pump

ActiveCN101514699BCompact structureImprove oil and gas separation effectRotary piston pumpsRotary piston liquid enginesBodies oilCheck valve

The invention relates to an oil-gas separation circular arc type inside engaged gear combined oil pump which comprises a pump body (1), the bottom of the pump body (1) is provided with an oil suction hole (1.1) and an oil suction hole check valve (12); the lower part in the pump body (1) is provided with an oil inlet cavity (1.2); the middle in the pump body (1) is provided with an oil inlet chamber (1.3), an eccentric body (4), an oil outlet chamber (1.4) and an oil-gas separation chamber (14), wherein, the eccentric body (4) is internally provided with a combined pump spindle (6) which is provided with a circular arc type inside and outside gear set (5), the wall of a shell of the eccentric body (4) is provided with an eccentric body oil inlet (4.1) and an eccentric body oil outlet (4.2); the upper part in the pump body (1) is provided with an oil outlet channel (1.5); the top of the pump body (1) is provided with a pump cover (13), the top of which is provided with an oil outlet (13.1); the oil outlet channel (1.5) is internally provided with an oil-gas separation pipe (8); the lower part of the oil-gas separation chamber (14) is provided with an oil return float valve (15), and a gas bleeder (16) and a gas bleeding float valve (17) are arranged on the top of the pump cover (13) arranged above the oil-gas separation chamber (14). The combined oil pump has stronger oil-gas separation capability and compacter structure.

Owner:JIANGYIN FUREN HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com