Rotary oil-gas separator

An oil-gas separator and rotary separation technology, which is applied in the field of refrigeration compressors, can solve the problems of insignificant effect and insufficient oil-gas separation of the oil-gas separator, and achieve the effect of improving the effect of oil-gas separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

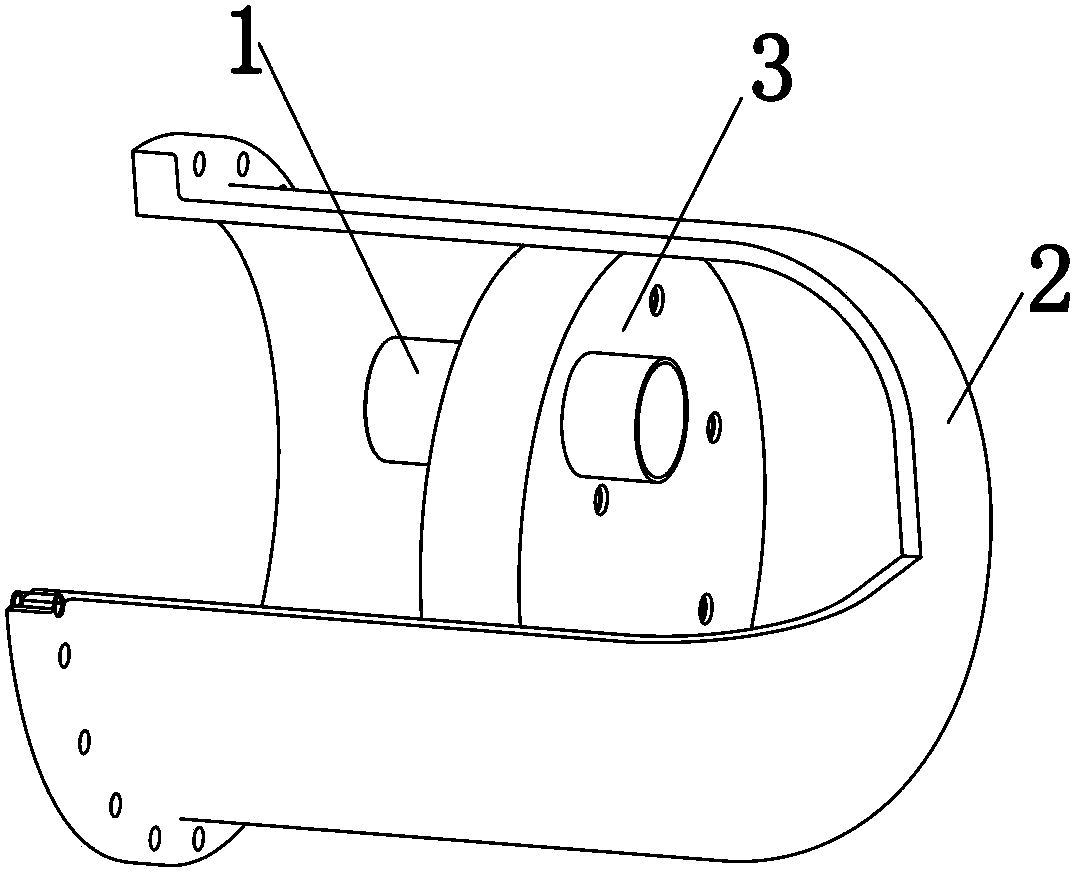

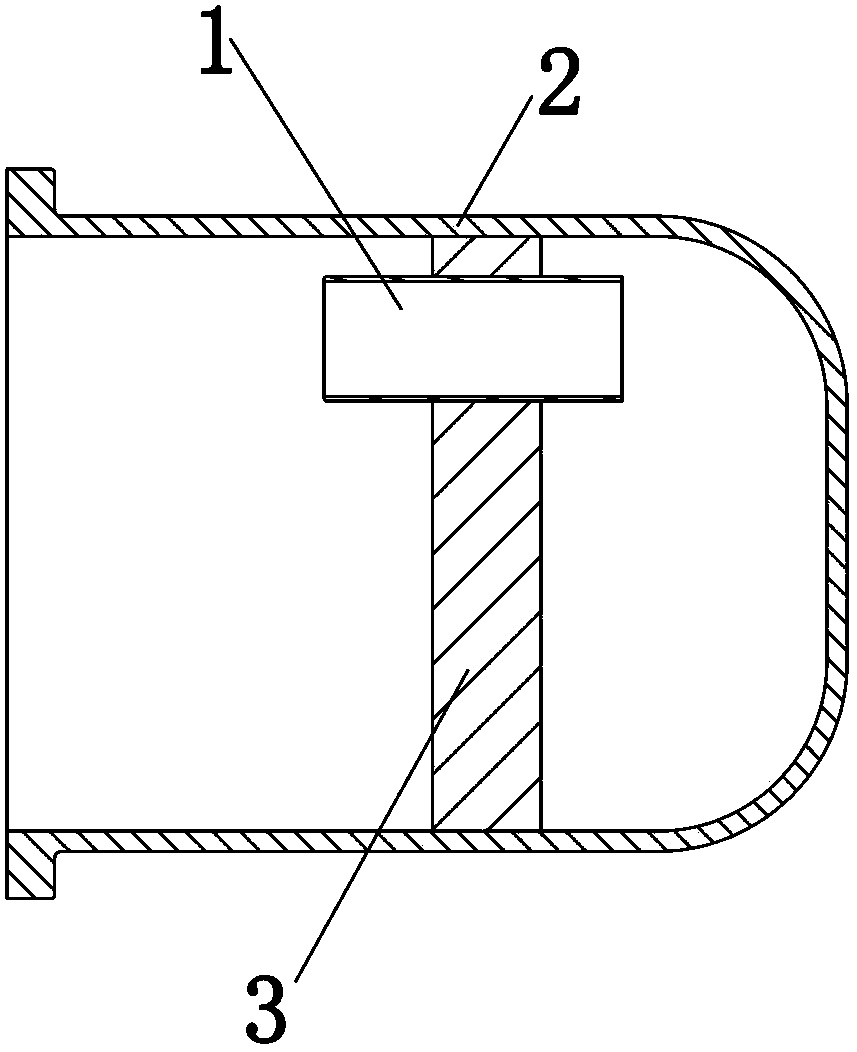

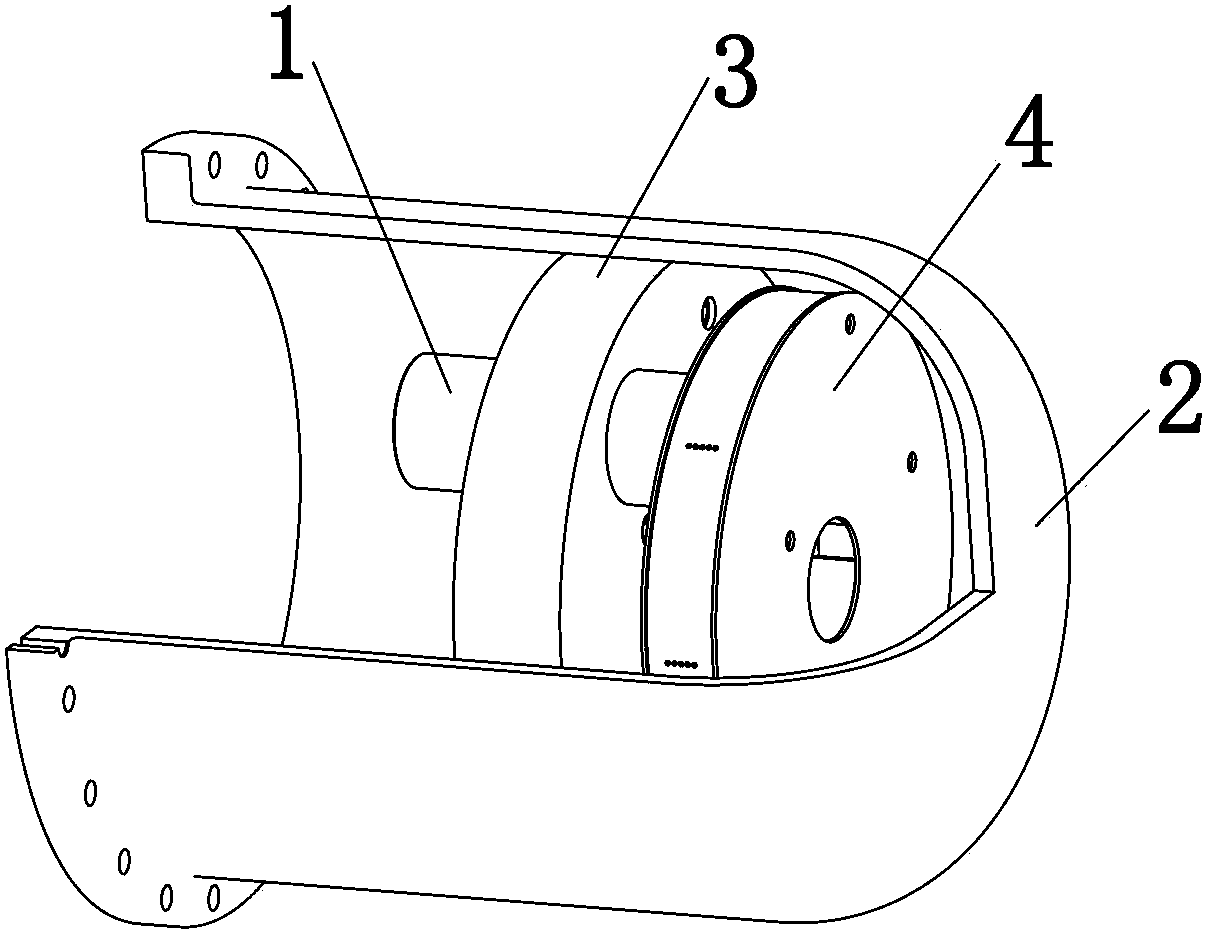

[0030] An embodiment of the rotary oil-gas separator of the present invention, such as Figure 3 to Figure 8 shown.

[0031] The rotary oil-gas separator of the present invention comprises an exhaust pipe 1, an oil-gas separation barrel 2 and an oil-gas separation filter 3;

[0032] The oil-gas separation filter 3 is arranged in the cavity of the oil-gas separation barrel 2;

[0033] The exhaust pipe 1 is arranged on the oil-gas sub-filter 3 and communicates with both sides of the oil-gas sub-filter 3;

[0034] The rotary oil-gas separator also includes a rotary separation device 4;

[0035] The rotary separation device 4 is arranged between the bottom of the oil-gas separation screen 3 and the oil-gas separation barrel 2; the rotary separation device 4 includes a feed port 41, a discharge port 42 and The internal spiral channel 40 of the device 4, one end of the feed port 41 communicates with the spiral channel 40, the other end of the feed port 42 communicates with one en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com