Oil-gas separation circular arc type inside engaged gear combined oil pump

An internal meshing gear and arc-shaped technology, applied to pumps, pump components, rotary piston pumps, etc., can solve the problems of complex structural arrangement of the whole machine, noise, large volume, unstable measurement, etc., and achieve strong shock absorption performance , noise and volume are small, and the effect of enhanced oil and gas separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

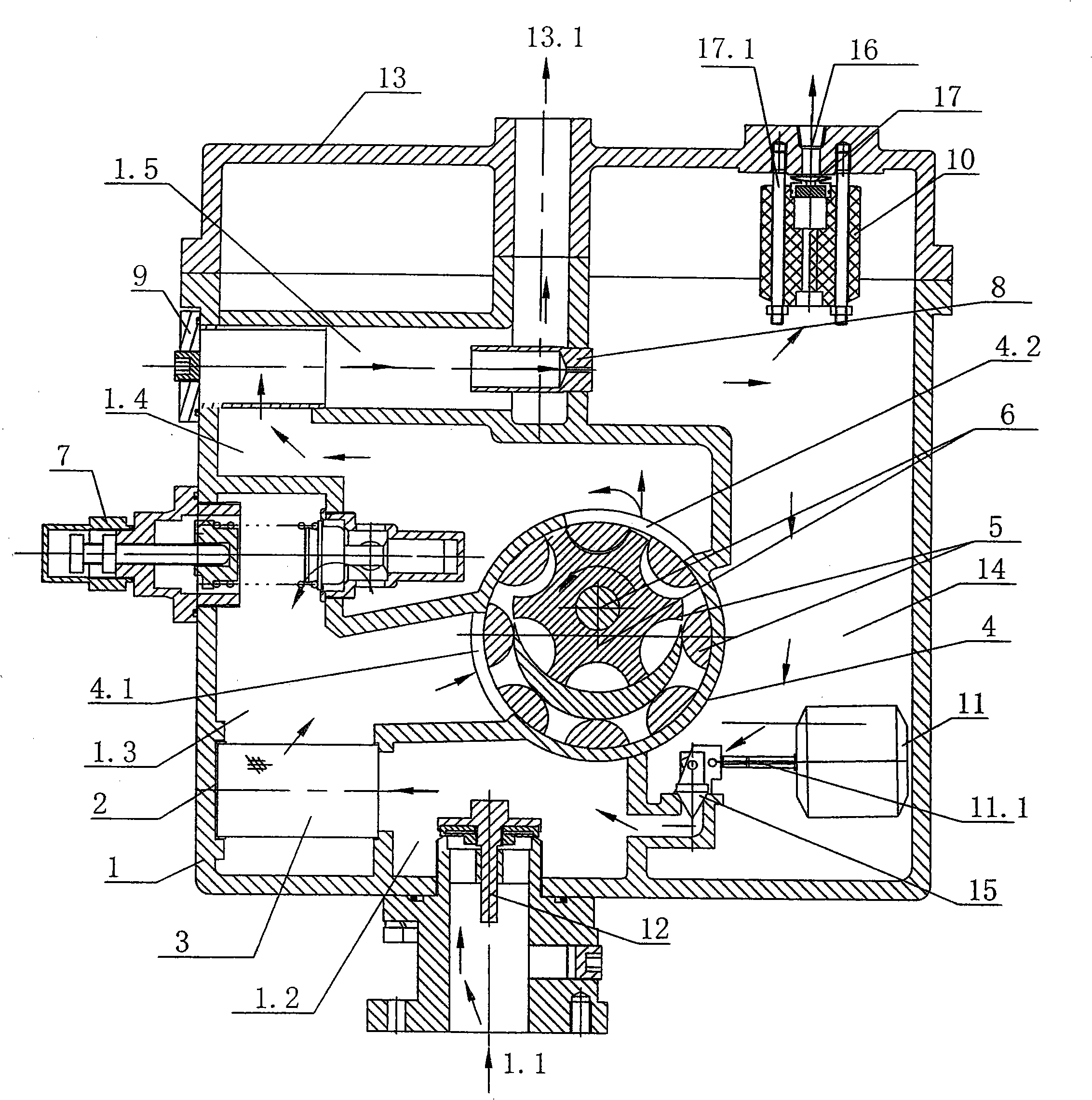

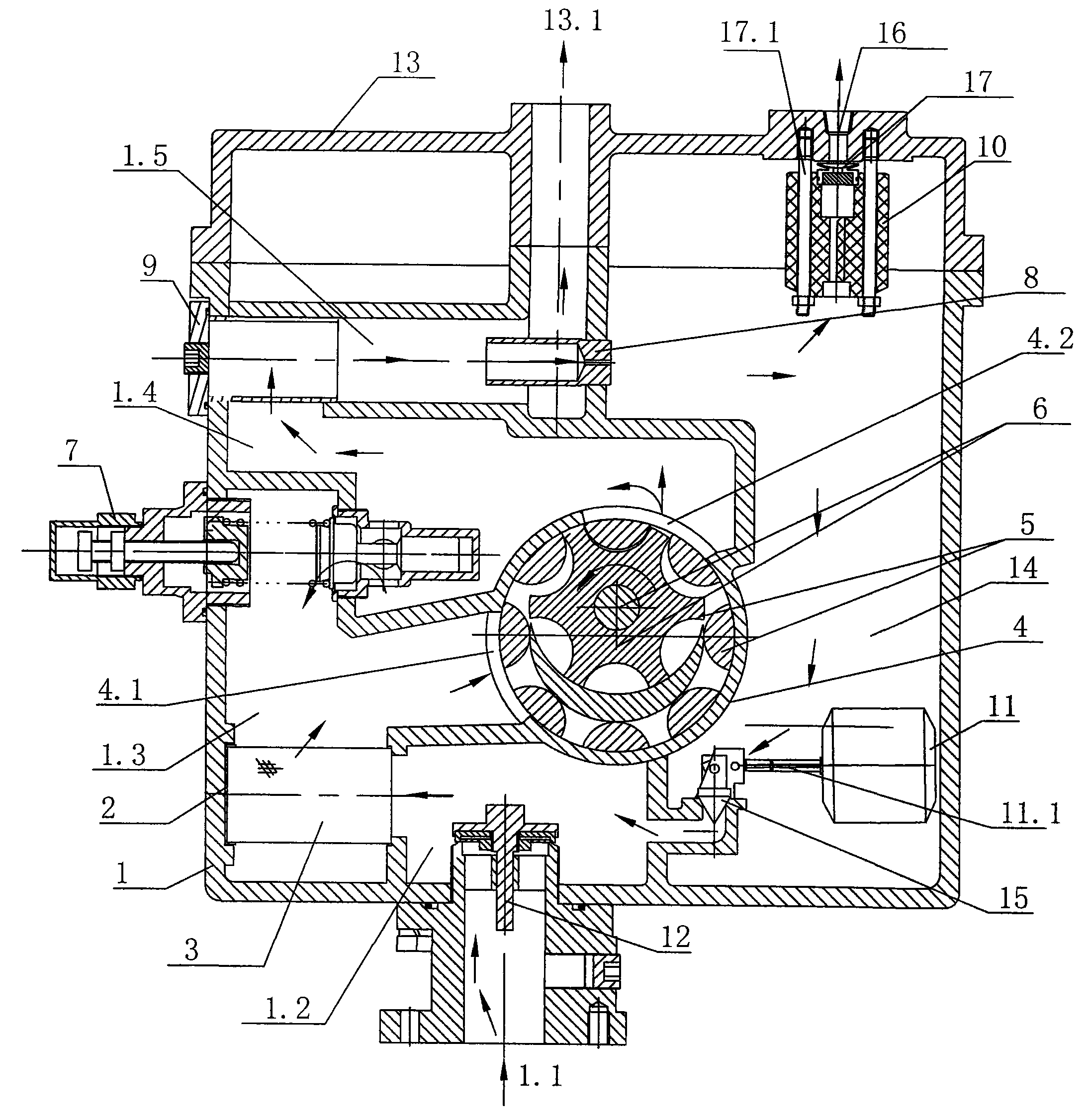

[0014] see figure 1 , an oil-gas separation arc type internal meshing gear combined oil pump, comprising a pump body 1, the bottom of the pump body 1 is provided with an oil suction port 1.1, the oil suction port 1.1 is provided with an oil suction port check valve 12, and the inner and lower part of the pump body 1 is provided with a The oil inlet chamber 1.2, the outlet of the oil suction port check valve 12 is set in the oil inlet chamber 1.2, and the middle of the pump body 1 is provided with an oil inlet chamber 1.3, an eccentric body 4, an oil outlet chamber 1.4 and an oil-gas separation chamber chamber 14, the oil inlet chamber 1.3 is provided with an oil inlet filter 3, the inlet on one side of the oil inlet filter 3 is connected with the oil inlet chamber 1.2, and the other end of the oil inlet filter 3 is provided on the side of the oil inlet filter Cover 2, the eccentric body 4 is provided with a combined pump shaft 6, the combined pump shaft 6 is equipped with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com