Optical fiber sensing system for dissolved gas in transformer bushing oil

An optical fiber sensing system and a technology of dissolved gas in oil, applied in the field of optical sensing systems, can solve problems such as inability to achieve continuous measurement, prone to cross-sensitivity, and decreased detection accuracy, to achieve guaranteed sensitivity and lower detection limit, increased High efficiency and distance, effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the specific embodiments of the present invention are further described in detail with reference to the accompanying drawings.

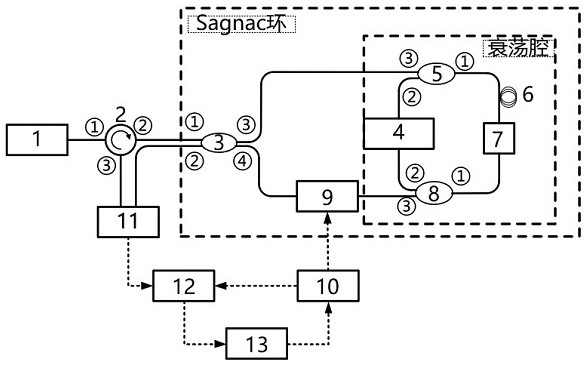

[0030] see figure 1, The present invention proposes an optical fiber sensing system for dissolved gas in transformer bushing oil, comprising a light source 1, a circulator 2, a 2×2 coupler 3, an erbium-doped fiber amplifier 4, a first 1×2 coupler 5, a delay fiber 6. Gas sensing module 7 , second 1×2 coupler 8 , acousto-optic modulator 9 , acousto-optic modulator driver 10 , balanced photodetector 11 , data collector 12 and host computer 13 . The first 1×2 coupler 5 , the delay fiber 6 , the gas sensing module 7 , the second 1×2 coupler 8 and the erbium-doped fiber amplifier 4 form a ring-down cavity; ③ The split ratio of the ports is 99:1, and the split ratio of ports ② and ③ of the second 1×2 coupler 8 is 99:1; Port ③ of the second 1×2 coup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com