Medium-high pressure screw compressor

A screw compressor, medium and high pressure technology, applied in the field of compressors and screw compressors, can solve the problems of increasing the volume of the oil separator of the compressor, reducing the exhaust efficiency of the compressor, reducing the working efficiency of the compressor, etc. Small, good effect, smooth exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

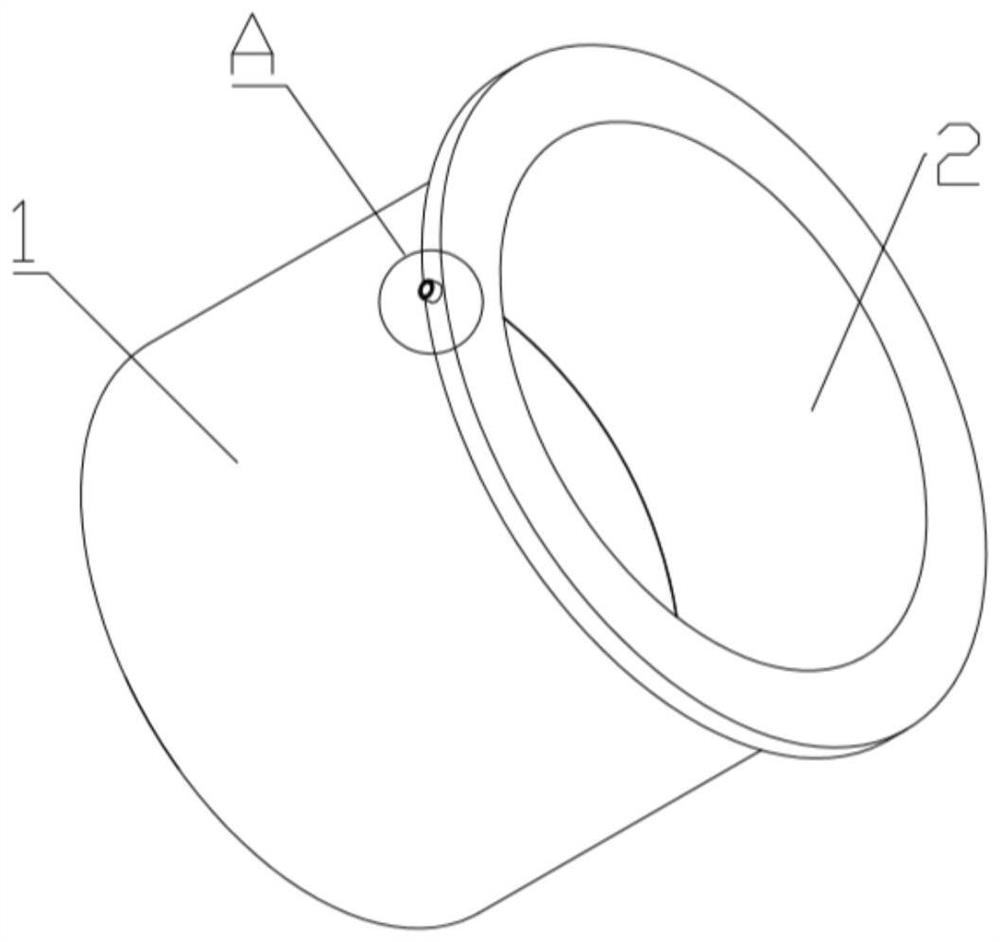

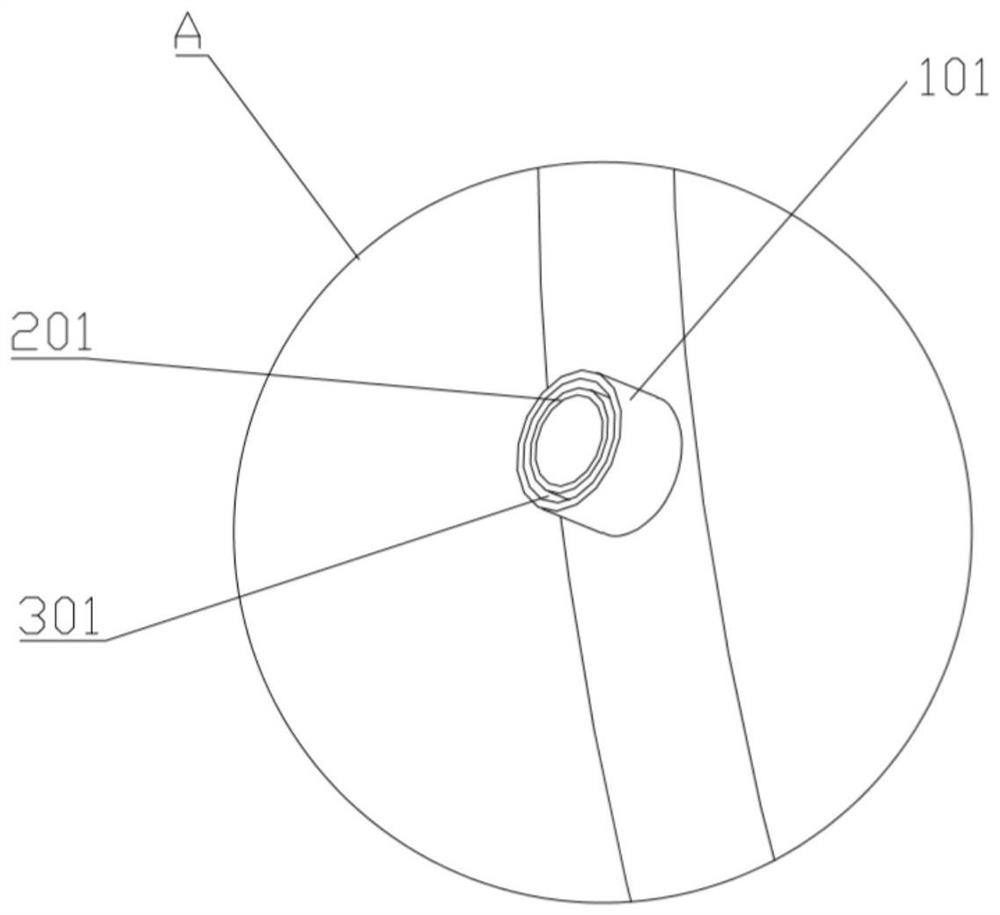

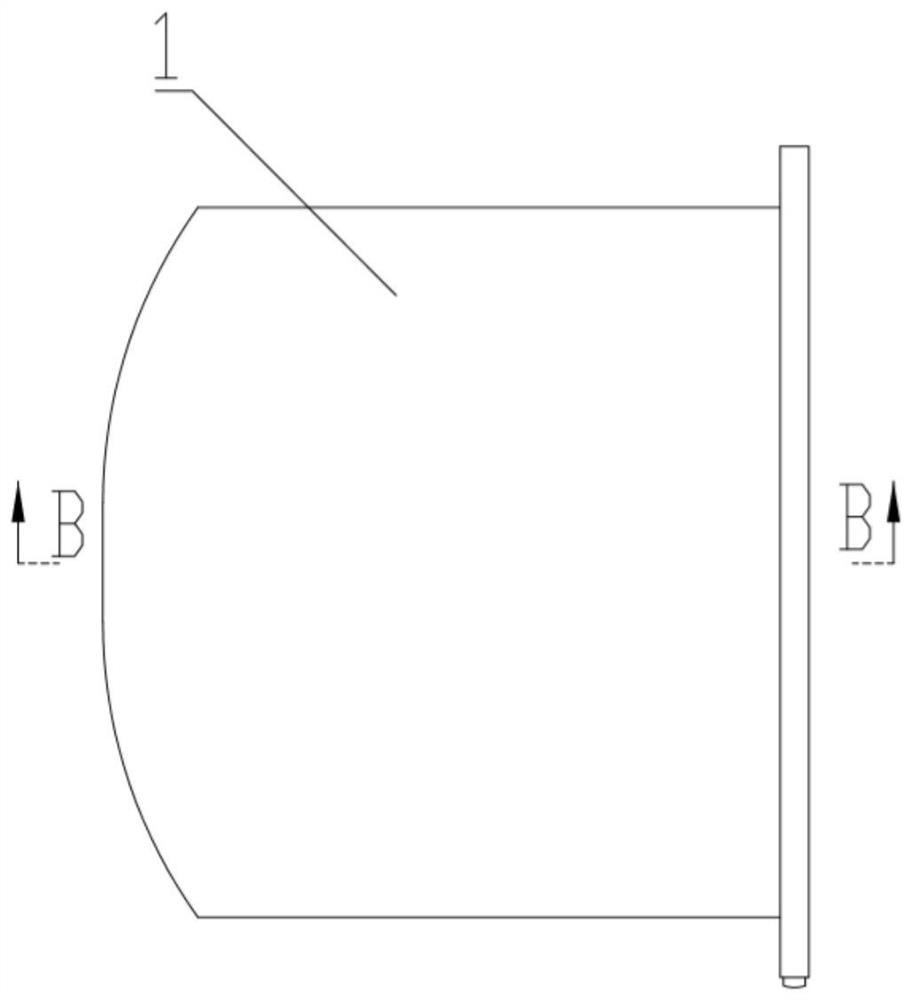

[0043] Such as Figure 1-19 As shown, a medium-high pressure screw compressor includes a pair of female and male screw rotors arranged in parallel and capable of meshing with each other, a motor that drives the screw rotors to rotate, a capacity control valve that can change the volume ratio, and a capacity control valve that can control the volume ratio of the motor. The inverter for changing the rotational speed, the oil separation barrel capable of separating the oil-air mixture, and the outer casing arranged on the outer surface of the compressor.

[0044] In addition, the medium and high pressure screw compressor also includes an air filter, an intake controller, a cooler, and the like. When the medium and high pressure screw compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com