Oil-gas separation system with secondary separation function

A separation system and secondary separation technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of large space occupation, inability to compress the number of filter elements, poor deceleration effect of the impact channel, etc., to reduce deformation, improve oil and gas Separation effect, effect of reducing impact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and specific embodiments.

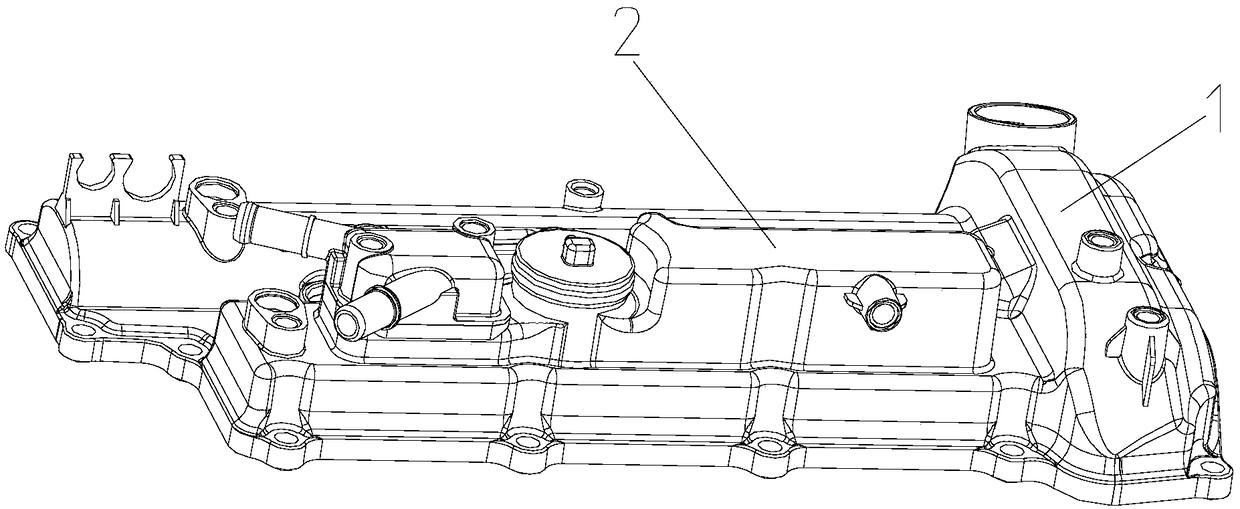

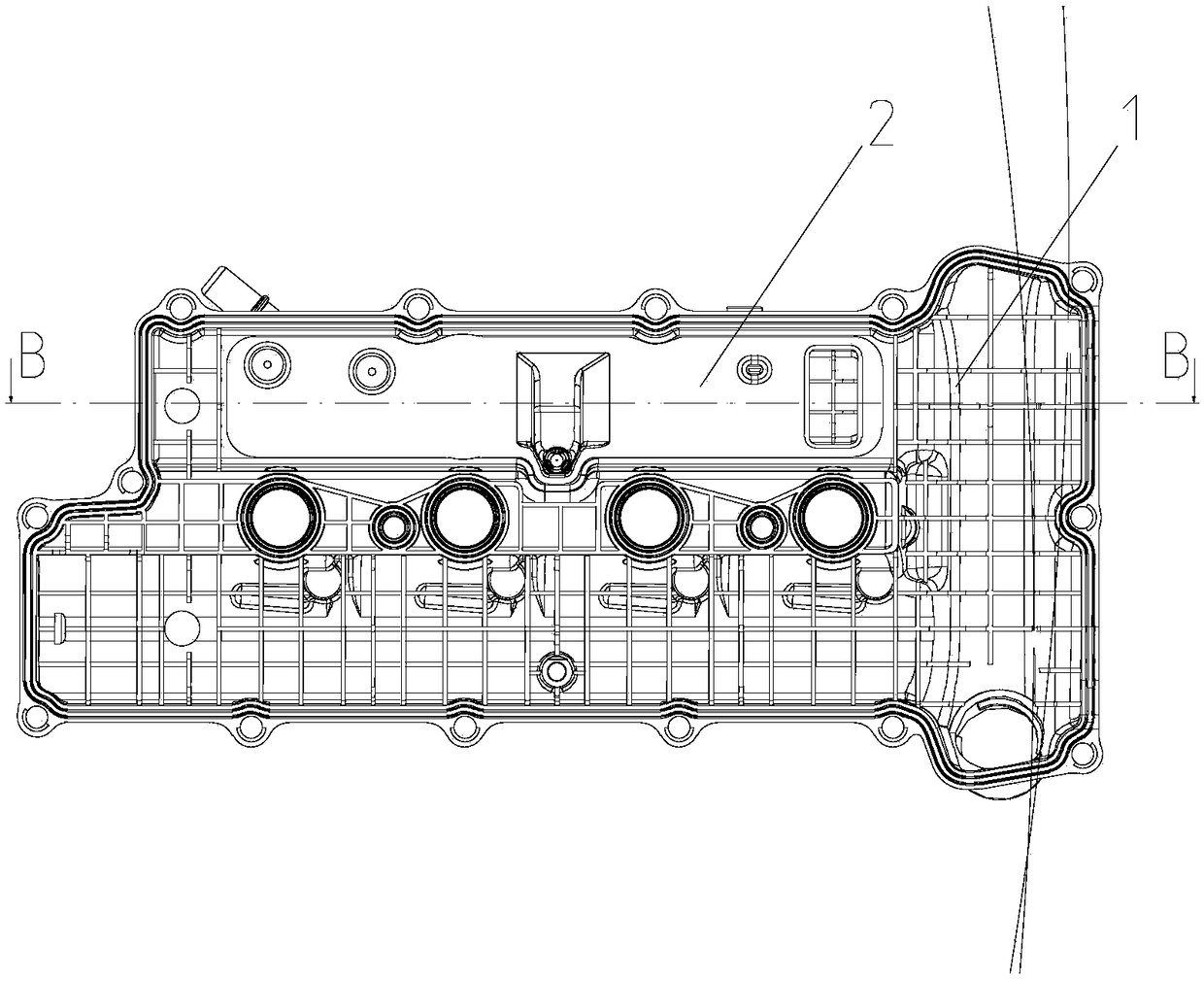

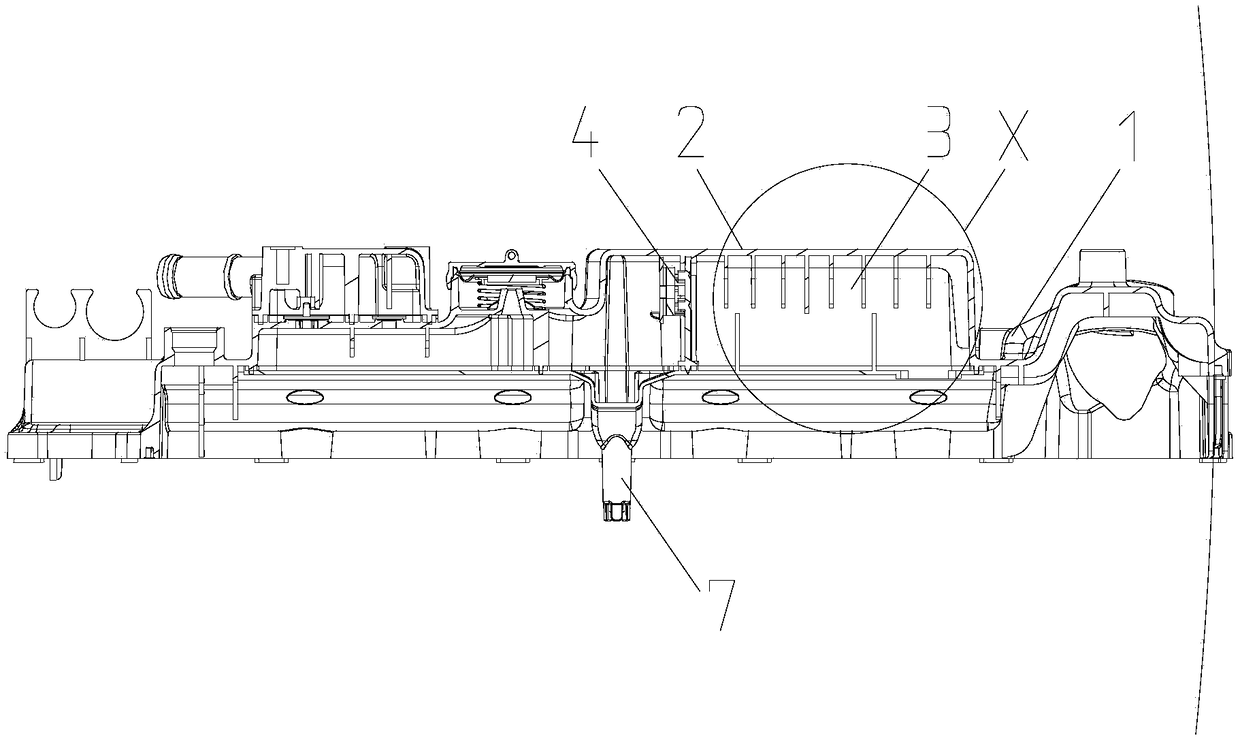

[0022] Such as figure 1 , figure 2 , image 3 The illustrated embodiment is a secondary separation oil and gas separation system, which is mainly used to separate oil and gas from the gas mixed with oil from the engine.

[0023] The separation system of this example includes a cylinder cover body 1, a cover 2 is provided on the cylinder cover body, a coarse separation structure 3 and a fine separation structure 4 are provided on the oil and gas circuit under the cover, and the coarse separation structure is located on the upstream side. The fine separation structure is located on the downstream side.

[0024] Such as Figure 4 As shown, the coarse separation structure includes a labyrinth air passage 3 arranged on the oil and gas circuit, and several labyrinth air passage retaining walls 8 are provided in the labyrinth air passage. A number of airflow decelerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com