A kind of engine oil gas separator

An oil and gas separator and engine technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of large resistance, large filter element resistance and high separation efficiency, and achieves reduced resistance, better oil and gas separation effect, and reduced system The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

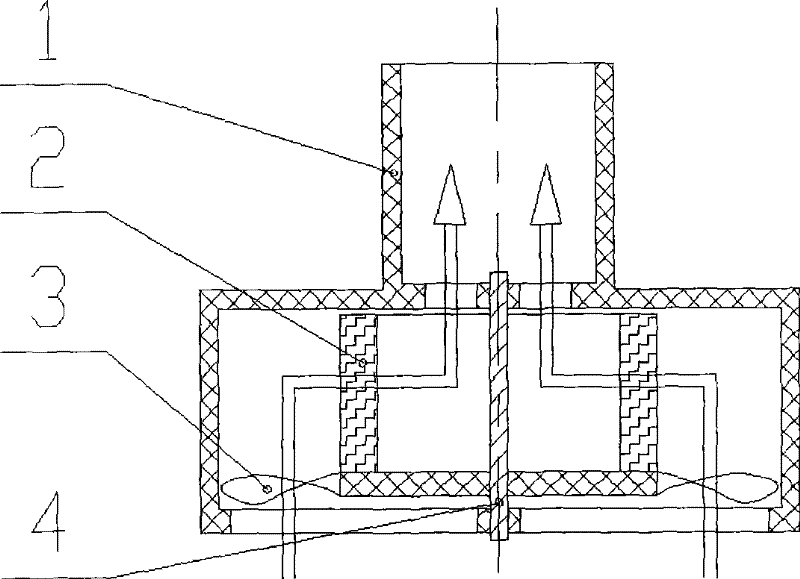

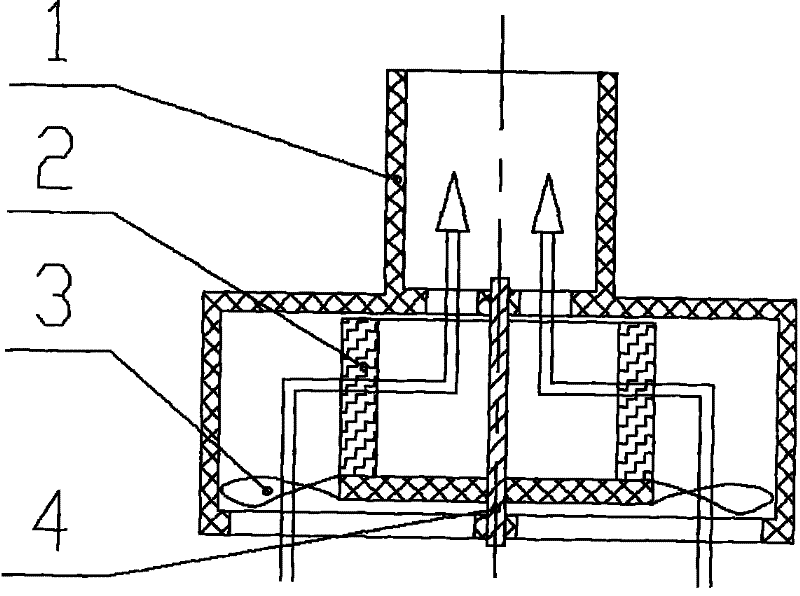

[0010] As shown in the figure, the engine oil and gas separator has a housing 1, a blade 3, a filter element 2, and a rotating shaft 4, wherein the blade 3 and the filter element 2 are fixed on the rotating shaft 4, and the rotating shaft is mounted on the housing 1.

[0011] The blade 3, the filter element 2, and the rotating shaft 4 are all rigidly connected, and the filter element is located above the blade. The housing 1 is provided with a rotating shaft installation hole. The housing can be arranged on the valve chamber cover, timing cover or crankcase, or integrated with the valve chamber cover, timing cover or crankcase to make the engine structure More compact.

[0012] The arrow in the figure shows the flow direction of the crankcase gas. The crankcase gas first drives the filter element 2 to rotate around the rotating shaft 4 through the blades 3, while the crankcase gas flows radially, resulting in cyclone separation, which can separate the larger oil droplets in the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com