Two-stage membrane method oil-gas recovery apparatus and recovery method thereof

An oil and gas, membrane technology, applied in the field of two-stage membrane oil and gas recovery devices, can solve the problems of reducing equipment reliability and ease of use, unable to effectively ensure that the emission concentration meets the requirements of the national standard, increasing process complexity and danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention proposes a two-stage membrane oil gas recovery device and its recovery method. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be further clearly and completely described in conjunction with specific examples below.

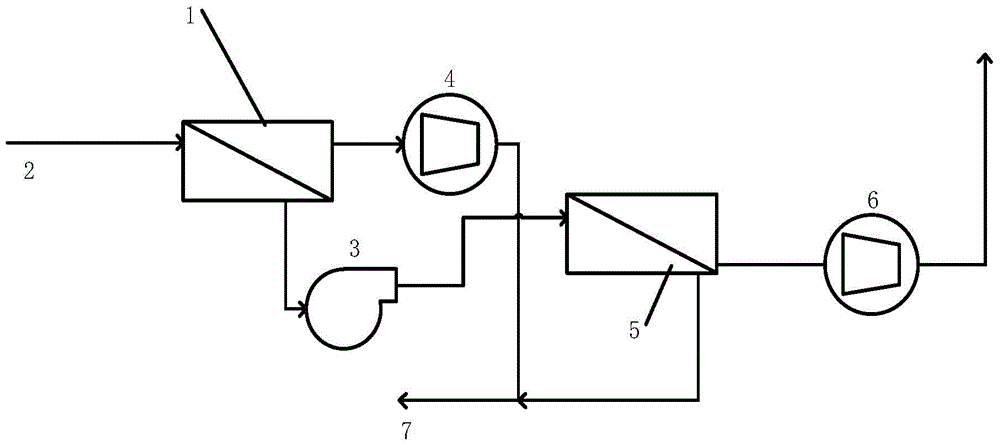

[0021] Such as figure 1 As shown, a two-stage membrane method oil and gas recovery device, which specifically includes a rubber membrane module 1, on one side of the rubber membrane module 1 is the inlet port 2 of the rubber membrane module, and in the pipeline connected to the inlet port 2 A micro-pressure sensor can be preferably arranged on the top, and when it is detected that the pressure in the oil storage tank connected with the pipeline is higher than the set value, the device is opened to allow oil and gas to enter the oil and gas recovery device of the present invention.

[0022] The oil and gas first enter the rubber state membrane module 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com