High-segmentation upward deep hole ore extraction zero-dead-zone following filling mining method

A technology of filling mining method and zero void area, which is applied in the direction of filling, mining equipment, earth drilling and mining, etc., can solve the problems of high support cost, complicated process, poor loss, etc., to ensure the structure and stability of the force, The effect of efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

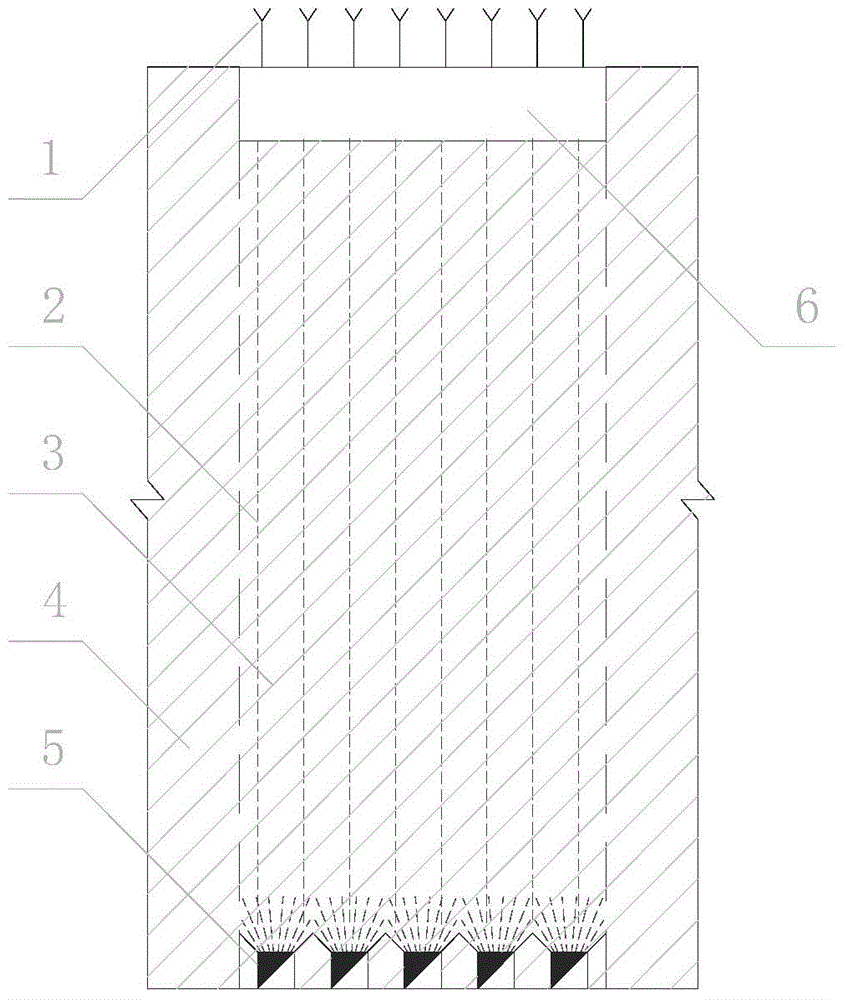

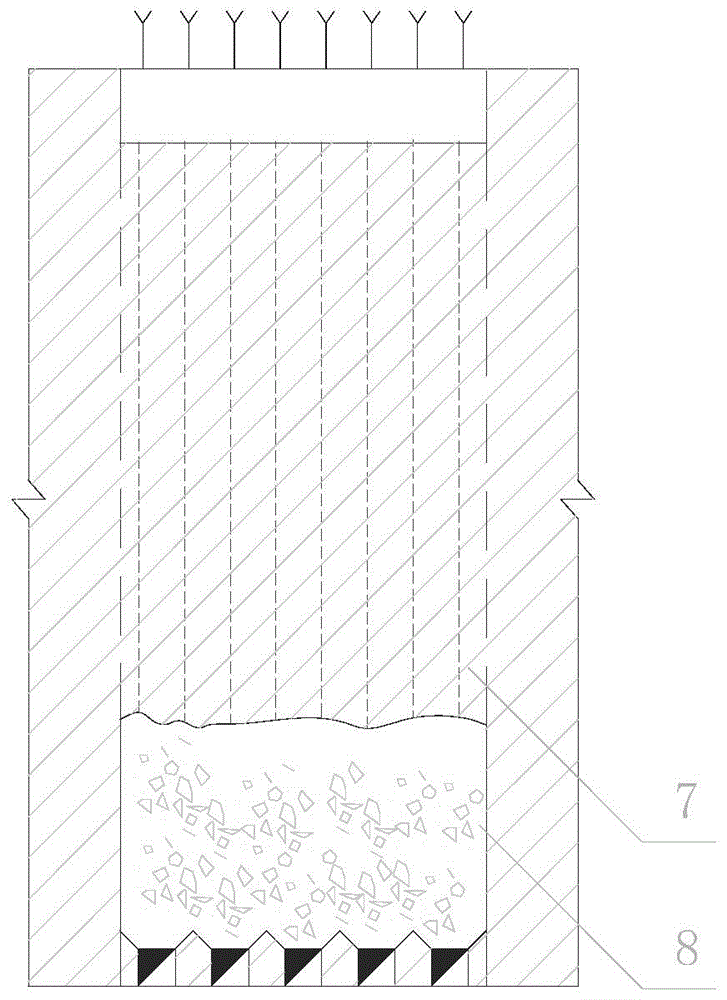

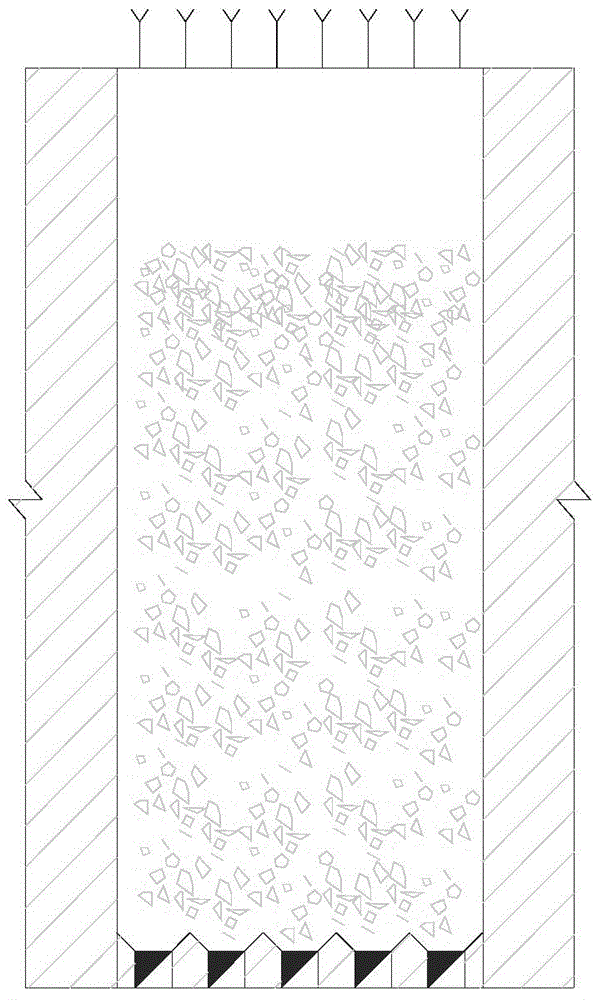

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , the present invention provides the mining method of following the filling of the zero-empty area of the deep hole falling into the deep hole in the high section, and the steps are as follows:

[0031] (1) The mine houses are arranged parallel to the ore body, and the pillars of the mine houses are mined at intervals. The height of the mine house is the height of the stage, and the thickness is the effective service thickness of 1 to 2 rows of ore-receiving funnels;

[0032] (2) Parallelly arrange the transport level roadway along the upper and lower walls of the bottom of the ore body. The transport level roadway is excavated into the ore body through the ore exit horizontal roadway. The ore exit cross roadway is dug and expanded to form the ore receiving funnel, and then continues...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com