Large-scale re-mining method for filling small-kiln destruction area

A technology for destroying areas and filling materials, applied in the fields of fillings, mining equipment, earthwork drilling, etc., can solve the problems of difficult recovery of large mines, inconvenient safe production of mines, and damage to the ecological environment of national coal resources. The effect of improving production efficiency and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

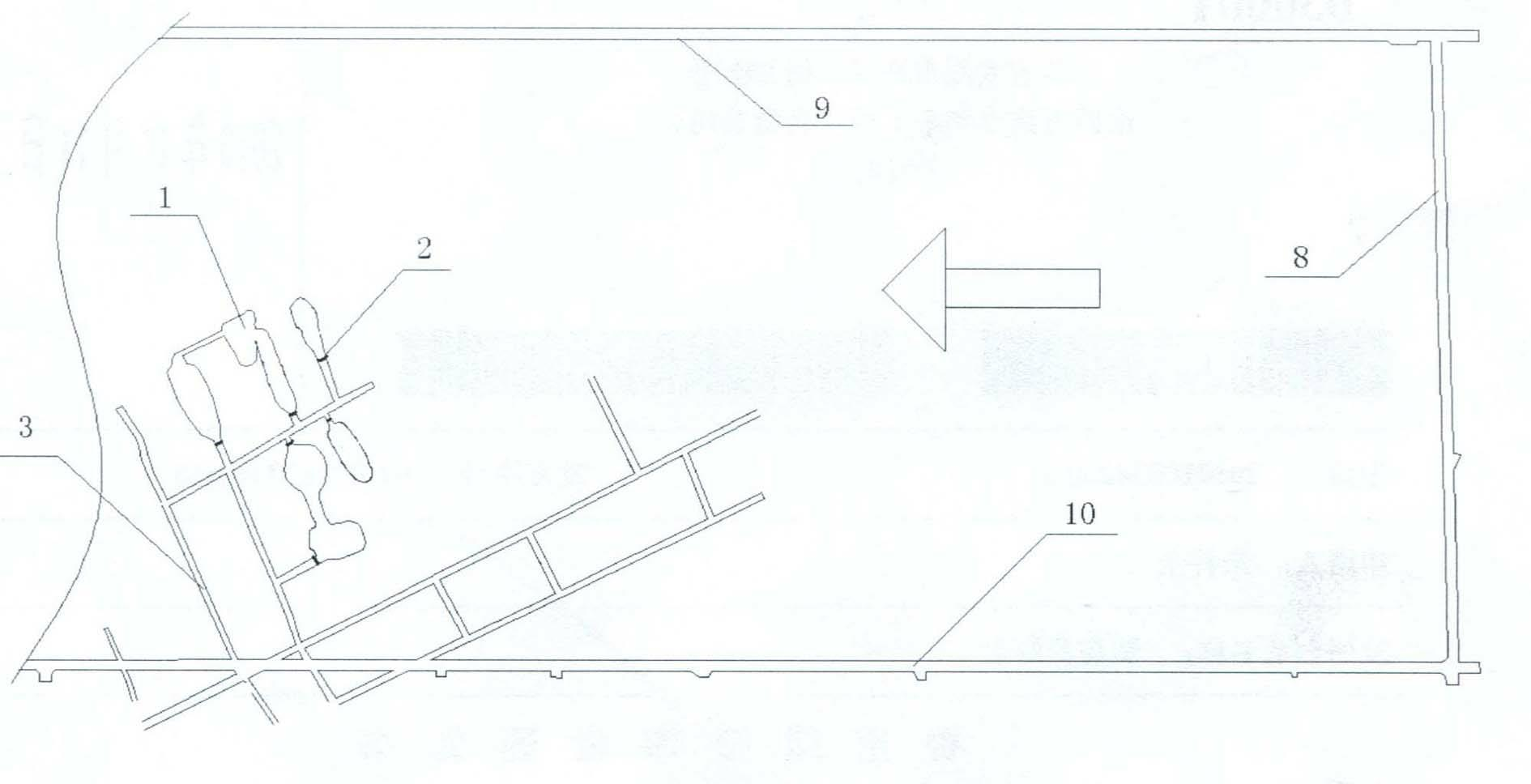

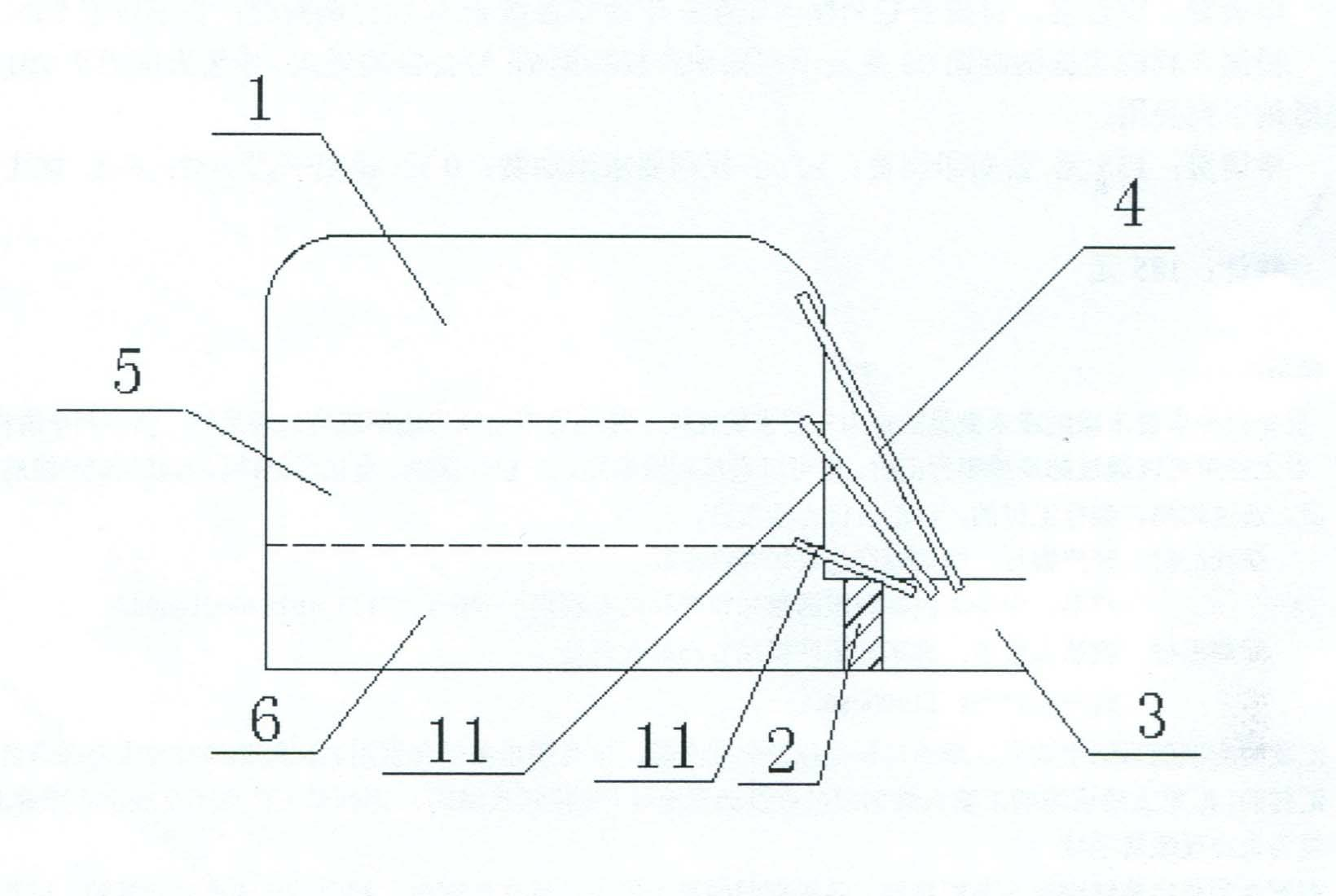

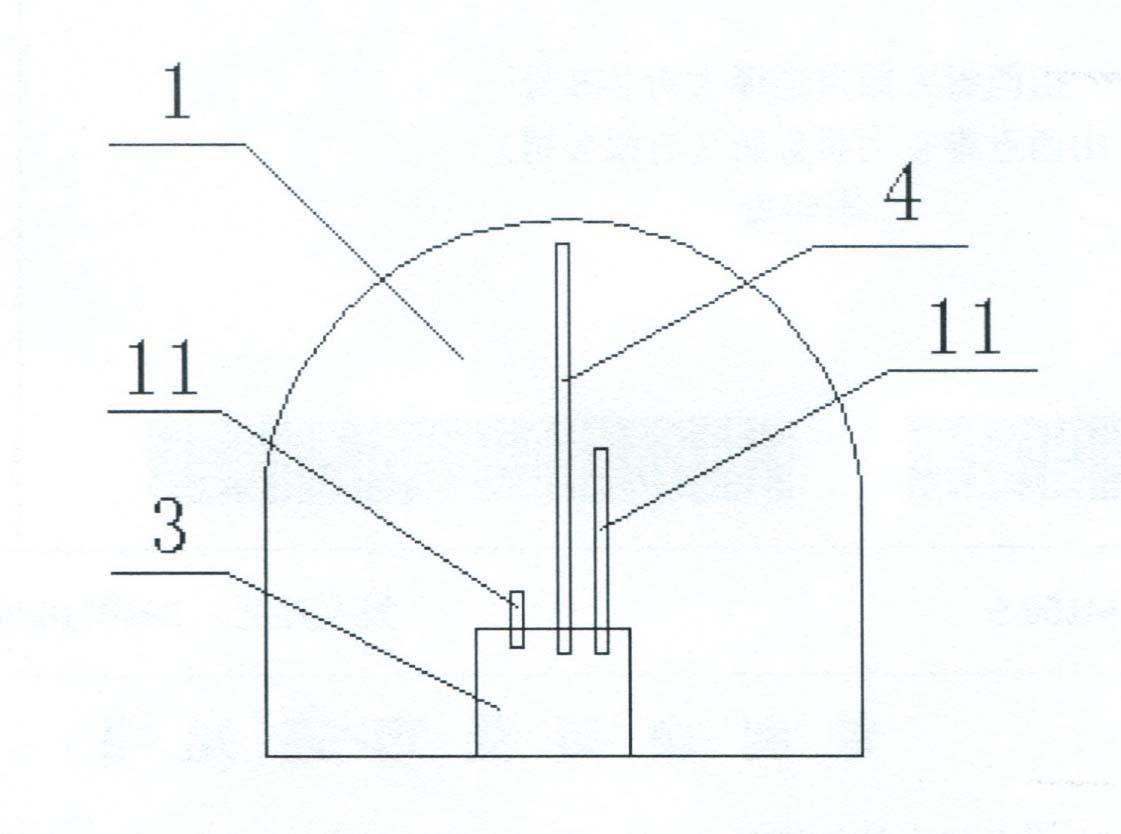

[0037] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a large-scale recovery method of filling in the damaged area of a small kiln is used to detect the goaf of the small kiln by means of geophysical prospecting, drilling, roadway exploration, etc. → master the distribution, size, and hidden dangers of the goaf of the small kiln → determine Thickness and strength of cutting layer→determination of thickness and strength of key bearing layer→construction grouting drilling→construction exhaust drilling→grouting and filling→recovery in damaged area of small kiln.

[0038] The specific process steps of the method are as follows:

[0039] 1) Detection: Detect the goaf of the small kiln, master the distribution of the goaf of the small kiln, the size of the internal space, the layer, and the existing safety hazards, and obtain on-site data for hidden danger treatment, grouting filling, and re-mining;

[0040] 2) Repair: To deal with potential safety hazards a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com