Grading zonal paste backfilling system and method for total tailings of metal minerals

A technology of paste filling and full tailings, which is applied in the direction of fillings, safety devices, mining equipment, etc., can solve the problems of underground debris flow accidents, poor permeability of full tailings non-cemented fillings, etc., to reduce filling costs and equipment technology Mature and reliable, easy to implement the effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

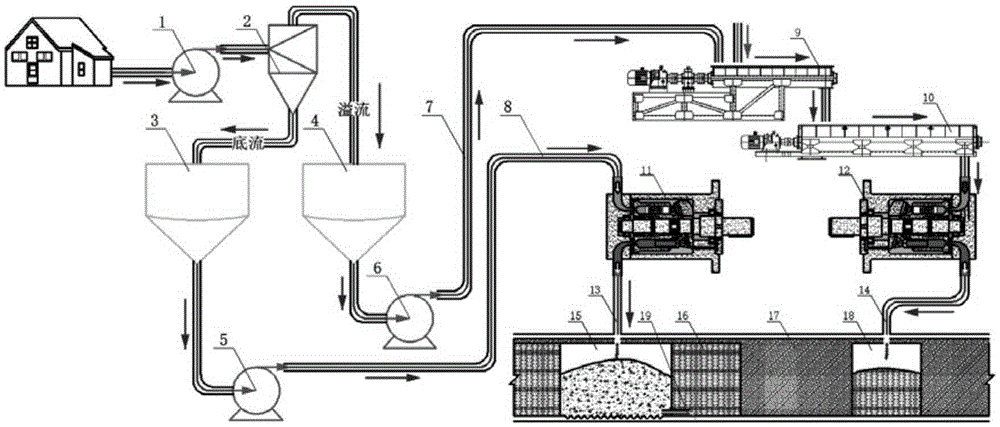

[0031] The average particle size of the whole tailings of a mine is less than 0.03mm, the -800 mesh is more than 50%, and the +400 mesh is less than 30%, which belongs to ultra-fine full tailings. The ultra-fine full tailings have poor permeability, and the downhole full tailings non-cemented filling body is always in a saturated state, and there is a risk of debris flow. The surrounding rock of the mine is in good condition, but there are a large number of old empty areas in the mine, and the deep ore body needs to be mined by the filling method. The main mining plan is the room-and-pillar method followed by filling mining. The application of graded tailings partitioned paste filling technology makes non-cemented filling possible. The whole tailings are classified with 525 mesh as the classification limit, and the classified underflow (+525 mesh) enters the coarse-grained thickener to thicken into a high-concentration slurry. The first pump body (5) is transported to the surf...

example 2

[0034] The surrounding rock conditions of a certain mine are moderate, and the Platts coefficient f=3~4; Underground ground temperature is high, stope temperature can reach above 35°C. At the same time, the ground stress is large and the ore grade is high. The upward layered filling mining method is adopted for mining, and the graded tailings partition paste filling technology is used for subsequent filling, and the stope layout is alternately mining. After the mine is put into production, the whole tailings of the dressing plant are classified by the hydrocyclone (2), and the classification limit is controlled at 400 mesh (37 μm). The underflow and overflow of the cyclone are respectively thickened into high-concentration tailings slurry through coarse and fine thickeners (3) and (4). The mass concentration of coarse-grained tailings slurry can reach 75-77%, and fine-grained The mass concentration of mortar body is between 67% and 70%. The fine-grained high-concentration ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com