Patents

Literature

170results about How to "Cost of operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

End-to-end service quality monitoring method and system in a radio network

ActiveUS20110096678A1Prevent data security threatGuaranteed continuous availabilityError preventionTransmission systemsQuality of serviceRadio networks

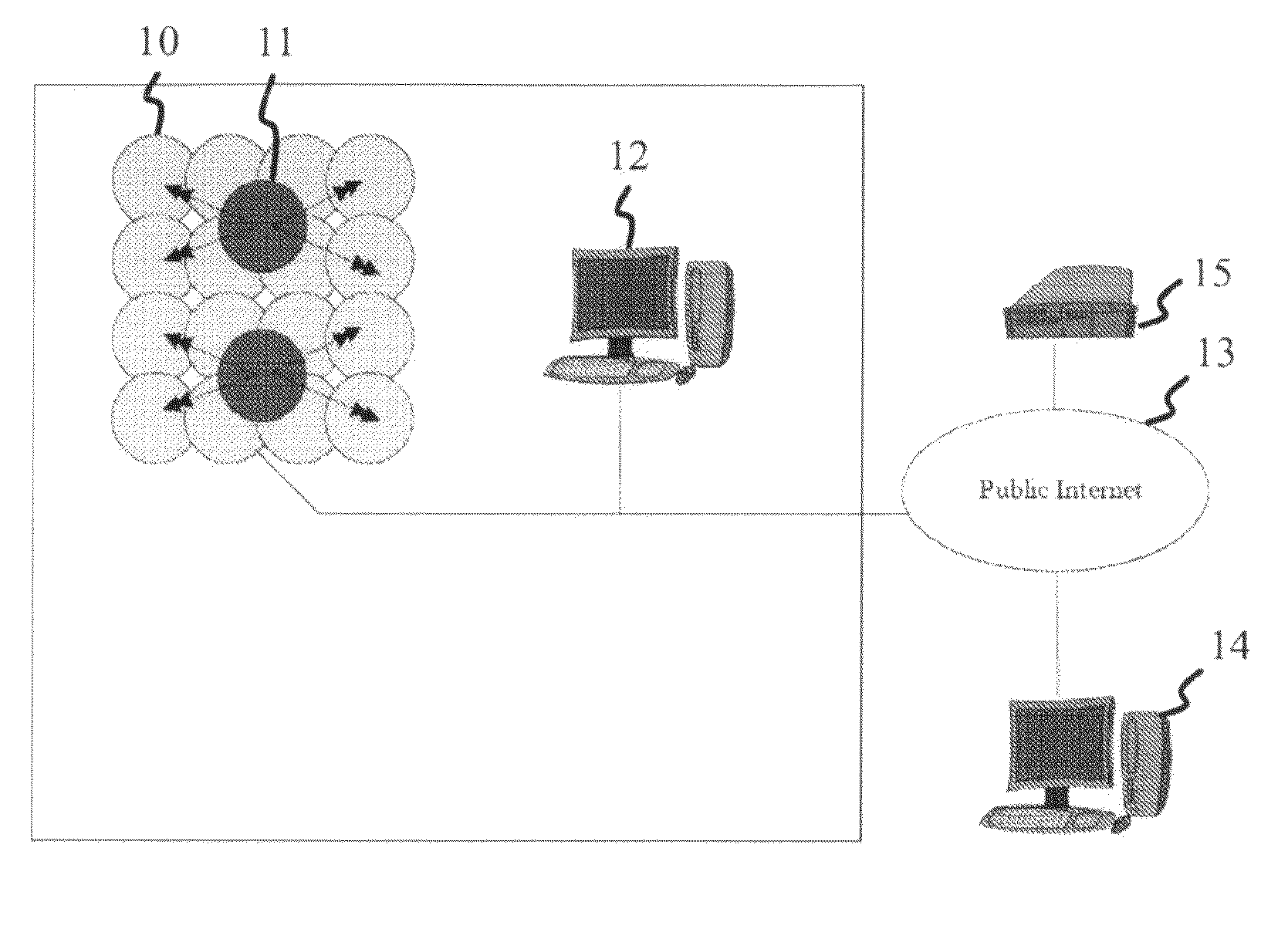

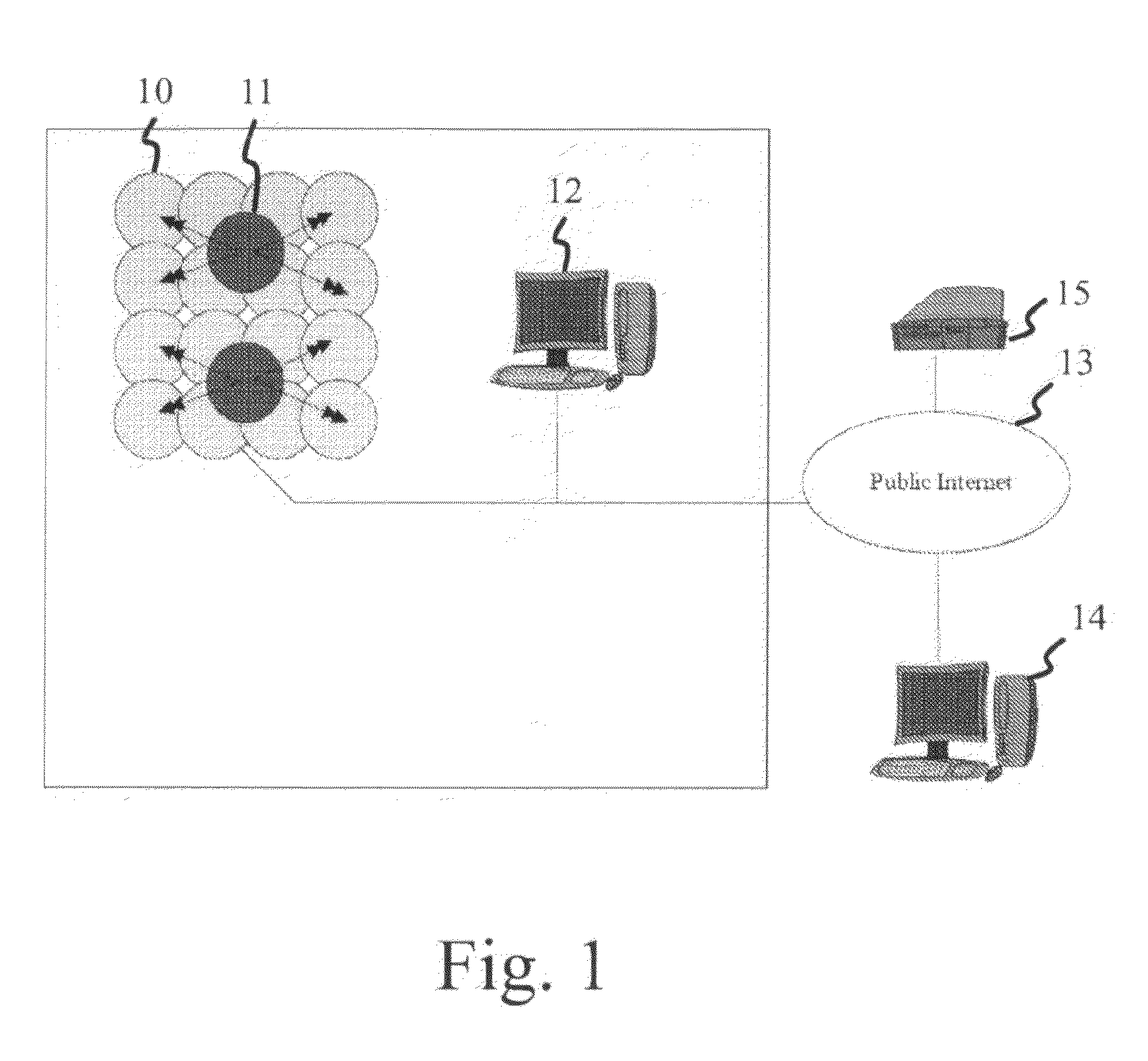

The present invention discloses a method and a system for service quality monitoring in a network comprising radio interfaces. The measurements are end-to-end measurements between the end user and chosen network element. The measurements are implemented using monitoring stations which can monitor the traffic passively or actively by transmitting test signals. The antenna beam directions of the monitoring stations can be controlled. The performance server works as a counterpart of the active tests. A reporting suite may define the performed measurements and it also collects the measurement data from different monitoring stations. Monitoring data from several corporate intranets can also be collected to an external server through internet connection.

Owner:7SIGNAL OY

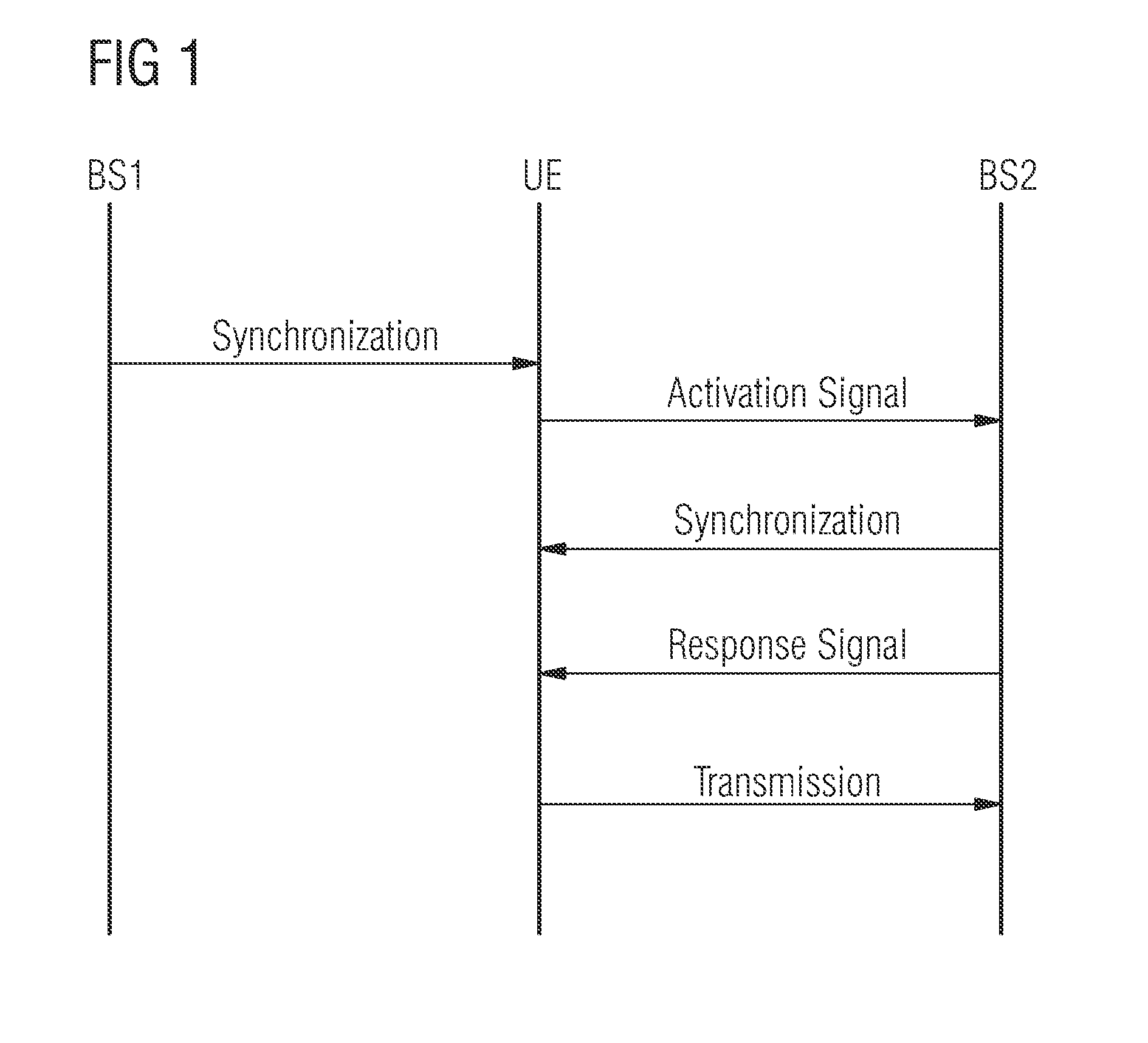

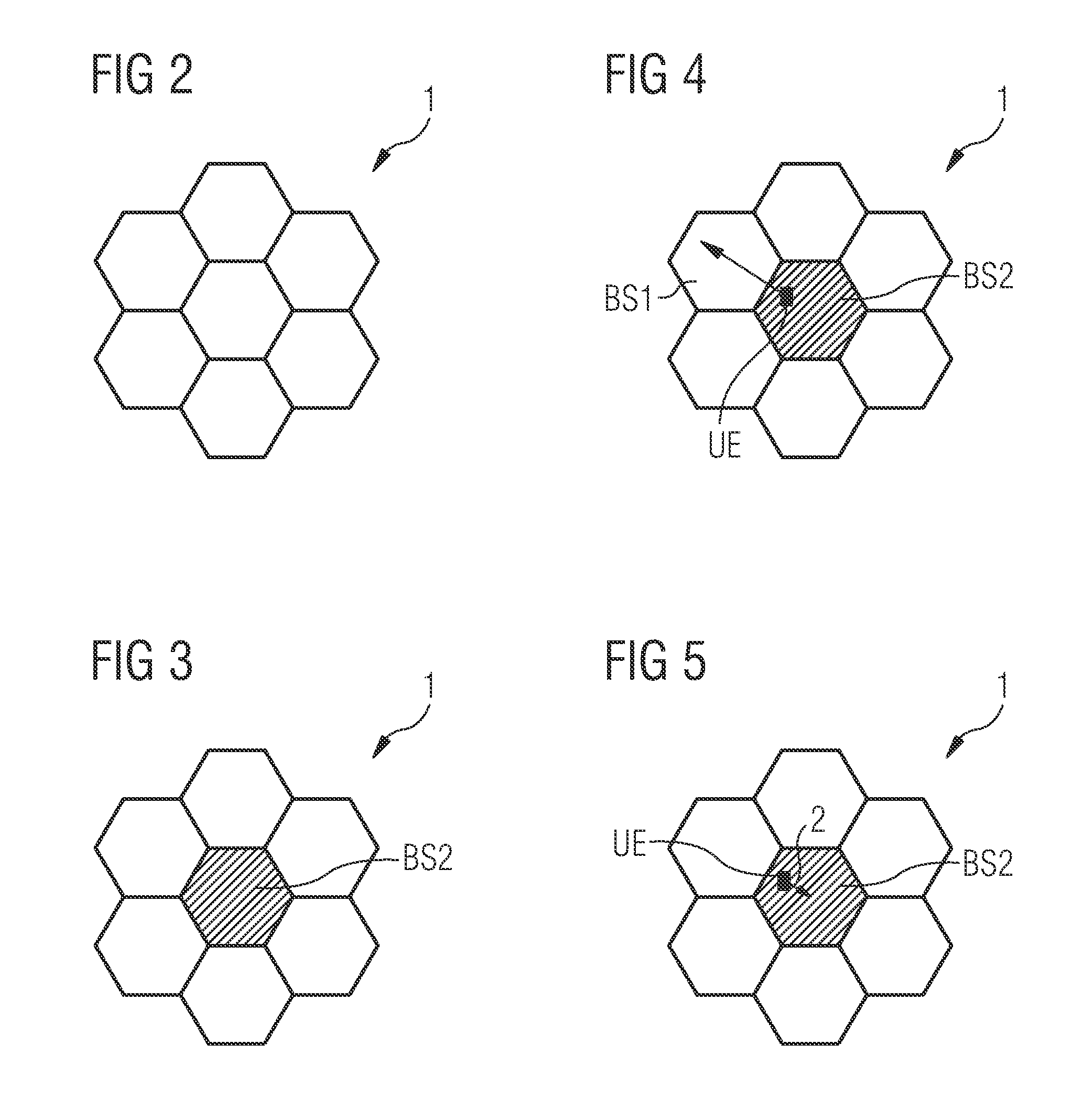

Method for Transferring a Base Station of a Wireless Communication Network from a Standby Mode to a Fully Activated Mode

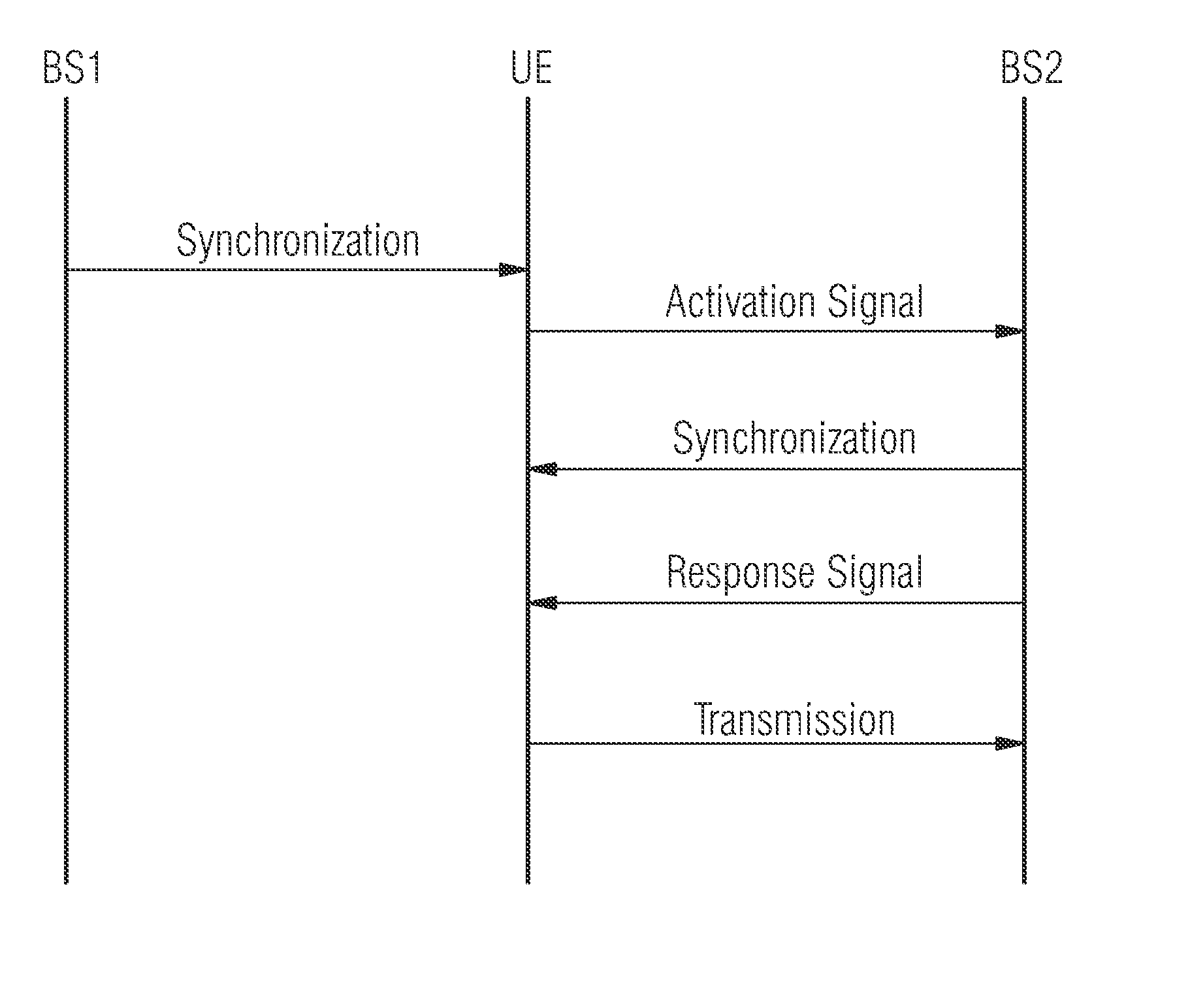

InactiveUS20110194493A1Minimize activity and power consumptionAvoid unnecessary signalingPower managementOrthogonal multiplexVIT signalsBiological activation

It is described a method for transferring a base station of a wireless communication network from a standby mode to a fully activated mode. The method includes sending an activation signal from a user equipment (UE) to the base station. The method further includes receiving the activation signal by the base station and transferring the base station (BS2) to the fully activated mode in response to the reception of the activation signal.

Owner:CENTONZA ANGELO +3

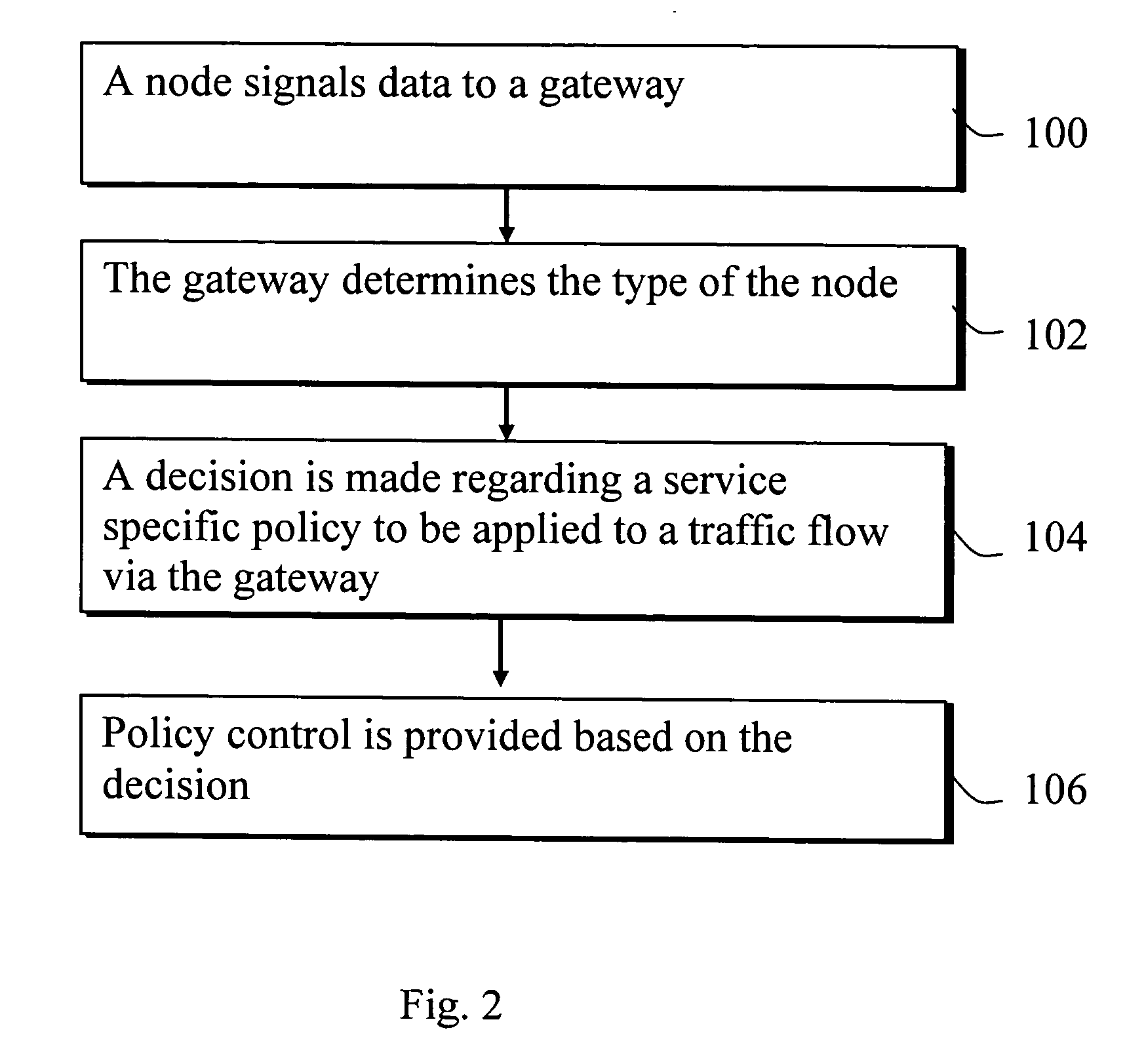

Control decisions in a communication system

ActiveUS20050135375A1Improve communication flexibilityCost of operationSpecial service provision for substationError preventionAccess networkControl communications

A method, system, network and gateway of deciding a policy for controlling communications in a communication system are disclosed. The method comprises determining the type of an access network associated with communications via a gateway. In a further step, a policy to apply to communications via the gateway is decided based on information regarding the type of the access network.

Owner:NOKIA TECHNOLOGLES OY

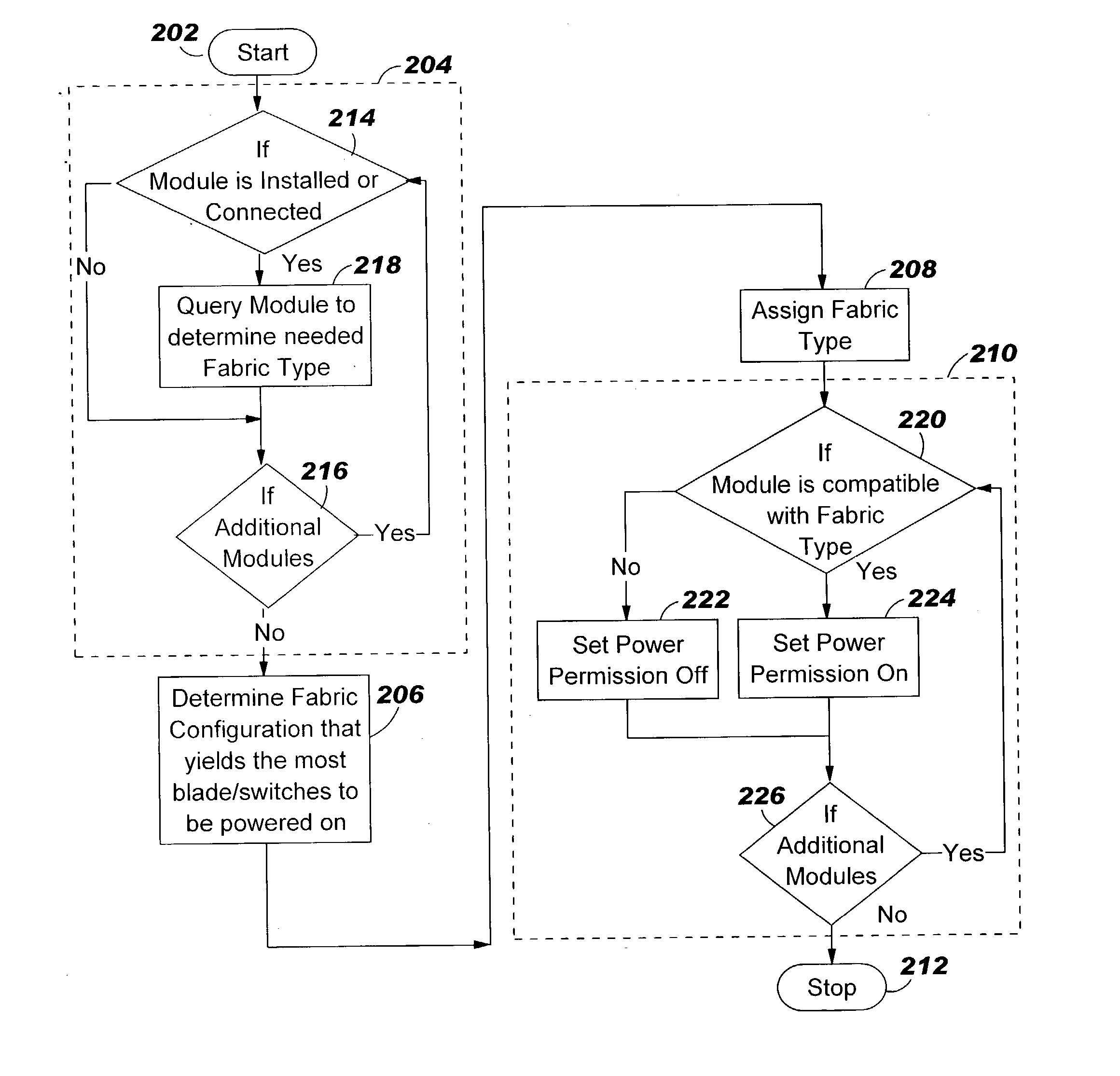

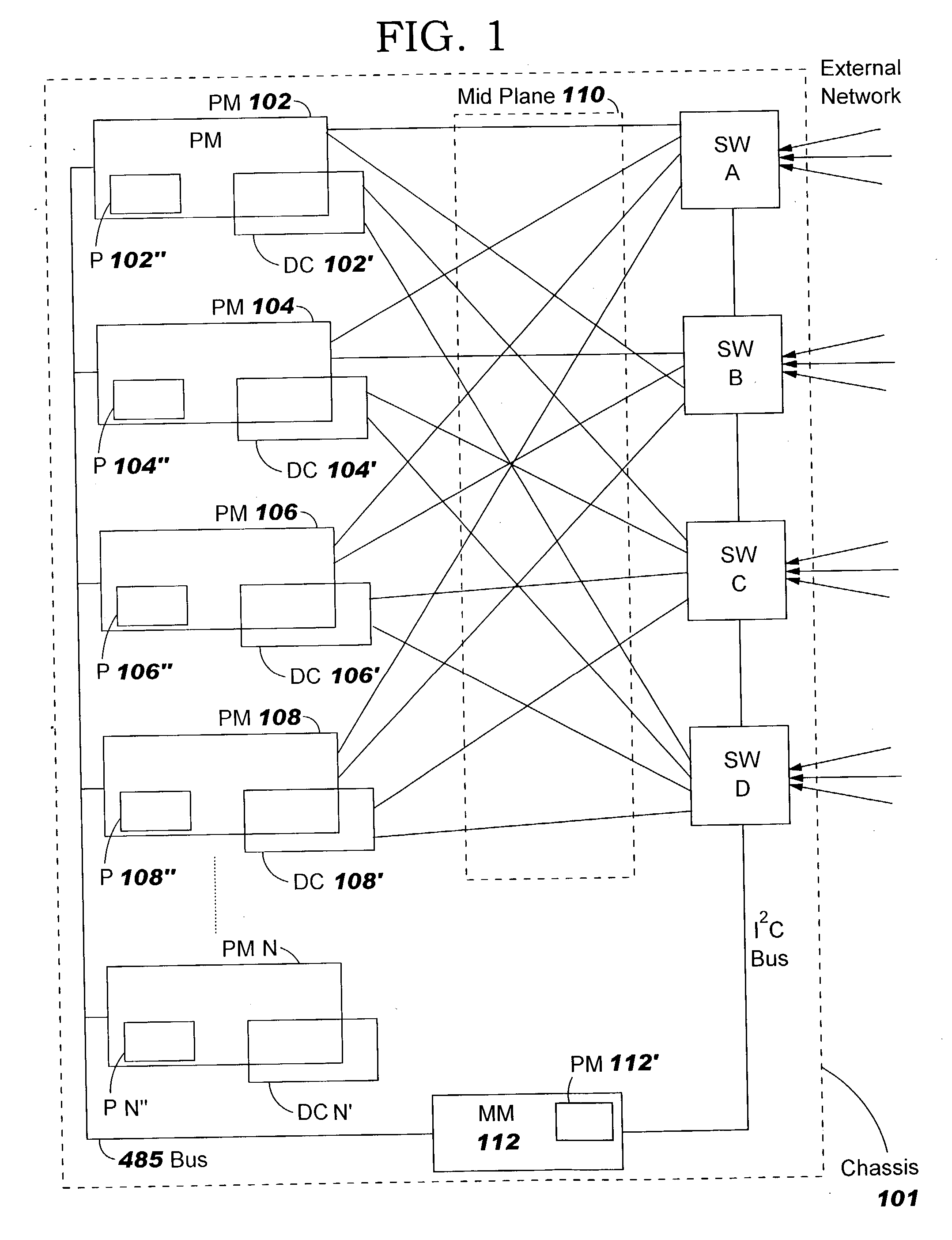

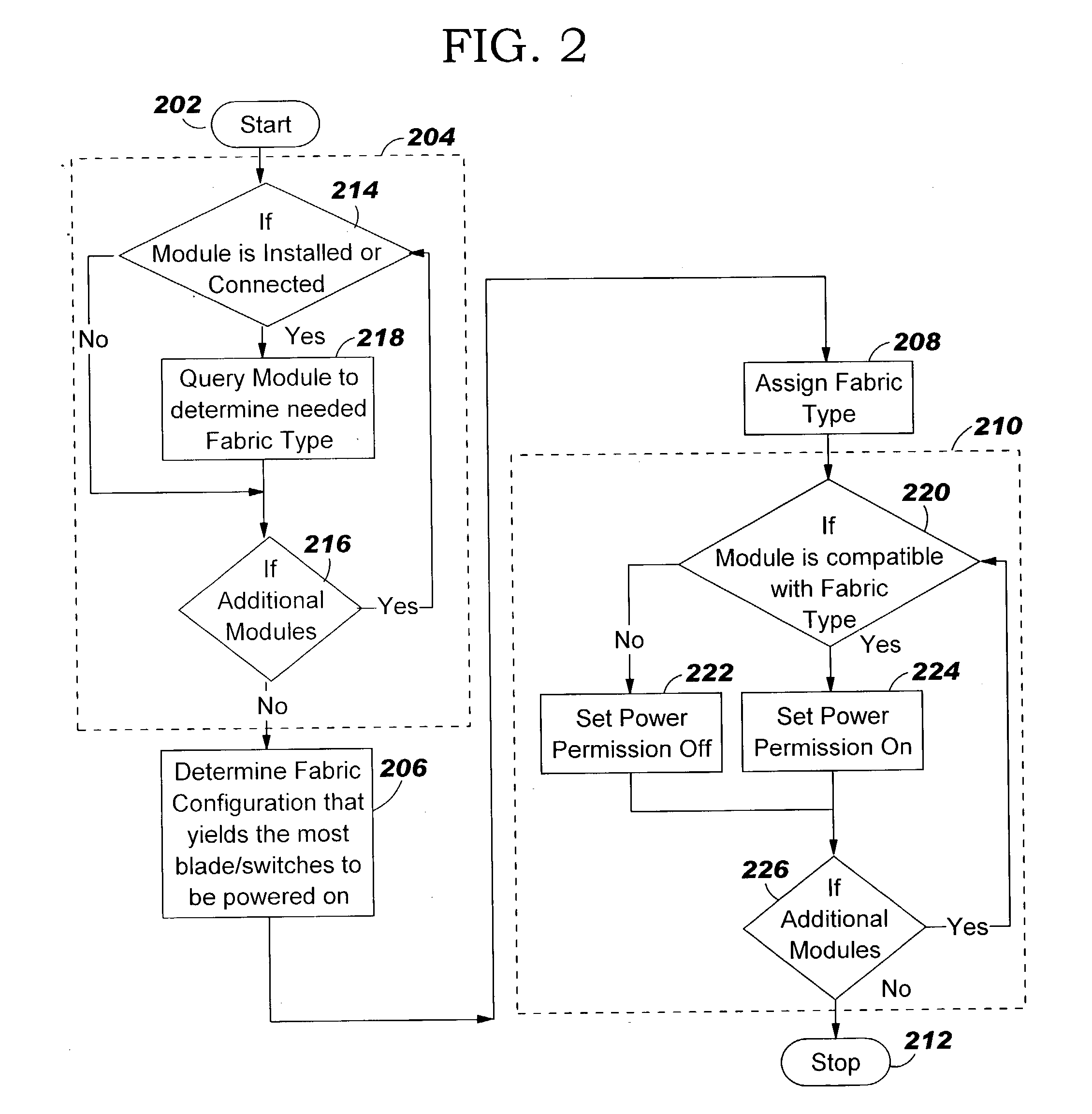

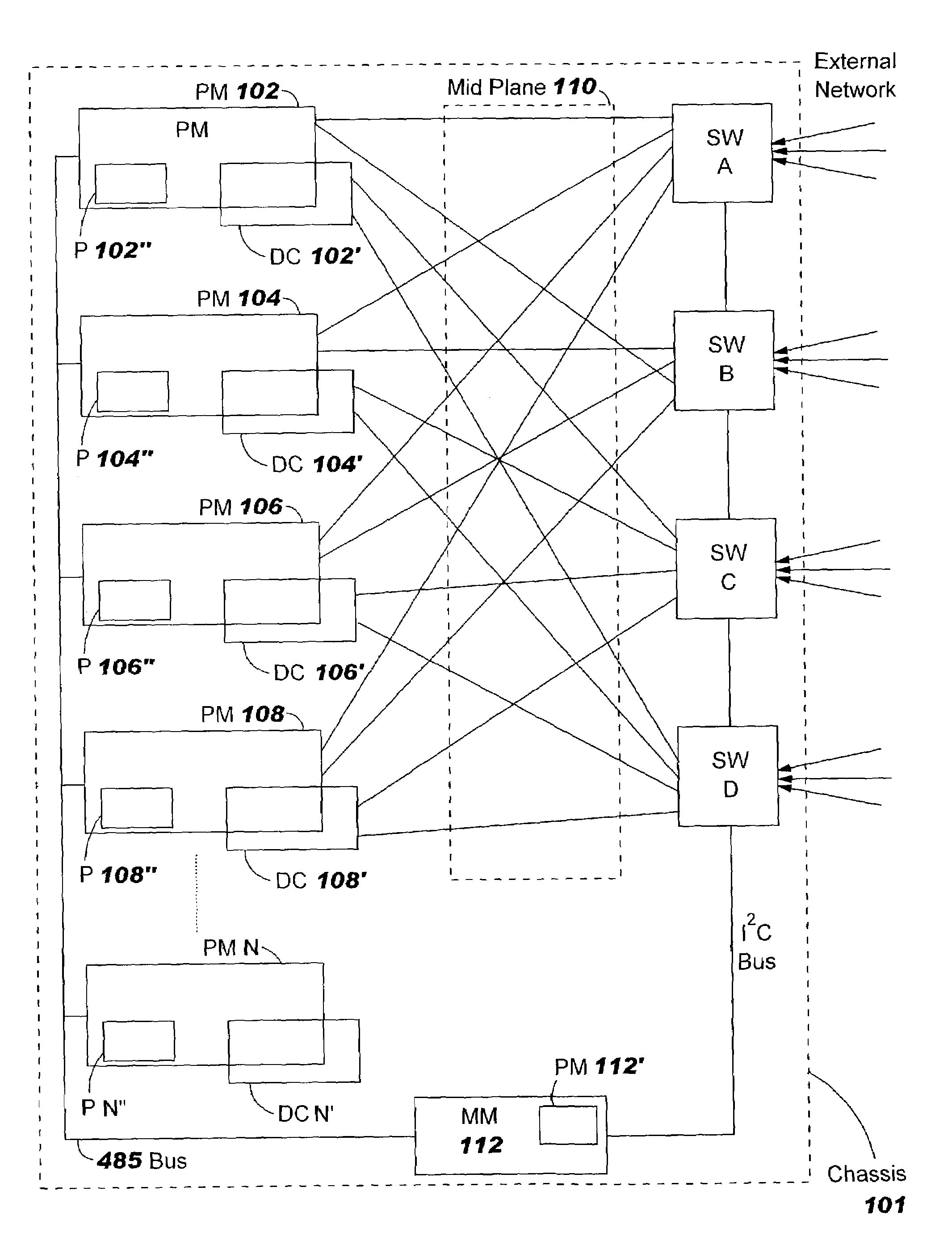

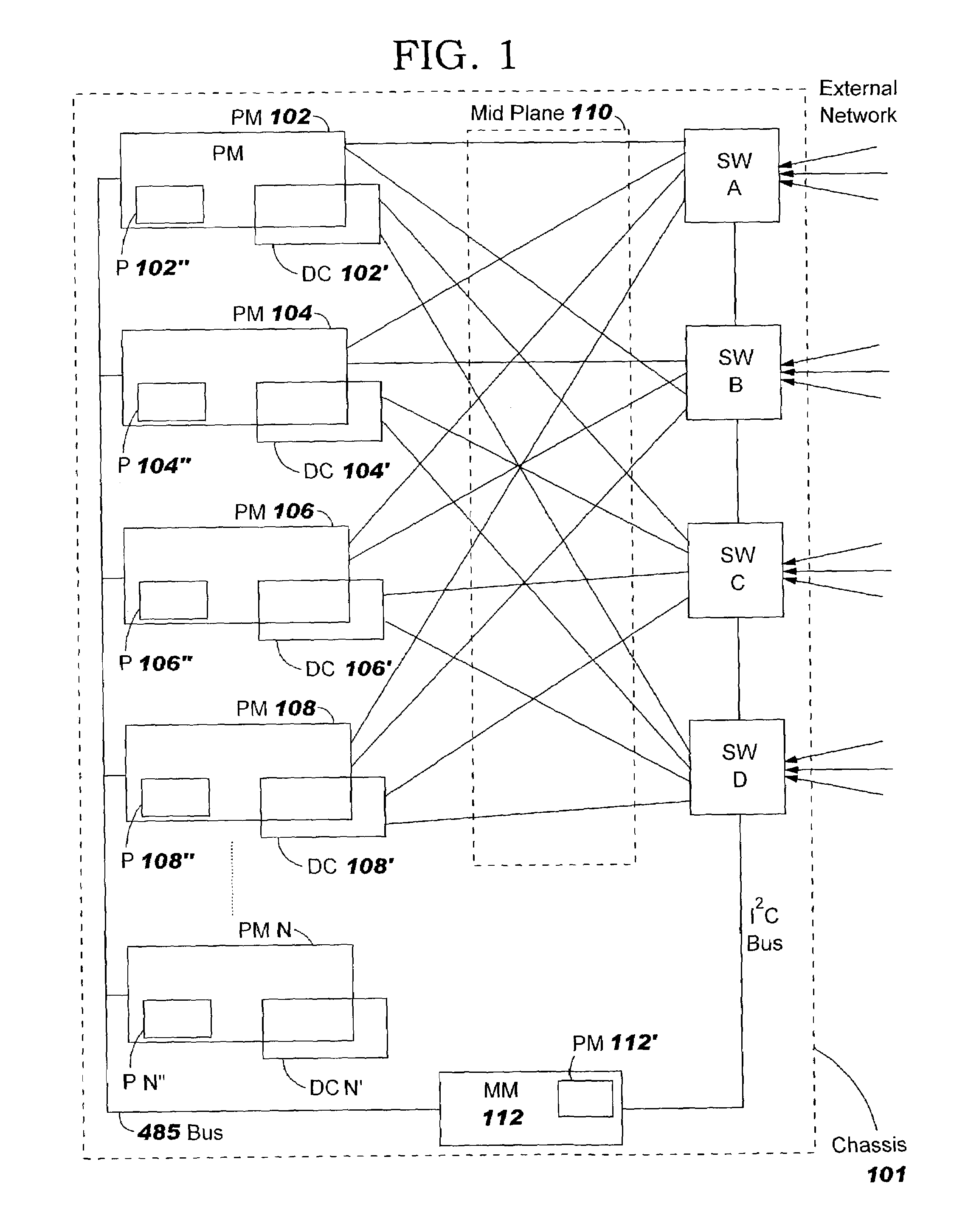

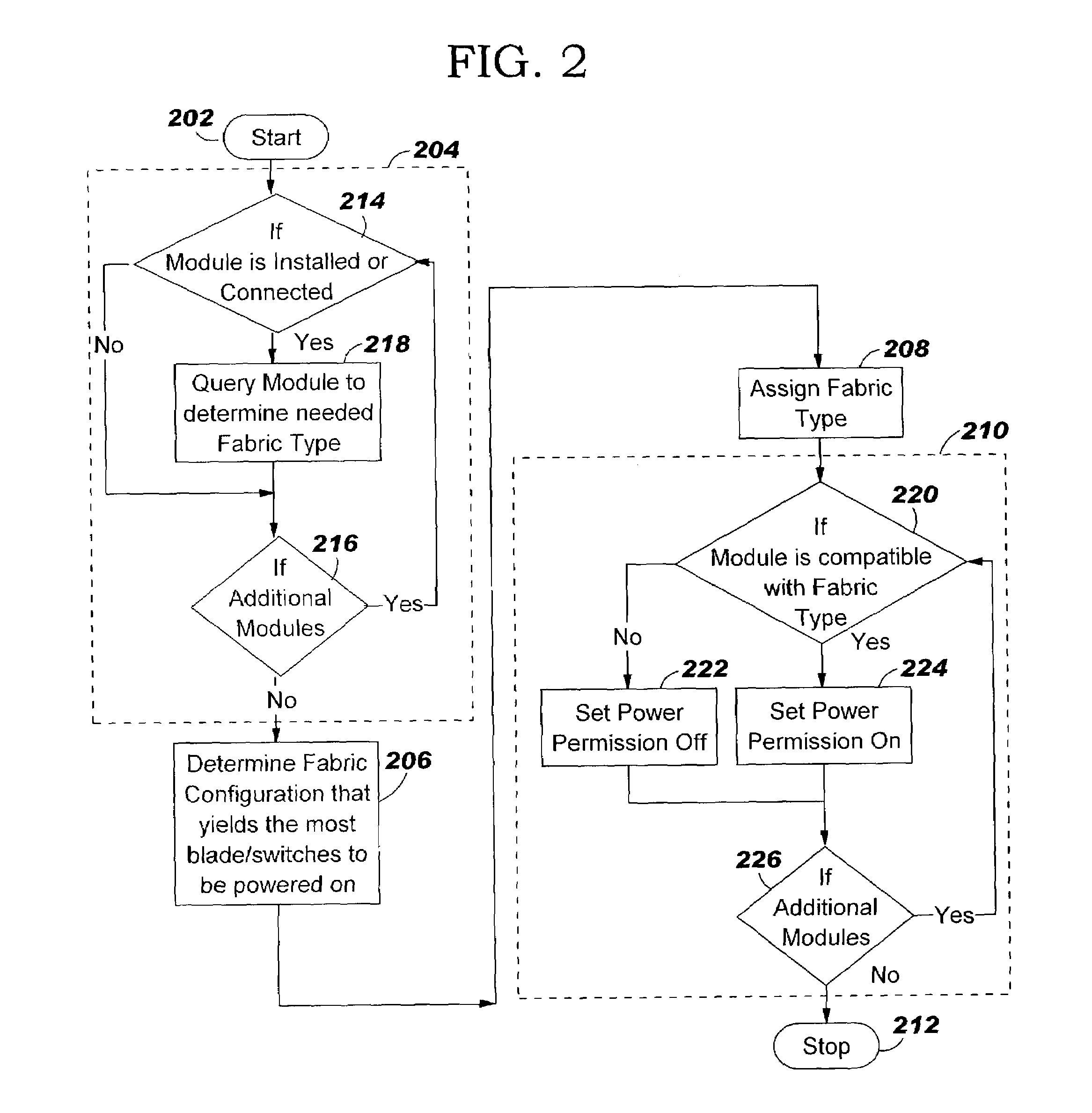

Apparatus, method and program product for automatically distributing power to modules inserted in live chassis

InactiveUS20040117536A1Error has likelihoodCost of operationData switching detailsVolume/mass flow measurementComputer moduleField service

When a blade and / or interconnect device is inserted into the chassis of a powered or live server the procedure is known as hot-plugging. Before power is applied to the hot-plugged blade and / or interconnect device the fabric type of already installed blades and / or interconnect devices is correlated with fabric types of newly hot-plugged blade and / or interconnect device. Depending upon results of the correlation, power to the hot-plugged blade and / or interconnect device is allowed or denied.

Owner:IBM CORP

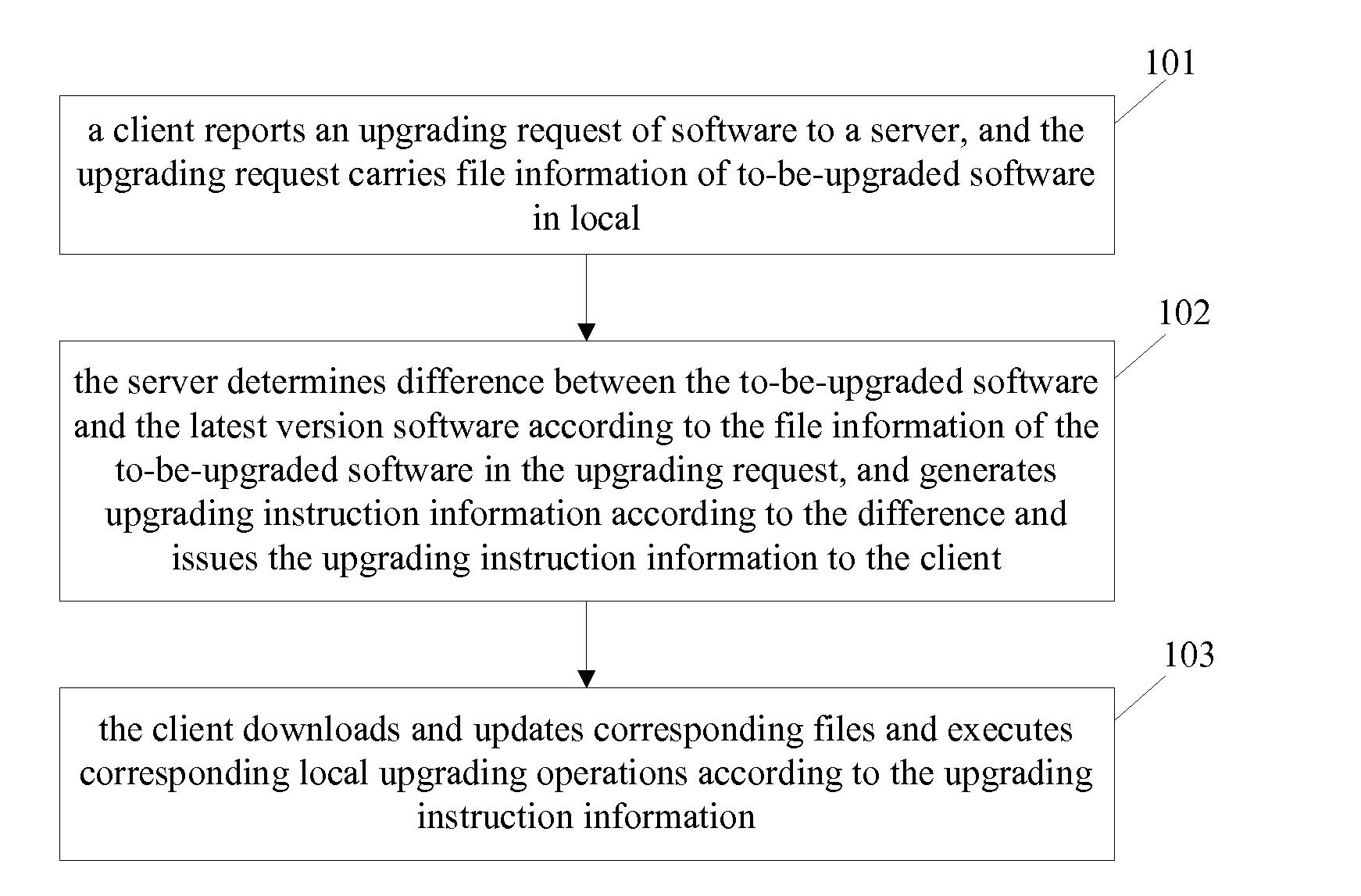

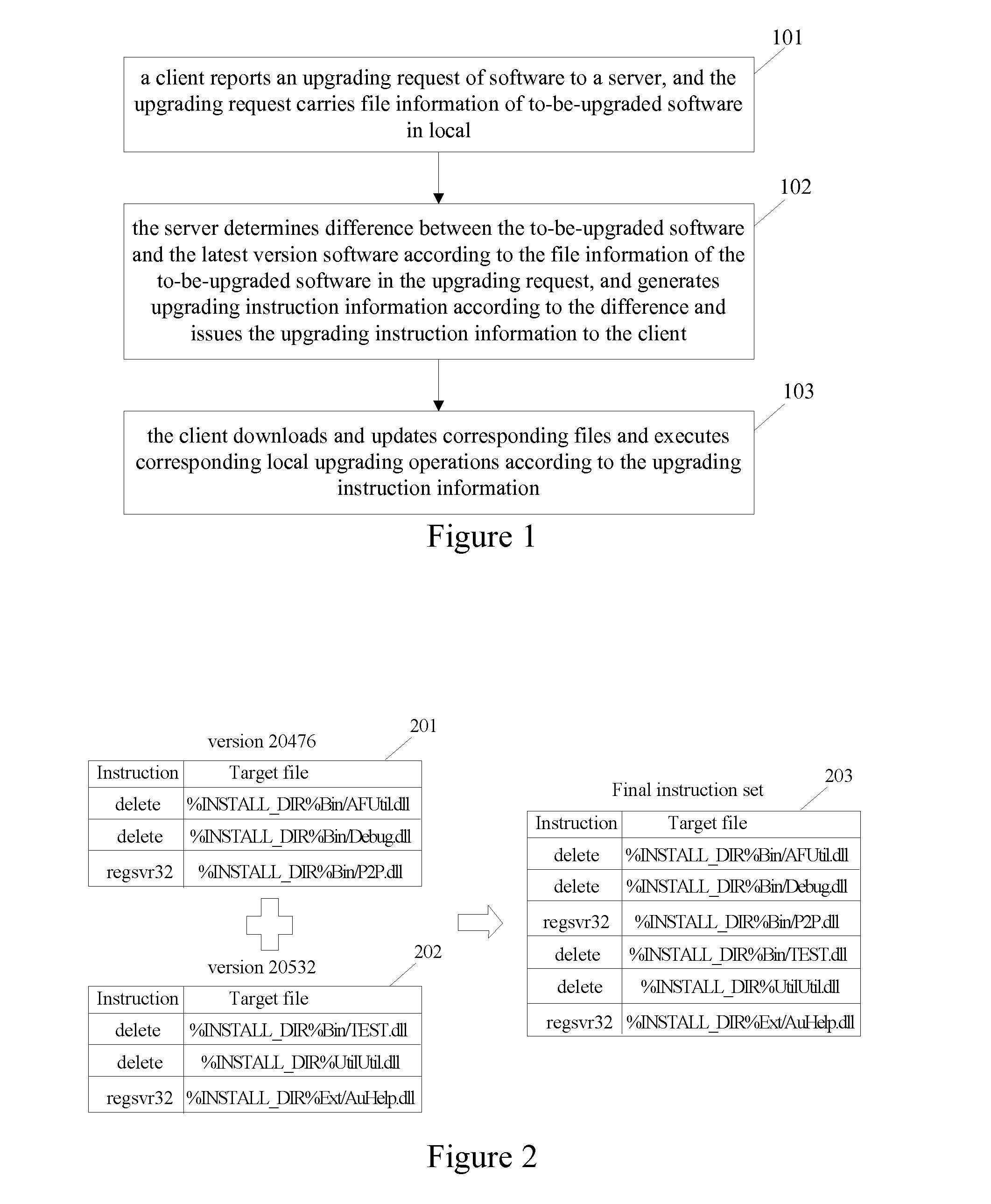

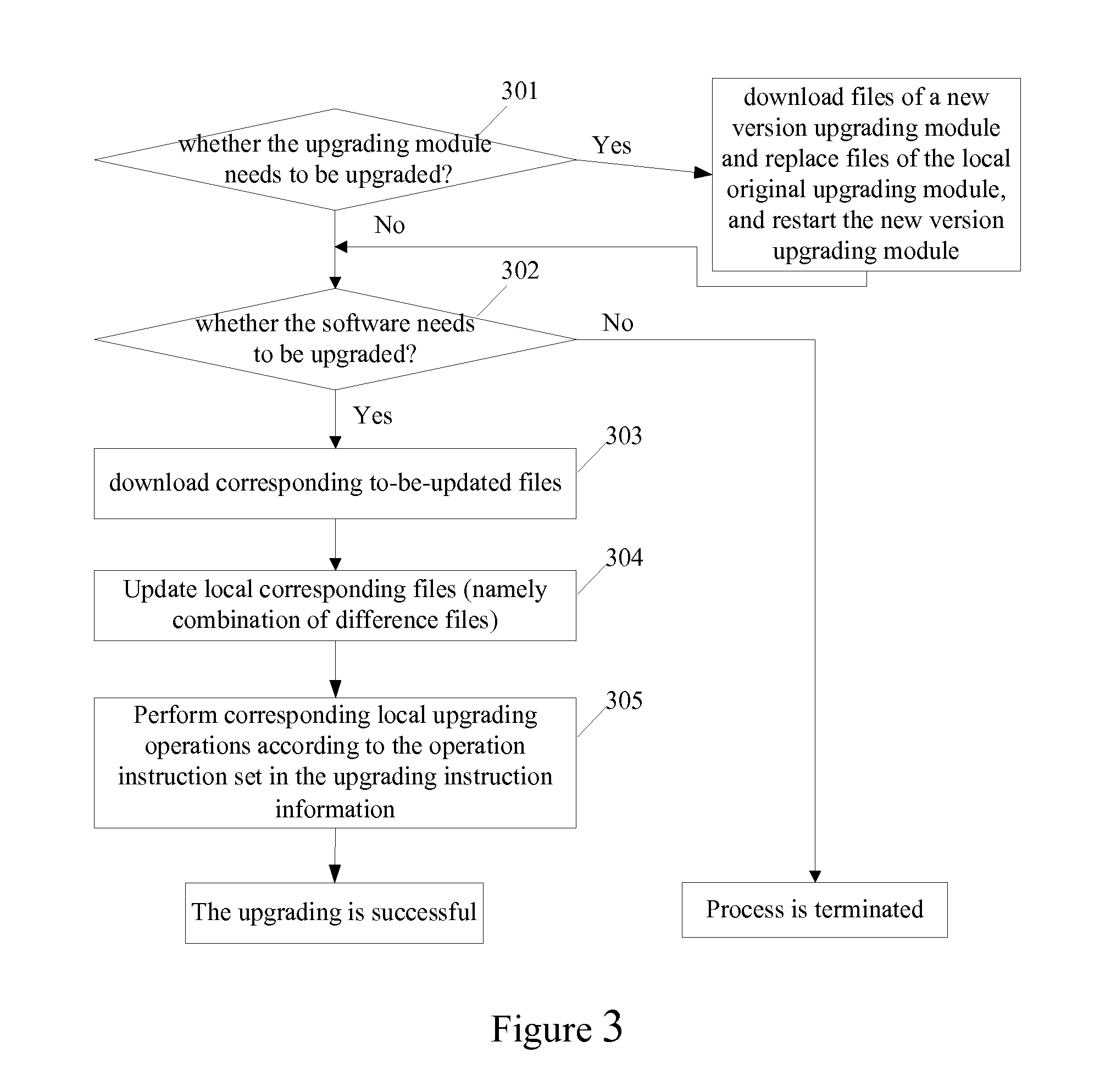

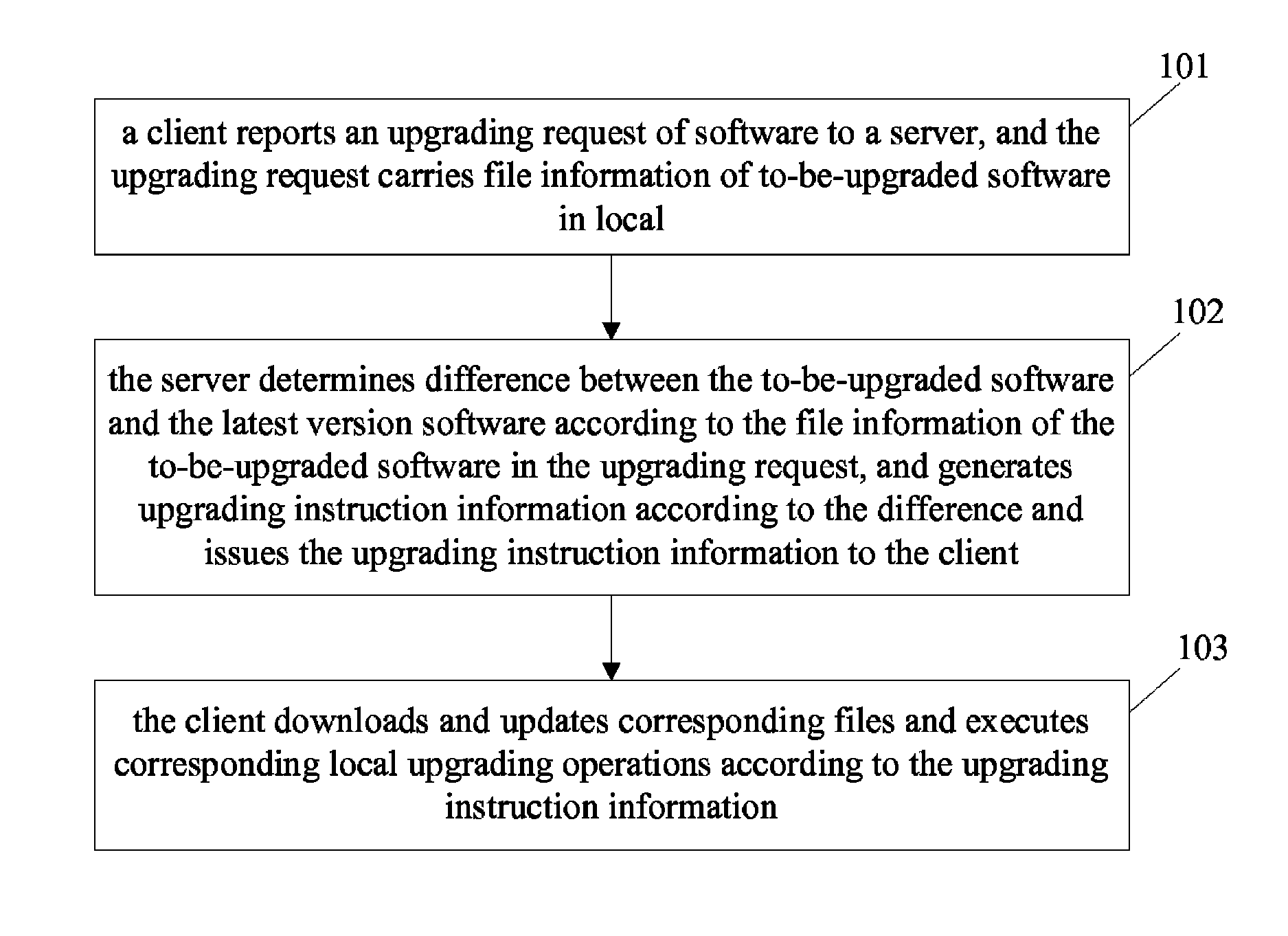

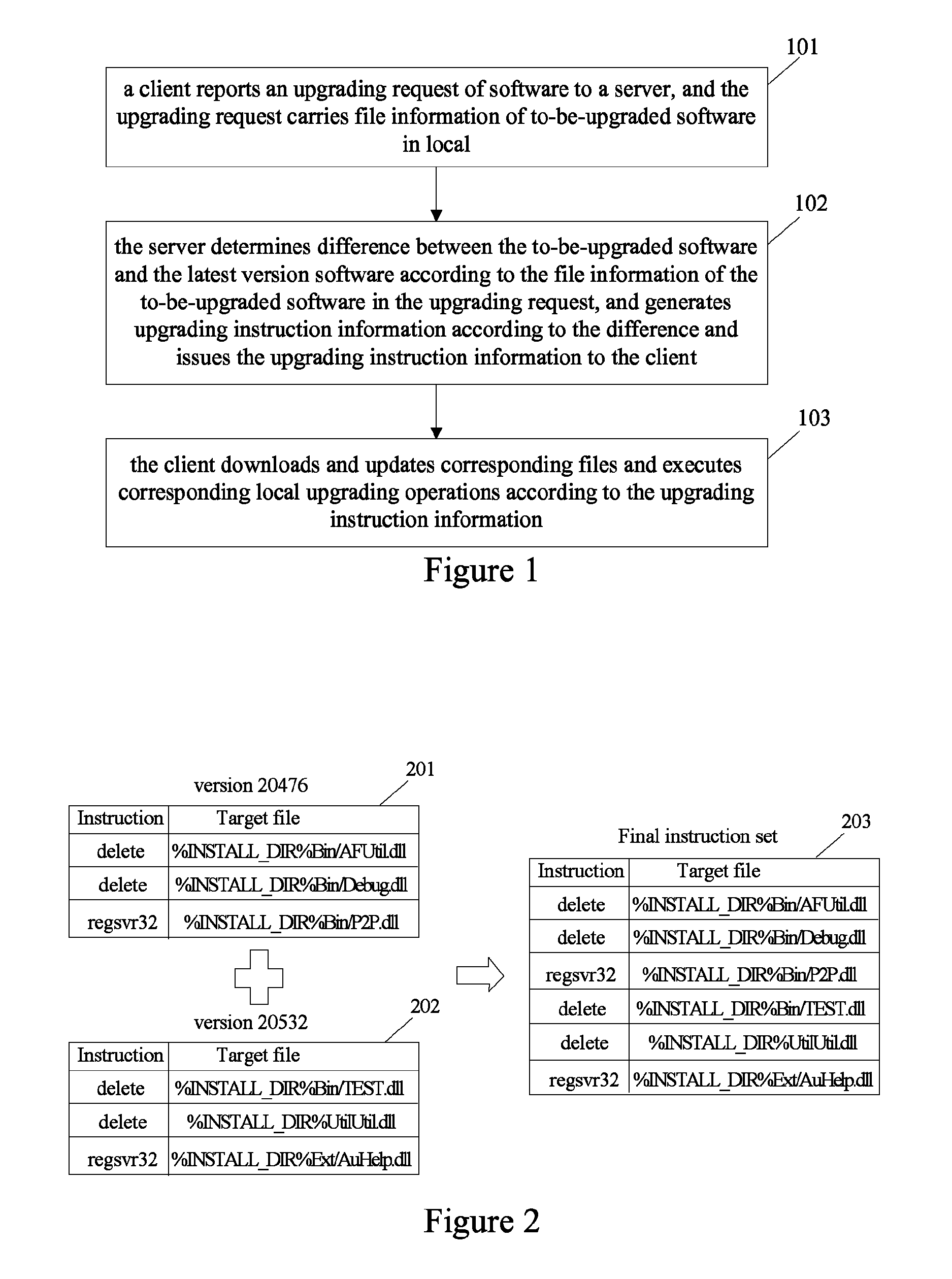

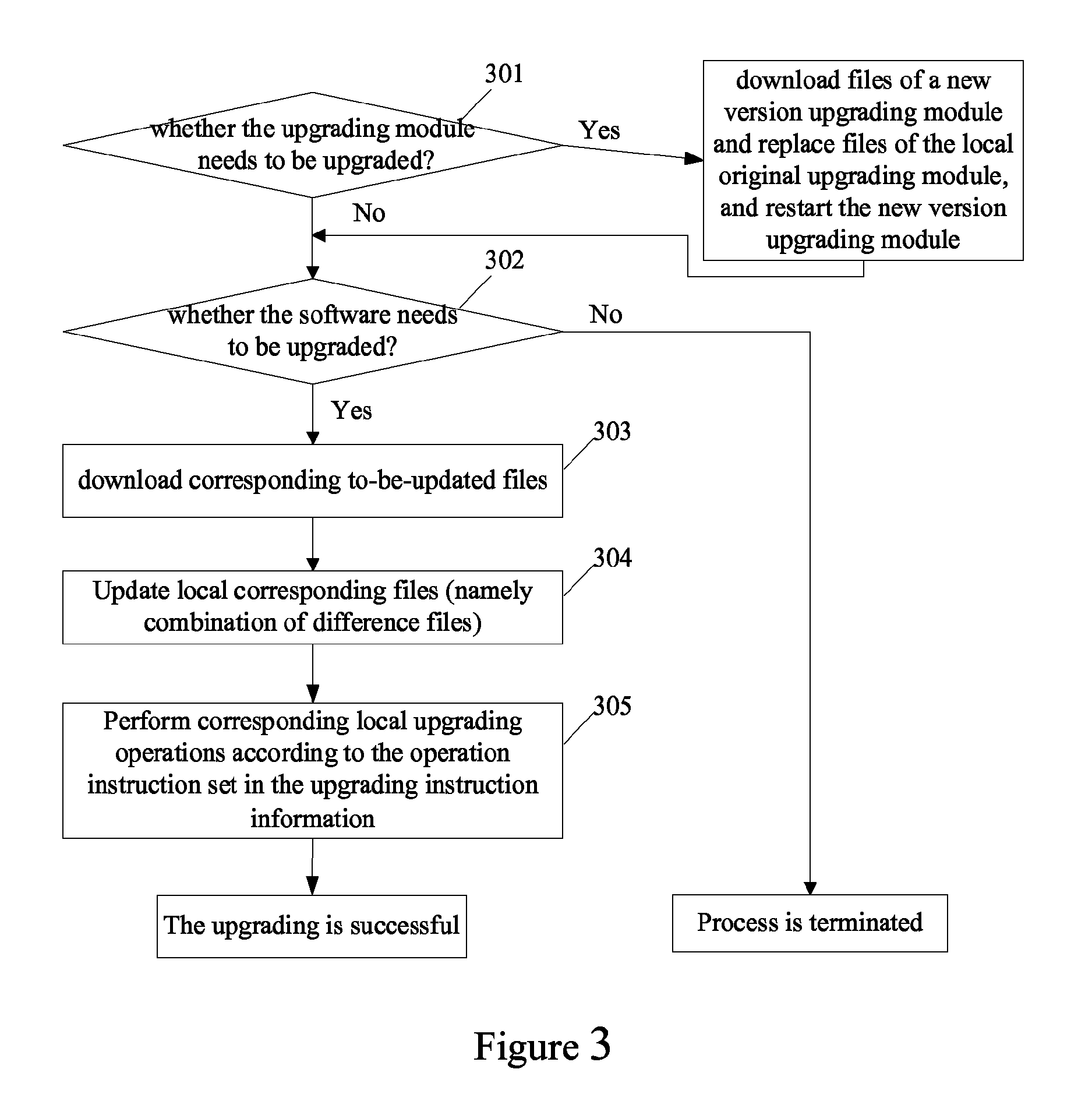

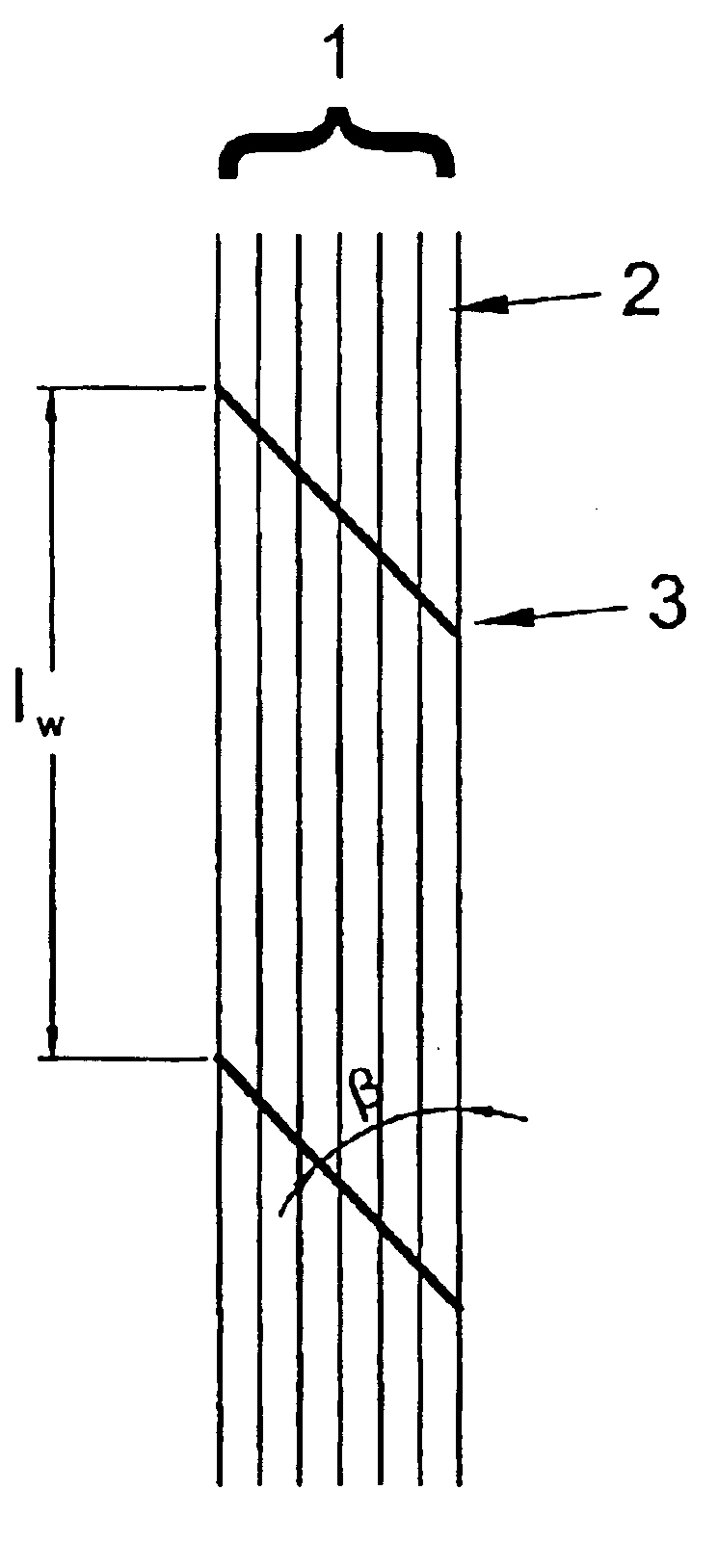

Method and system for upgrading software

ActiveUS20140304697A1Save bandwidth resourcesReduce software upgrading workloadDatabase updatingVersion controlSoftware engineeringWorkload

Embodiments of the present disclosure provide a method and a system for upgrading software. The method includes: a client reports a software upgrade request to a server, wherein the upgrade request carries file information of the local software to be upgraded; the server determines the difference with the latest version software according to the file information of the software to be upgraded in the upgrade request, and generates upgrade instruction information according to the difference and sends it to the client; the client downloads and updates the relevant files and performs the relevant local upgrade operations according to the instructions in received upgrade instruction information. Technical solutions of the present disclosure can save bandwidth resources and reduce the workload for upgrading software.

Owner:TENCENT TECH (SHENZHEN) CO LTD

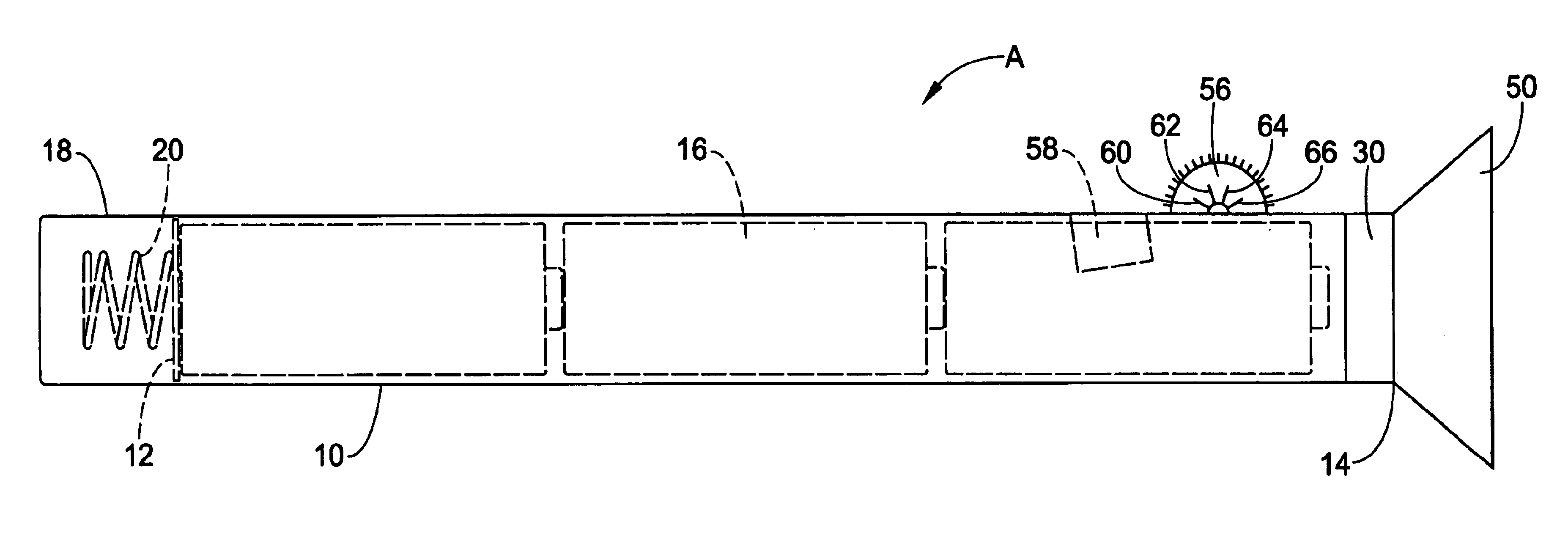

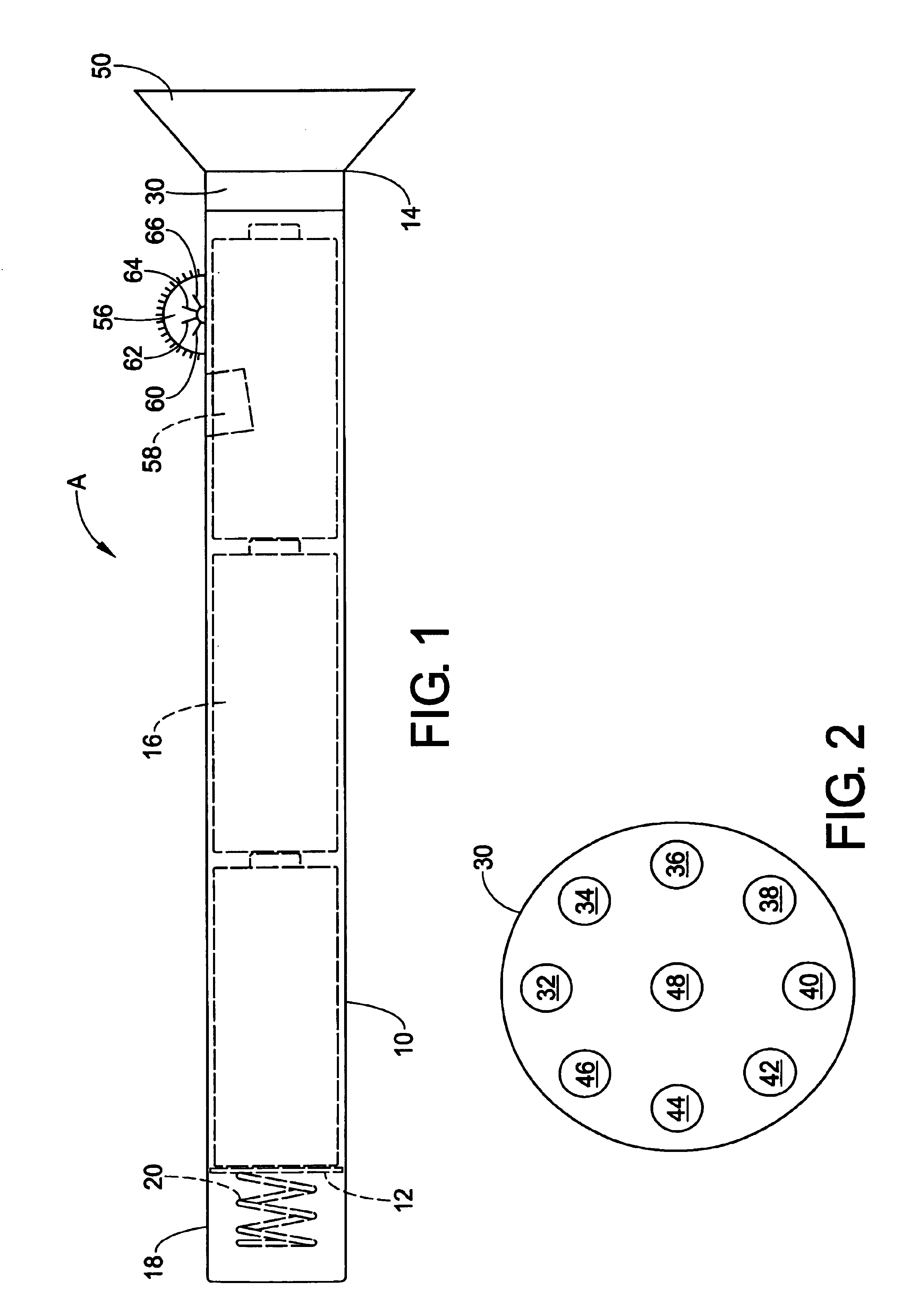

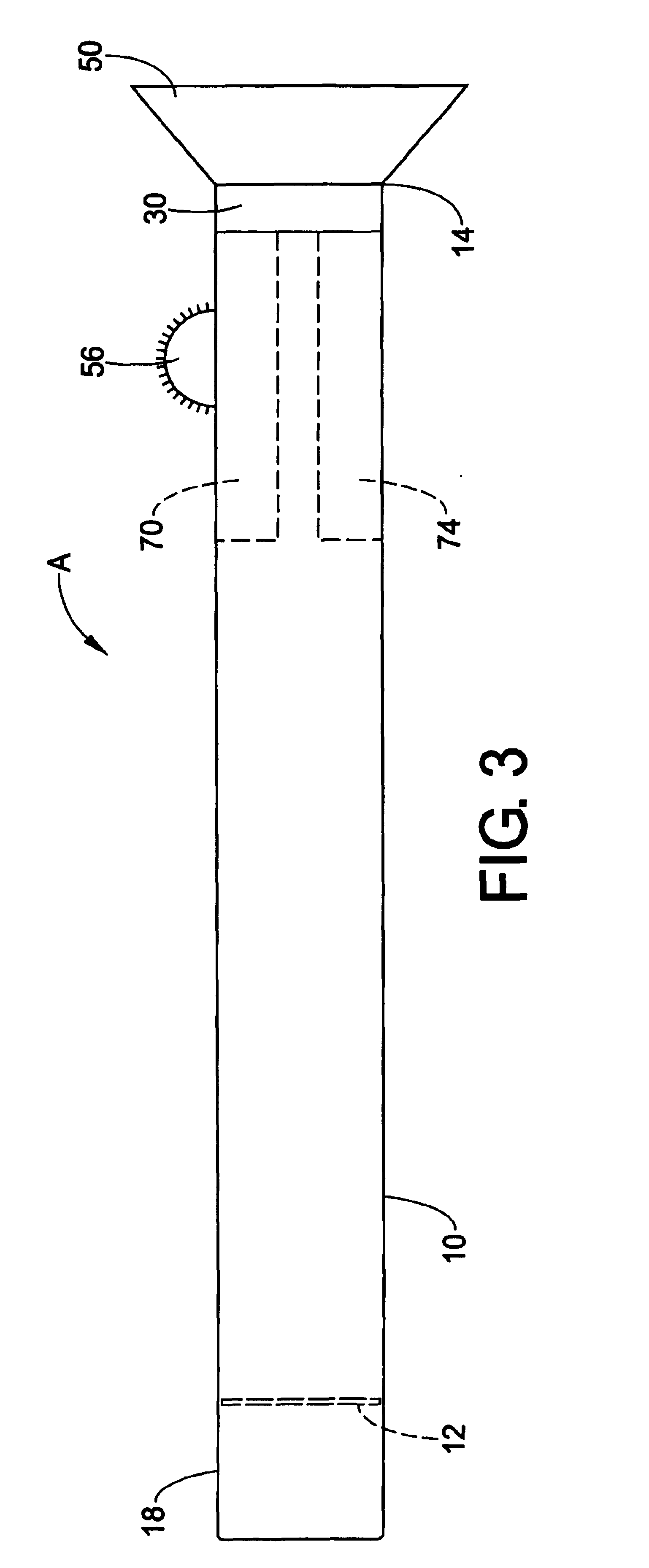

Flashlight with light emitting diode source

InactiveUS6957897B1Long lifeImprove reliabilityPoint-like light sourceElectric circuit arrangementsLight sourcePower flow

An apparatus for improving the performance of flashlights includes a substantially cylindrical housing (10) having a first end (12) and a second end (14). A battery cap (18) is operatively connected to the first end of the housing and functions to secure a series of batteries in place. A series (30) of light emitting diodes (LED) (32-48) are mounted within the flashlight housing at the end opposite the battery cap. The series of LEDs form an LED array which operates as the light source for the flashlight. A substantially cone-shaped optical assembly (50) extends outward from the second end of the housing and operates to focus and disperse the LED beam emitted by the LED array. The flashlight further includes an adjustable switch (56) disposed on the exterior of the housing. The switch is coupled to a variable resistor (58) which permits control over the light level and / or battery life. An electronic current regulator (70), enclosed by the housing, allows the LED beam to remain at a constant and desired light level, thereby increasing the efficiency of the battery life. A dynamic pulse control system (74) is coupled to the switch which takes advantage of the human eye perceiving the pulsed beam to be continuous. The pulse control also increases the peak current through the LED source.

Owner:GENERAL ELECTRIC CO

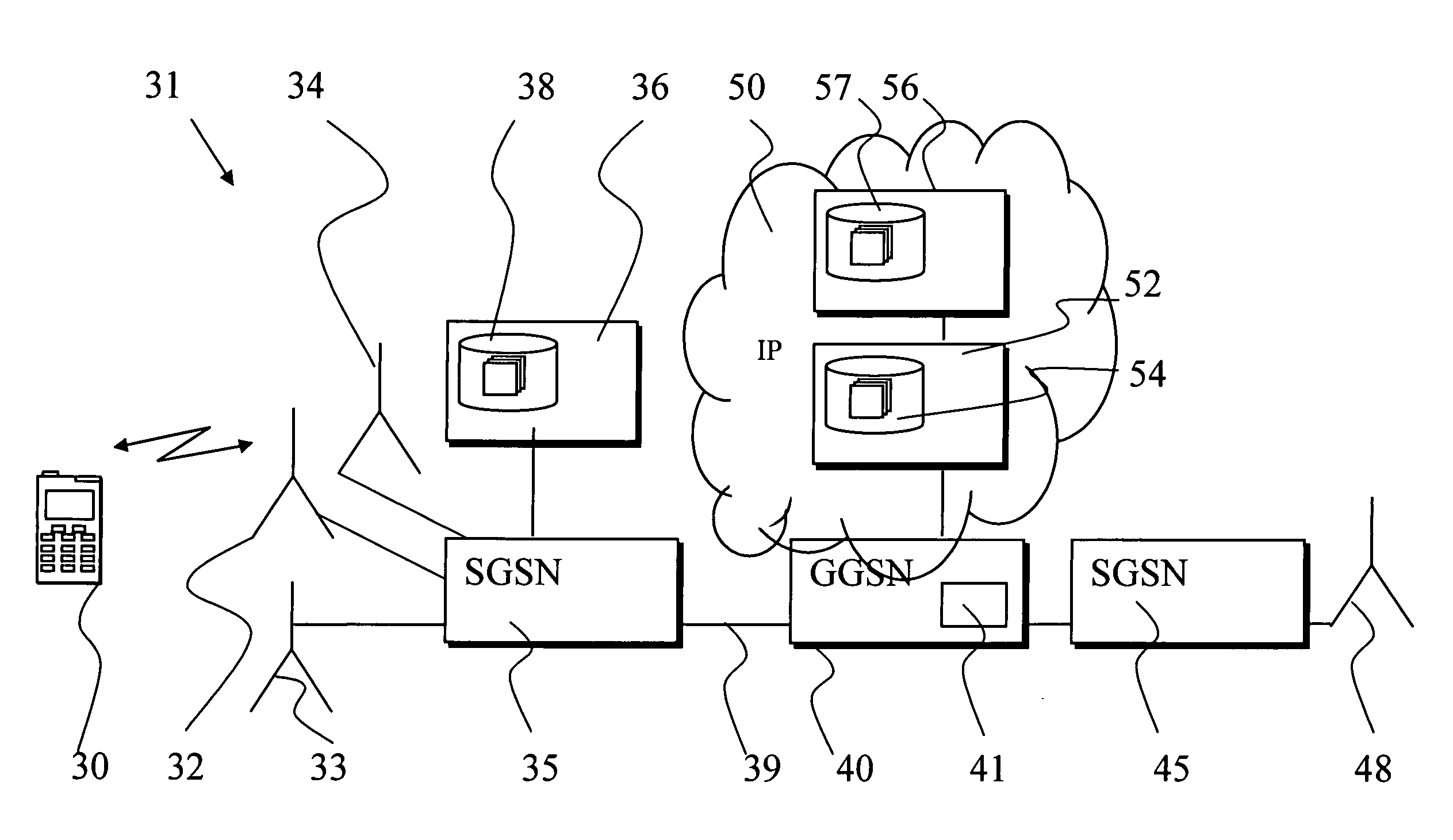

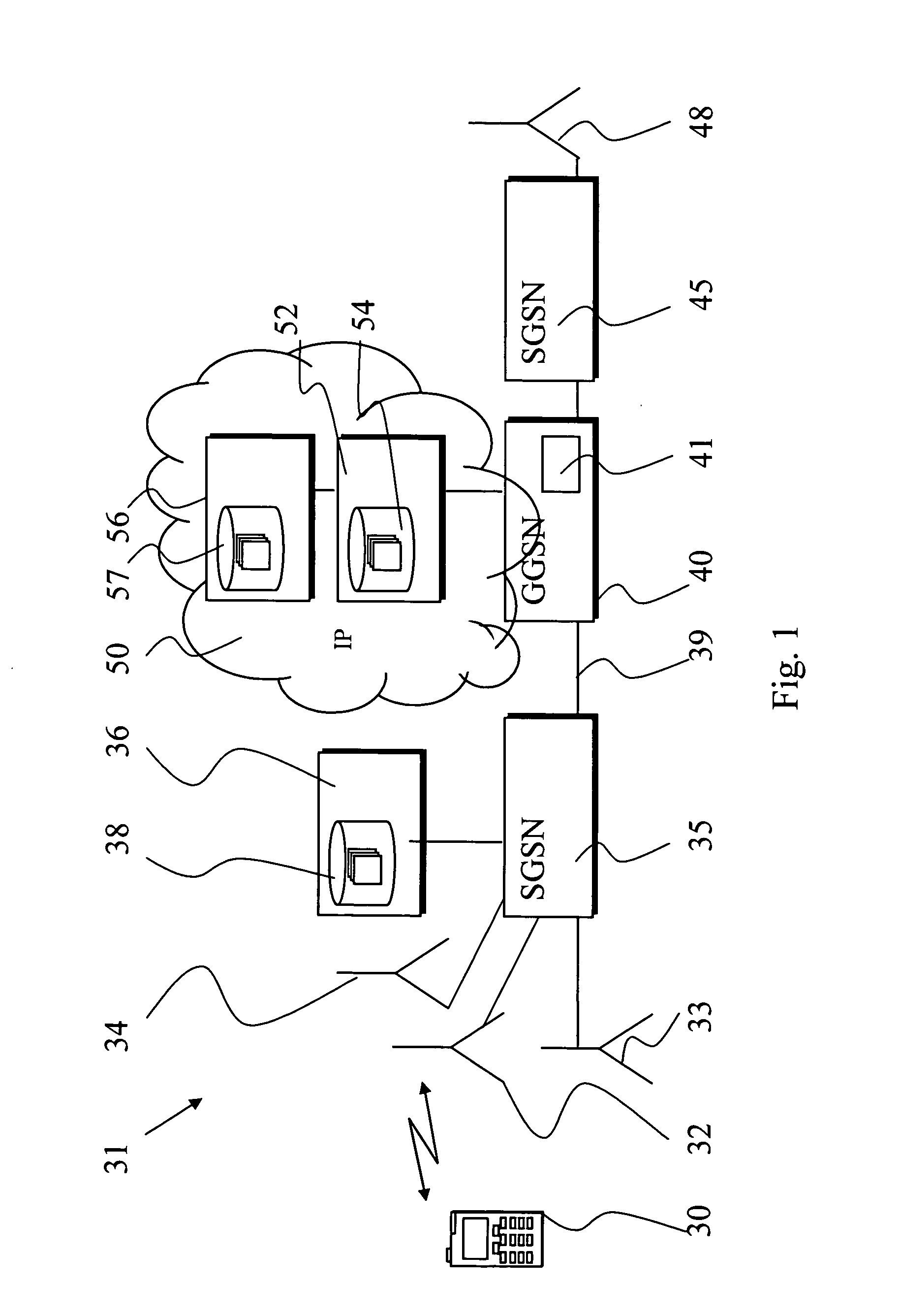

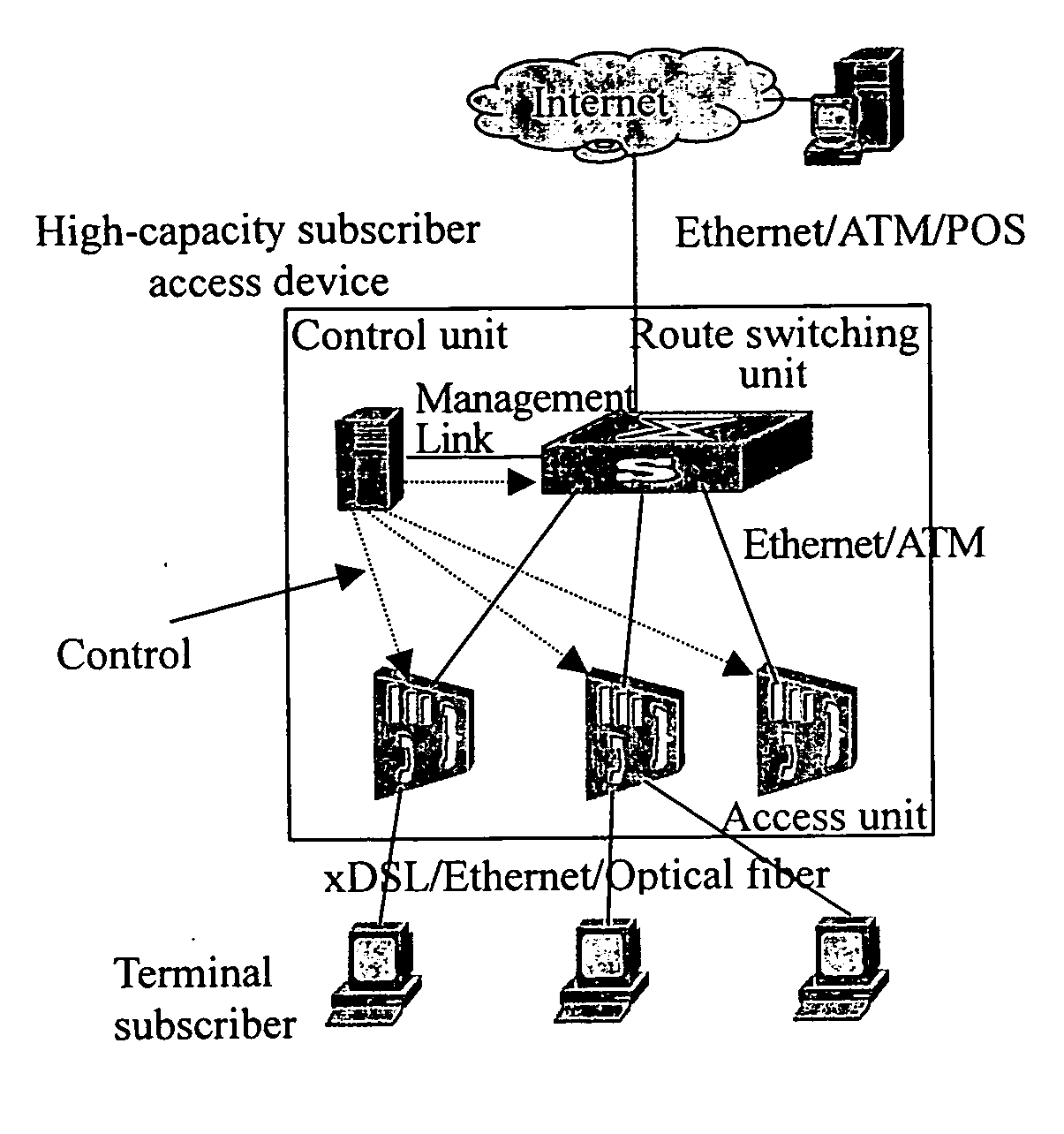

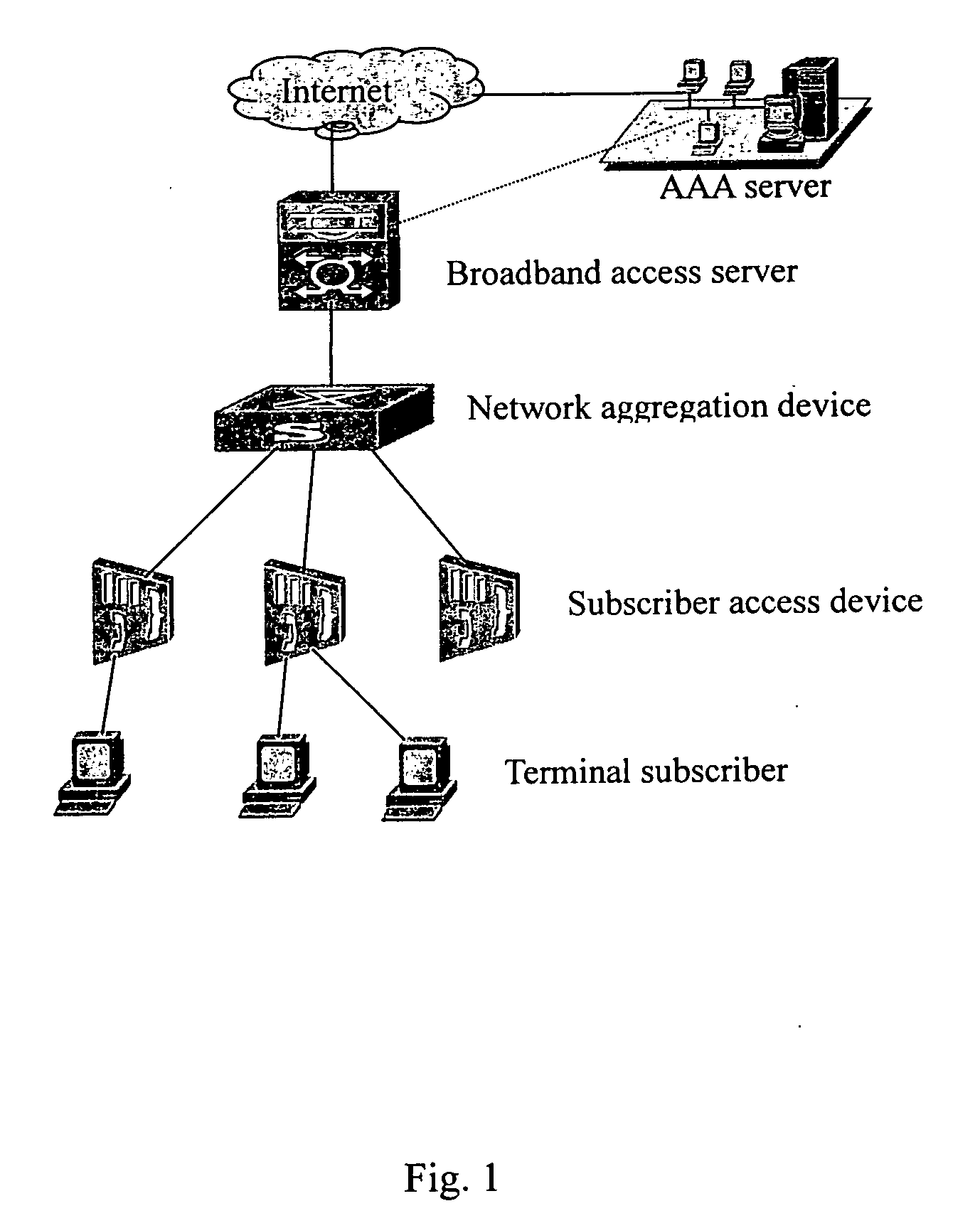

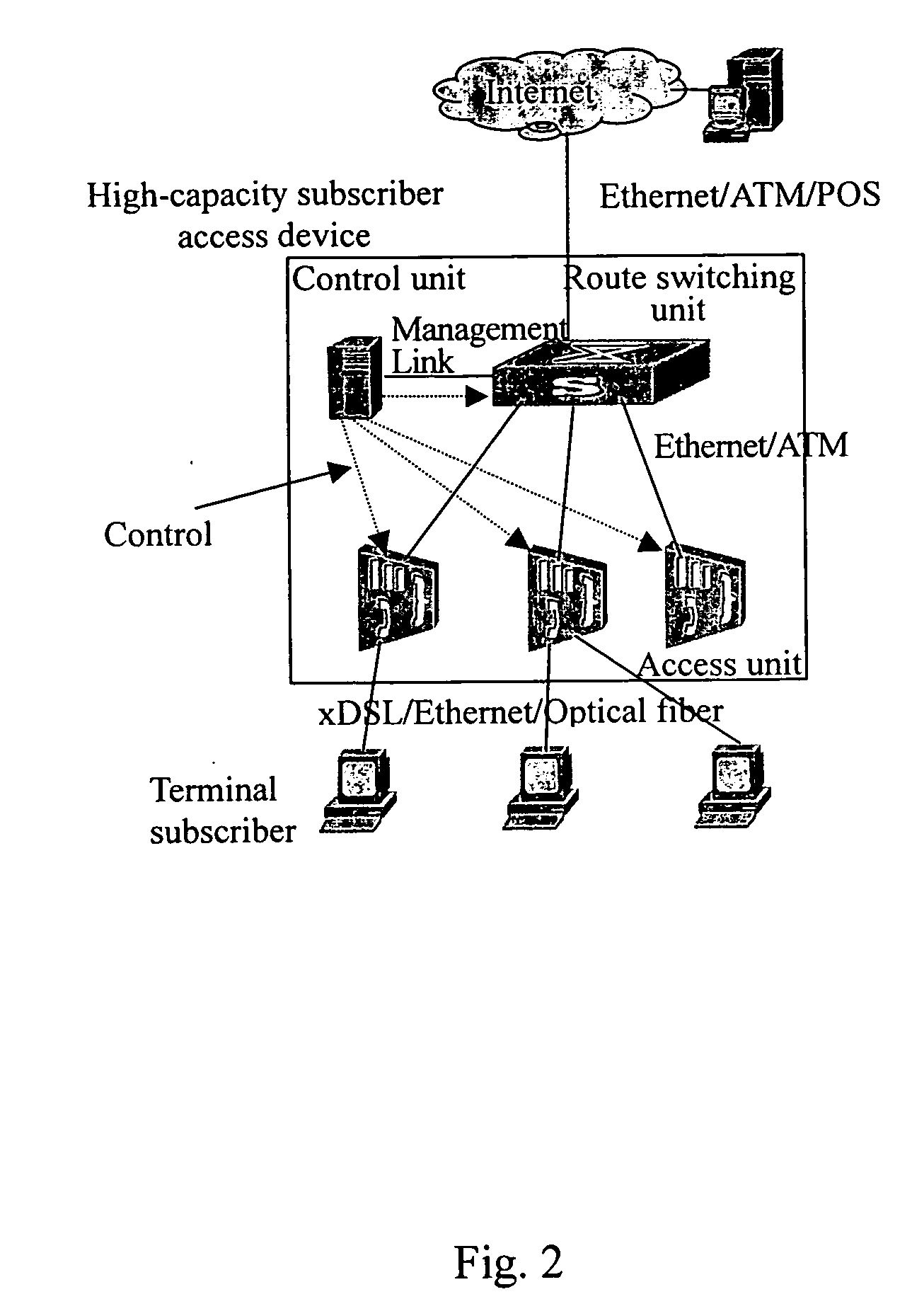

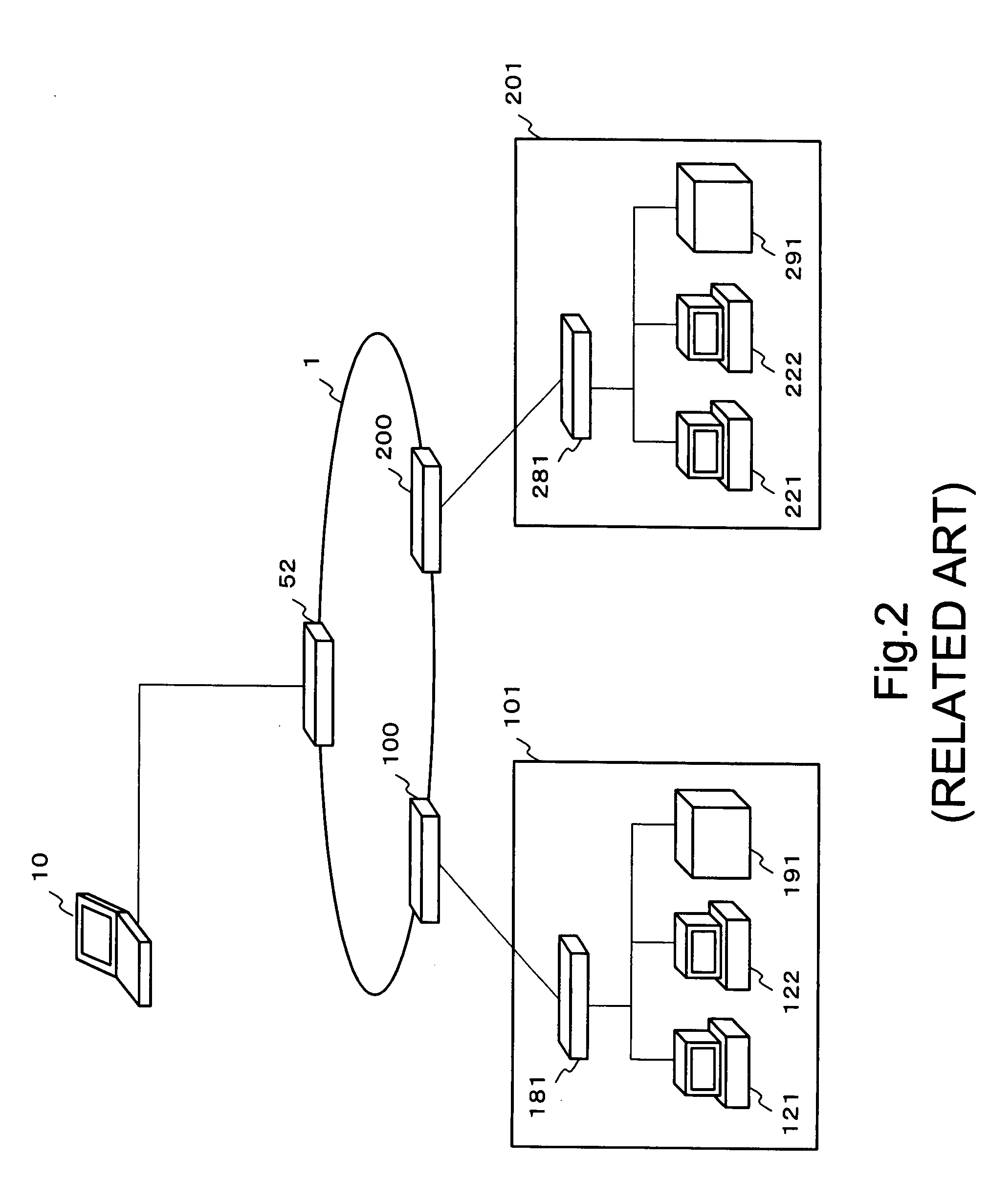

Broadband access method with great capacity and the system thereof

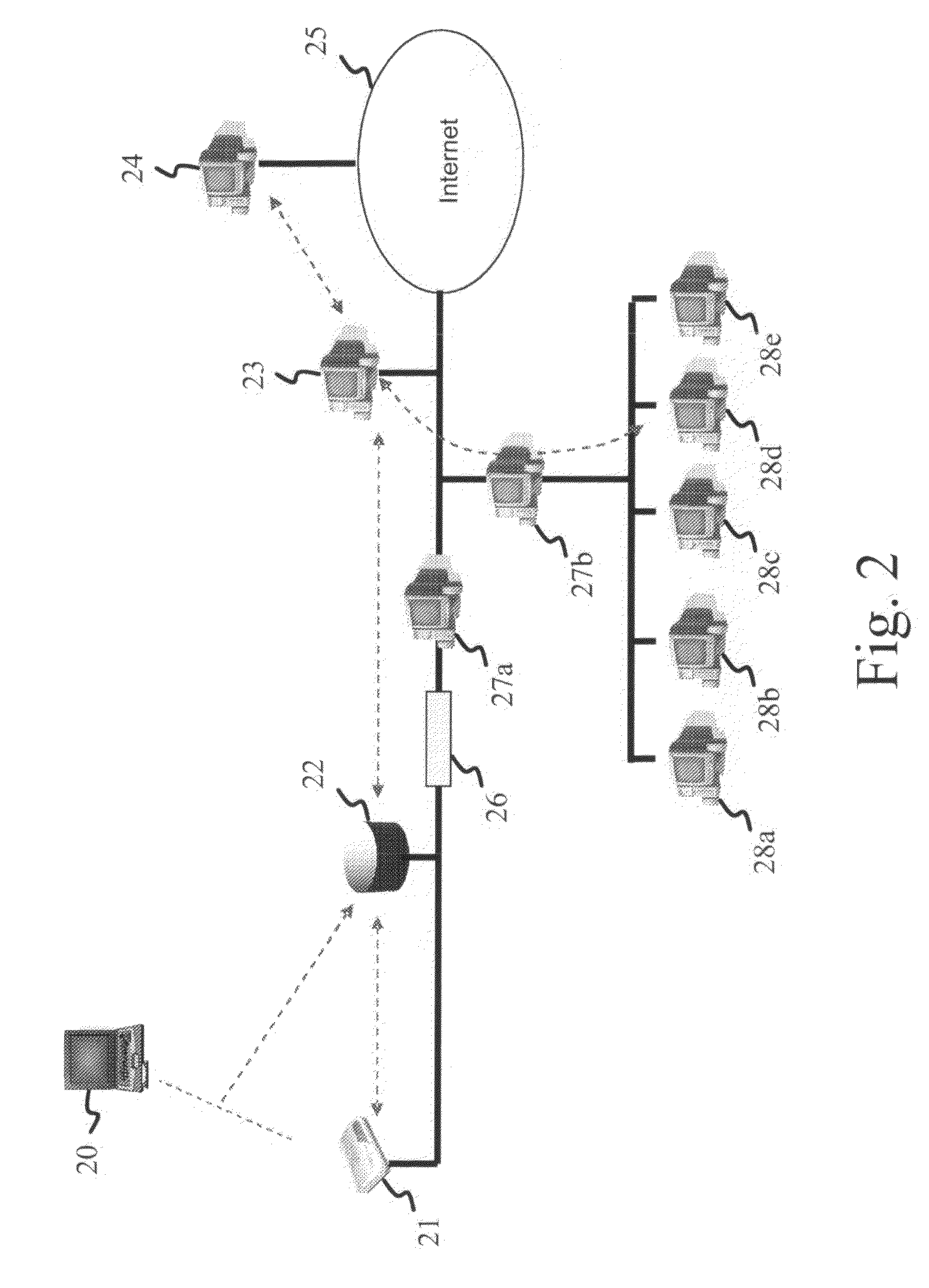

ActiveUS20070159971A1Low costReduce difficultyError preventionTransmission systemsAccess methodBroadband

The present invention discloses a high-capacity broadband access method, comprising: a broadband subscriber initiating an access request to an access unit; the access unit sending the subscriber authentication information to a control unit via a route switching unit; the control unit authenticating the subscriber with an internal or external authentication, authorization and accounting server, returning the authentication result to the access unit via the route switching unit, and sending the configuration information to the accessed subscriber; the route switching unit and the access unit accomplishing configuration of the subscriber information, allocating corresponding resource to the subscriber, and establishing a data channel for network access of the subscriber. The present invention also discloses a high-capacity broadband access device and a system thereof.

Owner:HUAWEI TECH CO LTD

Apparatus, method and program product for automatically distributing power to modules inserted in live chassis

InactiveUS6976112B2Likelihood of equipment damage dueCost of operationData switching detailsVolume/mass flow measurementDistributed powerEmbedded system

When a blade and / or interconnect device is inserted into the chassis of a powered or live server the procedure is known as hot-plugging. Before power is applied to the hot-plugged blade and / or interconnect device the fabric type of already installed blades and / or interconnect devices is correlated with fabric types of newly hot-plugged blade and / or interconnect device. Depending upon results of the correlation, power to the hot-plugged blade and / or interconnect device is allowed or denied.

Owner:INT BUSINESS MASCH CORP

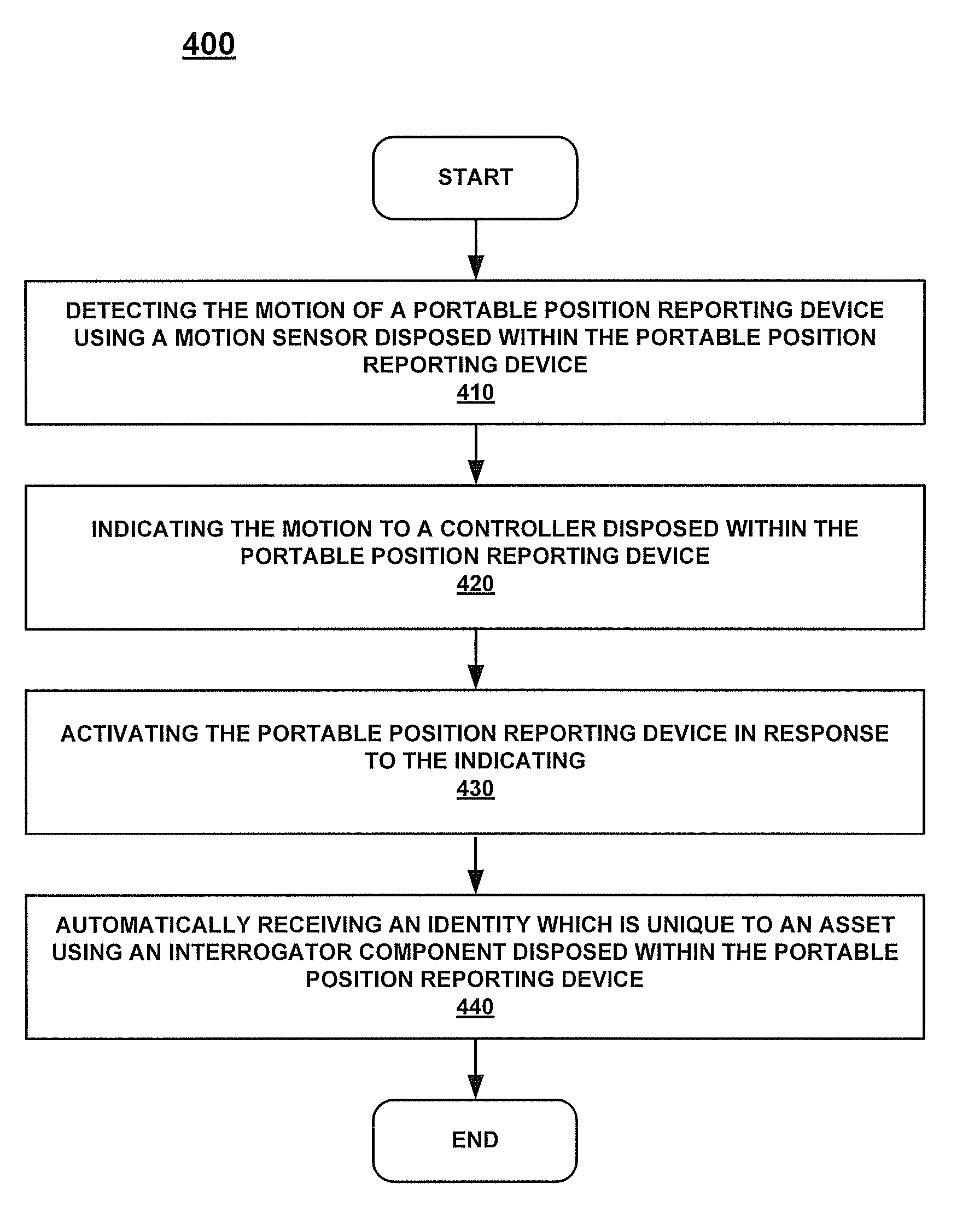

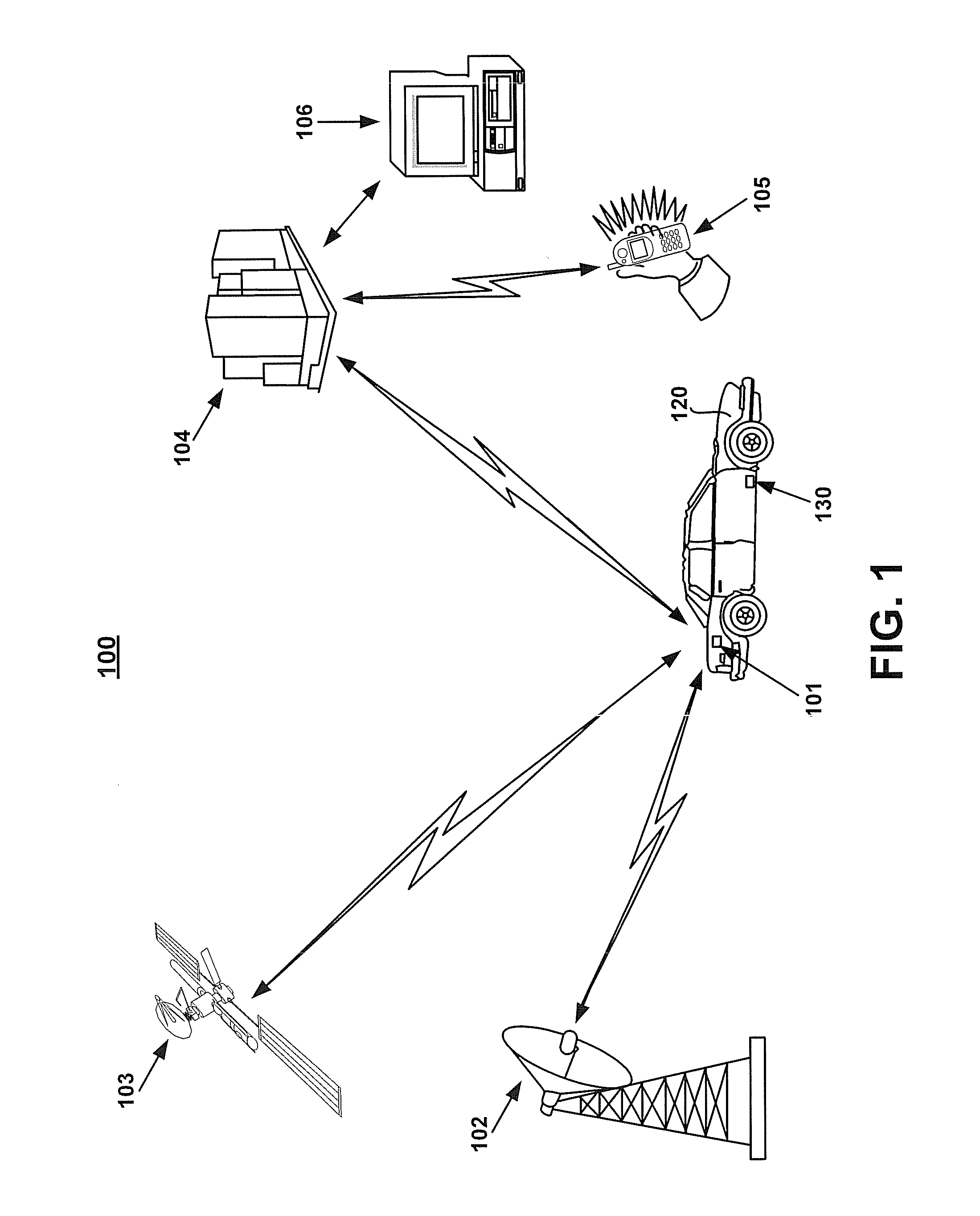

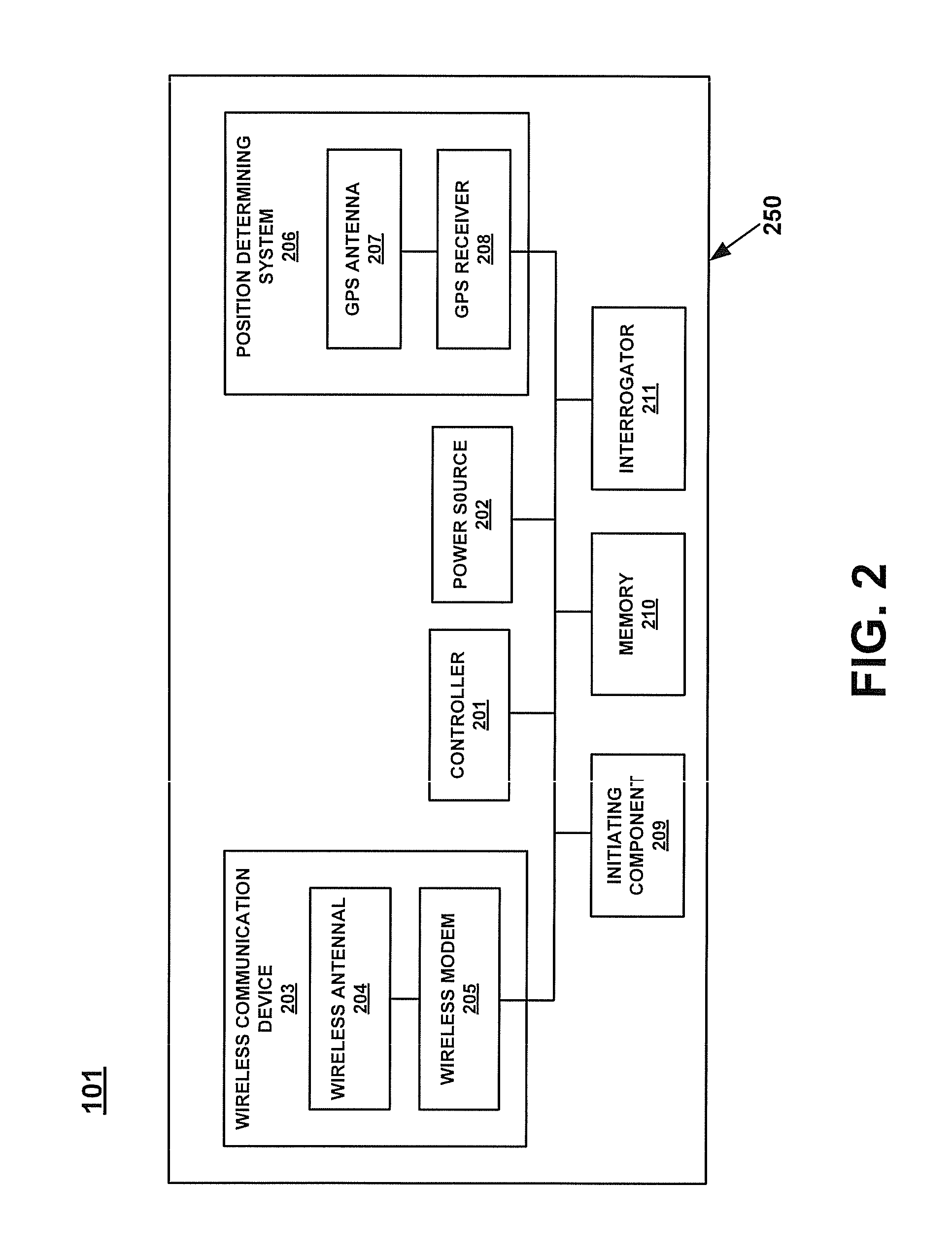

Portable motion-activated position reporting device

ActiveUS7398153B2Minimal installation and maintenanceEasy to moveRoad vehicles traffic controlPosition fixationEngineeringDevice Sensor

The present invention is a portable motion-activated position reporting device. In one embodiment, a controller is coupled with an interrogator component, a position determining component, a wireless communications component, and an initiating component. In one embodiment, the initiating component detects motion of the position reporting device and generates a signal to the controller indicating the motion. The controller, in response to the signal, activates the interrogator component and the position reporting device.

Owner:TRIMBLE NAVIGATION LTD

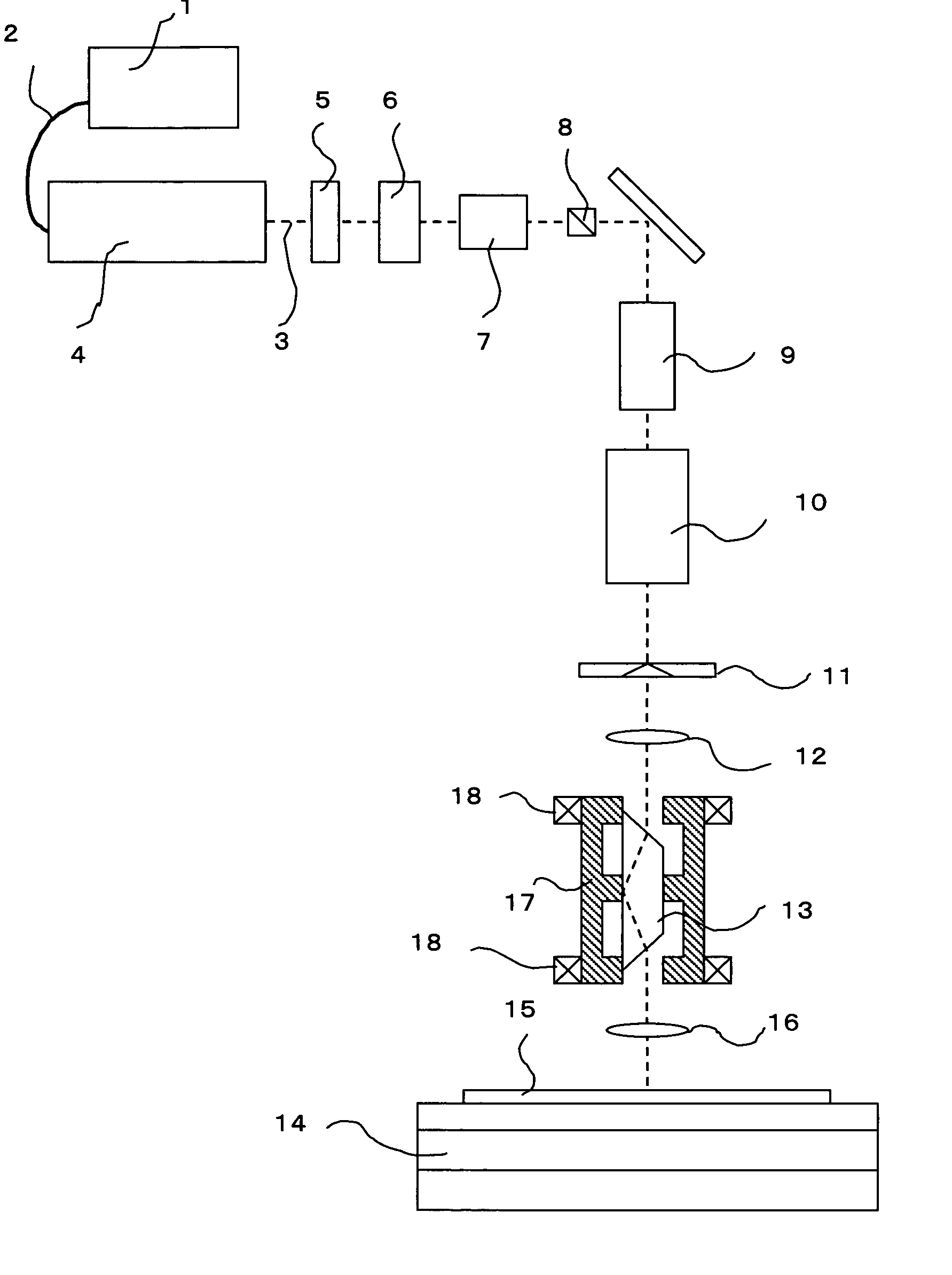

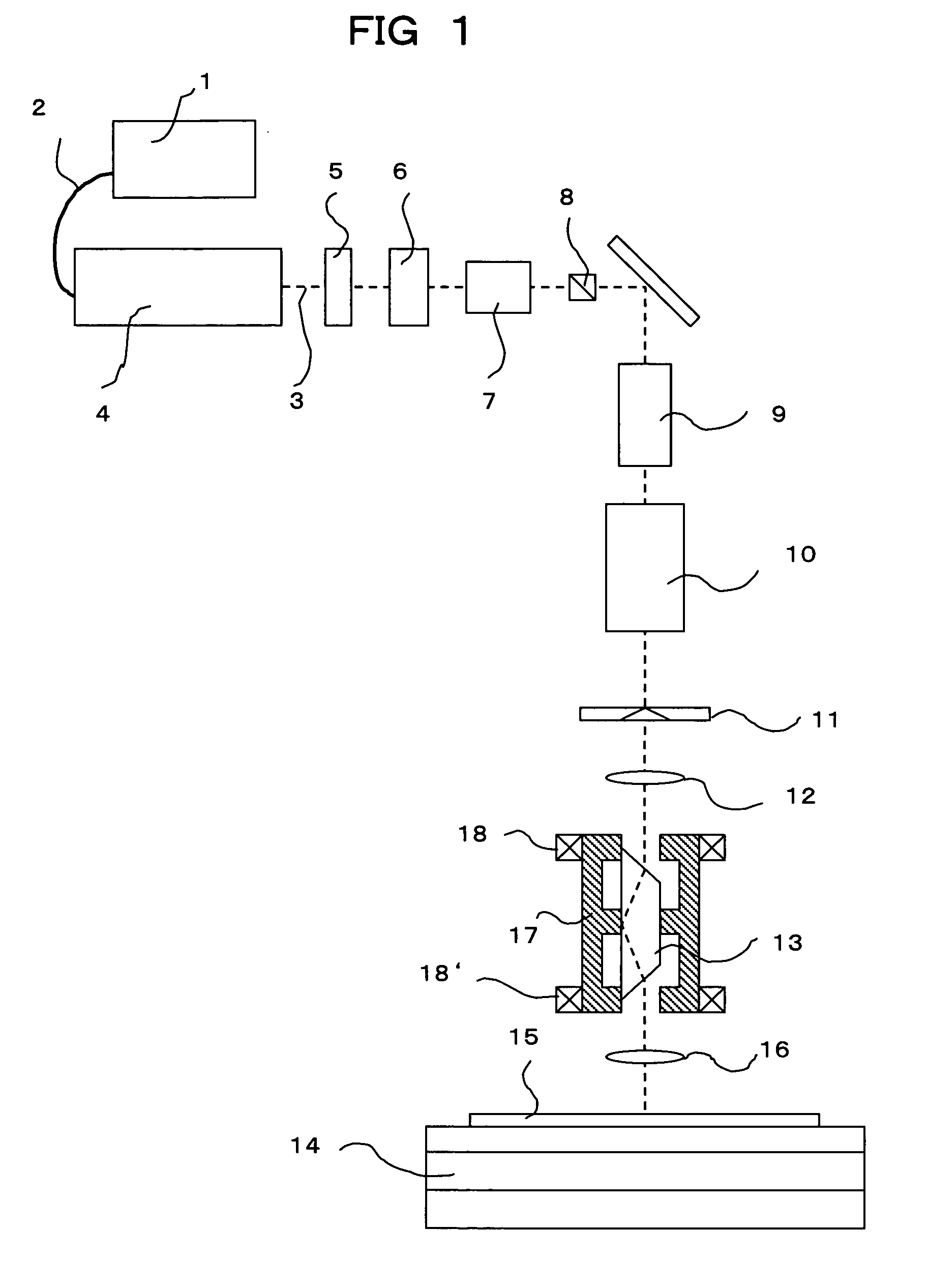

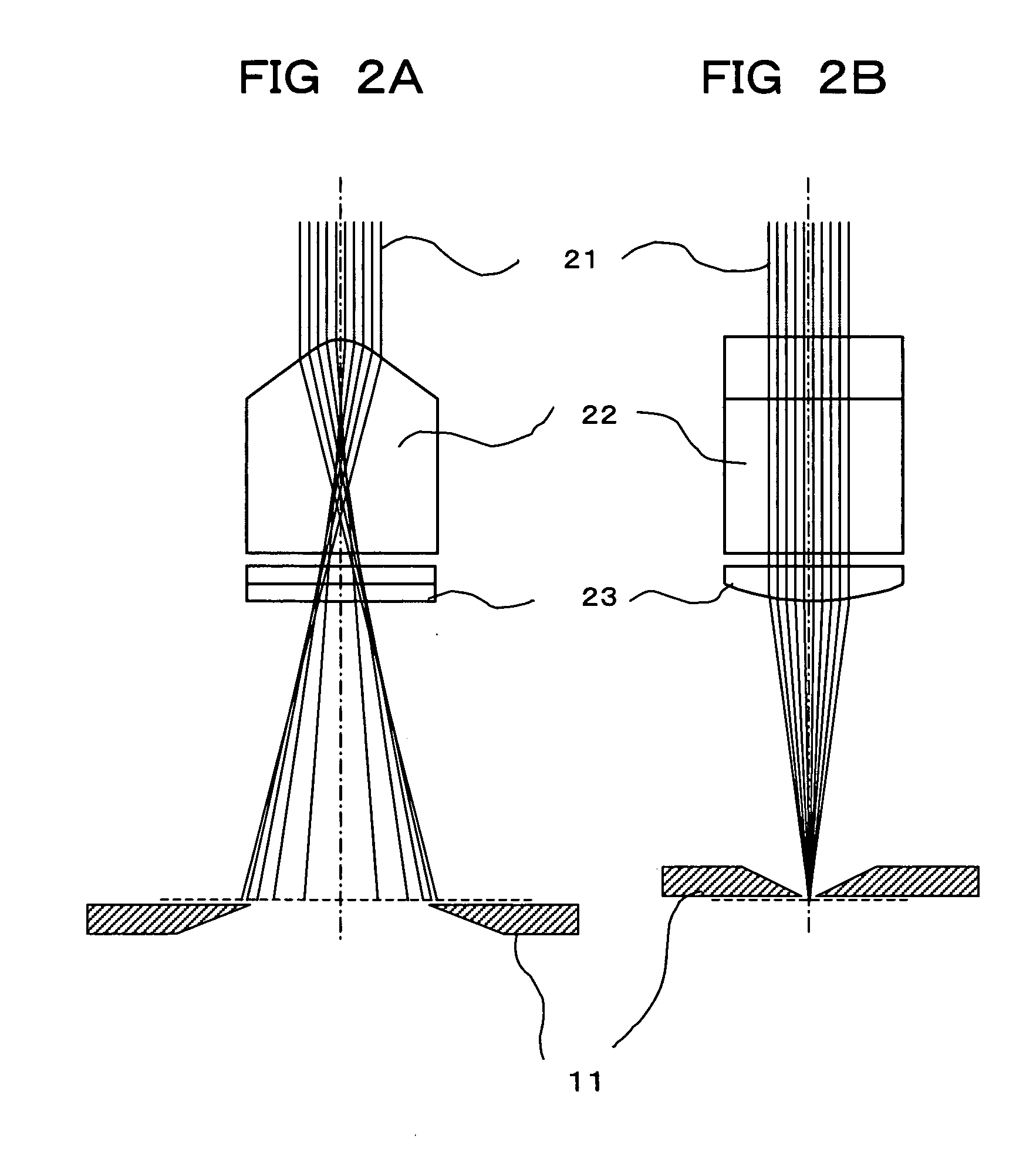

Laser annealing apparatus and annealing method of semiconductor thin film using the same

InactiveUS20050170572A1Prolong lifeCost of apparatus can be reducedLaser detailsElectrode and associated part arrangementsOptical axisLight beam

A laser beam temporally modulated in amplitude by a modulator and shaped into a long and narrow shape by a beam shaper is rotated around the optical axis of an image rotator inserted between the beam shaper and a substrate. Thus, the longitudinal direction of the laser beam having the long and narrow shape is rotated around the optical axis on the substrate. In order to perform annealing in a plurality of directions on the substrate, the laser beam shaped into the long and narrow shape is rotated on the substrate while a stage mounted with the substrate is moved only in two directions, that is, X- and Y-directions. In such a manner, the substrate can be scanned at a high speed with a continuous wave laser beam modulated temporally in amplitude and shaped into a long and narrow shape, without rotating the substrate. Thus, a semiconductor film can be annealed.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

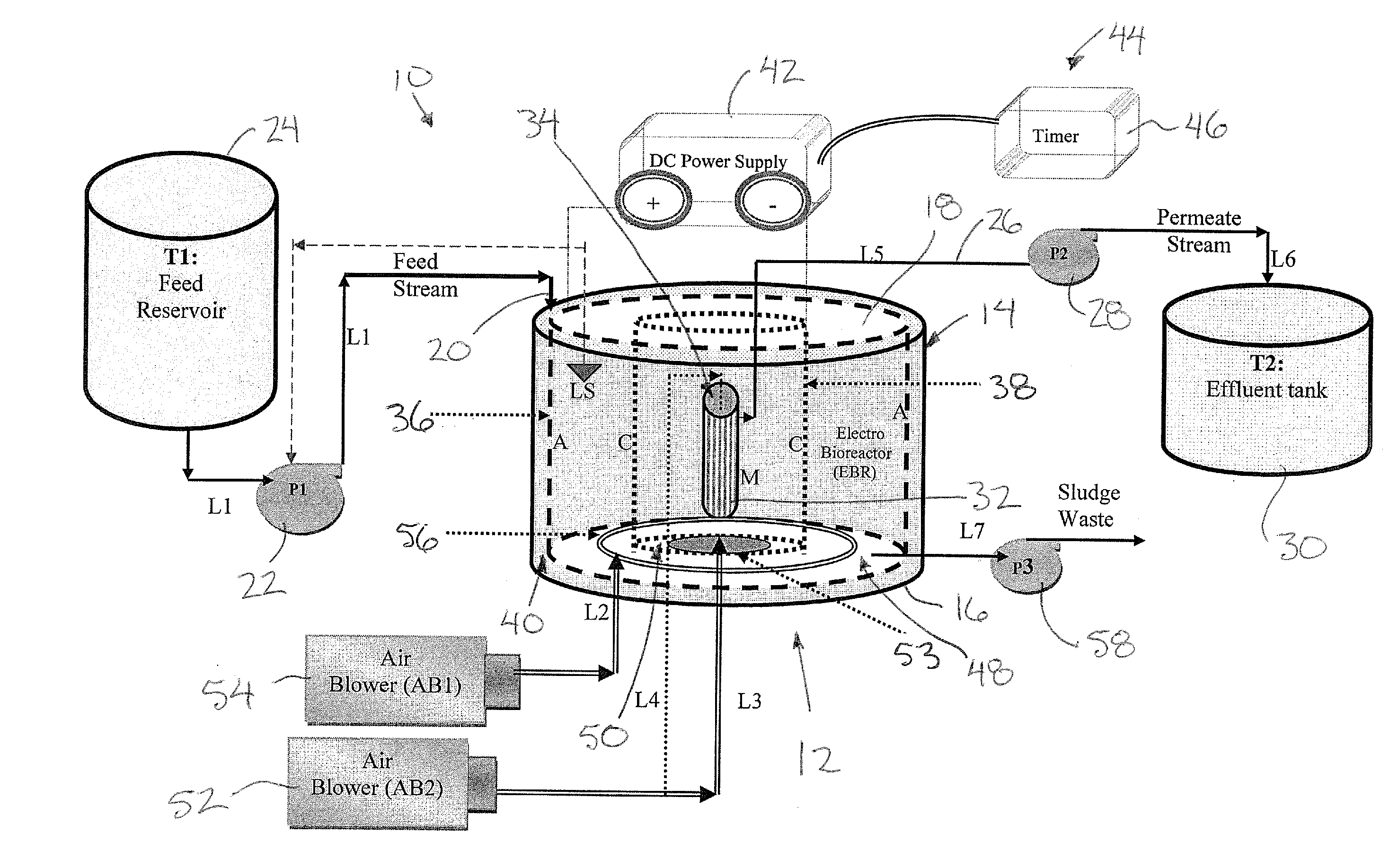

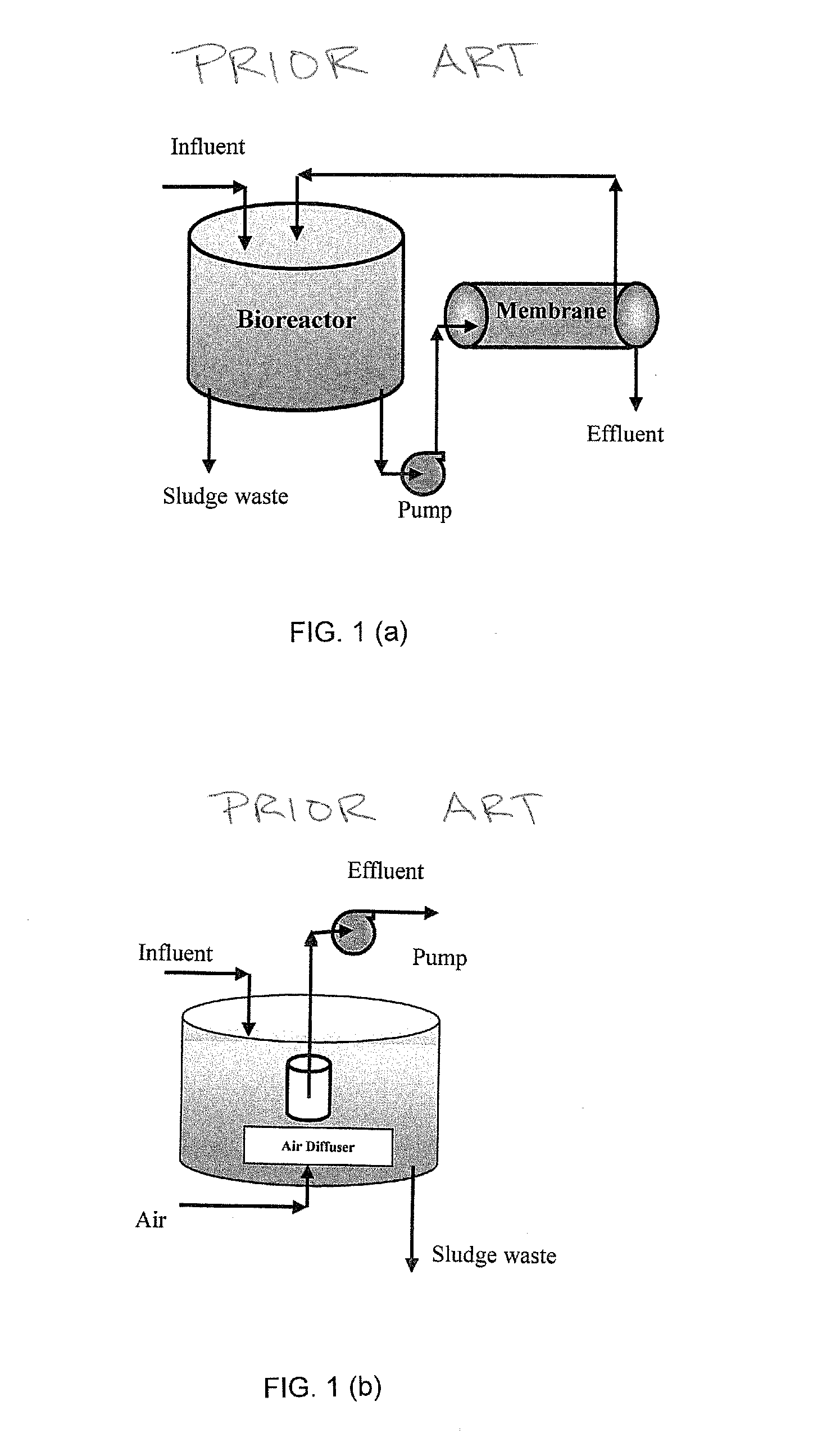

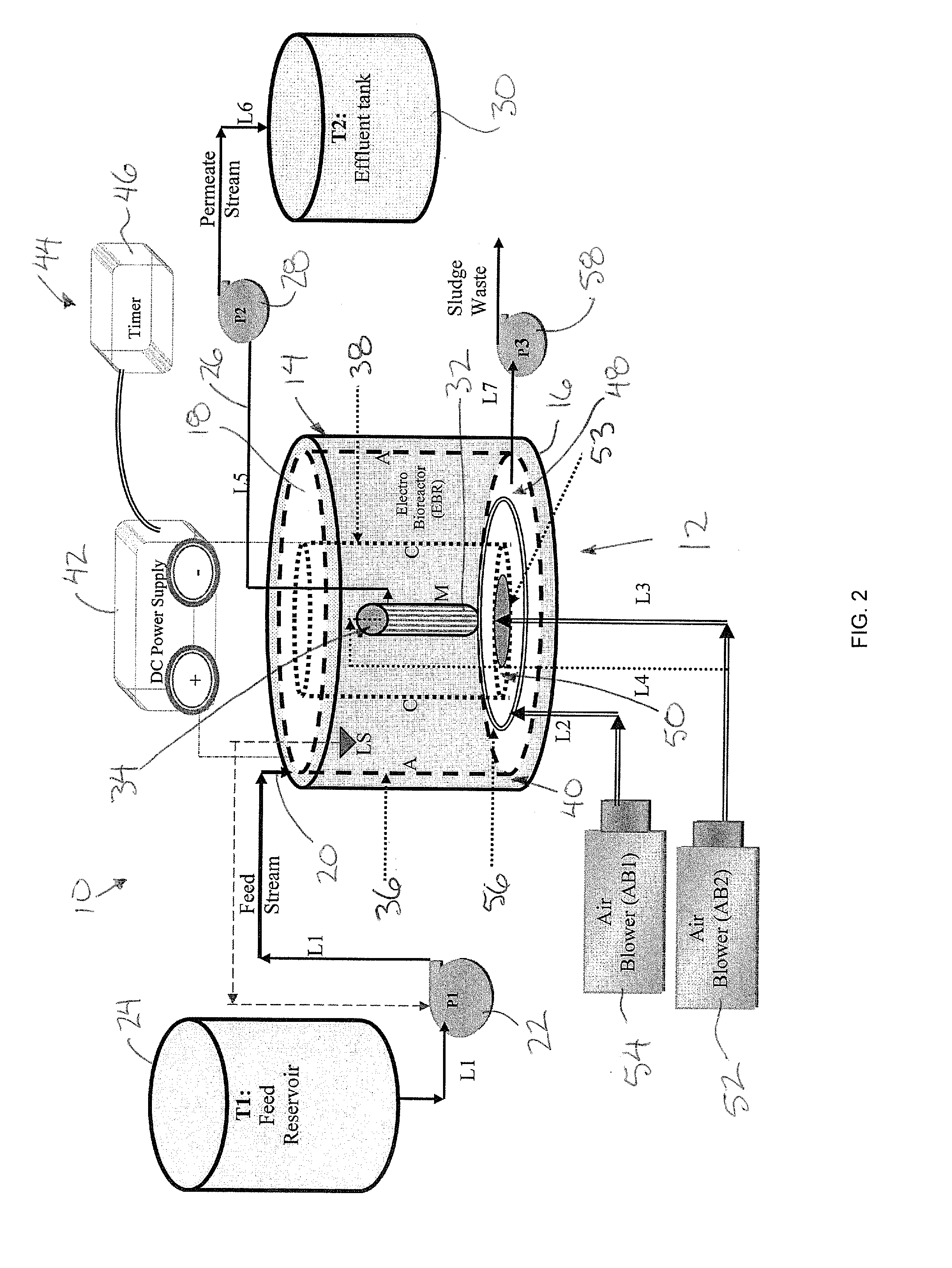

Wastewater Treatment System and Method

ActiveUS20100051542A1Reduce operating costsQuality improvementTreatment using aerobic processesTreatment by combined electrochemical biological processesFiltration membraneMedicine

A wastewater treatment system and method comprises a treatment chamber having a filtration membrane spanning an effluent outlet of the chamber and a pair of electrodes in the treatment chamber so as to be in communication with the wastewater. An electrical potential difference is applied between the electrodes such that one of the electrodes functions as an anode and one of the electrodes functions as a cathode. A flow of fluid is induced out of the treatment chamber through the filtration membrane to the effluent outlet. Accordingly the treatment chamber is arranged to biologically treat the wastewater, electrochemically treat the wastewater and mechanically filter the wastewater through the filtration membrane commonly therein.

Owner:ELEKTOROWICZ MARIA +2

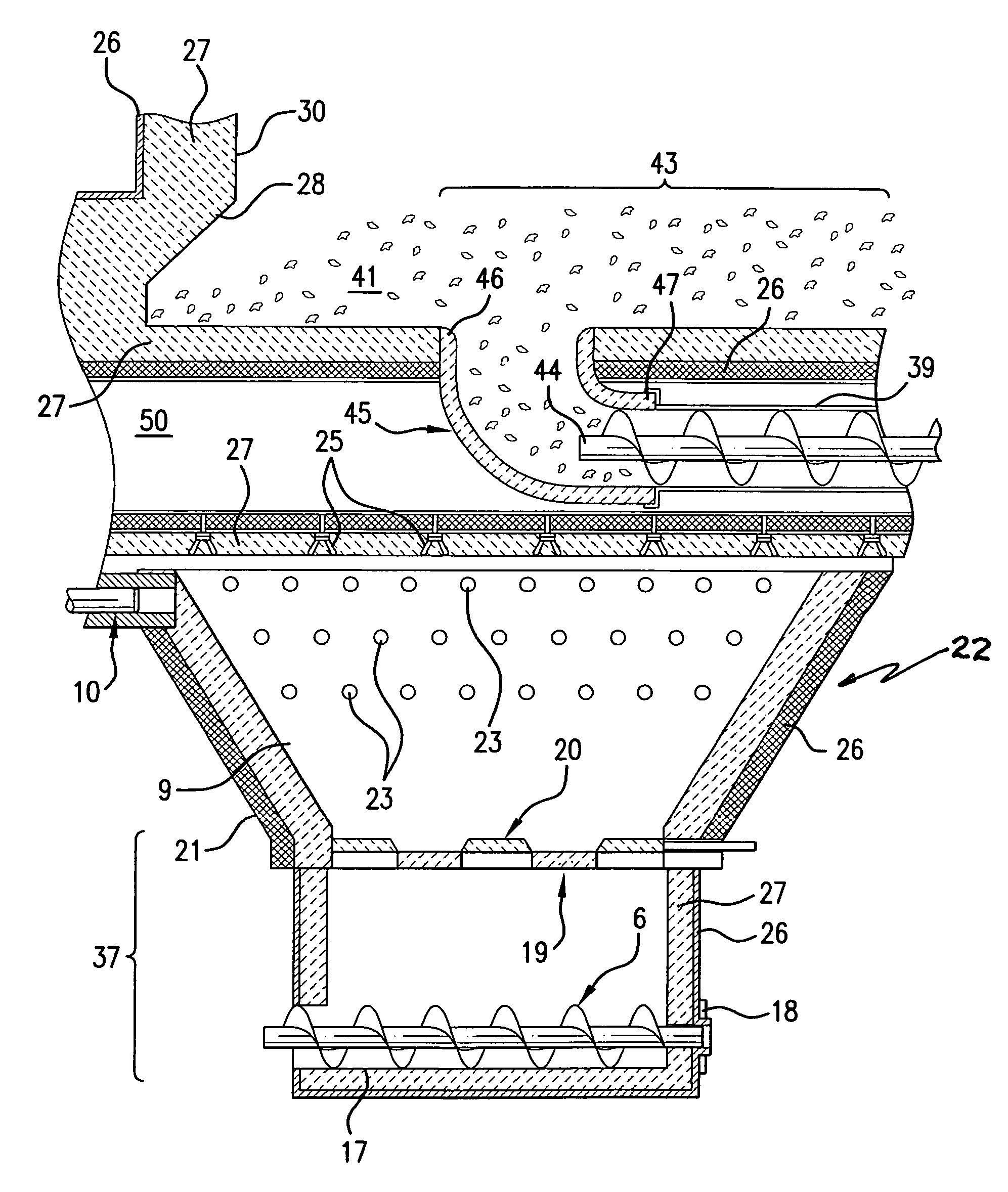

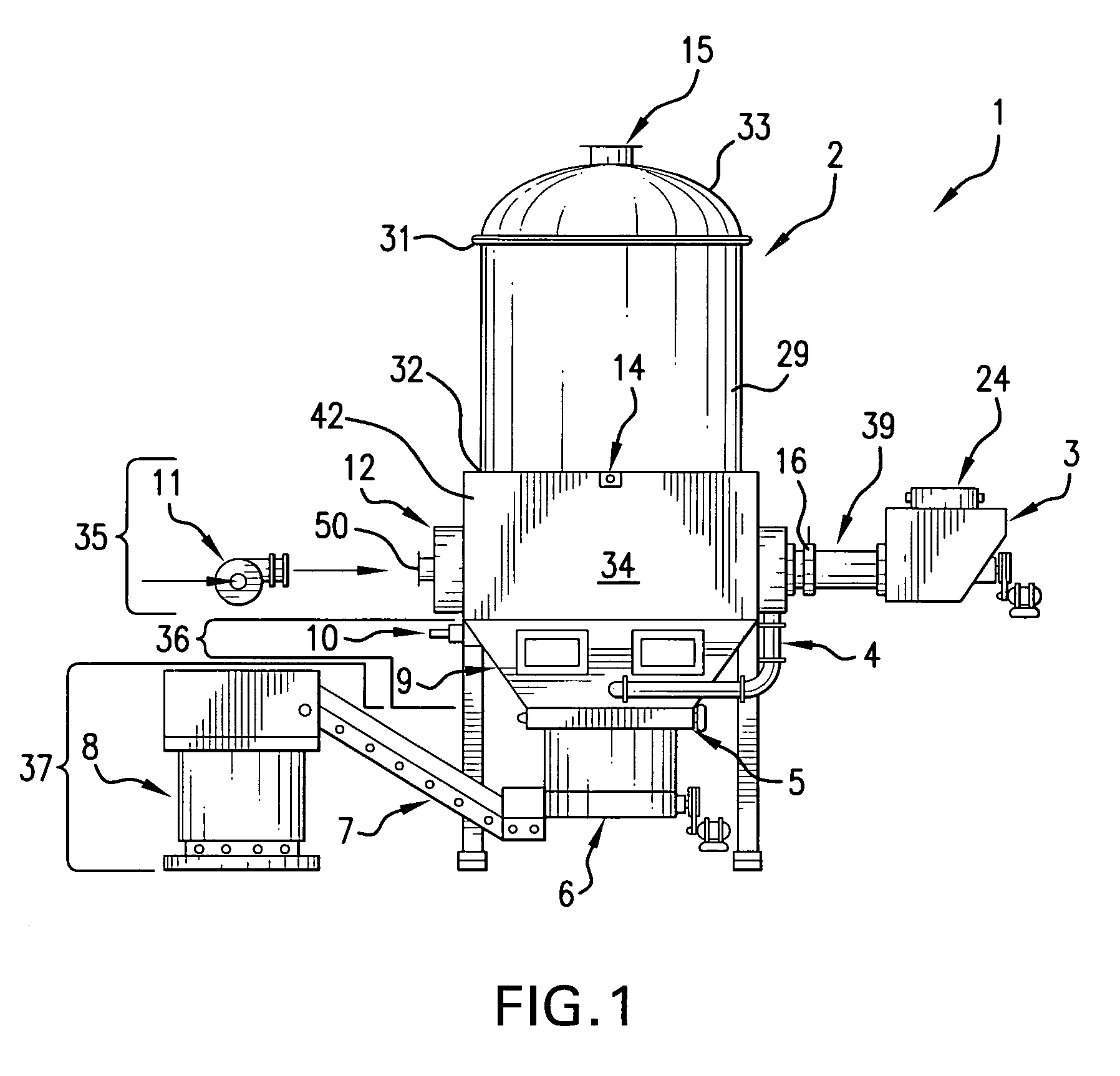

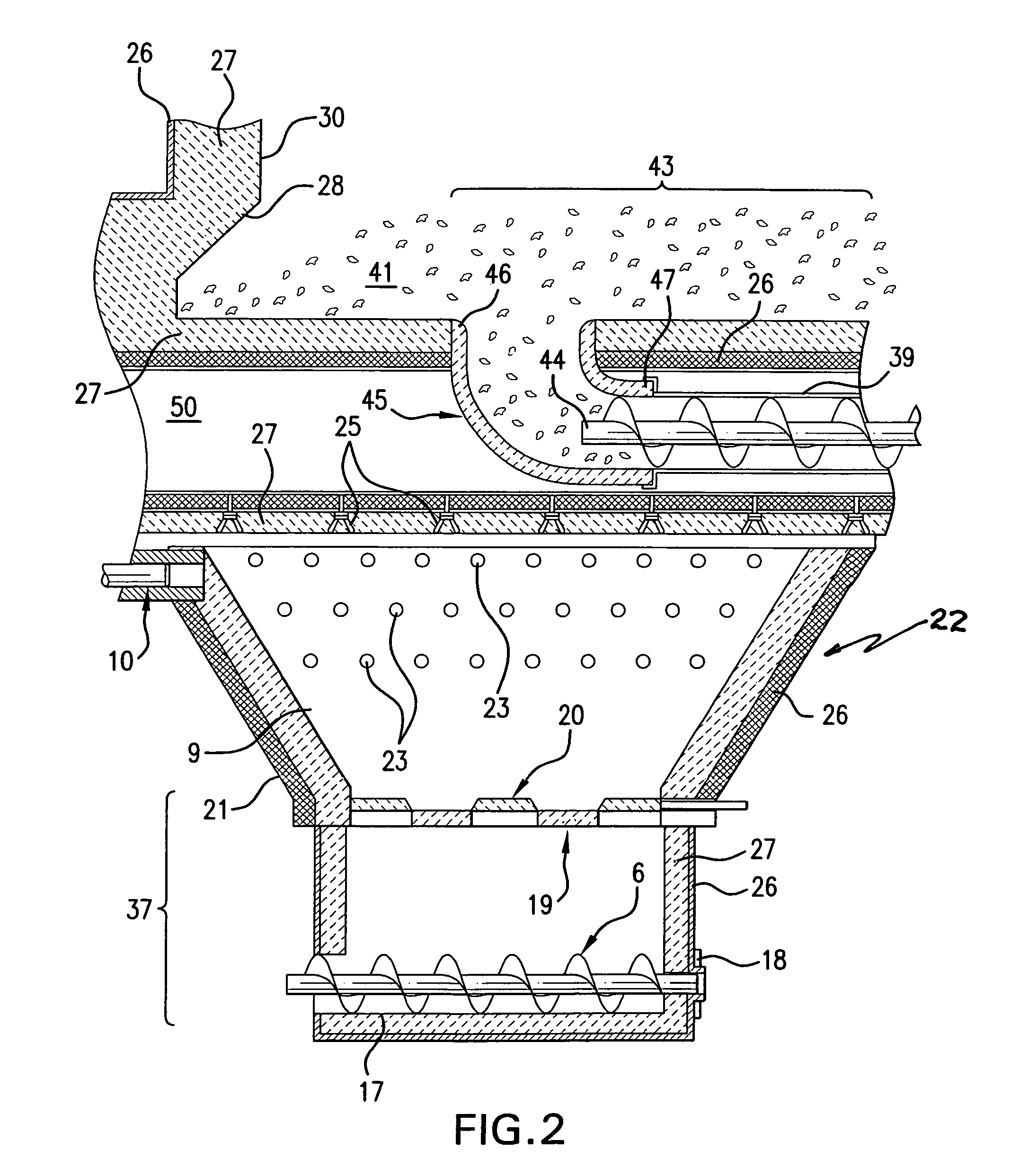

Gasifier and gasifier system for pyrolizing organic materials

InactiveUS7976593B2Lower buildCost of operationMuffle furnacesGasifier mechanical detailsMechanical engineeringEngineering

A gasifier and gasifier system based on the gasifier, which contains as a major component, a novel feed system for feeding organic materials into the burn pile of the gasifier. The gasifier feed system is a horizontal auger driven feed system that feeds directly through a ceramic elbow into the furnace without having to auger the feed through significant vertical elevations.

Owner:HEAT TRANSFER INT

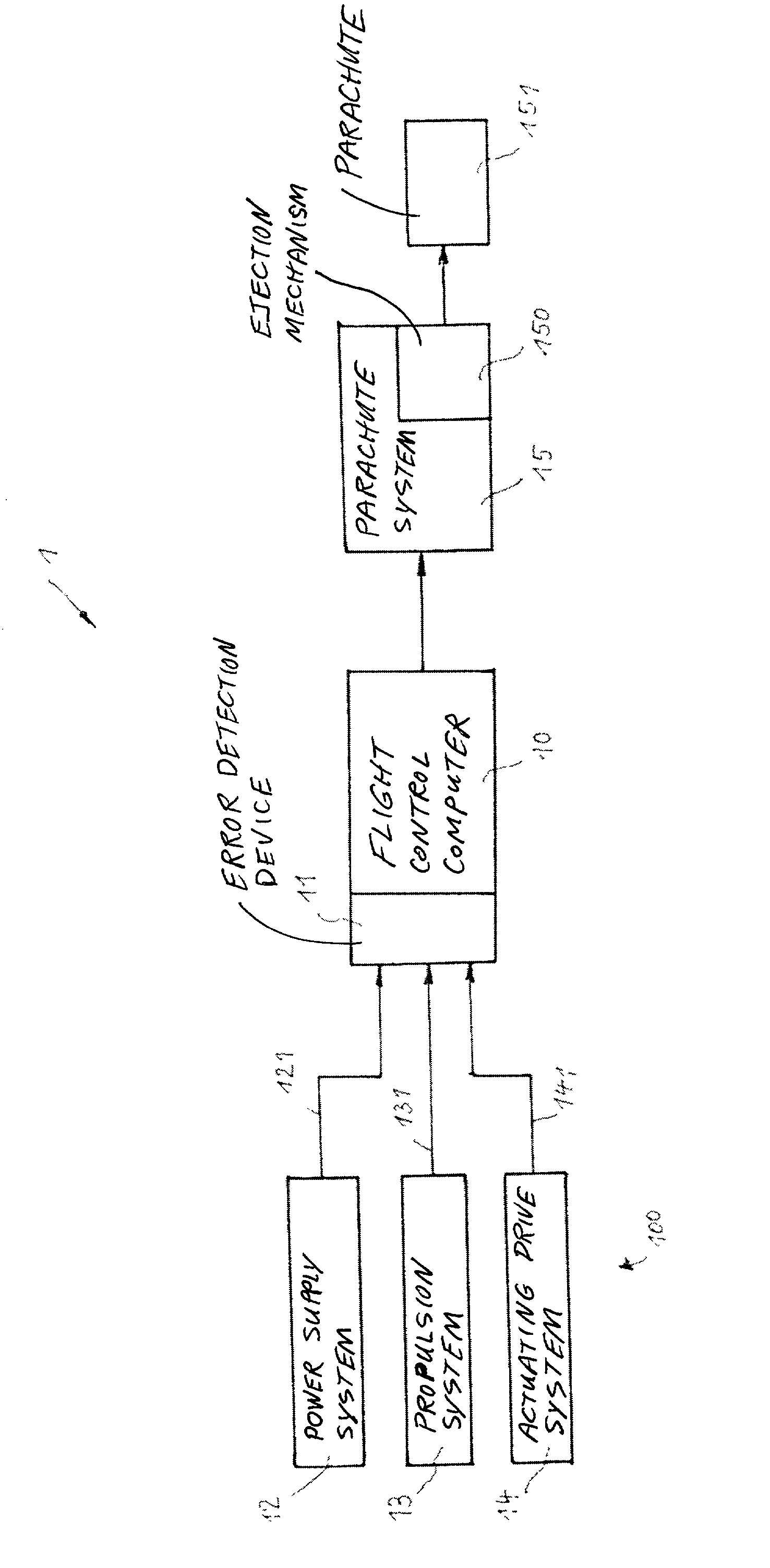

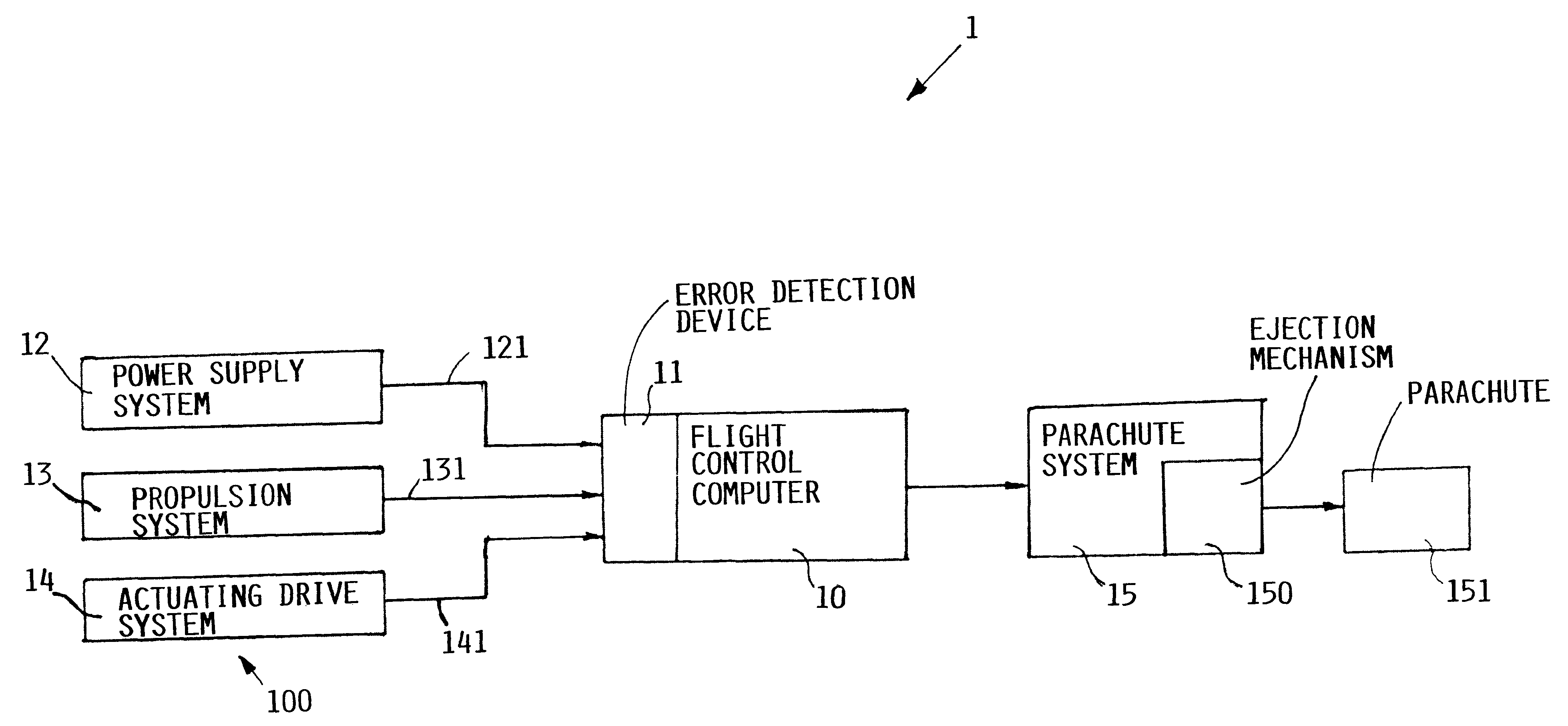

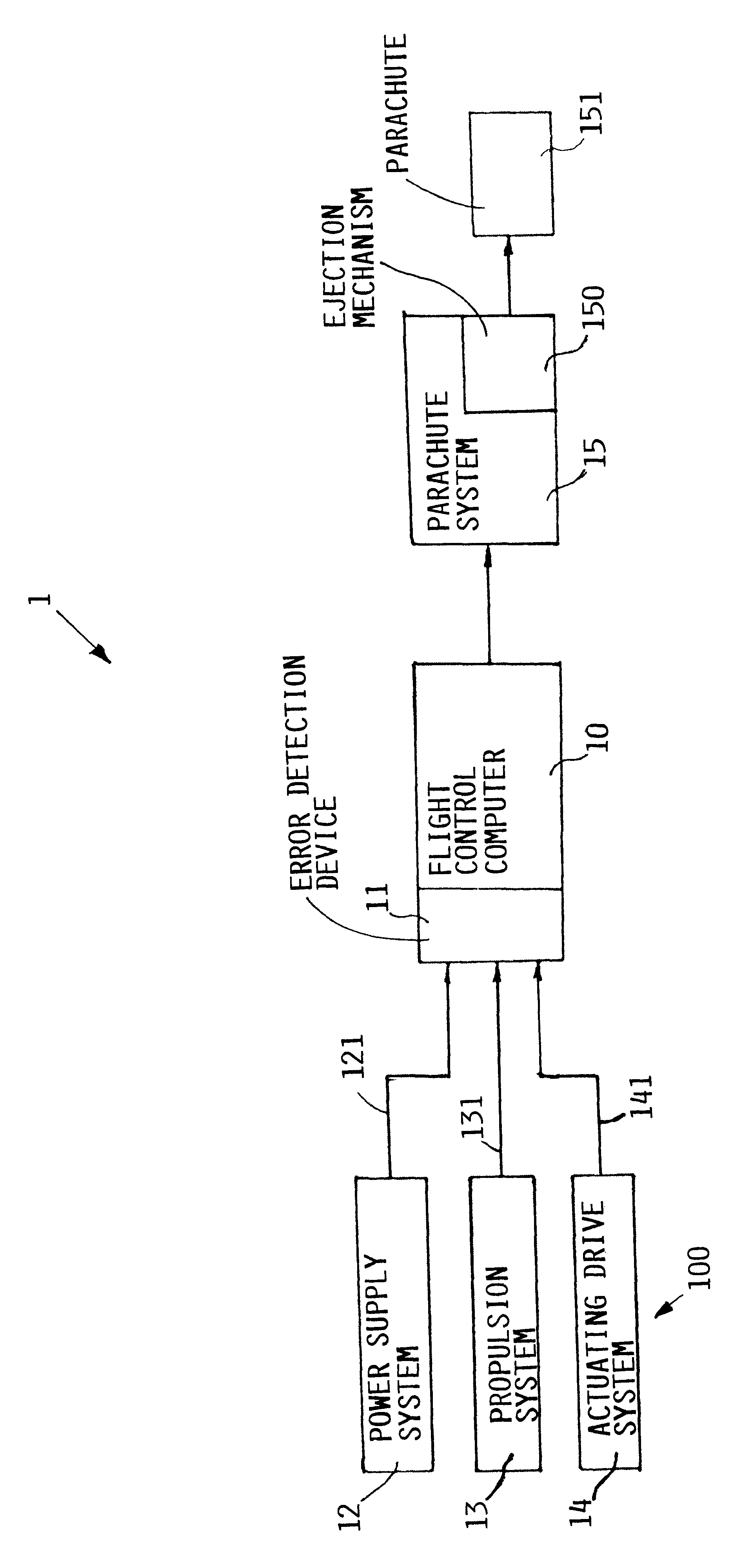

Method for deploying a parachute on a drone

InactiveUS20010048050A1Safe recoveryReduce riskUnmanned aerial vehiclesNon-canopied parachutesControl signalUncrewed vehicle

A flying drone includes a flight control computer, a parachute system with a parachute, a power supply system, a propulsion system, and an actuating drive system, without any of these systems being redundantly duplicated. To prevent uncontrolled crashing of the drone due to a critical error of any subsystem, signals or data are supplied from the power supply system, the propulsion system, and the actuating drive system, to an error detection or recognition device, which detects defined errors or error combinations in the provided signals or data and then supplies a deployment signal to the parachute system, which responsively generates a control signal that triggers an ejection mechanism to eject the parachute.

Owner:EUROCOPTER DEUT GMBH

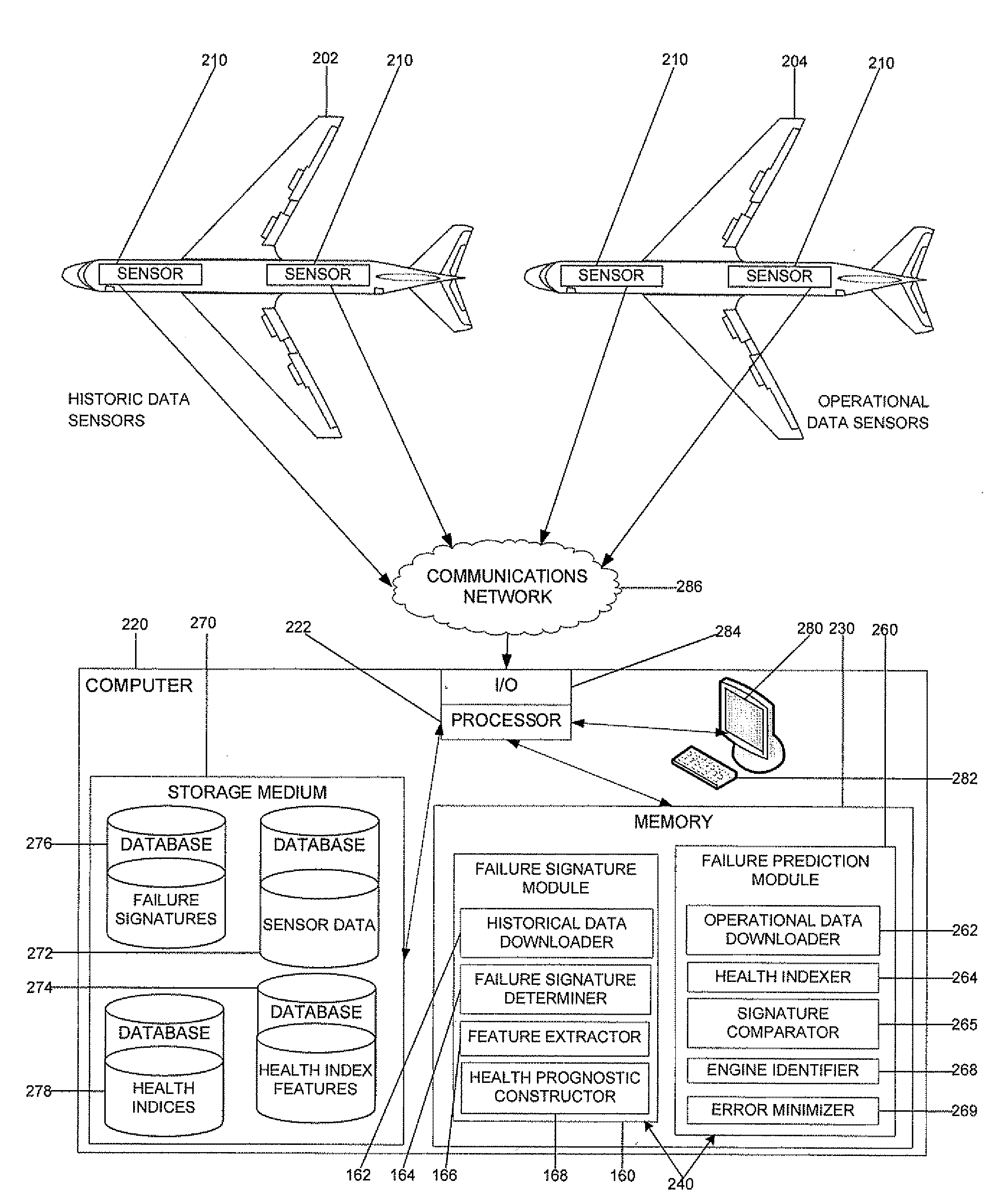

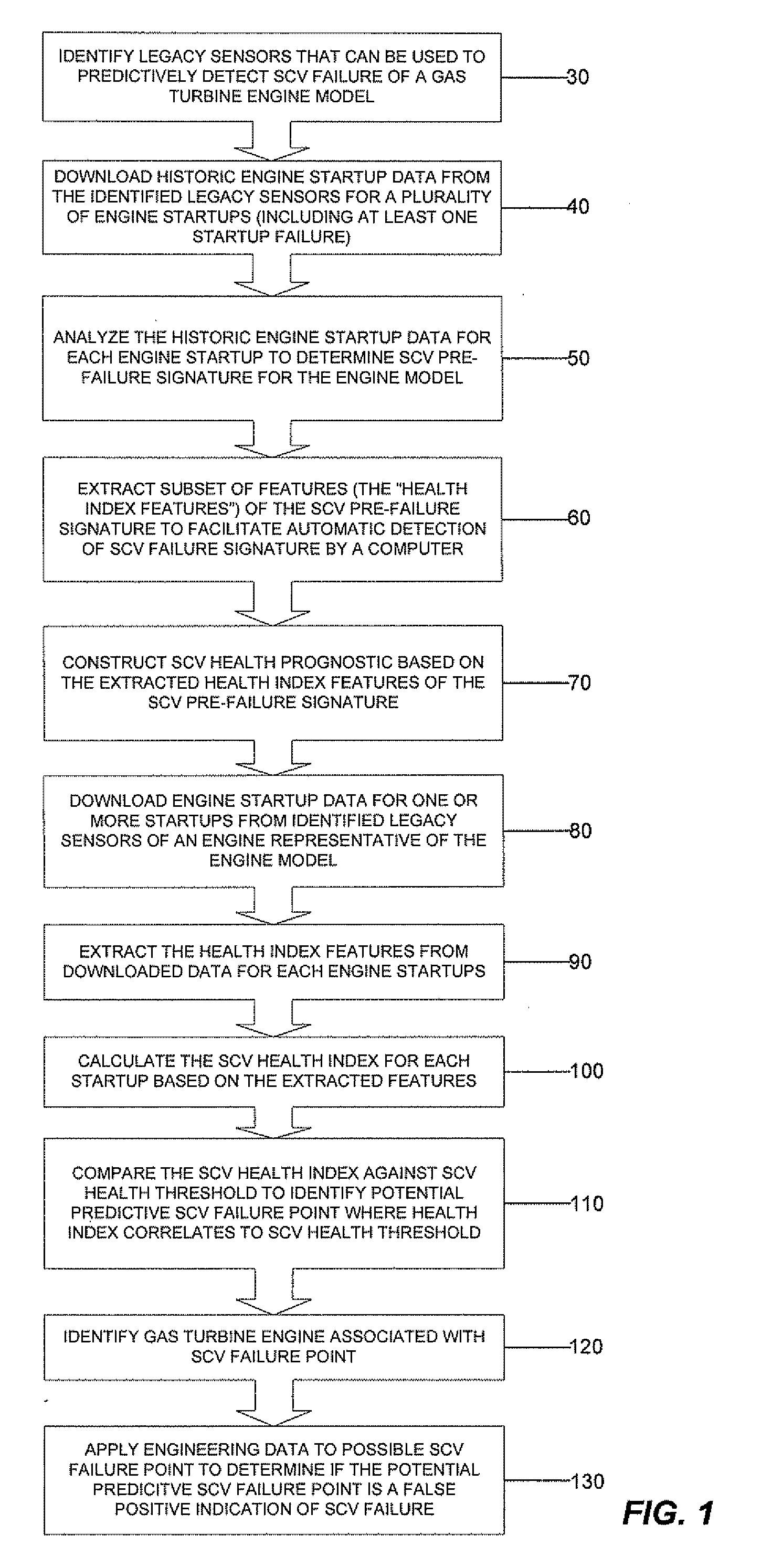

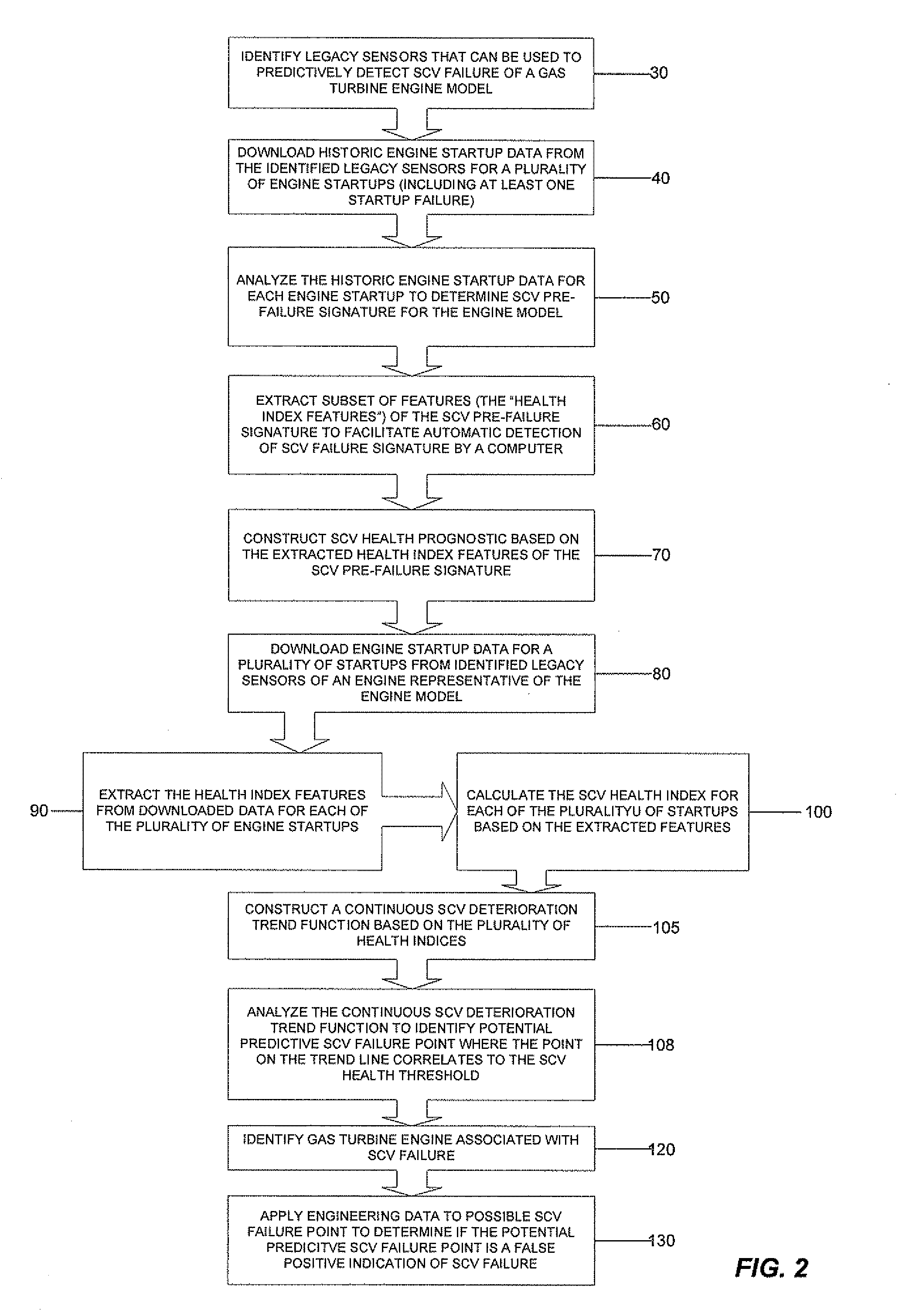

Starter Control Valve Failure Prediction Machine To Predict and Trend Starter Control Valve Failures In Gas Turbine Engines Using A Starter Control Valve Health Prognostic, Program Product and Related Methods

ActiveUS20110040470A1Reduce operating costsIncrease aircraft safetyAnalogue computers for vehiclesWind motor controlHealth indexControl valves

Starter control valve failure prediction machines, systems, program products, and computer implemented methods to predict and trend starter control valve failures in gas turbine engines using a starter control valve health prognostic and to make predictions of starter control valve failures, are provided. A computer implemented method according to an embodiment of the present invention can include the steps of generating a continuous starter control valve deterioration trend function responsive to a plurality of health indices derived from gas turbine engine startup data downloaded from gas turbine engine sensors for a plurality of startups and analyzing the continuous starter control valve deterioration trend function to identify potential starter control valve failure points where the points on the starter control valve deterioration trend function correlate to a starter control valve health prognostic responsive to historic gas turbine engine startup data downloaded from gas turbine engine sensors.

Owner:LOCKHEED MARTIN CORP

Method for deploying a parachute on a drone

InactiveUS6471160B2Safe recoveryReduce riskFloatsUnmanned aerial vehiclesControl signalUncrewed vehicle

Owner:AIRBUS HELICOPTERS DEUT GMBH

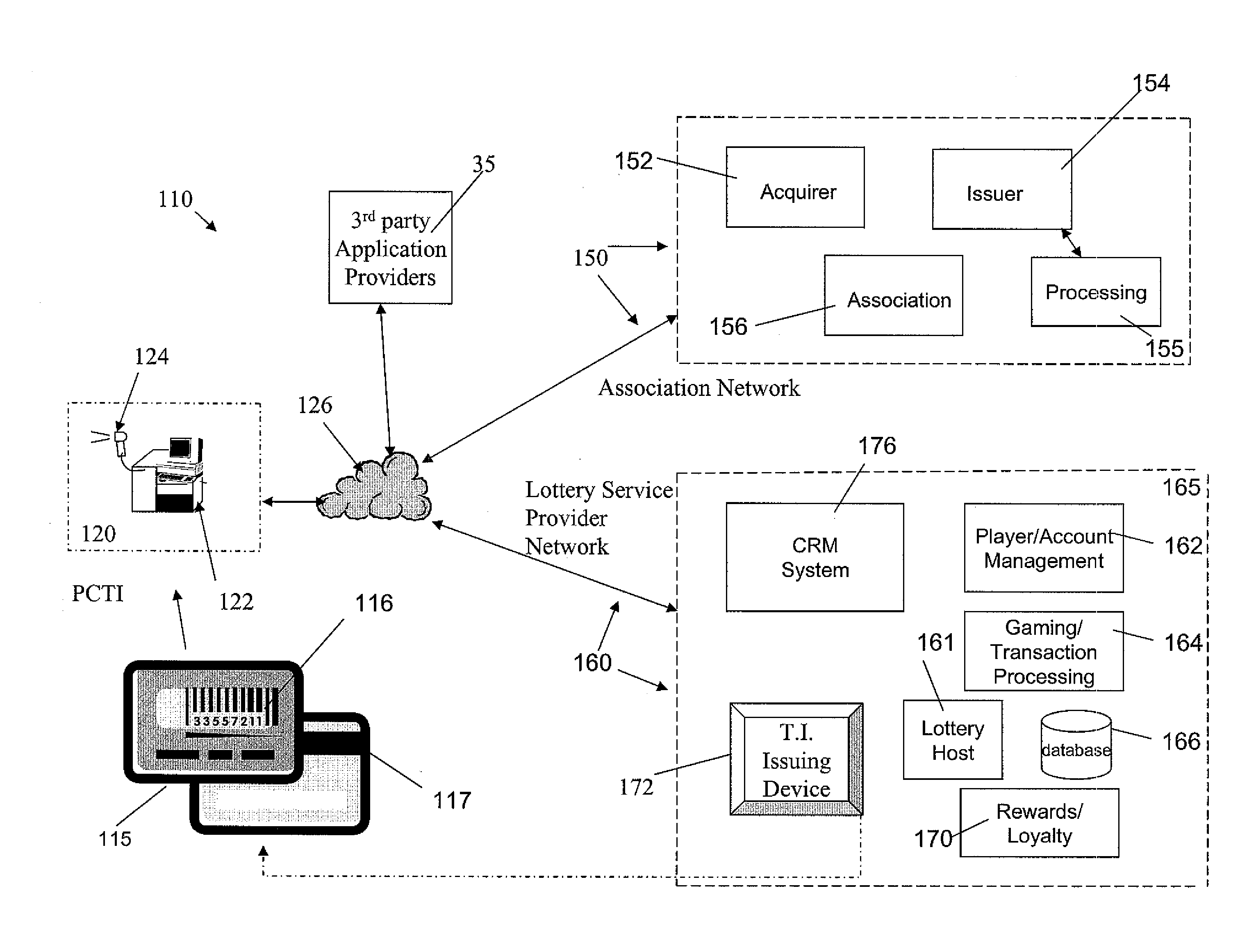

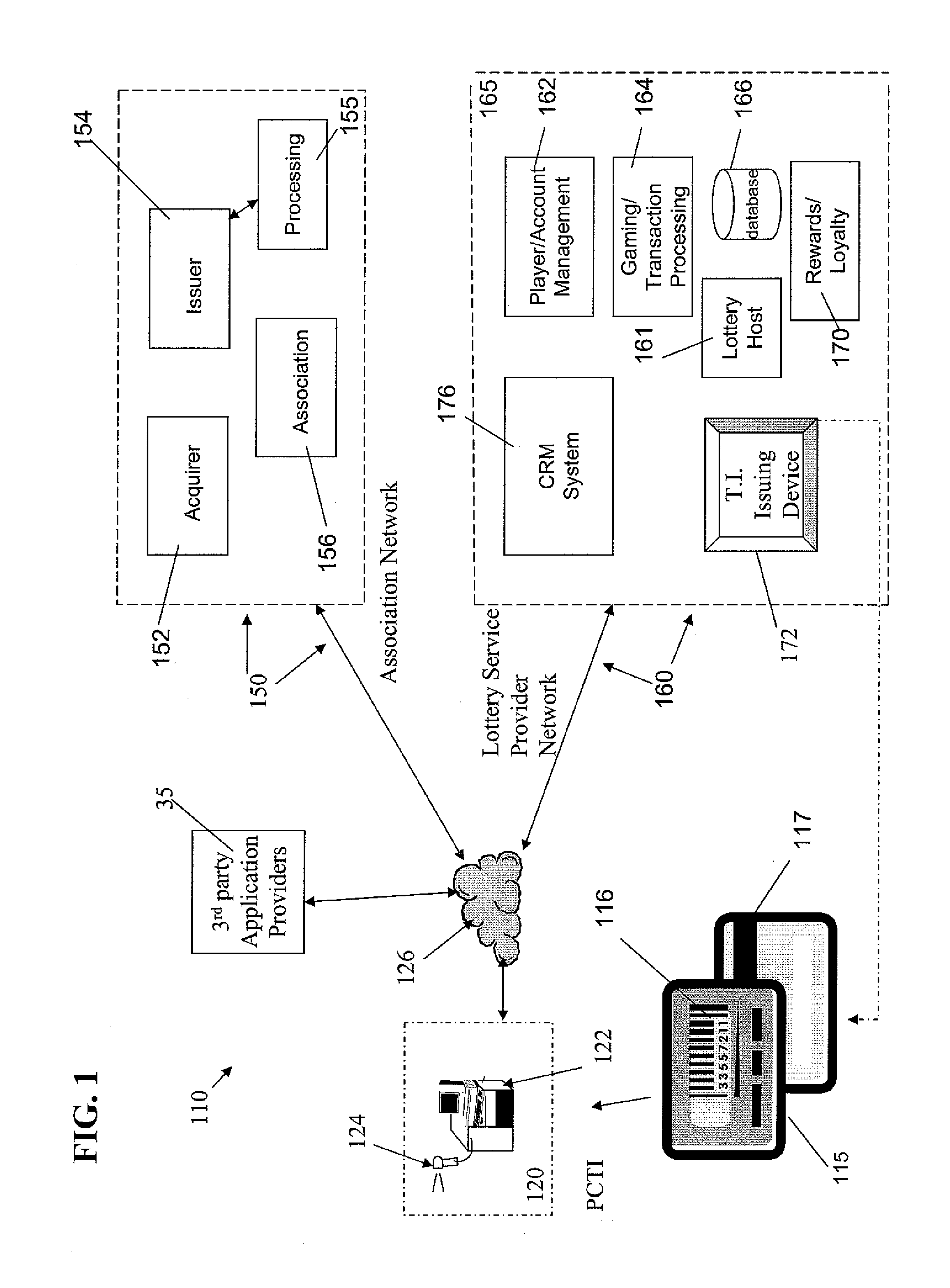

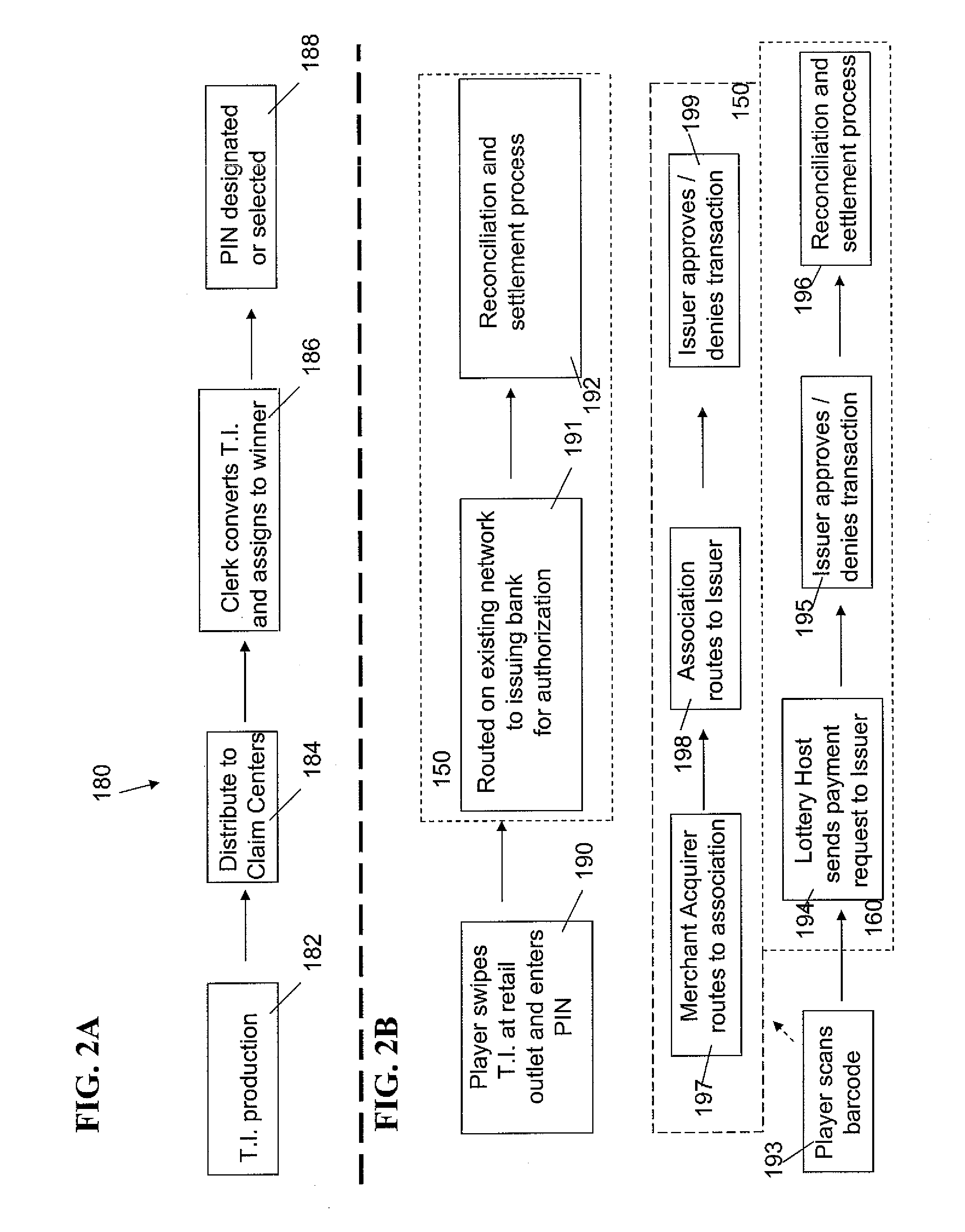

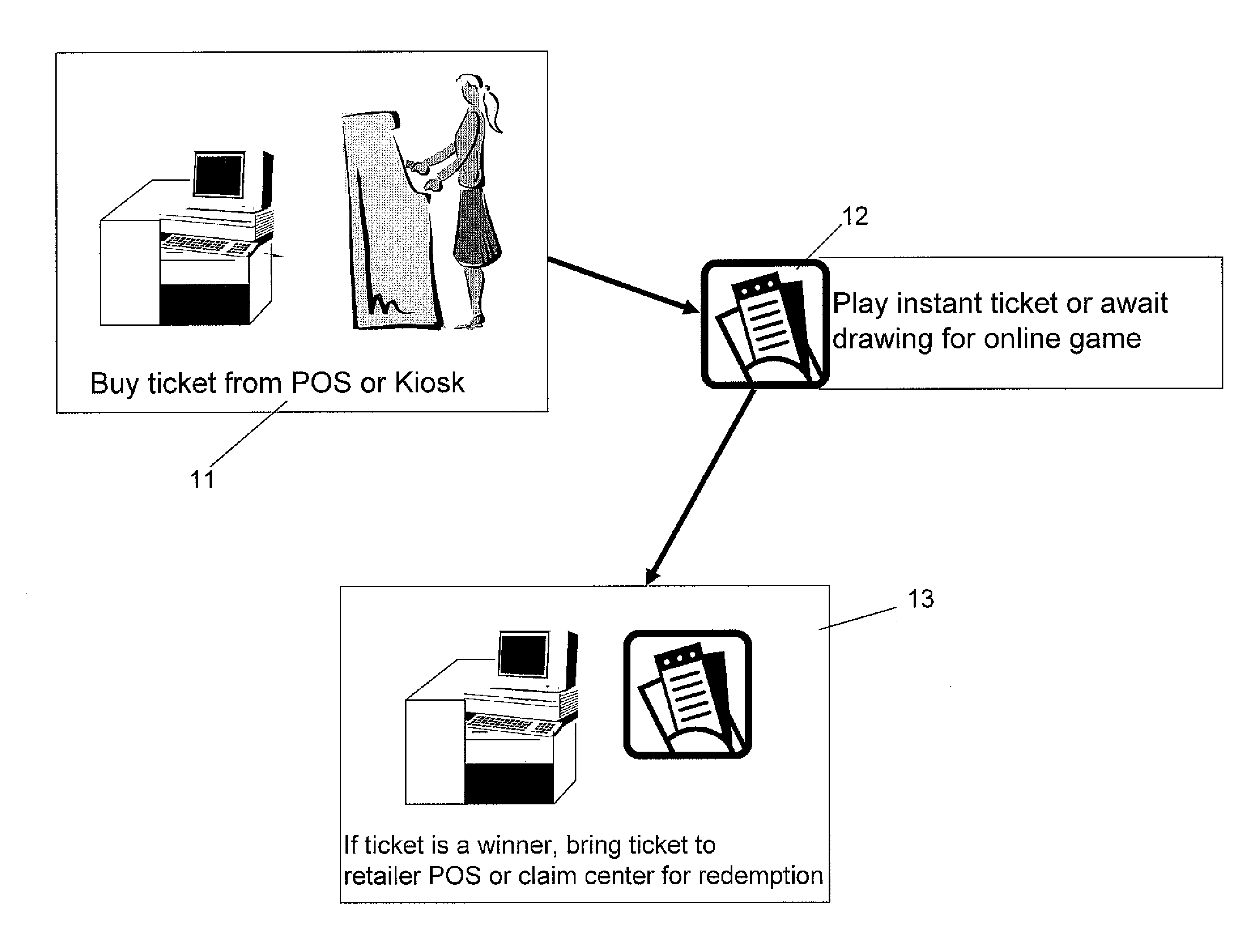

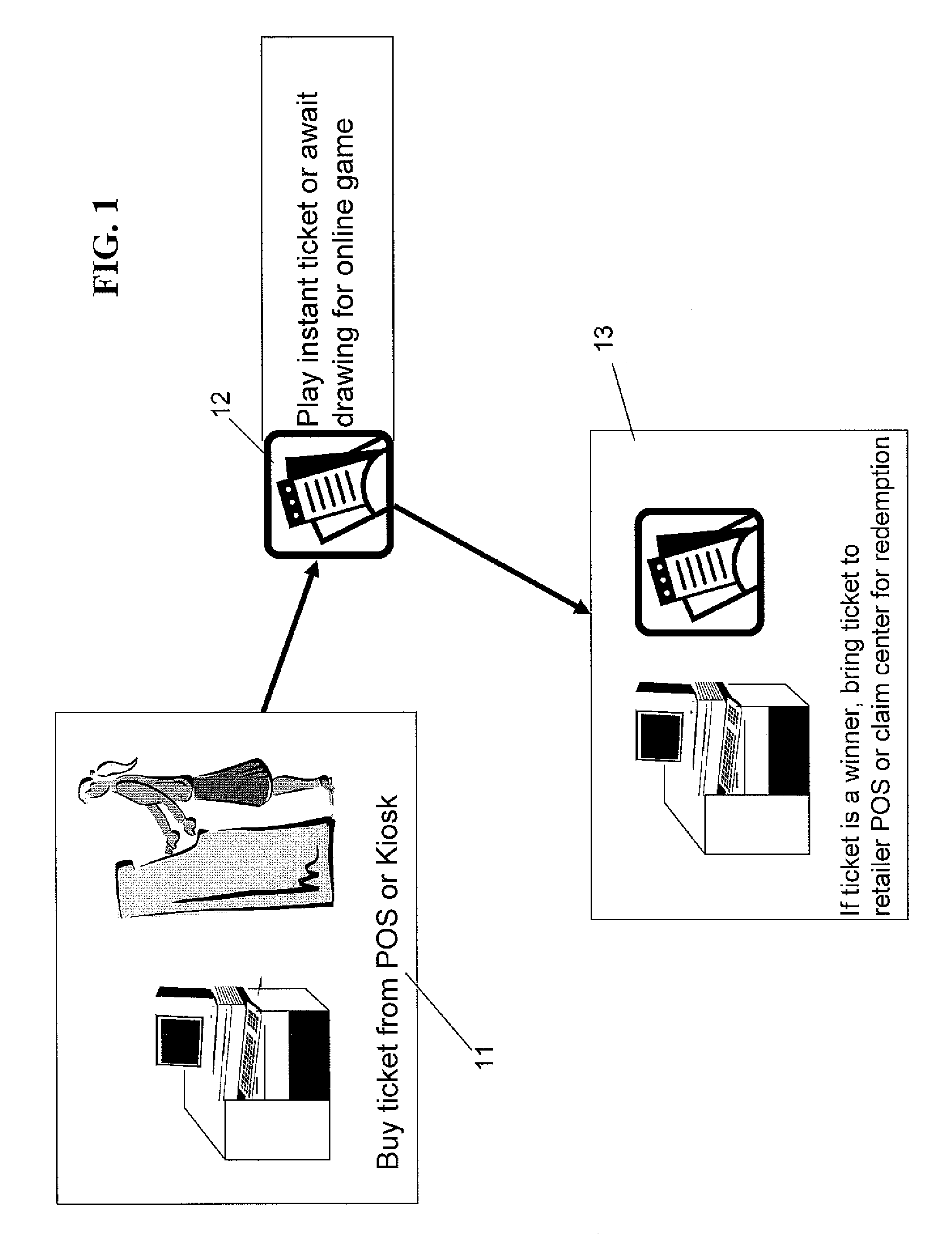

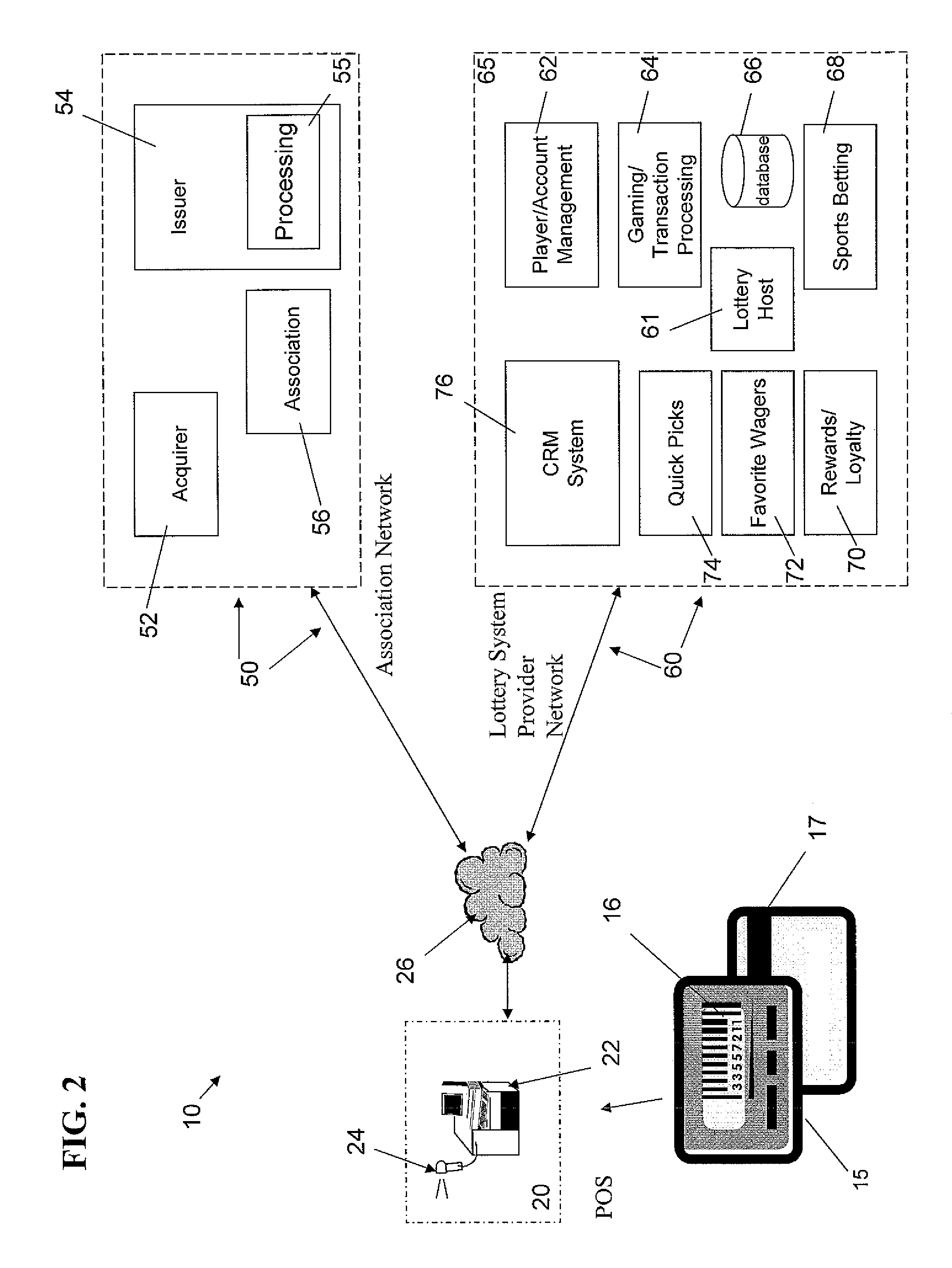

Lottery Transaction Device, System and Method with Paperless Wagering and Payment of Winnings

InactiveUS20100222125A1Easy to understandEasy to operateApparatus for meter-controlled dispensingVideo gamesPaymentDatabase

A lottery device, system and method incorporate lottery and non-lottery transaction capabilities within a single device that also provides for paperless wagering and payment of winnings. As part of the present invention, a transaction instrument facilitates typical consumer transactions as well as transactions related to lottery offerings and can use a reader terminal component to associate lottery tickets with the transaction instrument.

Owner:GTECH CORP

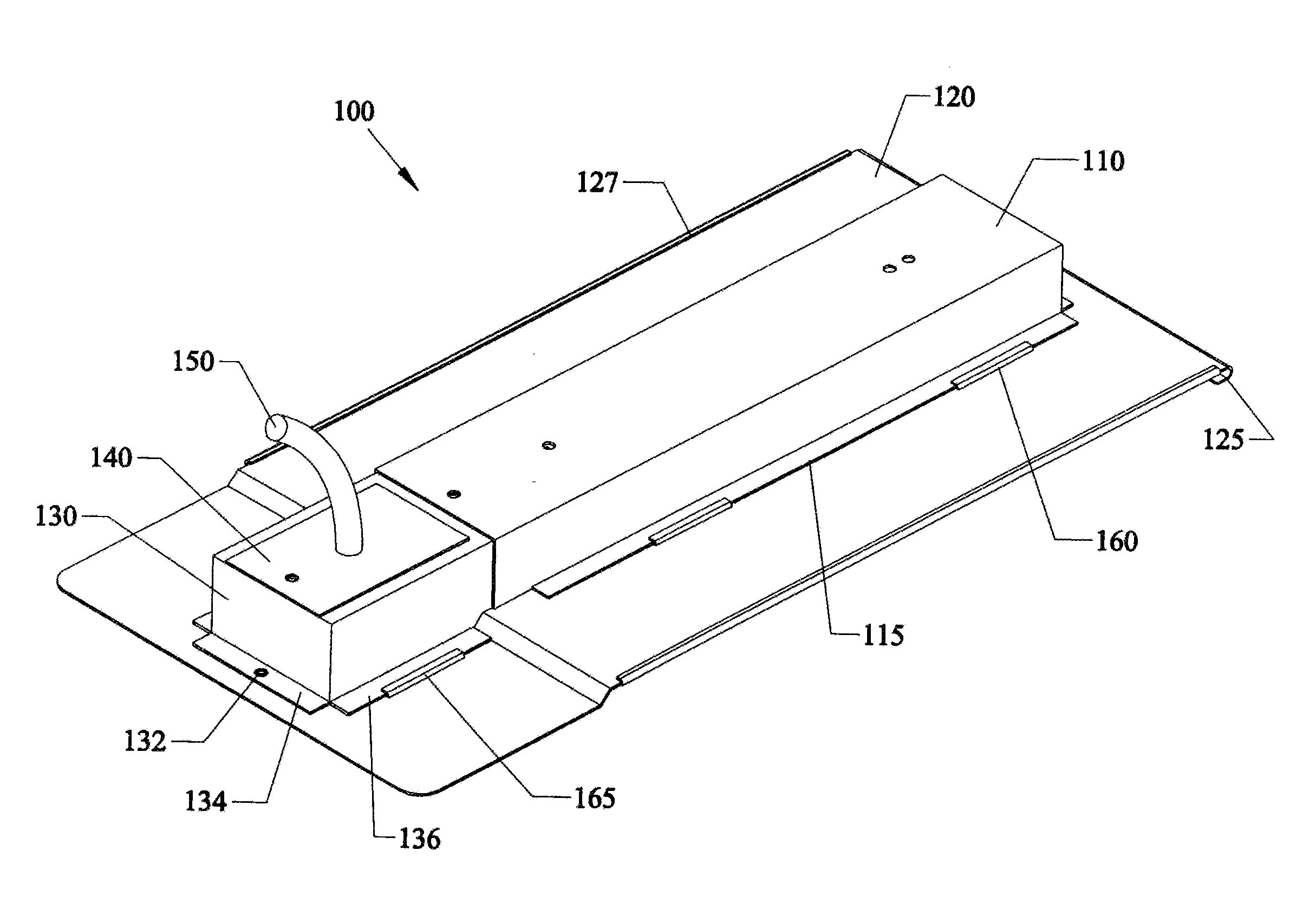

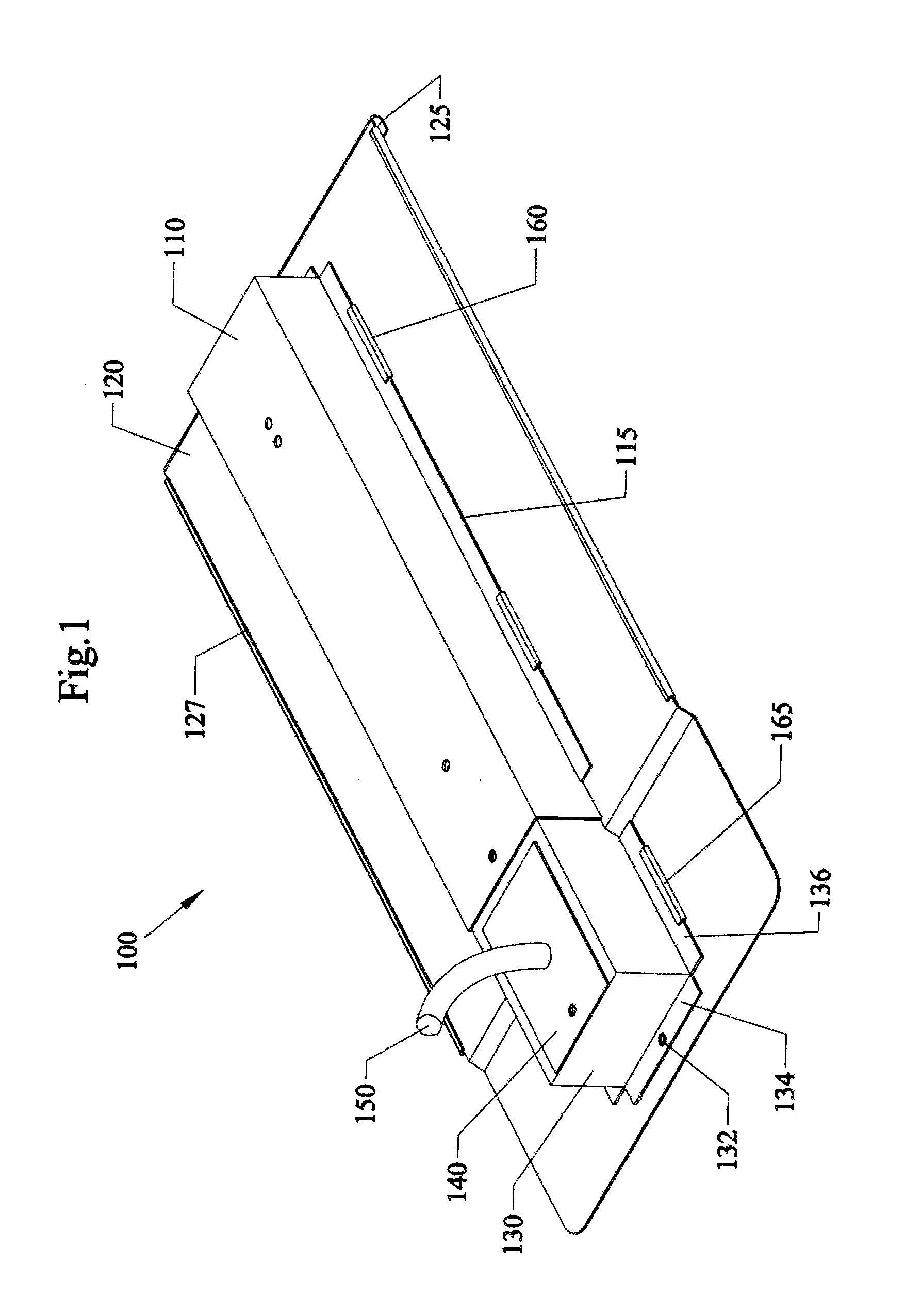

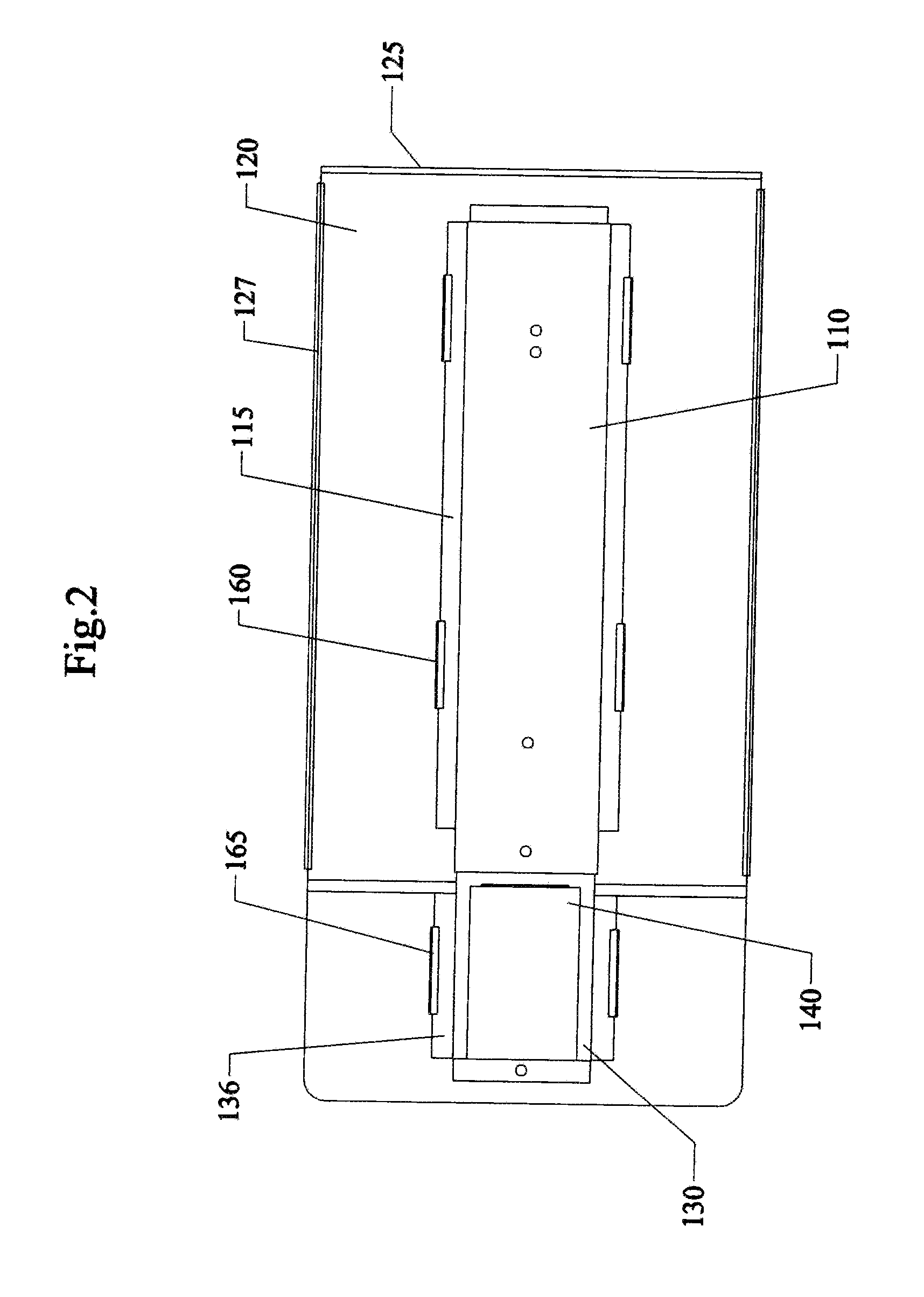

Quick Change Lamp Ballast Assembly

InactiveUS20100319953A1Reduce labor costsQuick changeWave amplification devicesElectric circuit arrangementsBallastCooling load

Method, apparatus and systems for a quick change lamp ballast assembly for newly manufactured lamp fixtures having the quick change ballast or a retrofit for an existing lamp fixture. The quick change ballast assembly includes a ballast mounting fixture 110 for housing the ballast 300, a wire connector fixture 130 and a mounting plate 120 for mounting the ballast mounting fixture 110. The ballast assembly allows for replacement of a non operating ballast to reduce replacement time and labor costs. In a new lamp fixture, the quick change ballast is thermally isolated from the lamp fixture, which reduces the effects of the waste heat from the ballast, and increase overall building efficiency by reducing the cooling load.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

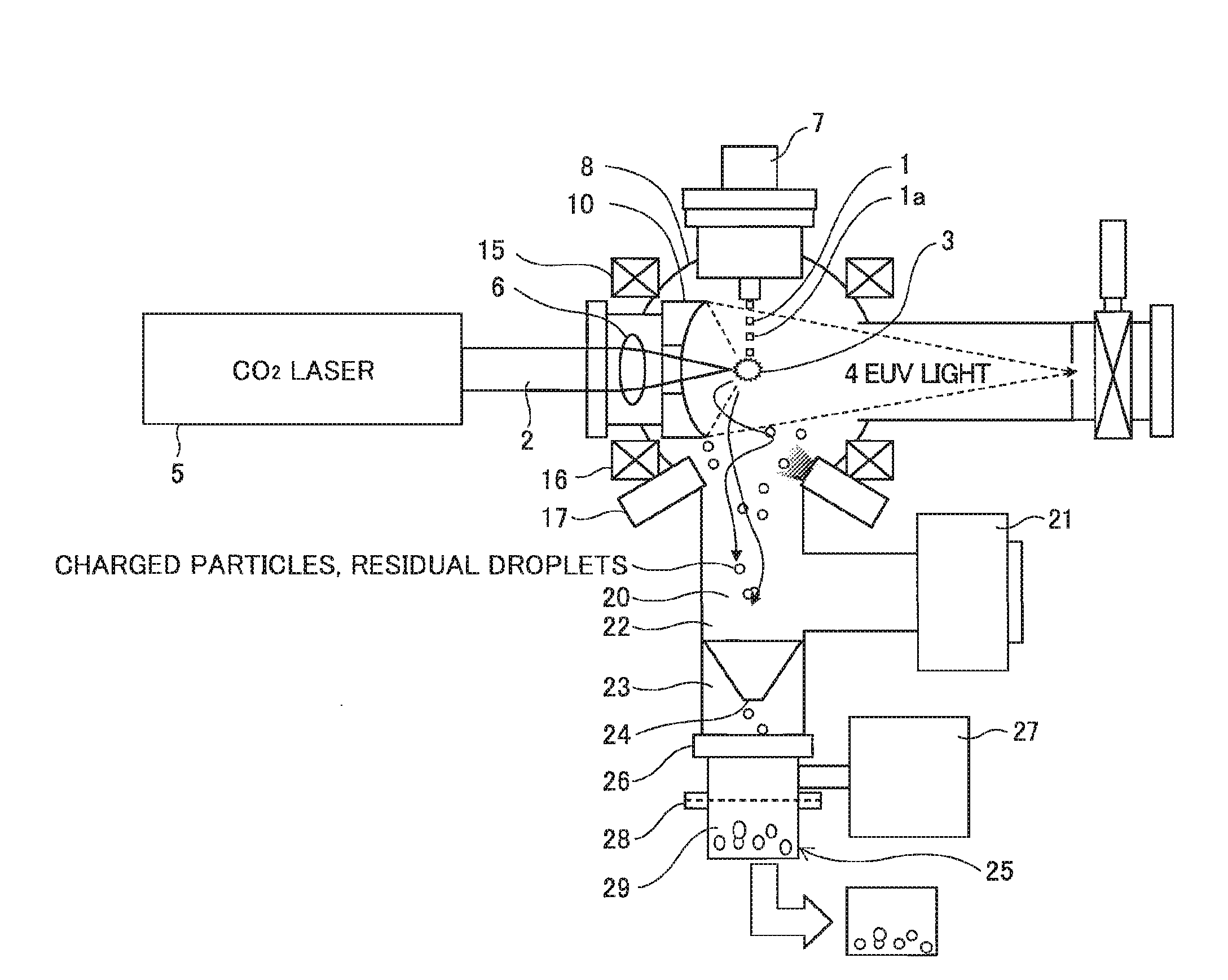

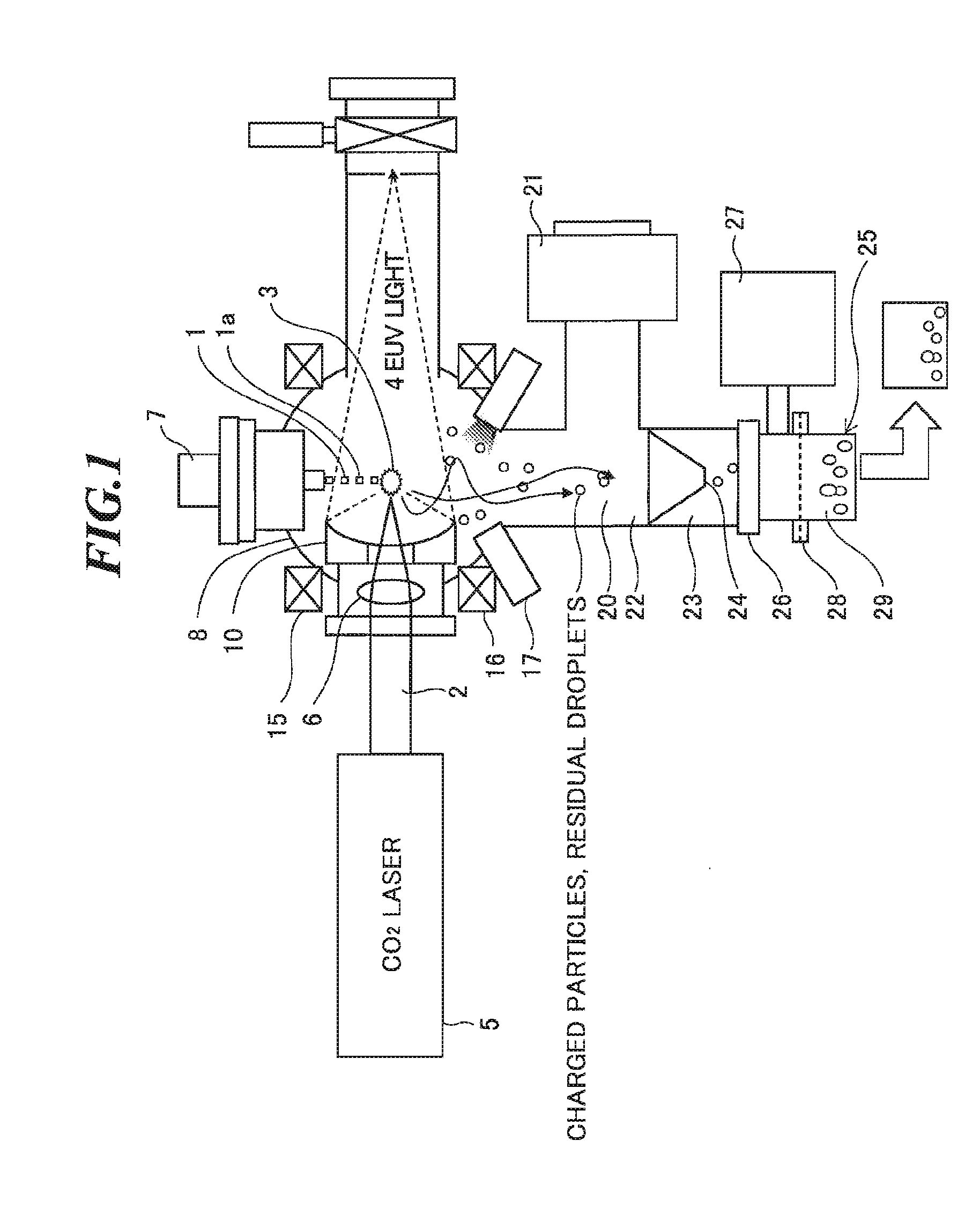

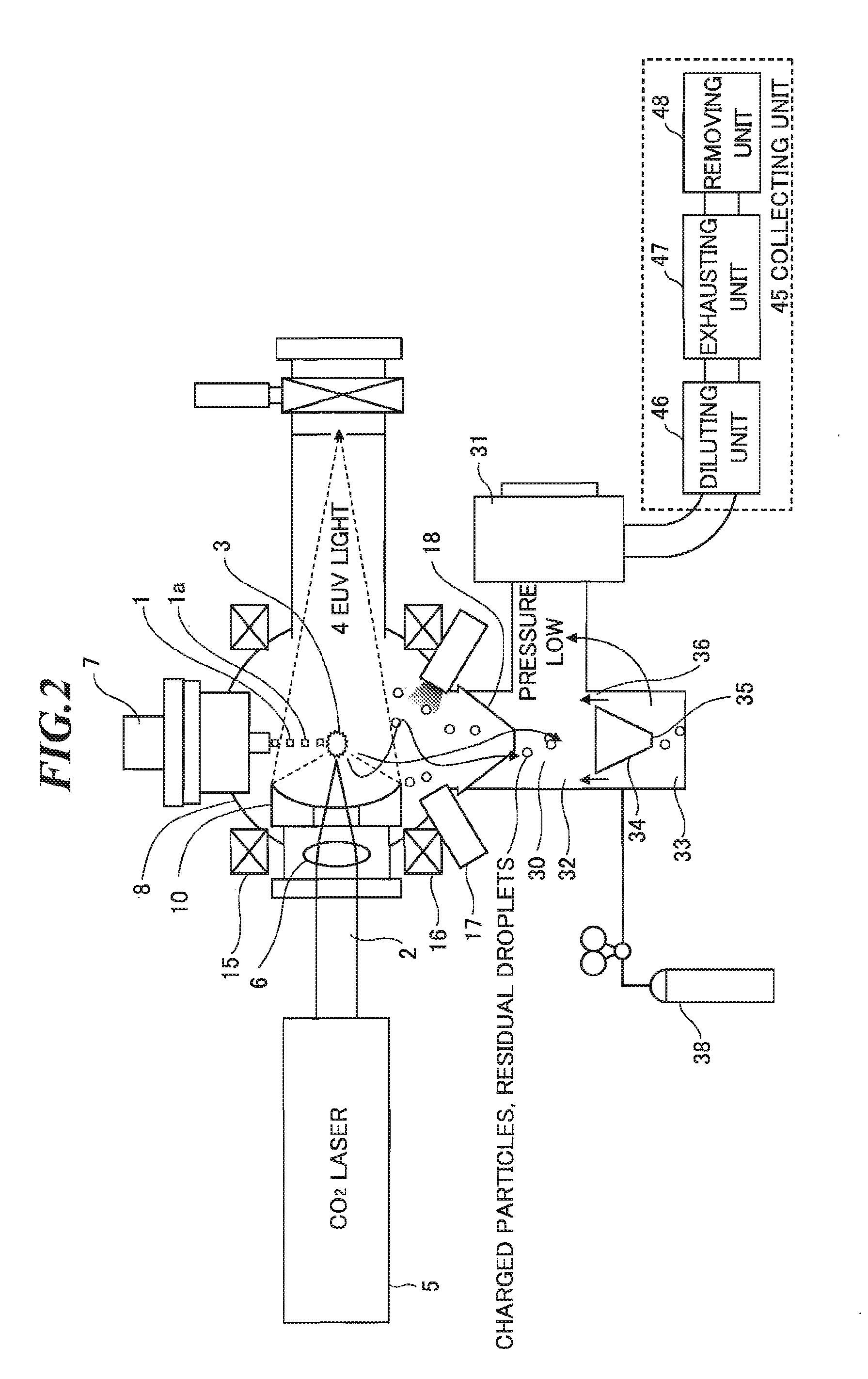

Extreme ultra violet light source apparatus

ActiveUS20090224181A1Performance deteriorationEfficient use ofRadiation pyrometryPhotometryExtreme ultravioletLaser beams

An extreme ultra violet light source apparatus in which debris staying and accumulating within a chamber can be prevented from contaminating the chamber and deteriorating the performance of important optical component. The extreme ultra violet light source apparatus includes: a chamber in which extreme ultra violet light is generated; a driver laser for applying a laser beam to a target supplied to a predetermined position within the chamber to generate plasma; a collector mirror provided within the chamber, for collecting and outputting the extreme ultra violet light radiated from the plasma; an exhaust path communicating with the chamber and connected to an exhausting device, for maintaining an interior of the chamber at a certain pressure; a catching chamber provided in the exhaust path, for catching debris generated from the plasma; and a collecting unit for collecting the caught debris out of the chamber.

Owner:GIGAPHOTON

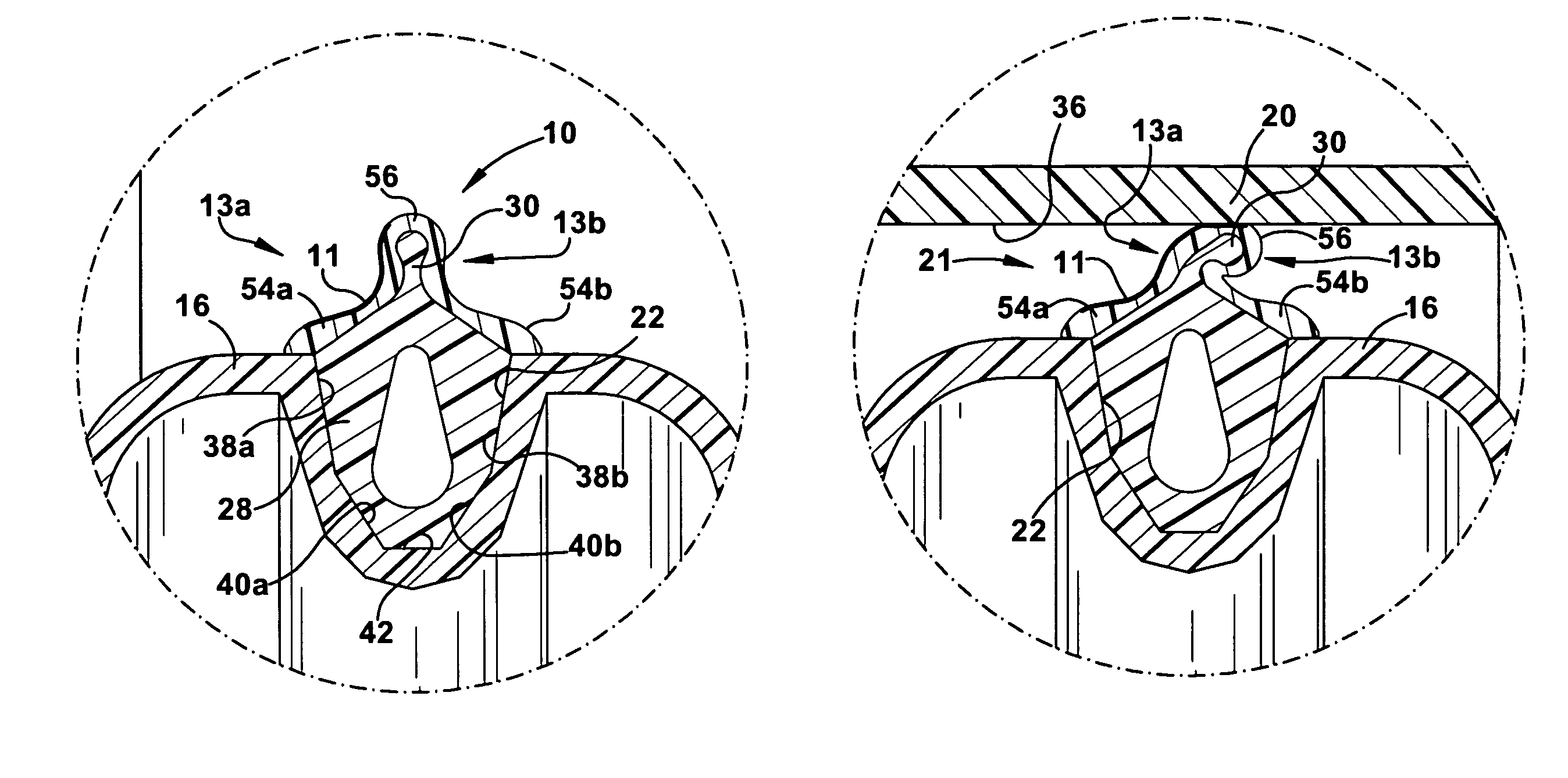

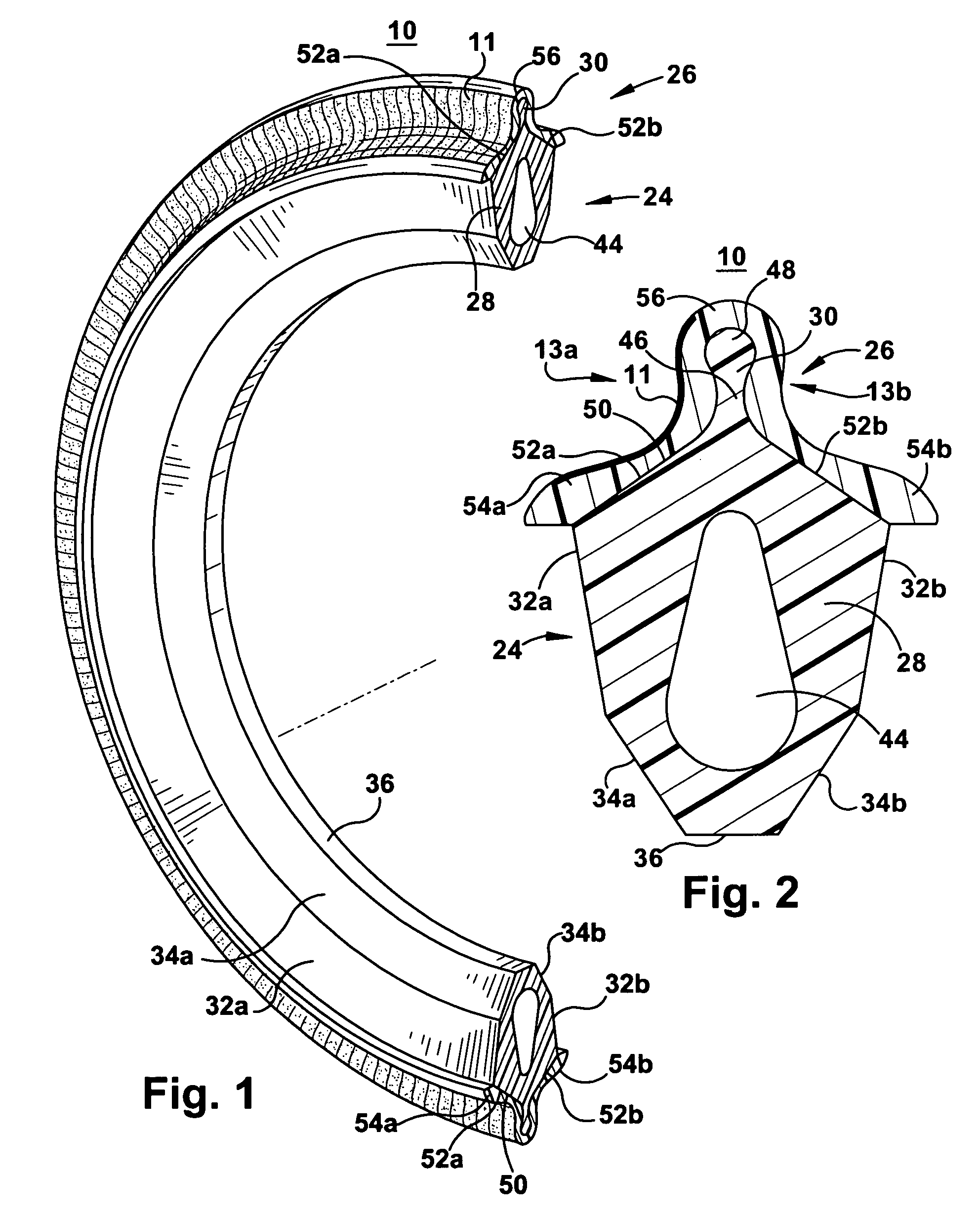

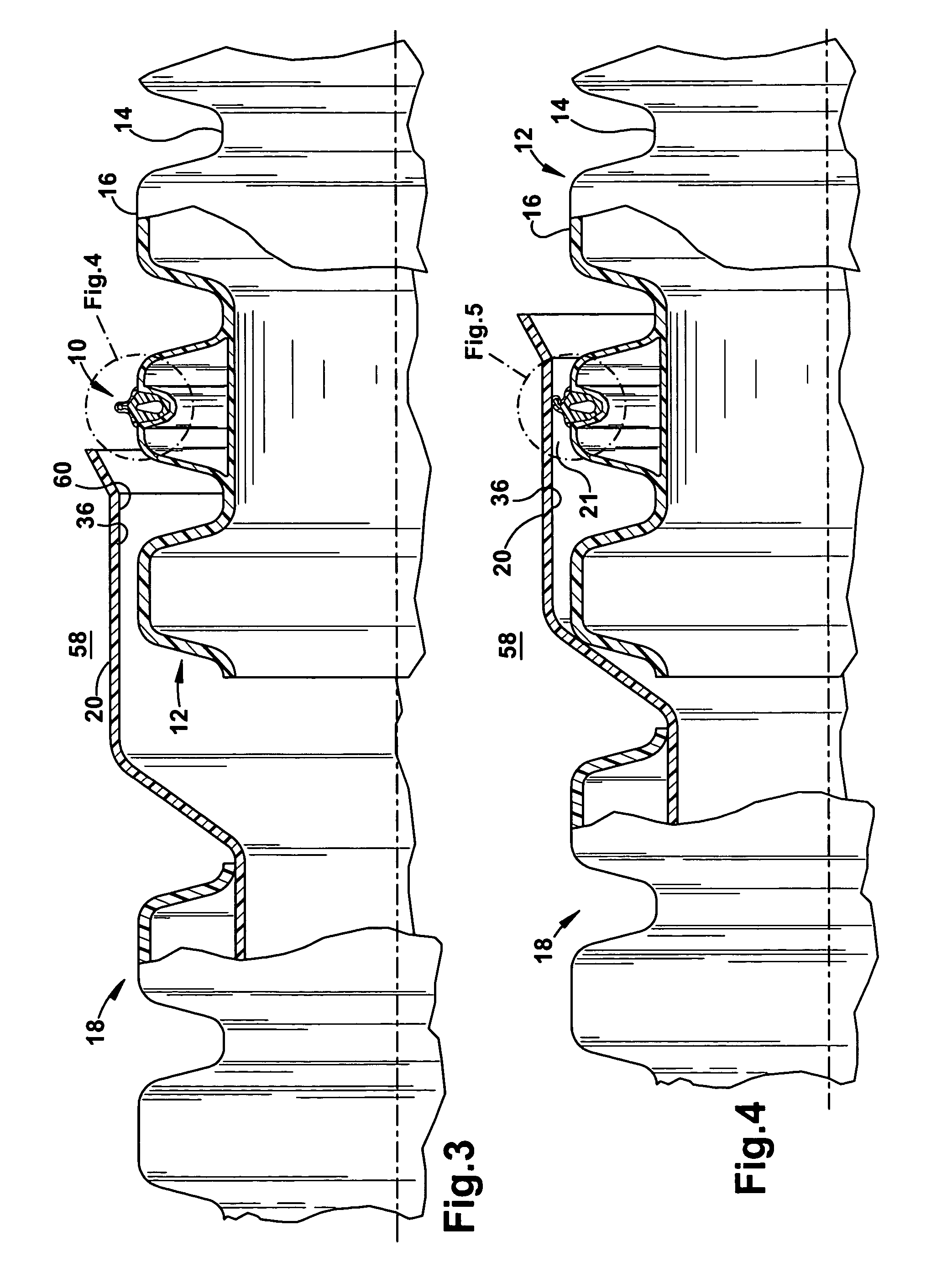

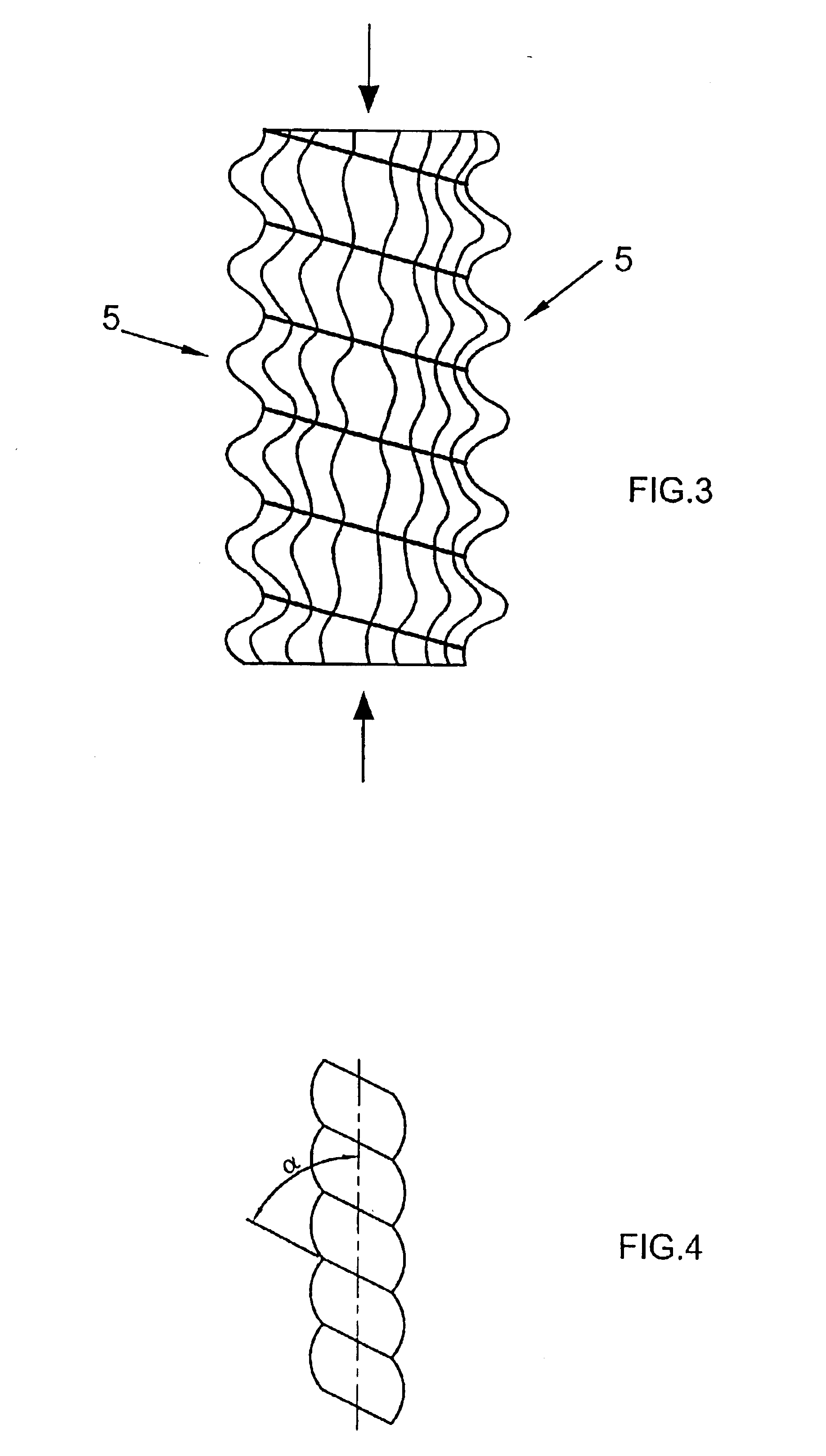

Permanently lubricated film gasket and method of manufacture

A permanently lubricated film gasket for providing a fluid-tight seal between a corrugated pipe and a smooth annular section of an outer pipe or section when the corrugated pipe and the outer pipe or section are in a relative surrounded and surrounding relationship. A first portion of the gasket is shaped to fit within a groove or recess of the corrugated pipe. A second portion of the gasket extends from the first portion. The second portion is at least partially comprised of permanently lubricated film for facilitating in the connection of the pipes along a single direction.

Owner:SPRINGSEAL

System, device and method for paperless wagering and payment of winnings

ActiveUS8333653B2Facilitate self-monitoring and independent monitoring of individual behaviorPromote responsible gamingFinancePayment architecturePaymentData processing system

A transaction card facilitates typical consumer transactions as well as transactions related to lottery offerings and can incorporate a reader terminal to associate lottery tickets with the transaction instrument. New gaming opportunities tied to the instrument are also facilitated, including a personalized guaranteed prize structure, a personalized and / or localized jackpot and an opportunity for winning additional prizes when making purchases using the instrument. The system according to one embodiment of the present invention provides at least a lottery data processing system for communicating a first funding amount to be applied to a multi-purpose transaction card based on winnings from a lottery offering, and a reader terminal for reading at least a portion of the transaction card, reading indicia on one or more gaming tickets, and associating the one or more gaming tickets with the transaction card. In one embodiment of the present invention, a custodian not associated with the winner or cardholder can derive non-transaction related earnings on the winnings without providing a fee to the cardholder.

Owner:IGT GLOBAL SOLUTIONS CORP

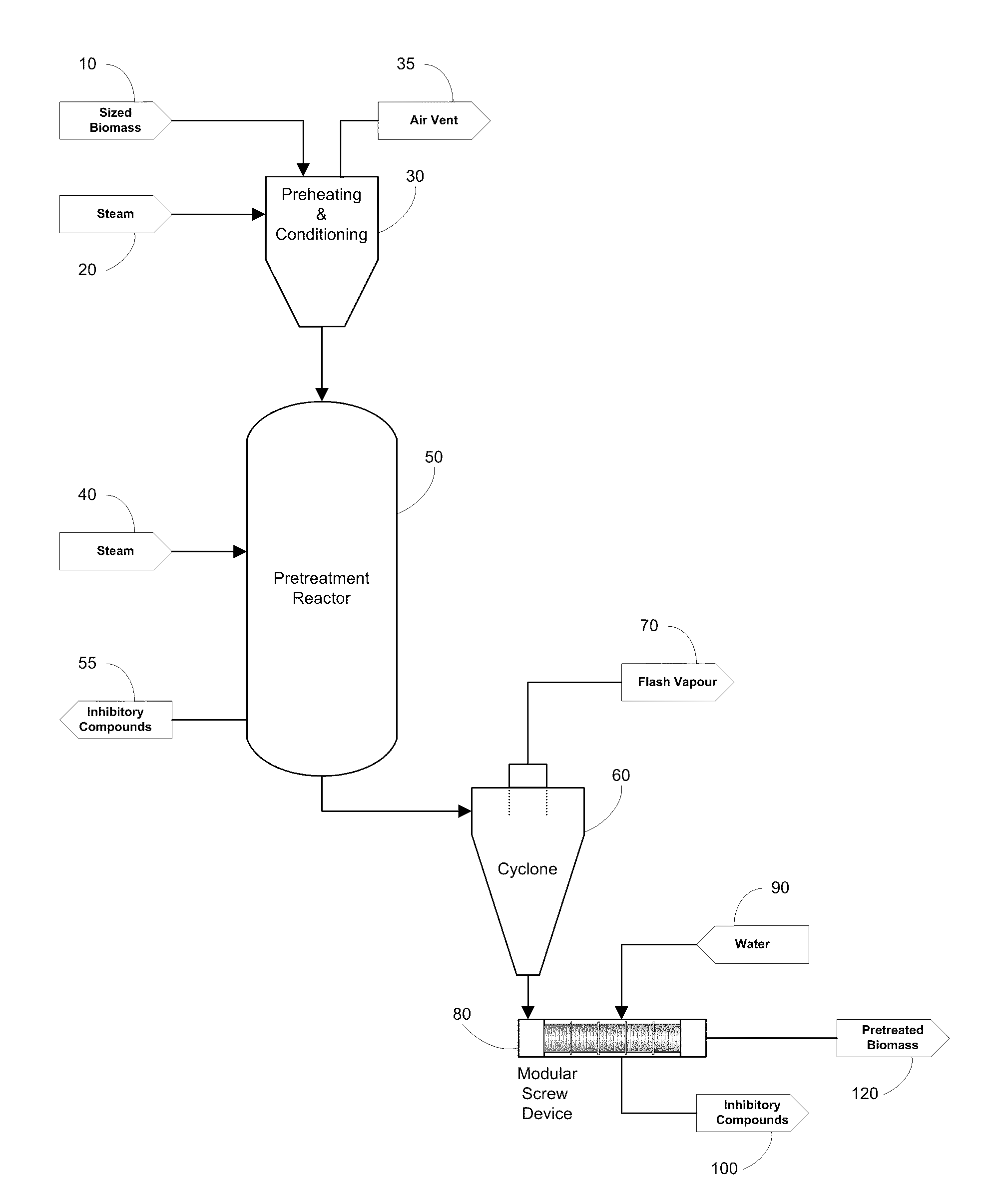

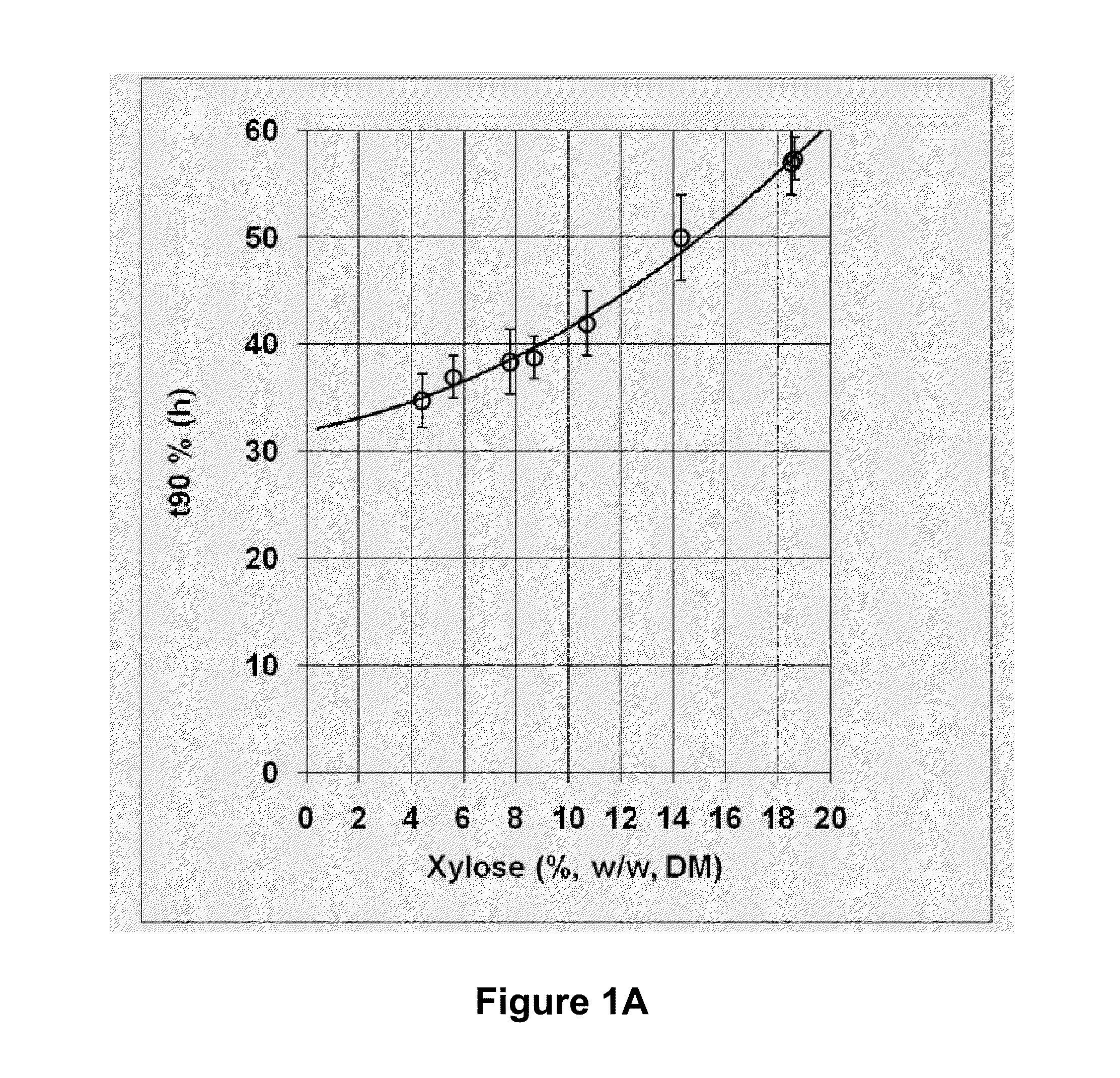

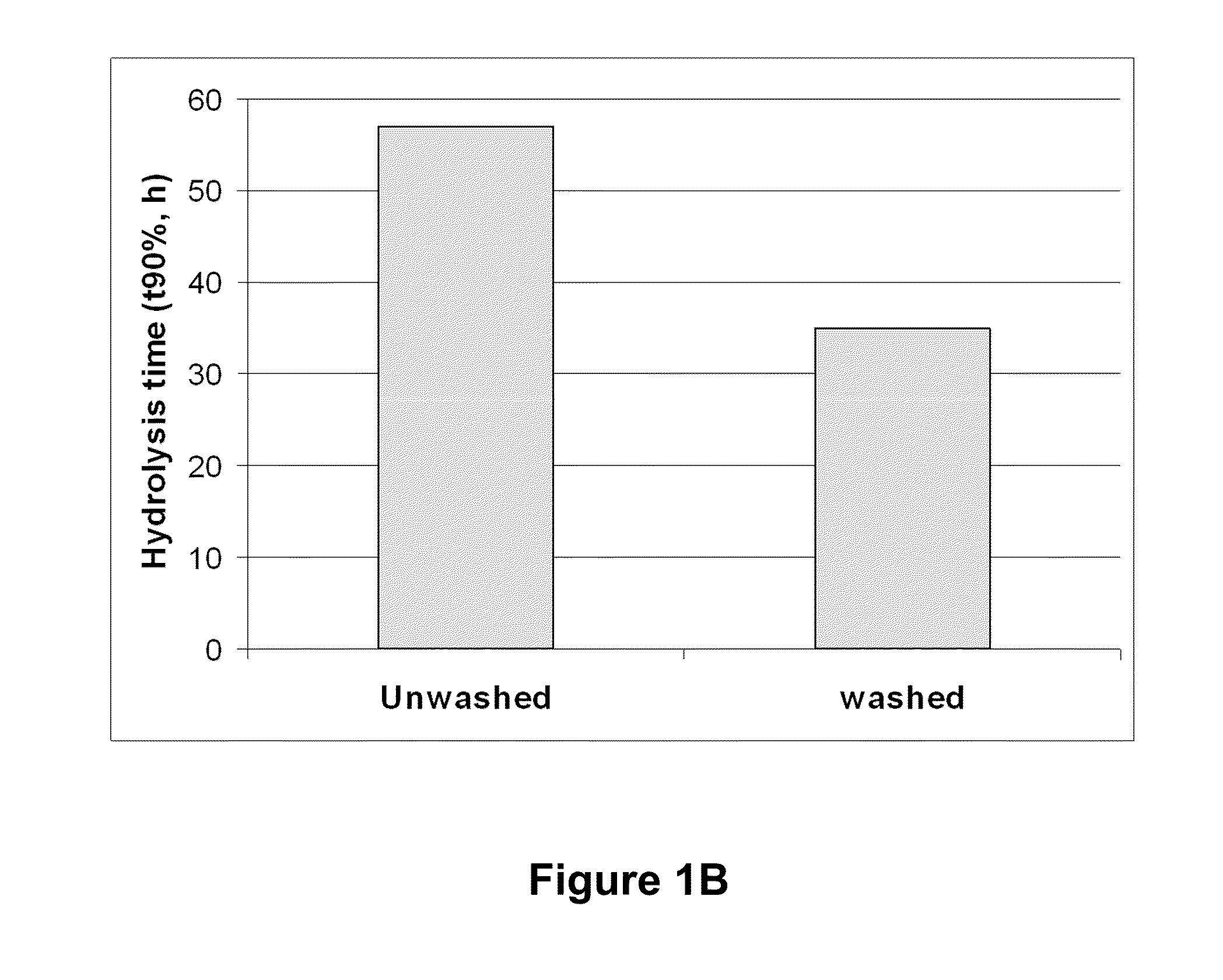

Pretreatment of lignocellulosic biomass through removal of inhibitory compounds

InactiveUS20100263814A1Reduce impactReducing the inhibition impact on the ratePretreatment with water/steamBiofuelsXyloseDecomposition

A process for the pretreatment of lignocellulosic biomass is disclosed. The process is intended for use in connection with biomass to ethanol processes and is directed in particular to an economical removal of inhibitory compounds generated in biomass pretreatment, which are inhibitory to downstream hydrolysis and fermentation steps. The process includes the steps of heating the lignocellulosic biomass with steam to a preselected temperature, at a preselected pressure and for a preselected time to hydrolyze and solubilize hemicelluloses in the biomass; explosively decomposing the biomass into fibers; and extracting from the resulting reaction mixture a liquefied portion of the lignocellulosic biomass before or after explosive decomposition. The liquefied portion is extracted to remove compounds from the lignocellulosic biomass which are inhibitory to enzymatic cellulose hydrolysis and sugar fermentation to ethanol. For improved efficiency and economy, the inhibitory compounds are not completely removed. Furthermore, xylose has been found to be a good indicator compound for the general level of inhibitory compounds in the reaction mixture and the extraction step is therefore controlled on the basis of the xylose content in the reaction mixture. In particular, the extracting step is discontinued once a dry matter (dm) content of xylose, as monomer or oligomer, in the reaction mixture of 4% to 8% (w / w dm) is achieved. This most economically balances the practical need for inhibitory compound removal with the economical need to control and preferably minimize the costs of the overall ethanol production process.

Owner:GREENFIELD SPECIALTY ALCOHOLS

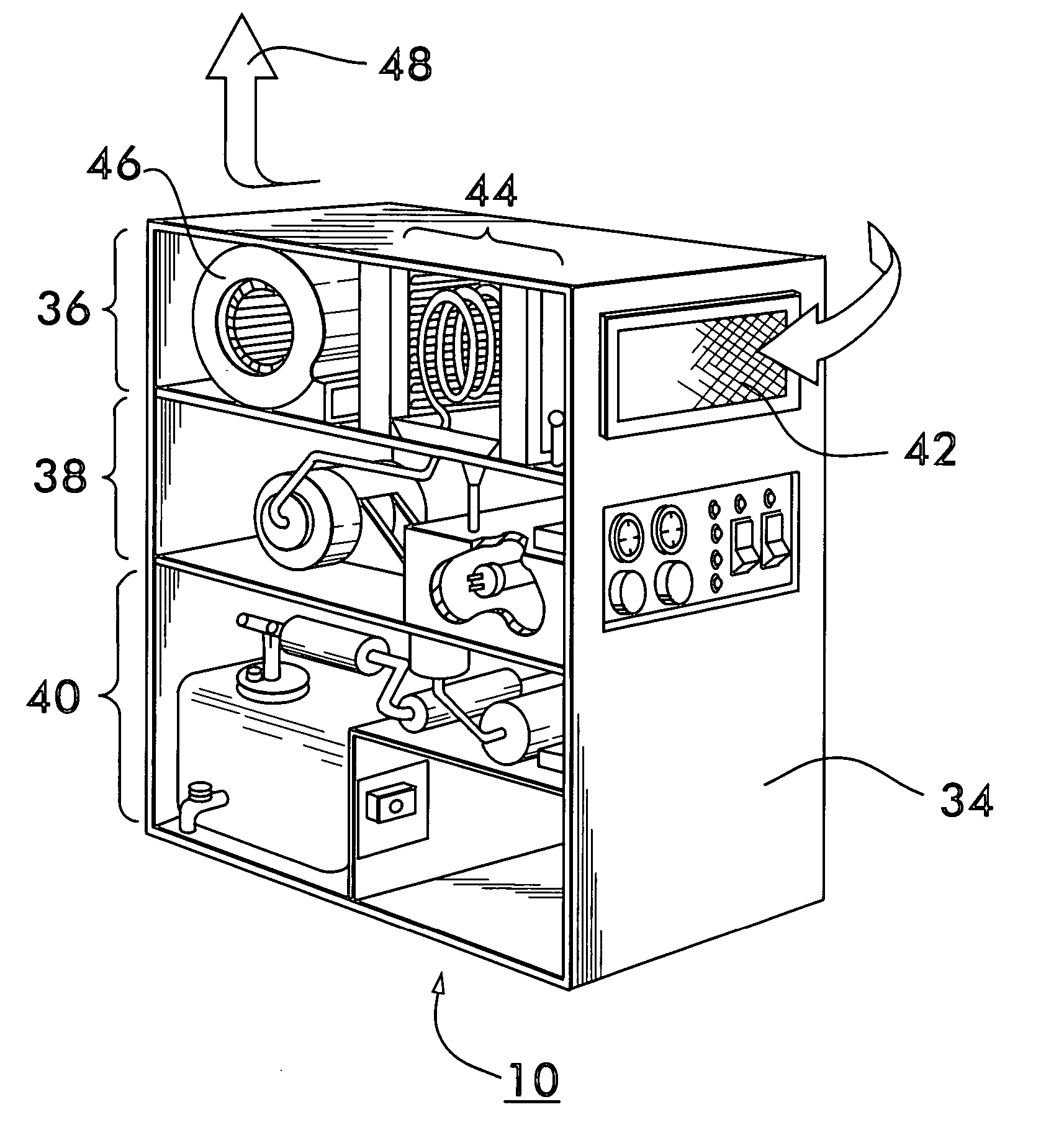

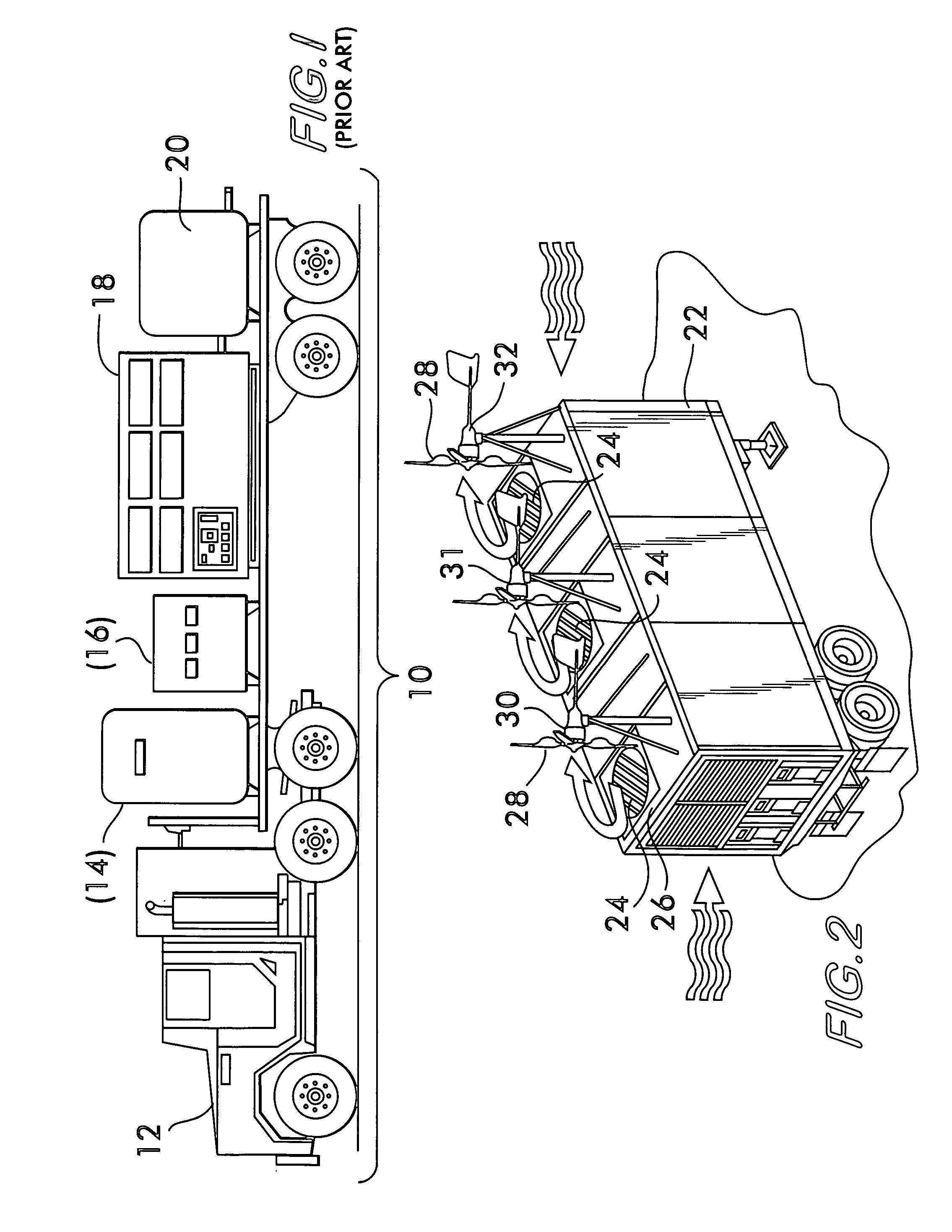

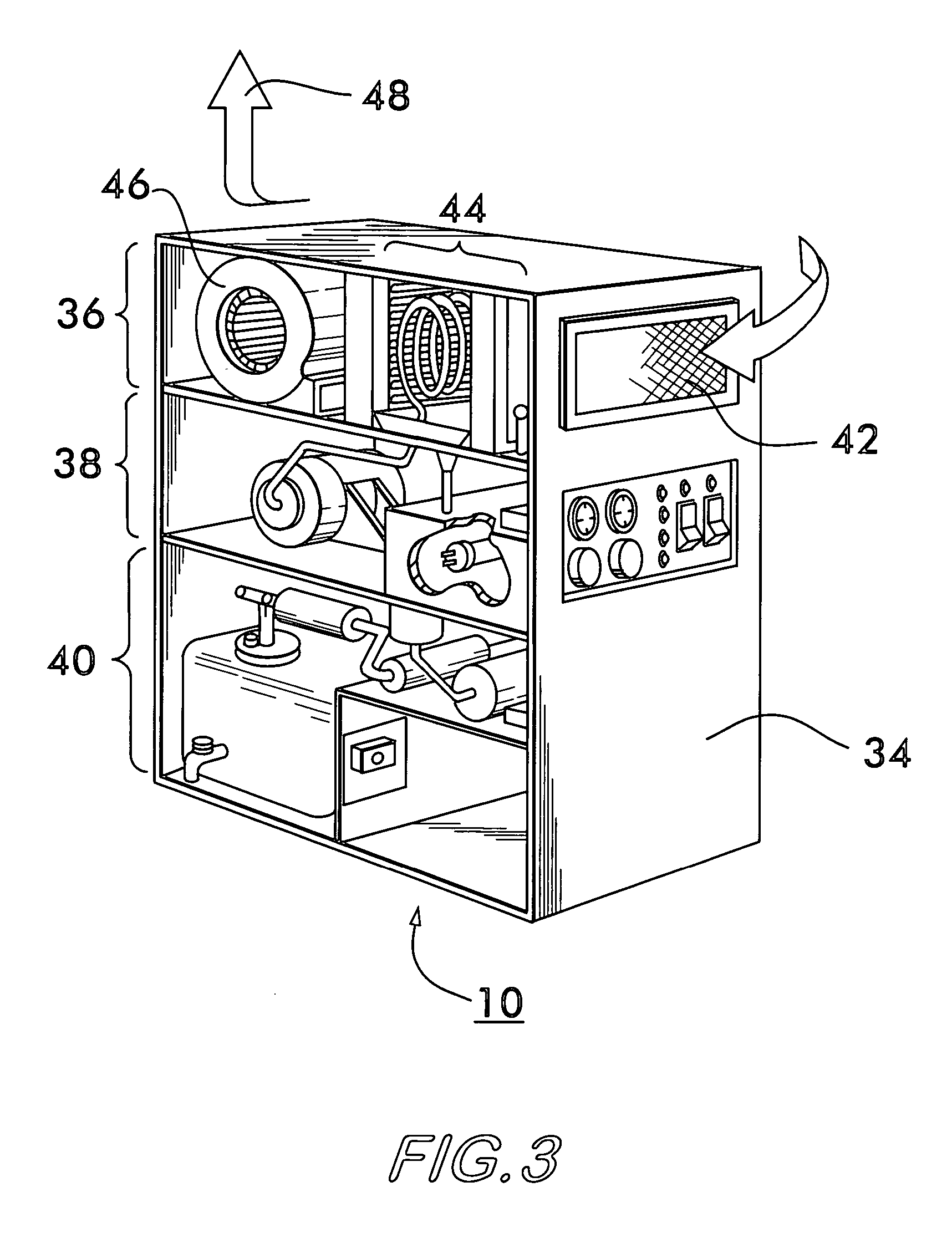

Co-generation power system for supplying electricity to an air-water recovery system

InactiveUS20060257258A1Reduce consumptionCost of operationPropellersPump componentsCogenerationForced-air

A mobile, self-propelled platform, which includes an enclosed trailer containing a portable air-water recovery system, is disclosed. This trailer includes a wind turbine mounted outside of the closed trailer environment, and adapted for recovery of energy from an exhaust air stream that is vented from within the enclosed trailer environment. The energy generated from such exhaust air stream is used to supplement traditional power sources associated with the operation of water generation process. The energy recovered from the exhaust air stream is projected to reduce the overall operating cost of the air-water recovery system by least 25%, based upon its current energy consumption needs. This system has application to other environments in which a force air stream is produce incident to operation of a primary process, as for example, where a high pressure, air dryer is used to remove moisture from a product, or to accelerate a curing operation.

Owner:ZWEBNER MICHAEL J

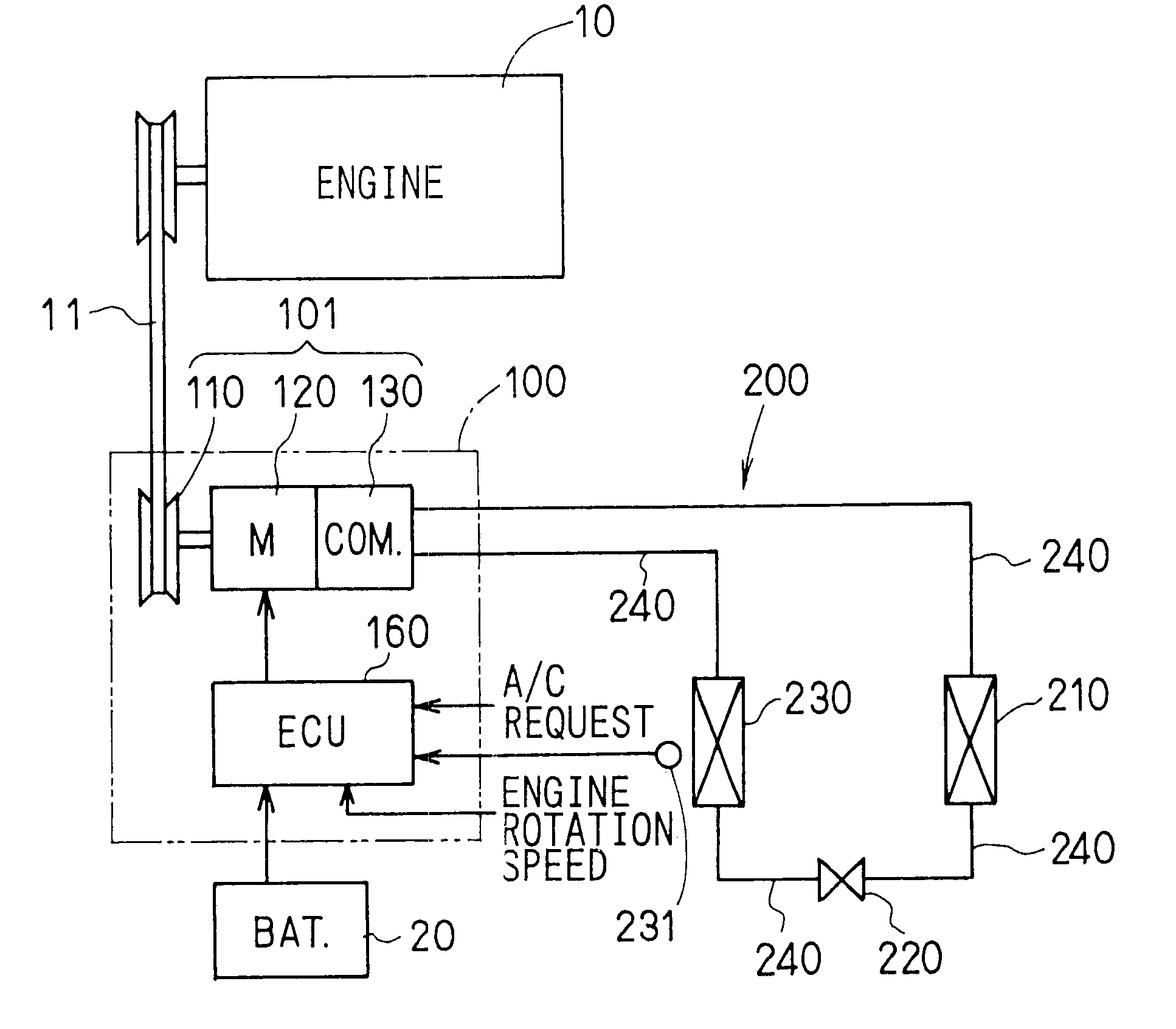

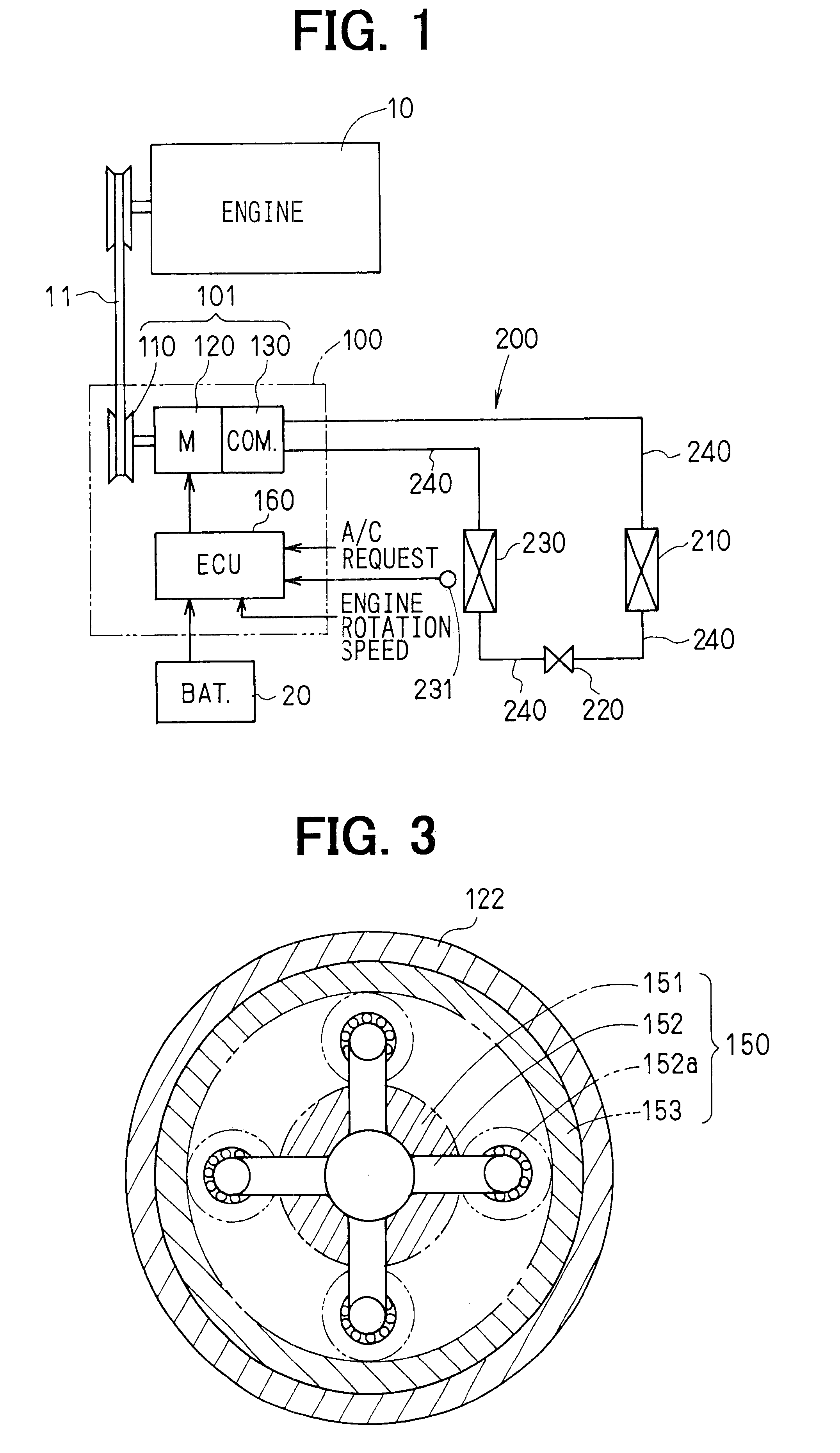

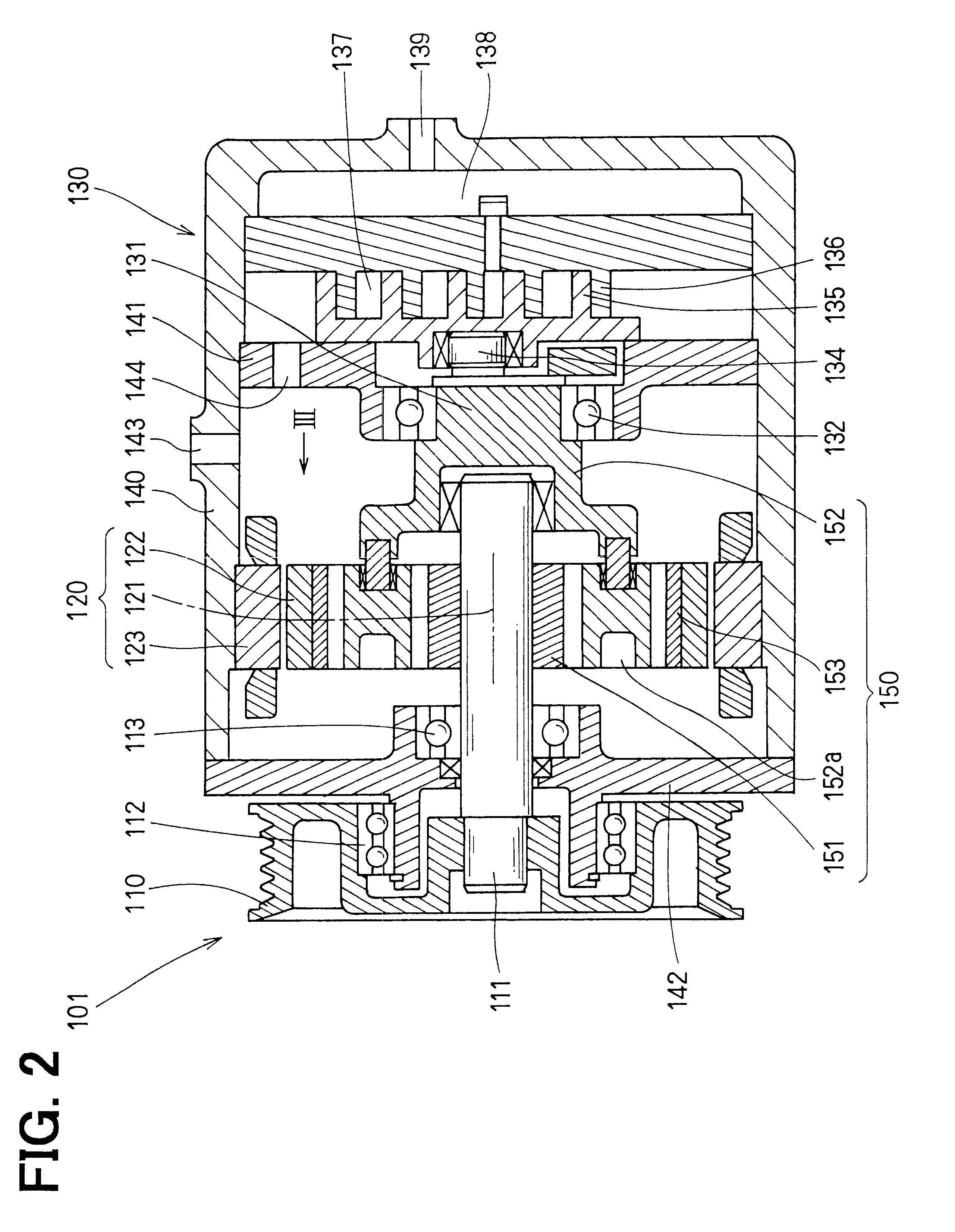

Hybrid compressor device

InactiveUS6742350B2Speed of compressor can be increased and decreasedEasy dischargeCompression machines with non-reversible cyclePump controlGear wheelEngineering

In a hybrid compressor for a vehicle where a vehicle engine is stopped when the vehicle is temporally stopped, a pulley, a motor and a compressor can be driven in independent from each other, and are connected to a sun gear, planetary carriers and a ring gear of a planetary gear. A rotational speed of the motor is adjusted by a controller, so that a rotational speed of the compressor is changed with respect to a rotational speed of the pulley. Accordingly, production cost of the hybrid compressor and the size thereof can be reduced, while a cooling function can be ensured even when the vehicle engine is stopped.

Owner:NIPPON SOKEN +1

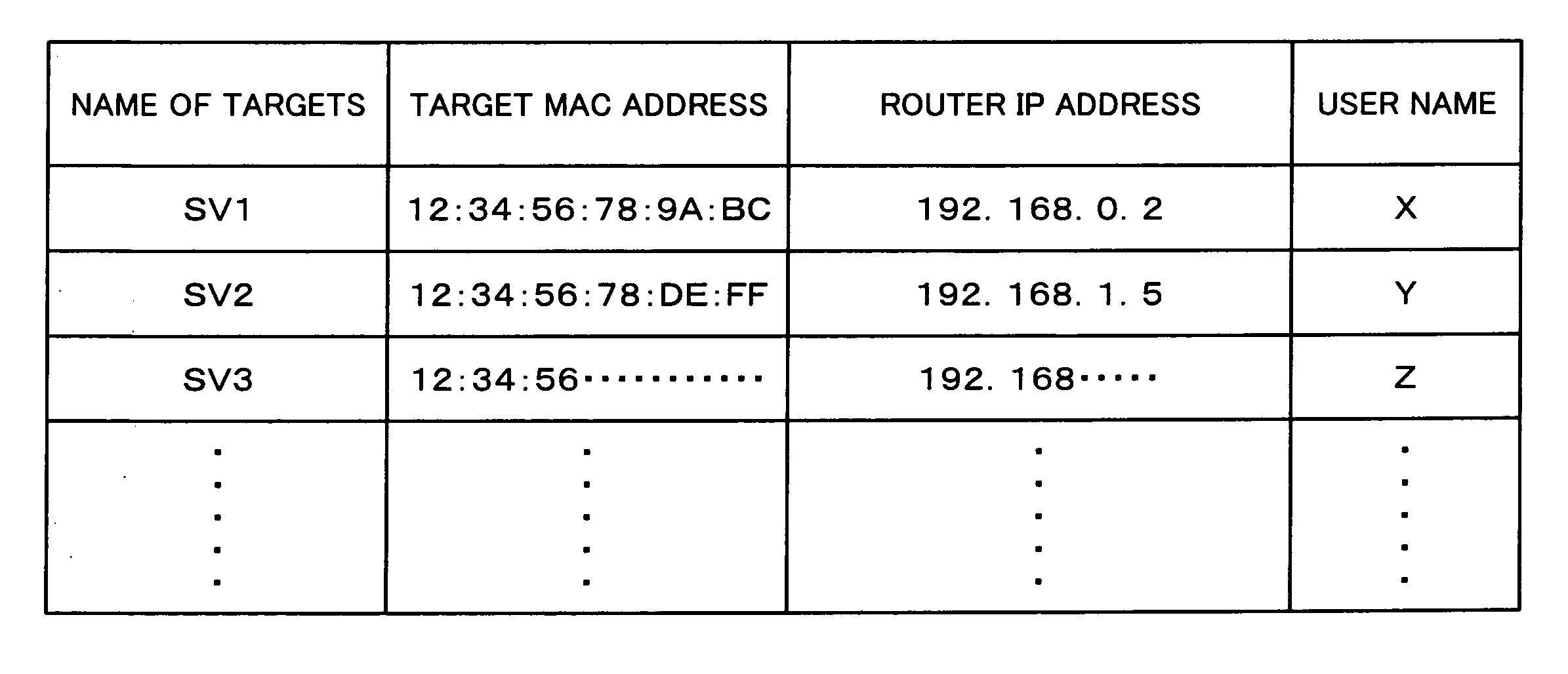

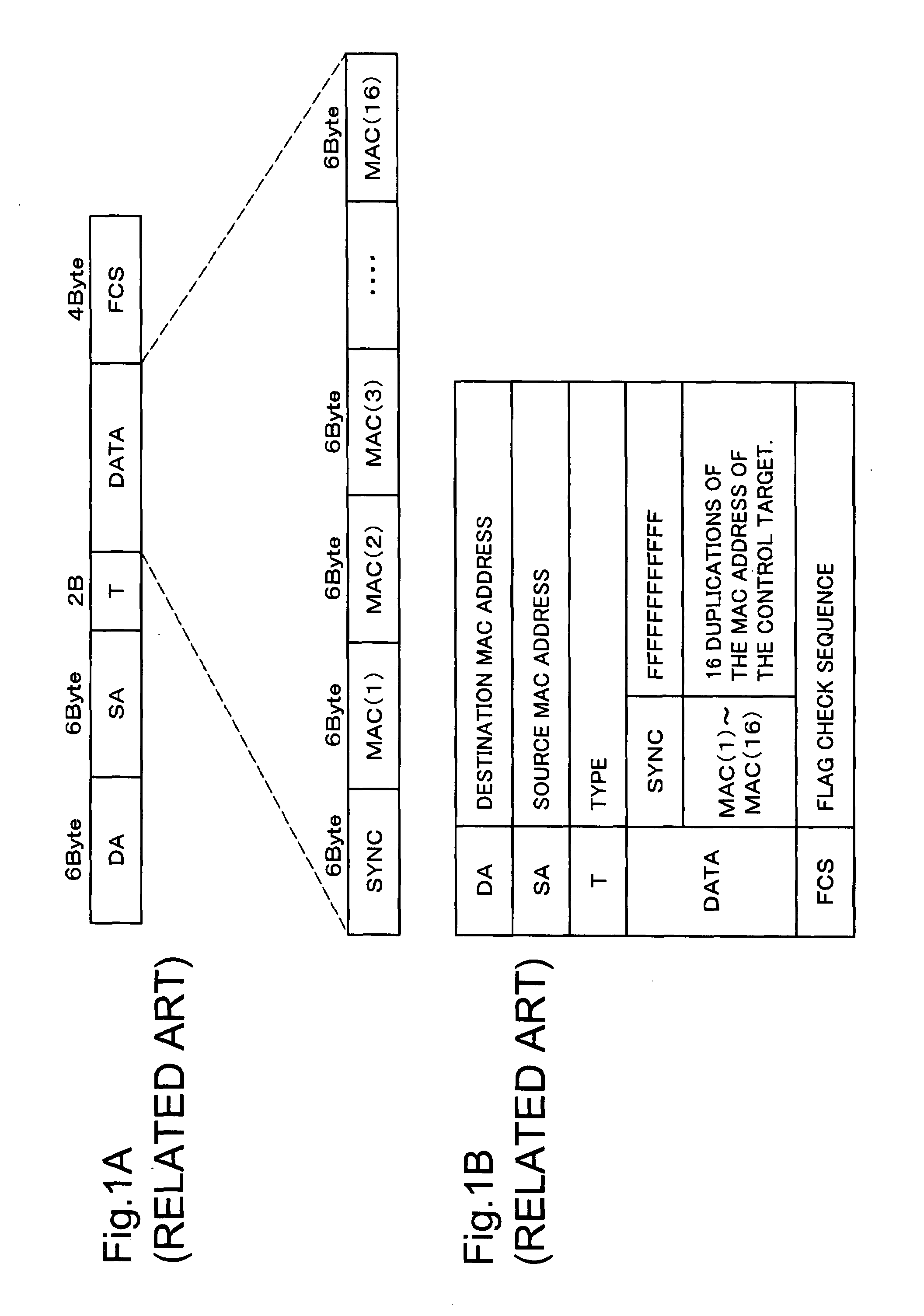

Apparatus and a system for remote control and a method thereof

InactiveUS20080080500A1Cost of operationLow costEnergy efficient ICTDigital data processing detailsComputer networkRemote control

Disclosed is a remote control system which includes a remote control apparatus on a network, a control packet transmitter which is on a sub network and connects with the remote control apparatus via a network interconnecting apparatus, an operation terminal which can connect with the remote control apparatus, and a control target on the sub network of the control packet transmitter. The operation terminal transmits information which includes a control content of the control target to the remote control apparatus. The remote control apparatus includes a table including an address of the control packet transmitter and an address of the control target. The remote control apparatus transmits a control request packet including the acquired address of the control target and control content to the control packet transmitter. The control packet transmitter transmits a control packet including a control content designated by a control request packet to the control target.

Owner:NEC CORP

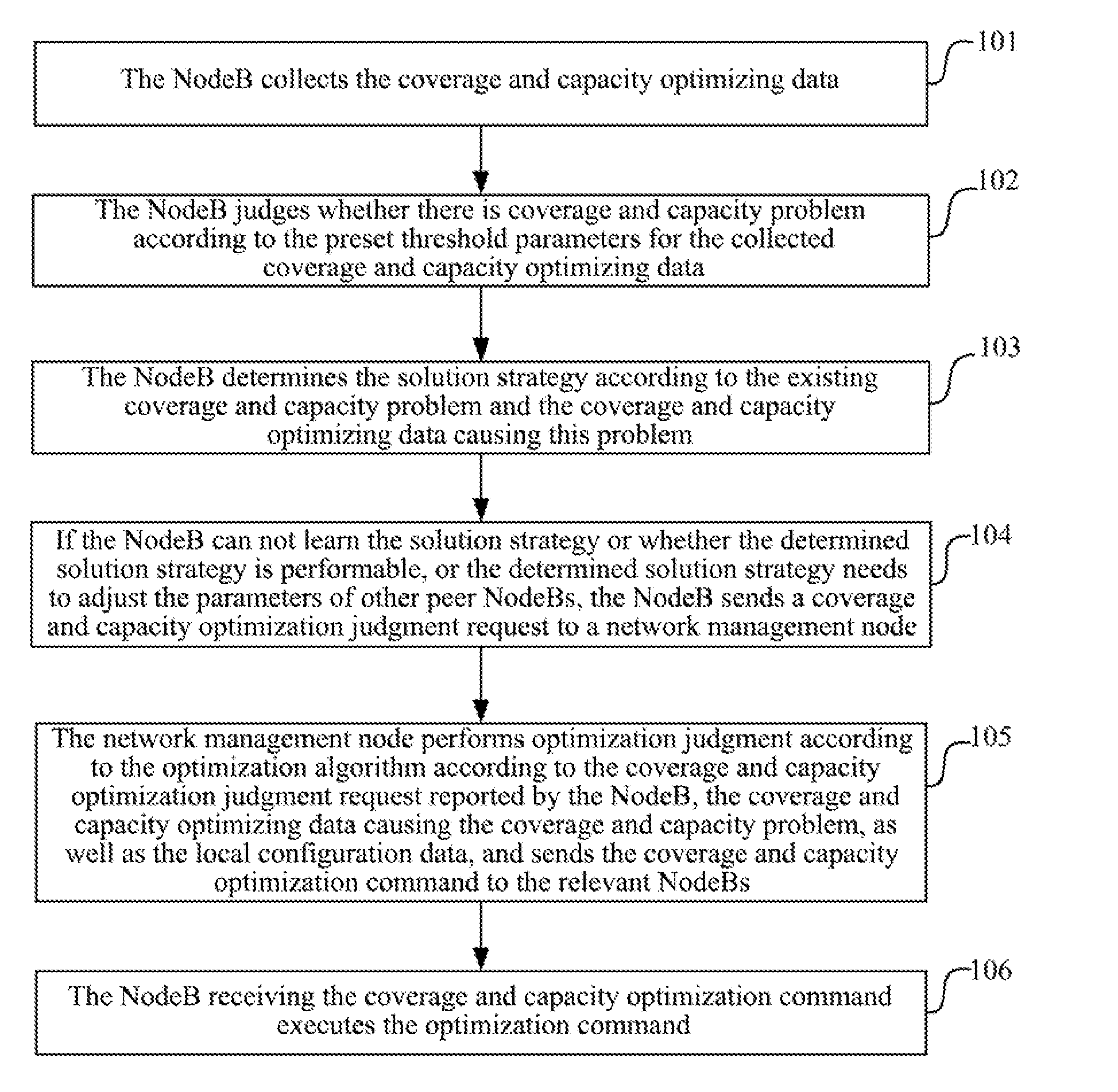

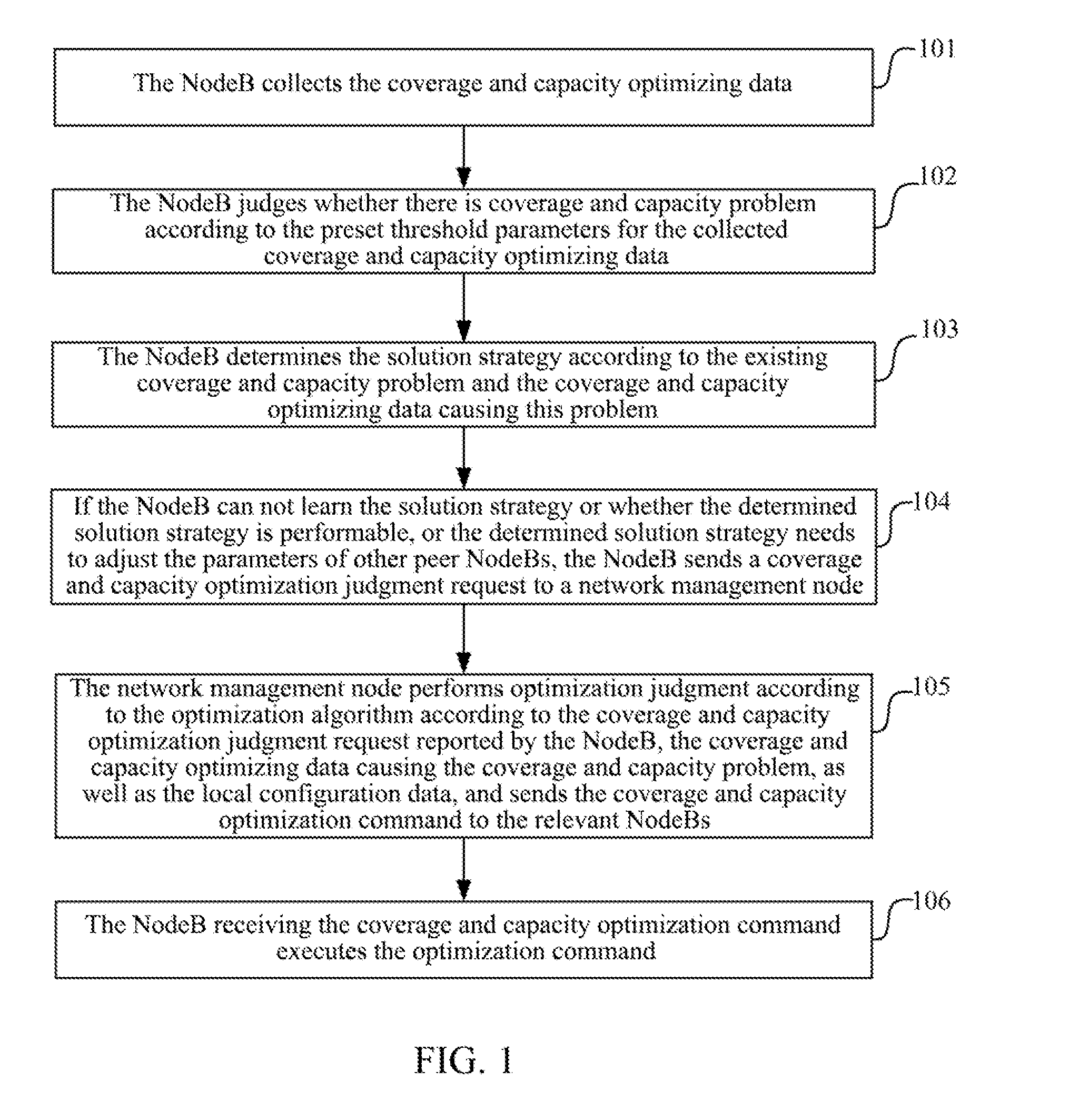

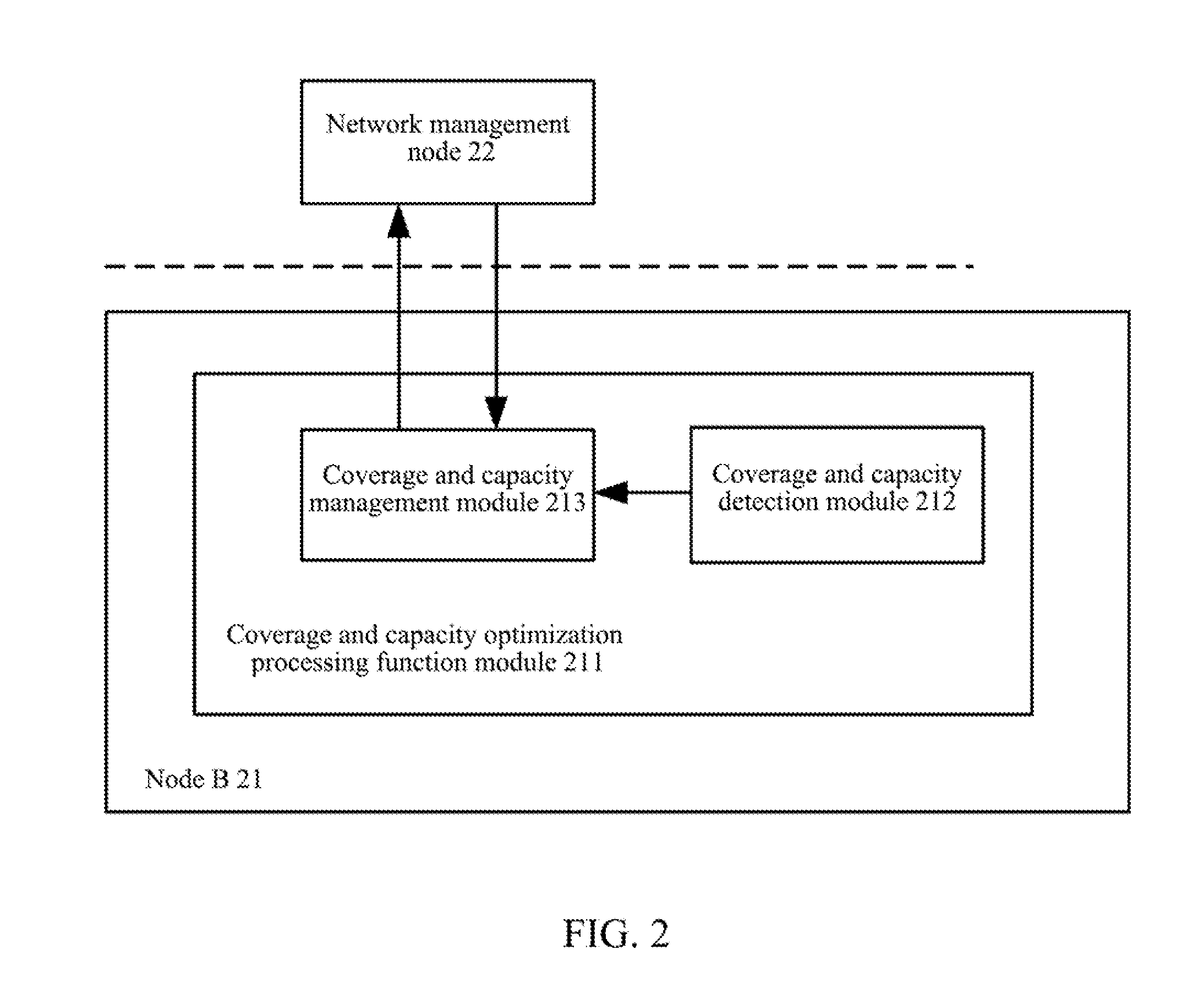

Method and System for Optimizing Network Coverage and Capacity

InactiveUS20120039166A1Increase capacityOptimize network coverageError preventionTransmission systemsMaterial resourcesAutomation

A method and system for optimizing network coverage and capacity are provided. The method comprises that: judging whether there is a problem of coverage and capacity according to the threshold set in a NodeB for the collected coverage and capacity optimizing data; if yes, the NodeB provides a solution strategy according to the problem of coverage and capacity as well as the coverage and capacity optimizing data causing the problem. The method achieves the automation of network coverage and capacity, saves a great deal of manpower and material resource needed by the traditional optimizing method, and decreases the cost of network operation and maintenance.

Owner:ZTE CORP

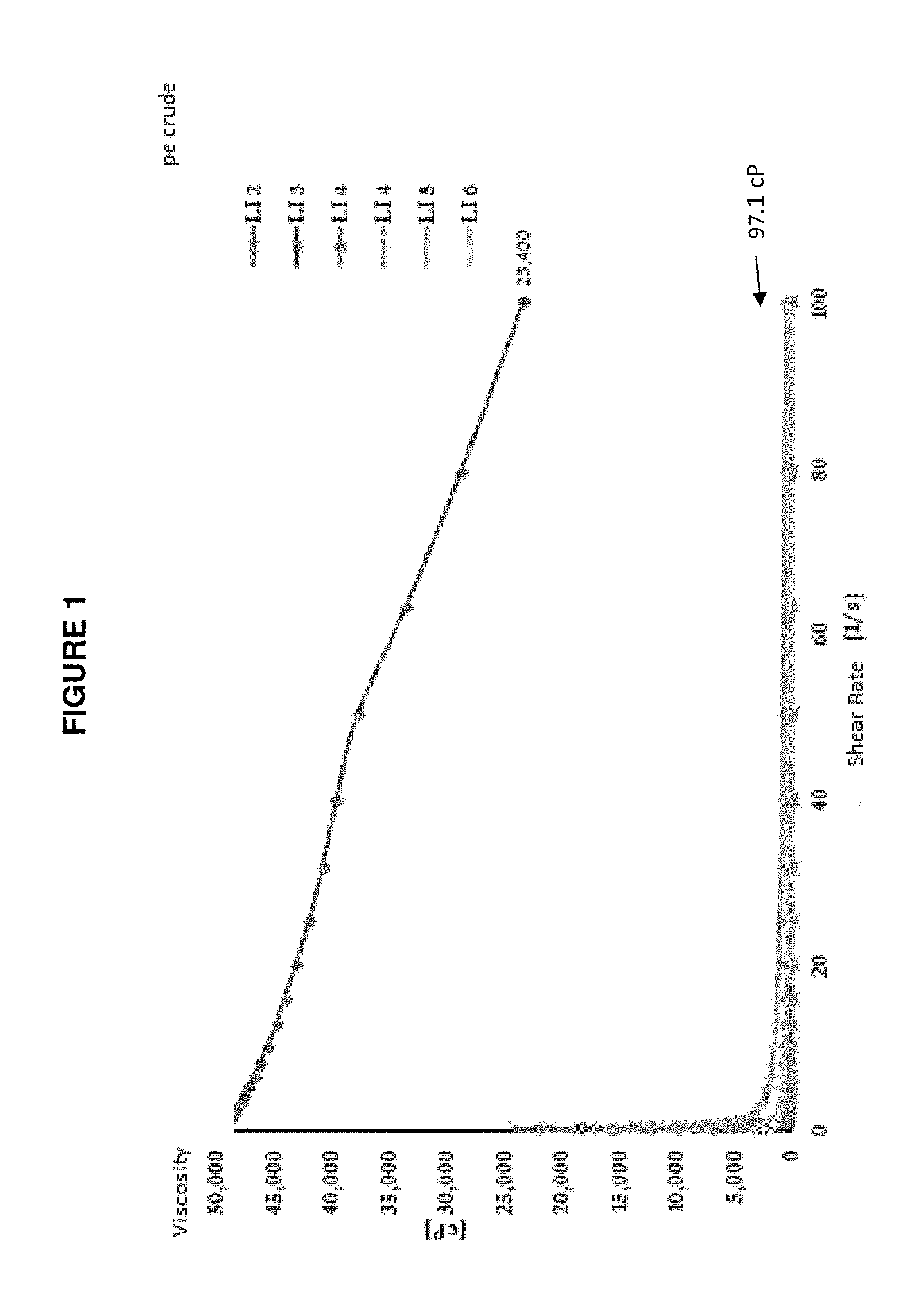

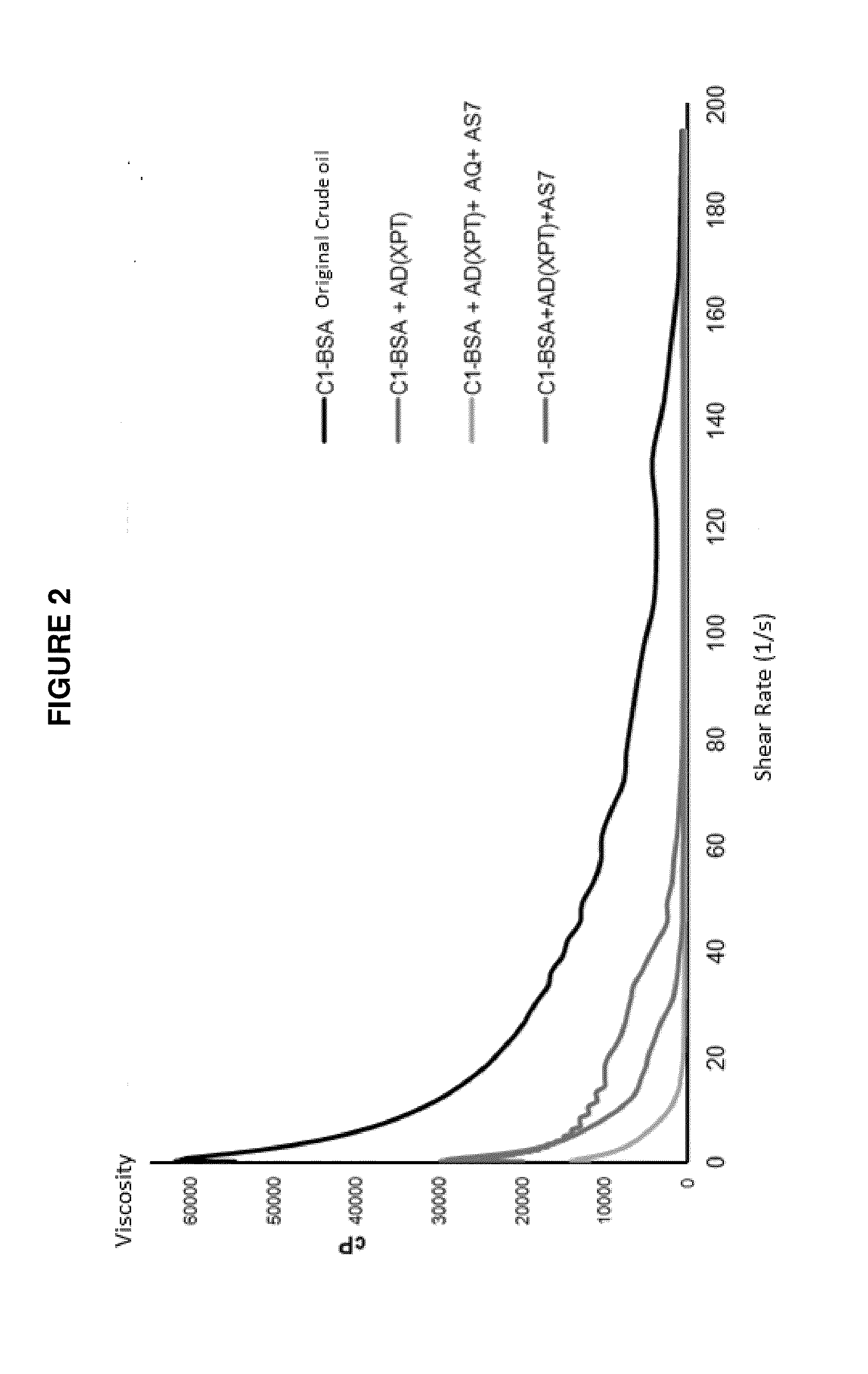

Application of a chemical composition for viscosity modification of heavy and extra-heavy crude oils

ActiveUS20150111799A1Low viscosityImprove liquidityDistillation purification/separationHydrocarbonsChemical compositionHeavy crude oil

The present invention relates to the use of a chemical composition to modify the physical properties (viscosity and interfacial tension) of heavy and extra-heavy crude oils, to increase their mobility. The chemical composition comprises or consists of a combination of systems based on ionic and non-ionic liquids, which may be pure or modified, mixed in an aqueous or organic medium as a dispersing agent, depending on the nature of the crude to be treated, together with a surfactant. The composition is mixed with the crude oil at a temperature between 5 and 100° C., at pressures from 1 atm (14.7 psi) up to about 680.2 atm (10,000 psi). The composition can be mixed with heavy crude oils, at the point of extraction from the well in the field, during the transport of crude oil in pipelines, or in the well discharge pipelines.

Owner:INST MEXICANO DEL GASOLINEEO +1

Method and system for upgrading software

ActiveUS9043778B2Save bandwidth resourcesReduce software upgrading workloadDatabase updatingVersion controlSoftware engineeringWorkload

Embodiments of the present disclosure provide a method and a system for upgrading software. The method includes: a client reports a software upgrade request to a server, wherein the upgrade request carries file information of the local software to be upgraded; the server determines the difference with the latest version software according to the file information of the software to be upgraded in the upgrade request, and generates upgrade instruction information according to the difference and sends it to the client; the client downloads and updates the relevant files and performs the relevant local upgrade operations according to the instructions in received upgrade instruction information. Technical solutions of the present disclosure can save bandwidth resources and reduce the workload for upgrading software.

Owner:TENCENT TECH (SHENZHEN) CO LTD

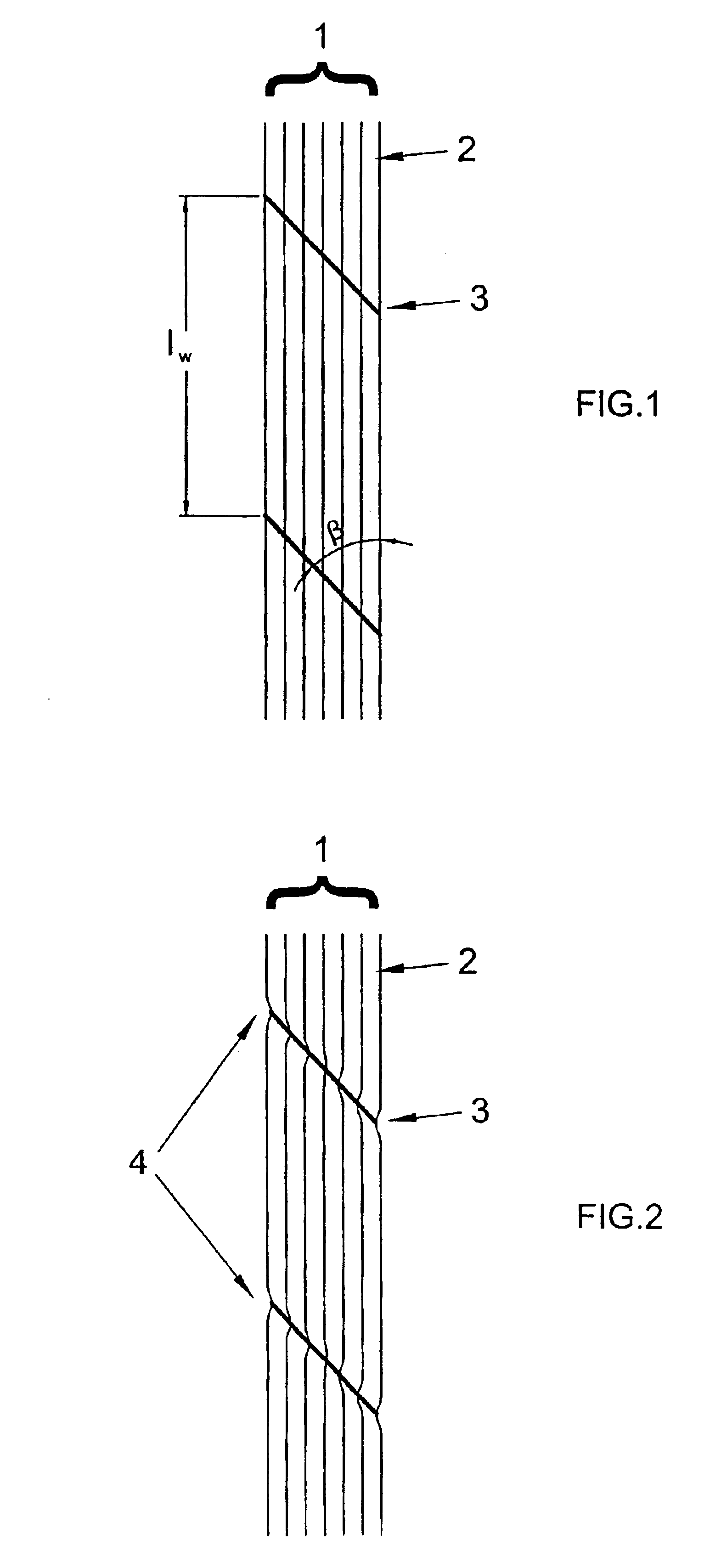

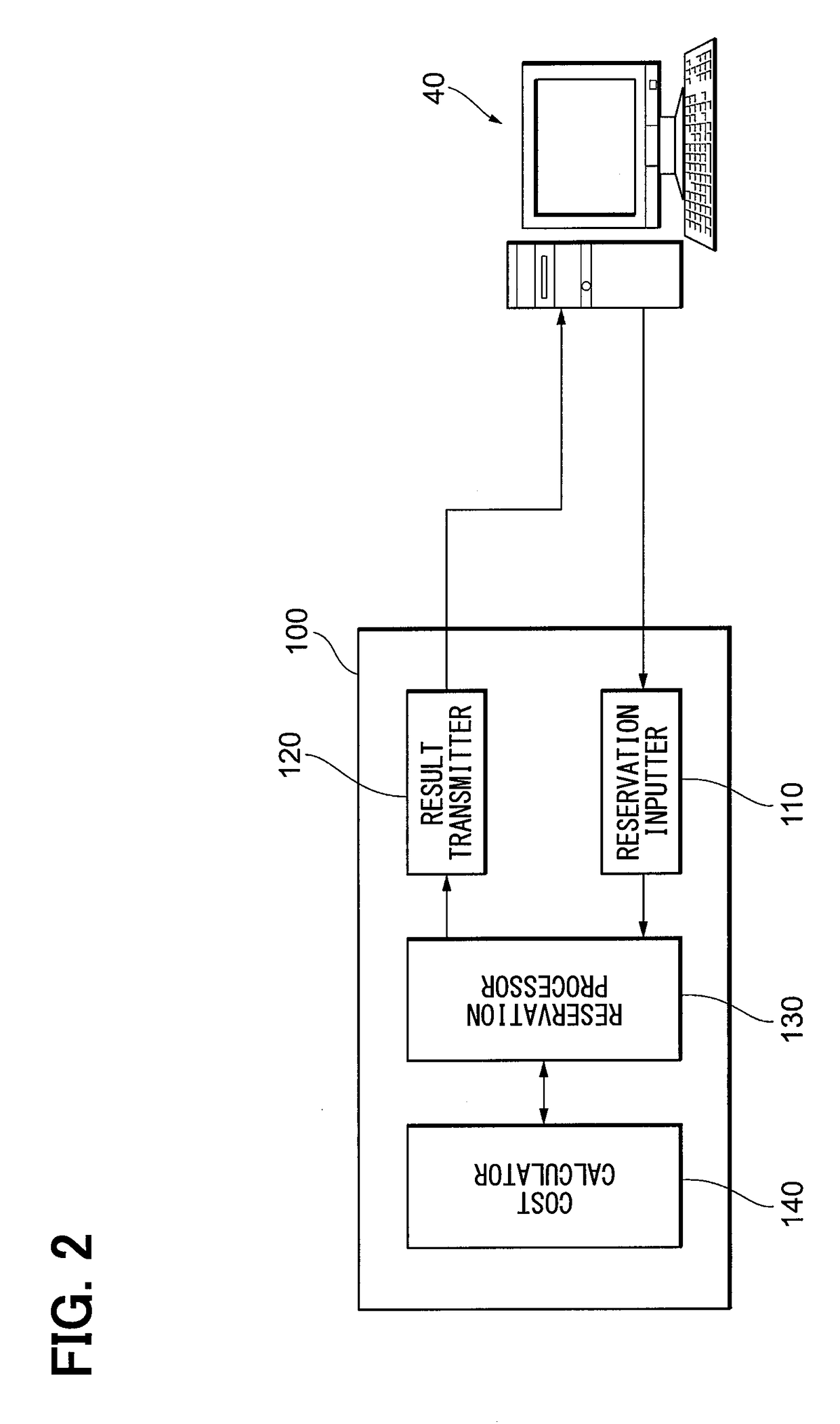

Wrapped cord

InactiveUS6855423B2Improve fatigue resistanceHigh breaking strengthSynthetic resin layered productsPneumatic tyre reinforcementsMedicineReinforced rubber

The present invention relates to a wrapped cord, to a method of making said wrapped cord, to a method of treating said wrapped cord with an adhesive treatment composition, to the treated wrapped cord obtainable by said method as well as to a reinforced rubber article comprising said treated cord, such as automotive tires.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

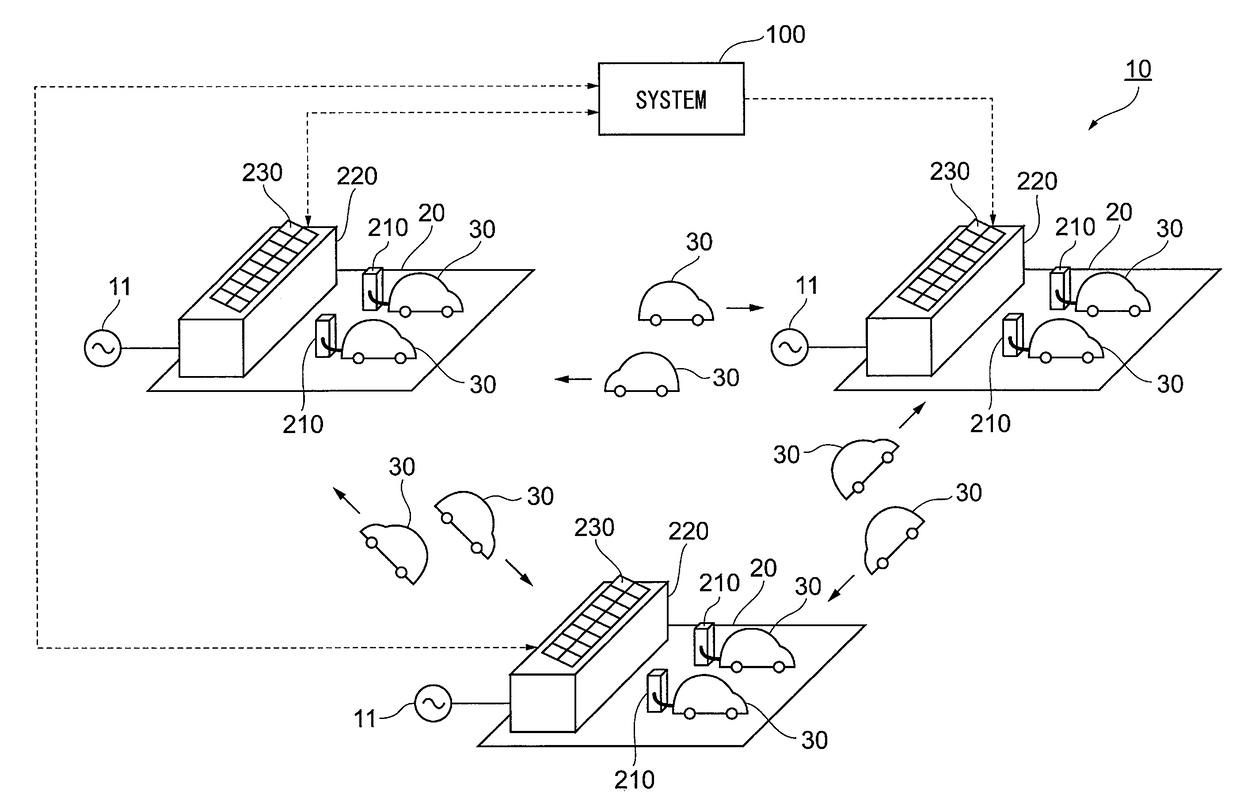

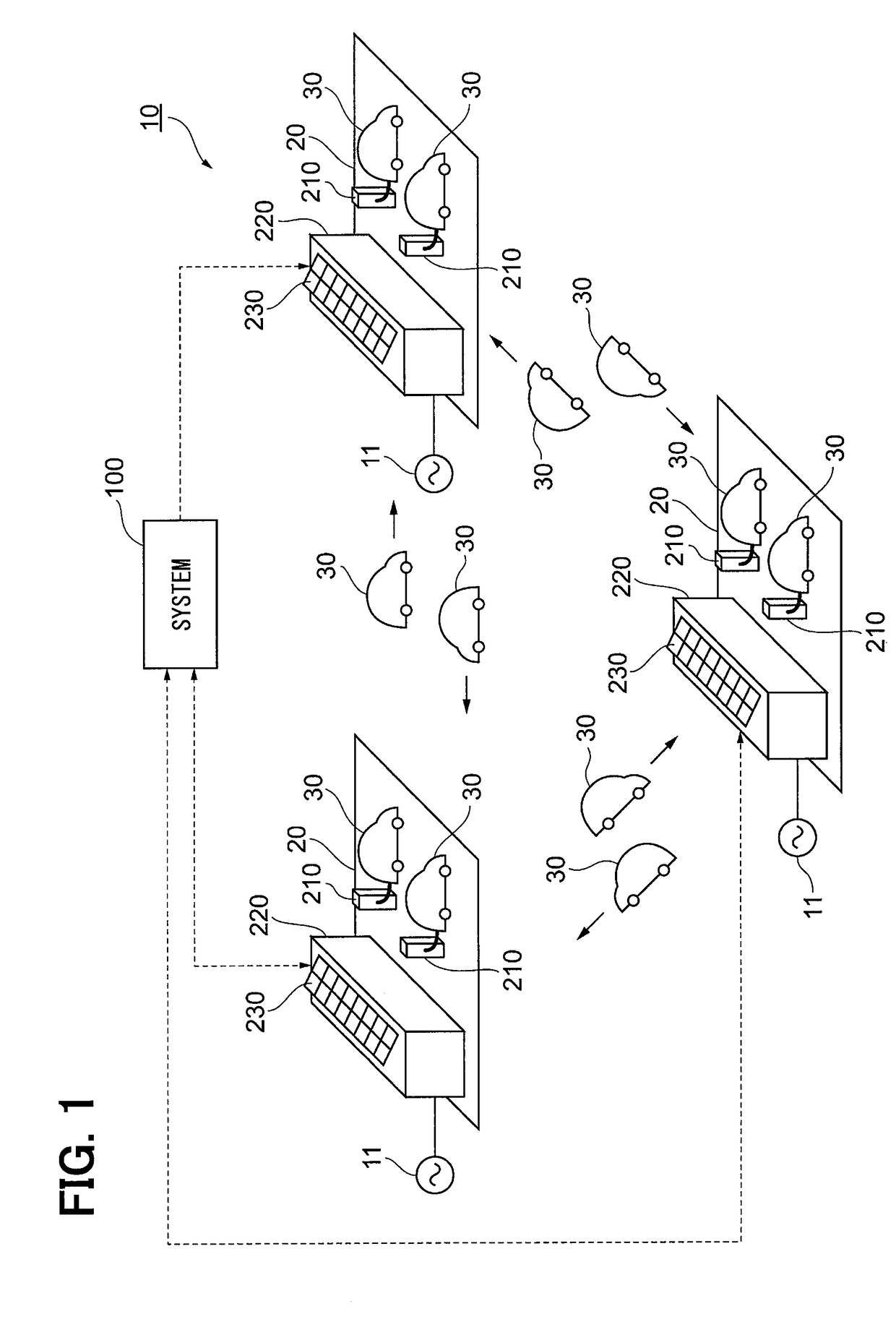

Vehicle management system for vehicle-sharing service

InactiveUS20180032920A1Short processing timeCost of operationReservationsForecastingStart timeOperational costs

A vehicle management system for handling vehicle reservations of a vehicle-sharing service includes a reservation request input device, a reservation result transmitter, and a reservation processor. When a new vehicle reservation request is input to the reservation request input device, the reservation processor performs a simple process for a vehicle allocation which allocates a vehicle to the new vehicle reservation request, and the result transmitter transmits a reservation result to a user. When the time duration after the performance of the simple process and before the rental start time for the new vehicle reservation is equal to or greater than a threshold value, the reservation processor performs an optimization process to update the vehicle allocation for the new vehicle reservation request, quickly presenting a reservation result to the user while reducing an operation cost of the vehicle-sharing service.

Owner:DENSO CORP

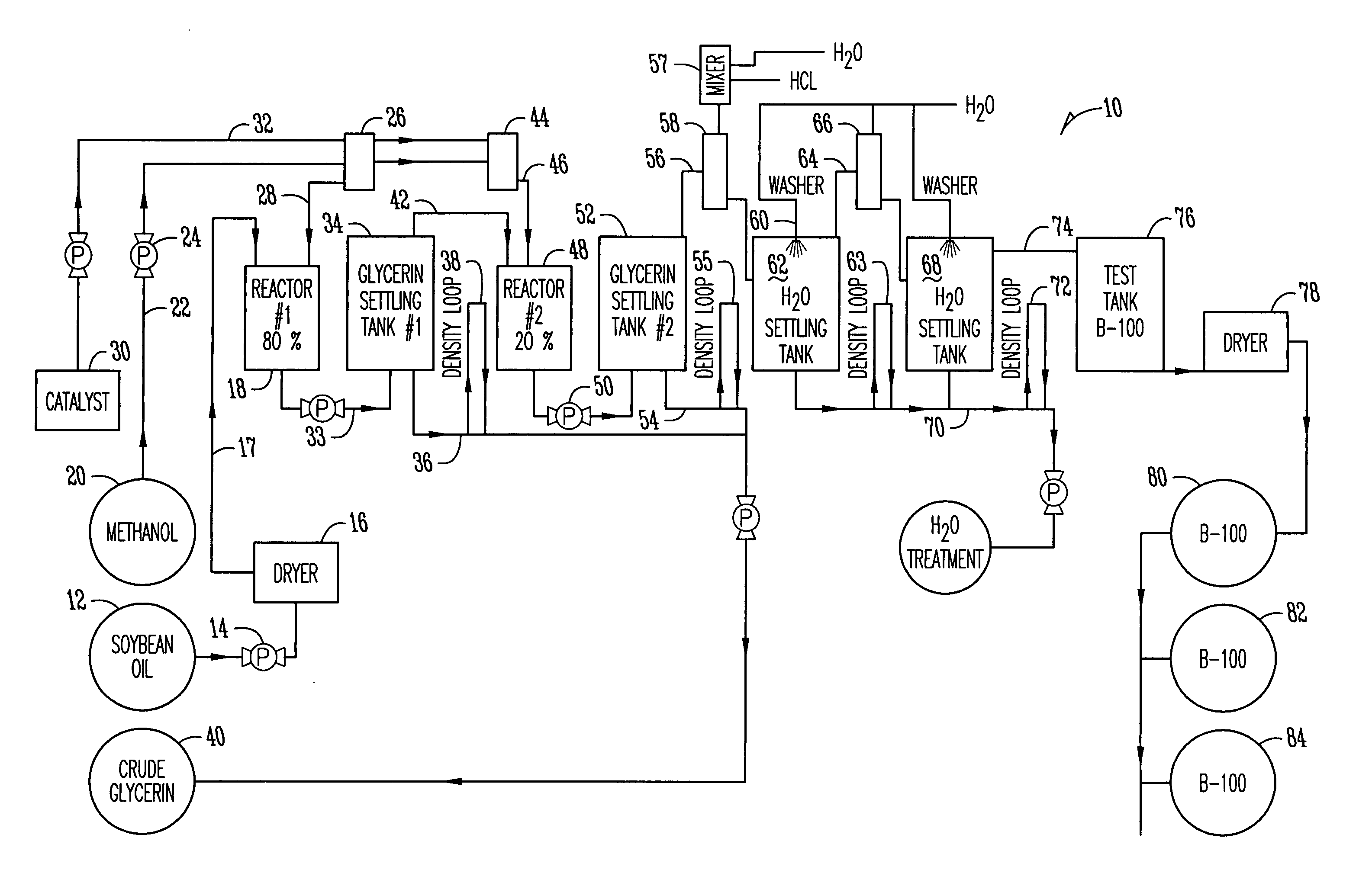

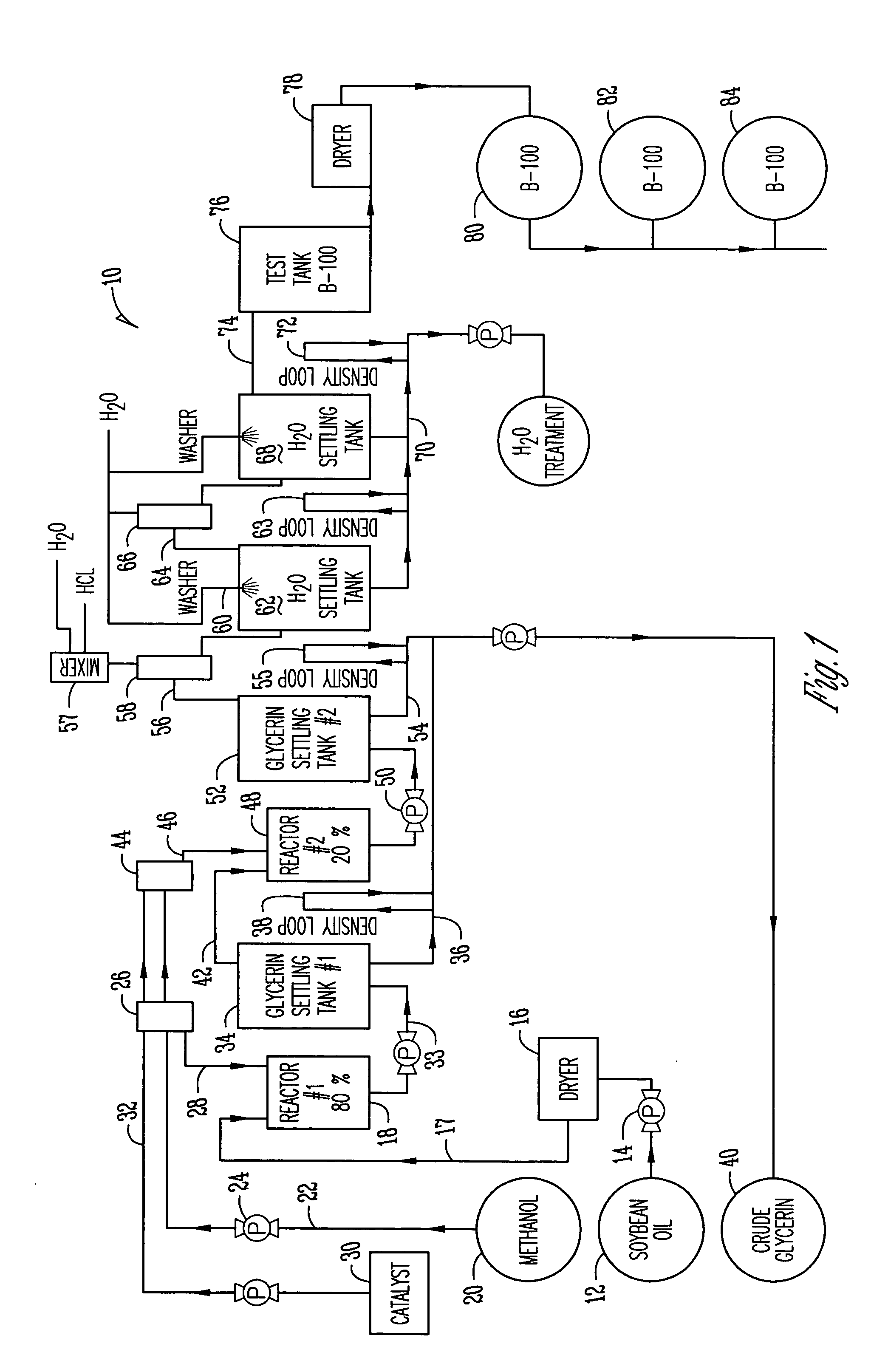

High yield bio diesel fuel preparation process

An improved biodiesel fuel preparation process using the step of simultaneous separation of biodiesel reaction product and glycerin, by specific gravity separation taking advantage of the pressure created by the heavier glycerin by using density loops, drawing of by-product glycerin from the bottom of the container while drawing off the lighter biodiesel reaction product from the top of the container as it is forced out by the density loop pressure. All of this is without the use of any pumps thereby reducing energy consumption and cost. Process efficiency is achieved by separating the methanolysis into two steps.

Owner:FARMERS COOP ELEVATOR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com