Cross-section coal uncovering accurate outburst elimination method for rock cross-cut

A section and Shimen technology, which is applied in the field of accurate outburst relief for cross-section coal mining in Shimen, can solve problems such as difficult to achieve rapid excavation, insufficient gas release, and inability to effectively reduce gas pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

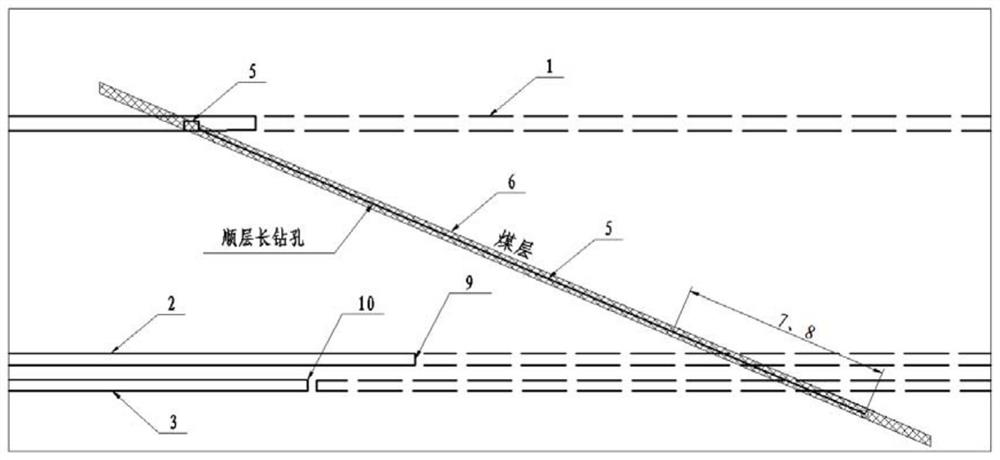

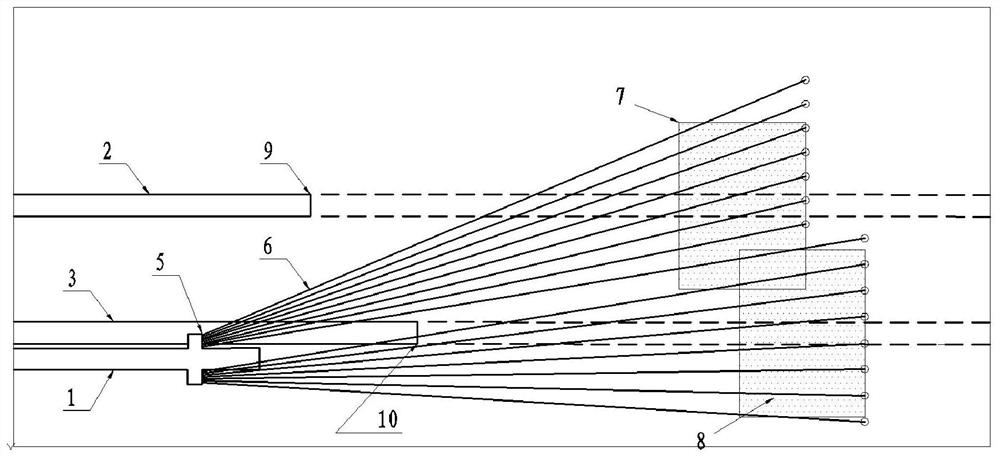

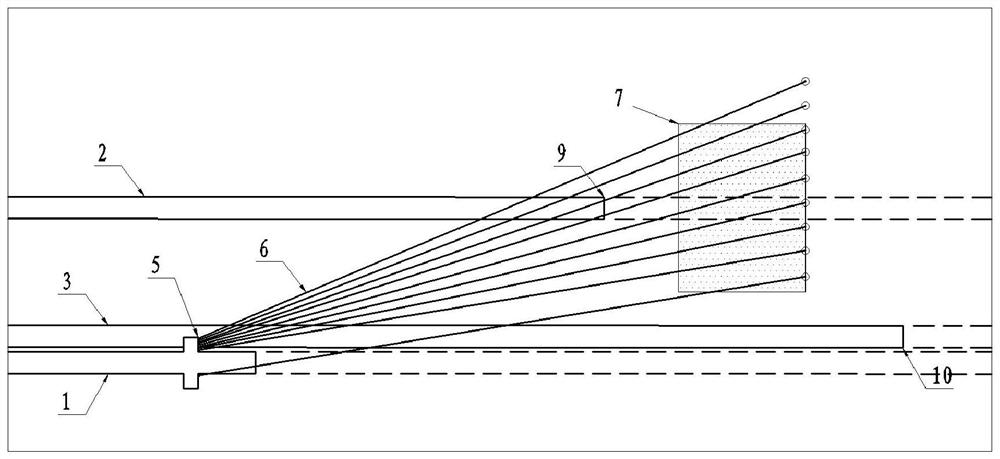

[0017] Example 1: An attached Figure 1 ~ 3 As shown, a stone door cross-zone segment is accurately displaced, and the method includes the following steps:

[0018] First, when the upper section of Shimen 1 has been taken into place or has uncovered the coal seam 4, there are two segments in the lower section of the lower zone, the down-zone of the lower zone is undergoing or willing to develop, and the lower section Shimen 3 will expose the coal seam 4, On both sides of the upper side of the upper section of the stone door, the construction drill field is applied, and the construction combined long drilling 6 (according to the mantle layer spacing of the upper and lower segments, the lane and the roadway arrangement of stone doors, which are orthose, unproved stone gates, determine the contrast length The number of drilled holes is controlled by the underlying section of the coal, Duan Shimen 2, Duan Shimen 2, and the outer line of Shimen 3 roadway exterior of Shimen 3, at least 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com