High-gas mine Y-shaped ventilation method

A ventilation method and gas technology, applied in mine/tunnel ventilation, gas discharge, mining equipment, etc., can solve problems such as the impact of safe and efficient production on the working face, and achieve the effects of eliminating the risk of gas outburst, good safety, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

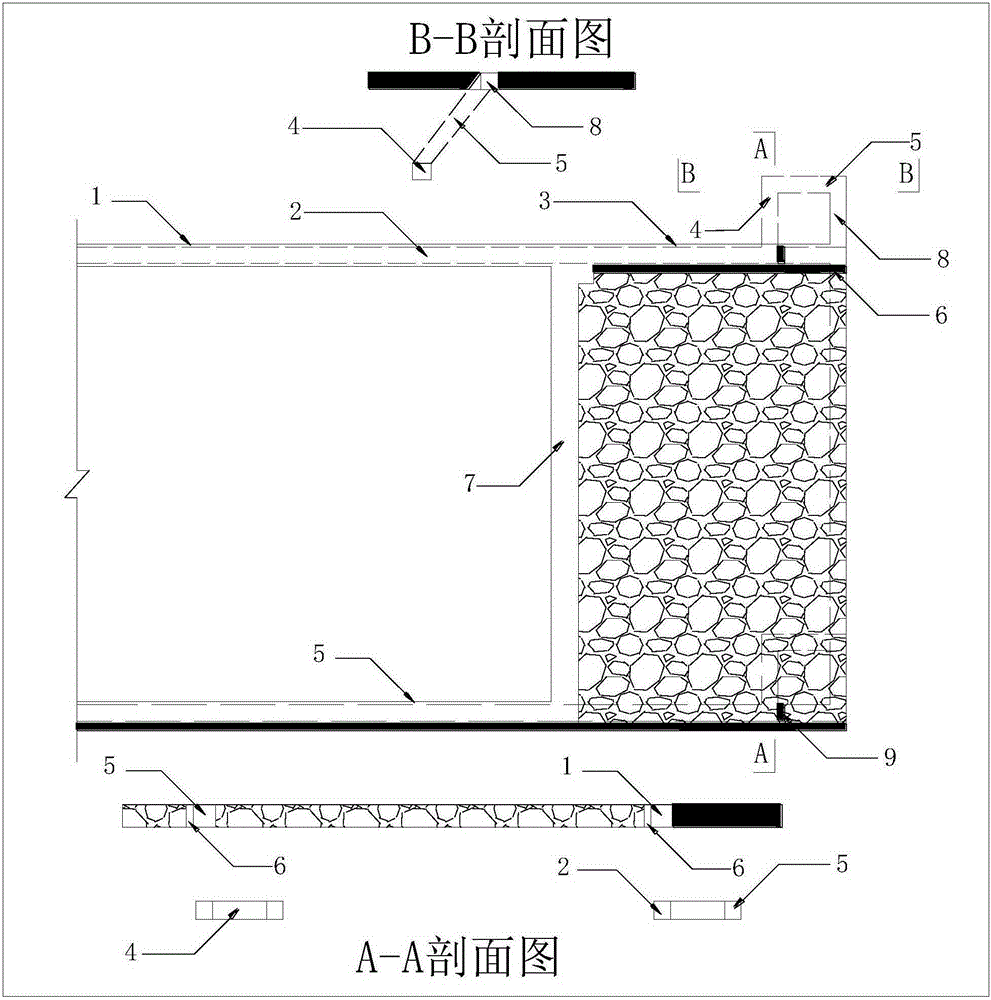

[0020] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and embodiments.

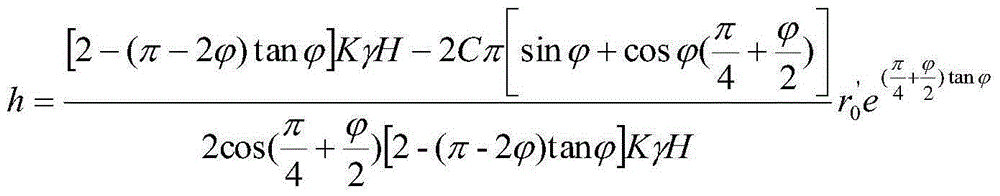

[0021] 1. First, excavate the bottom extraction roadway 2 at a certain depth from the coal seam floor, and the two bottom extraction roadways are located directly below the position of the designed track along the groove. The excavation depth of the bottom pumping roadway should be greater than the depth of floor damage caused by mining. The floor damage depth is determined according to the geological conditions of the well field and the thickness of the coal seam. It can be calculated by referring to the following formula:

[0022]

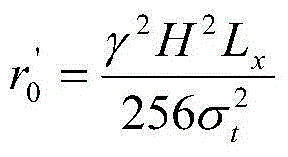

[0023] r 0 ′ = γ 2 H 2 L x 256 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com