Drilled hole effective extraction radius measuring method based on gas content method

A technology of gas content and gas drainage, which is applied in the field of measuring the effective drainage radius of boreholes based on the gas content method, can solve the problems of low success rate, save manpower and eliminate outburst risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is a detailed description of the preferred embodiments of the present invention. It should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

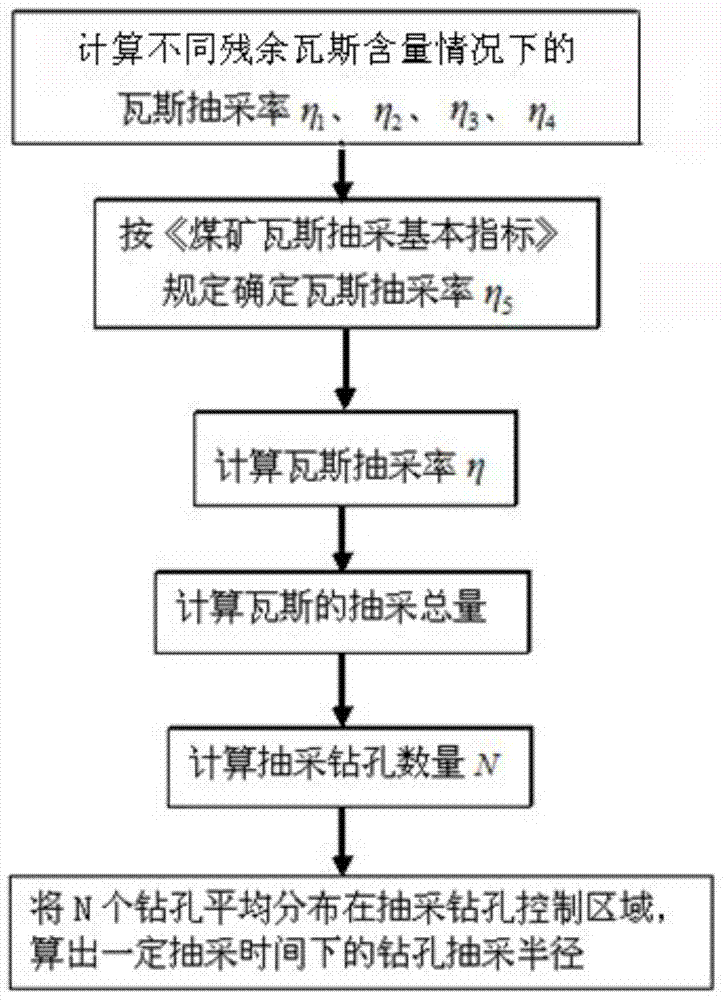

[0042] figure 1 It is a schematic flow sheet of the method for measuring the effective drainage radius of the borehole based on the gas content method of the present invention, referring to figure 1 , the present invention comprises the following steps:

[0043] 1) Calculate the gas drainage rate under different residual gas content conditions, including: the residual gas volume is reduced to 8m 3 Gas drainage rate η at / t 1 , The gas drainage rate η when the residual gas content is reduced to the corresponding gas content at the incipient depth 2 , The gas extraction rate η corresponding to the gas content when the residual gas pressure is reduced to 0.74MPa 3 , The gas extraction rate η corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com