Method for determining grid type layer-through drilling intervals of floor roadway

A technology of drilling through layers and measuring methods, which is applied in the directions of surveying, earthwork drilling, gas discharge, etc., and can solve the problem that the measured drilling holes cannot truly reflect the drilling drainage effect, cannot meet the requirements of rapid measurement, and the measurement results are unreliable, etc. problems, to achieve the effects of eliminating outstanding risks, measuring quickly, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

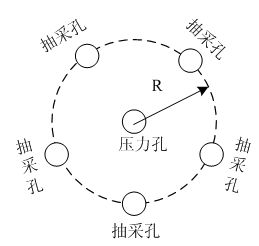

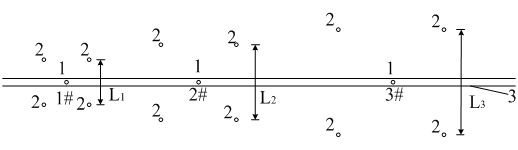

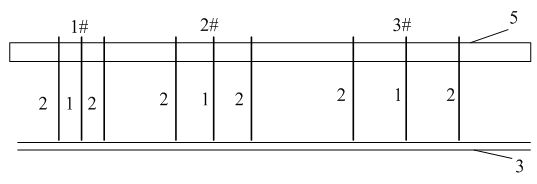

[0022] The method for measuring the interlayer drilling distance of the bottom slate roadway of the present invention is realized by measuring the layout of the boreholes and determining the spacing of the interlayer drilling holes in the grid format, and the specific steps are as follows:

[0023] (1) Determination of the layout of the borehole

[0024] a. First, at least three pressure holes 1 for measuring coal seam gas pressure are constructed in groups perpendicular to the coal seam direction in the floor rock roadway 3, and pressure gauges are installed, such as figure 2 , image 3 The layout shown is 1#, 2# and 3# pressure holes 1 respectively, the distance between each pressure hole 1 is not less than 40m, when the pressure gauge gradually rises to the maximum value, the pressure of 1# hole is 2.12MPa, 2# The pressure of the hole is 2.15MPa, and the pressure of the 3# hole is 2.05MPa. Through the analysis, it is considered that the gas pressure of the coal seam in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com