Low premeability high gas soft thick coal layer remote pressure relief gas exhausting method

A gas drainage and gas permeability technology, which is used in gas drainage, earthwork drilling, safety devices, etc., can solve the problems of ineffective gas drainage and inability to form gas, eliminate the danger of coal and gas outburst, reduce Destructive effect, the effect of safe and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

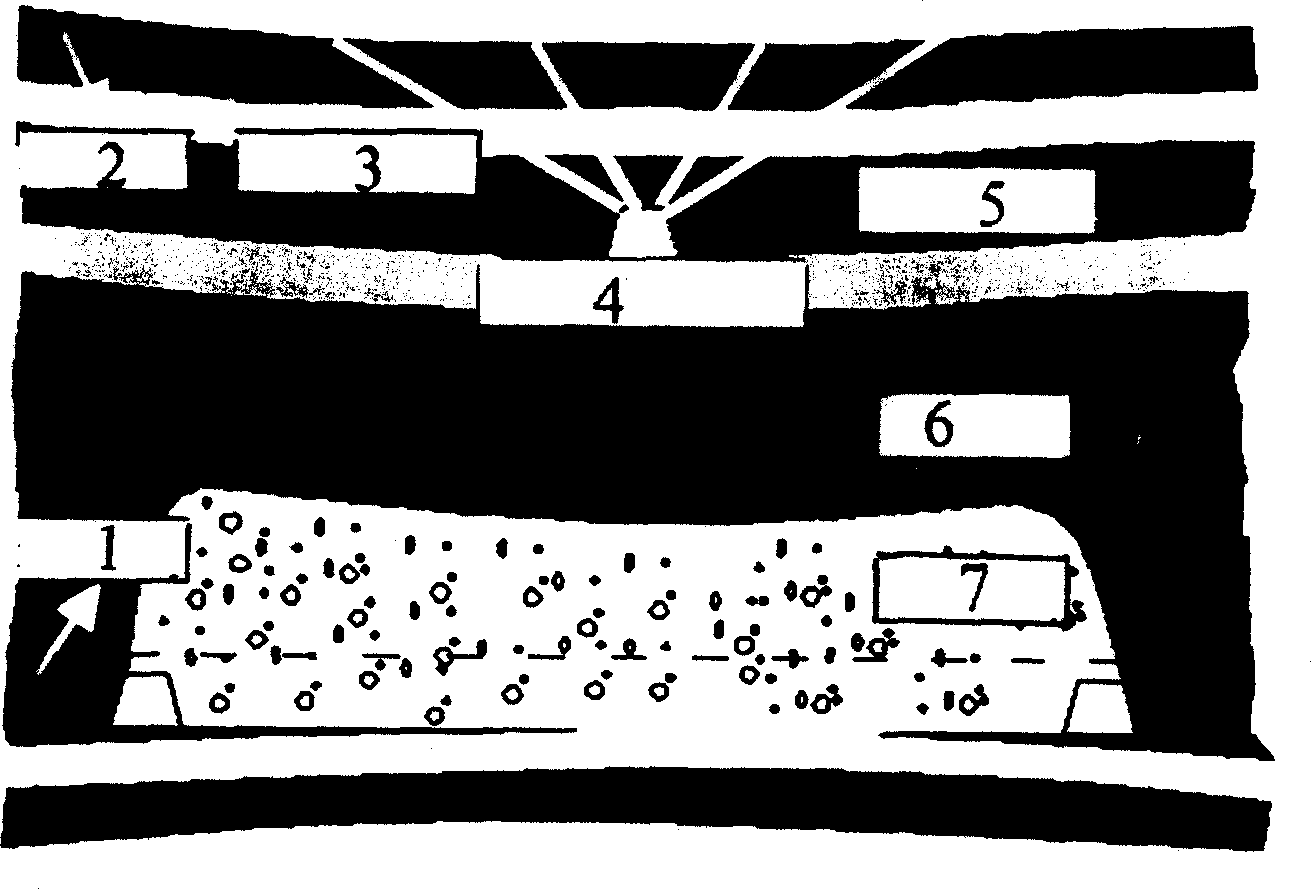

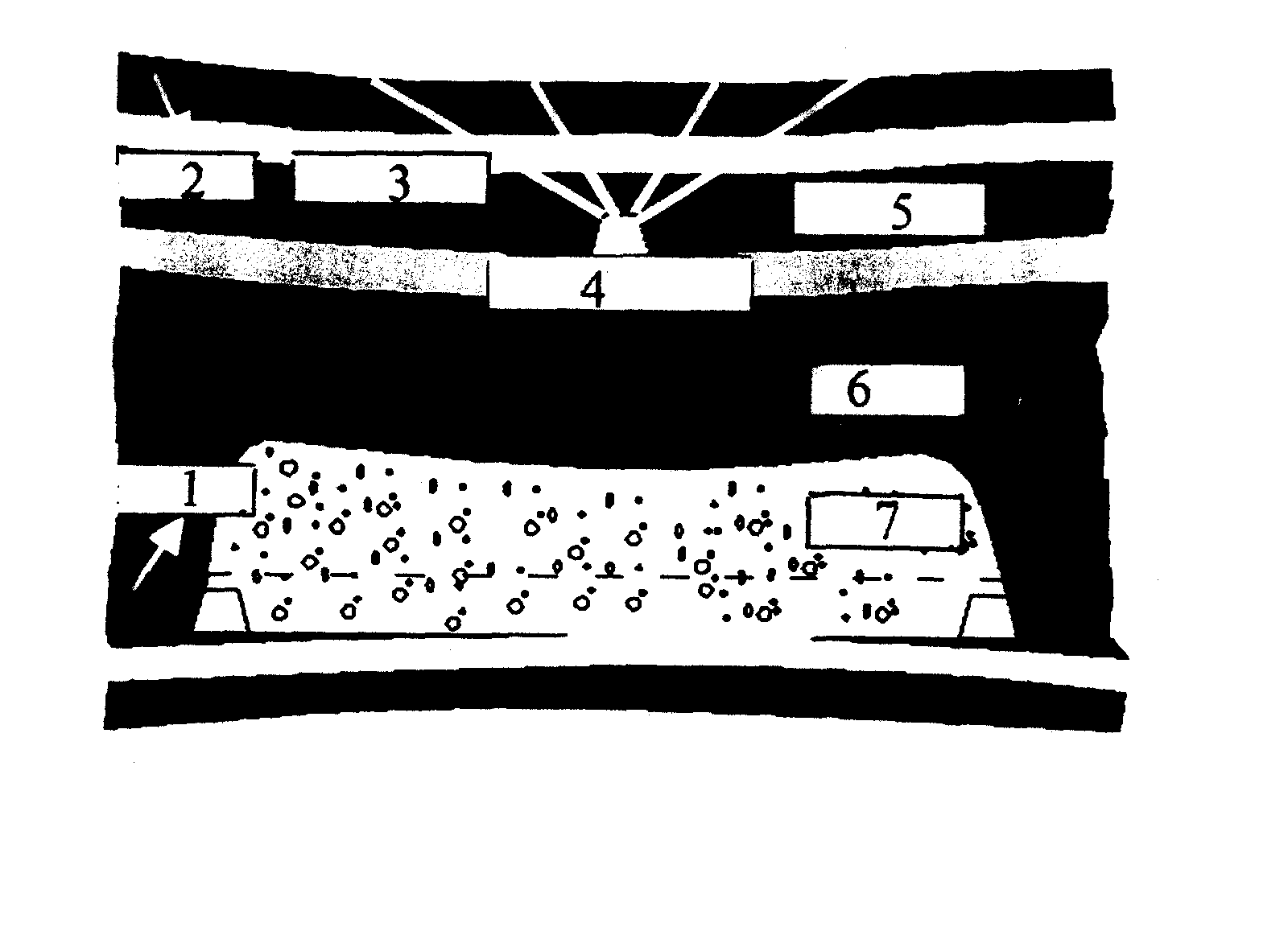

[0013] For the Huainan mining area, the 11# mining coal seam 1, which is 70m lower than the 13# pressure relief coal seam 2 and whose relative layer spacing is 30 to 40 times, is mined first. Affected by mining pressure relief and subsidence, pressure relief fractures along the bedding are formed in the 13# pressure relief coal seam 2, and an upward grid pattern is formed in advance from the pressure relief coal seam 2 floor gas drainage lane 4 to the pressure relief coal seam 2 Drain the borehole 3 through the bed, and the pressure relief gas gathers to the drainage borehole 3 along the cracks along the bedding, and is drained through the drainage pipeline.

[0014] In specific implementation:

[0015] 1. About the reasonable location of floor gas drainage roadway.

[0016] According to the theory of mine pressure, after the 11# mining coal seam 1 is mined, the overlying strata will form a caving zone 7 , a fissure zone 6 and a curved subsidence zone 5 . According to the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com