Temperature sensor mounting structure and battery module structure

A technology for temperature sensors and battery components, which is applied to battery pack parts, structural parts, electrical components, etc., can solve the problems of difficulty in ensuring the position accuracy of temperature sensors, inability to easily replace temperature sensors, and difficulty in replacing battery component units. Small and lightweight, improved assembly and disassembly workability, and simplified configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

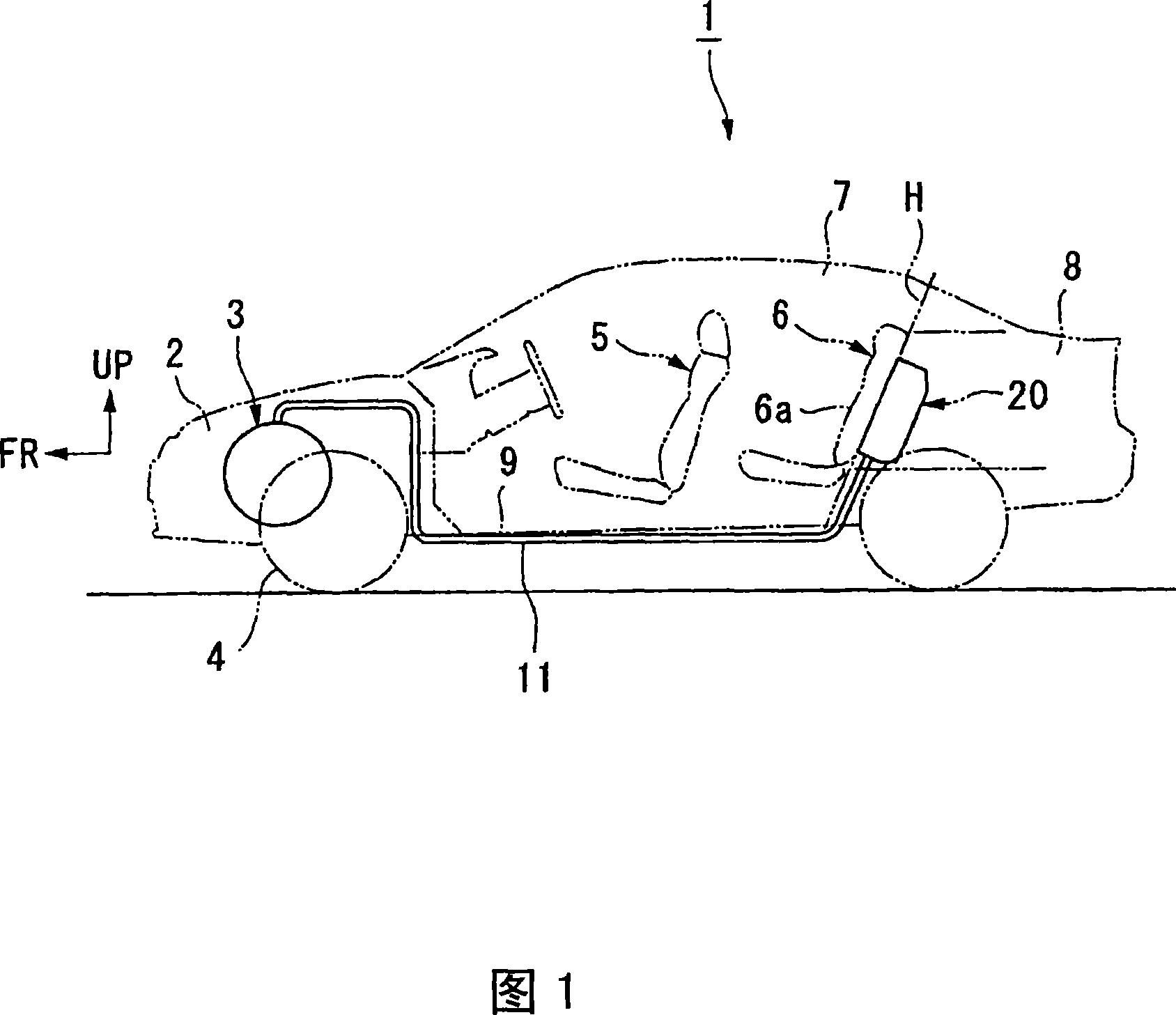

[0072] The vehicle 1 shown in FIG. 1 is a hybrid vehicle, and a motor generator (motor generator) is used to assist in driving an engine as an internal combustion engine, and its kinetic energy can be recovered as electric energy via the motor generator when the vehicle is decelerating. The recovered electrical energy charges the energy storage via the power converter.

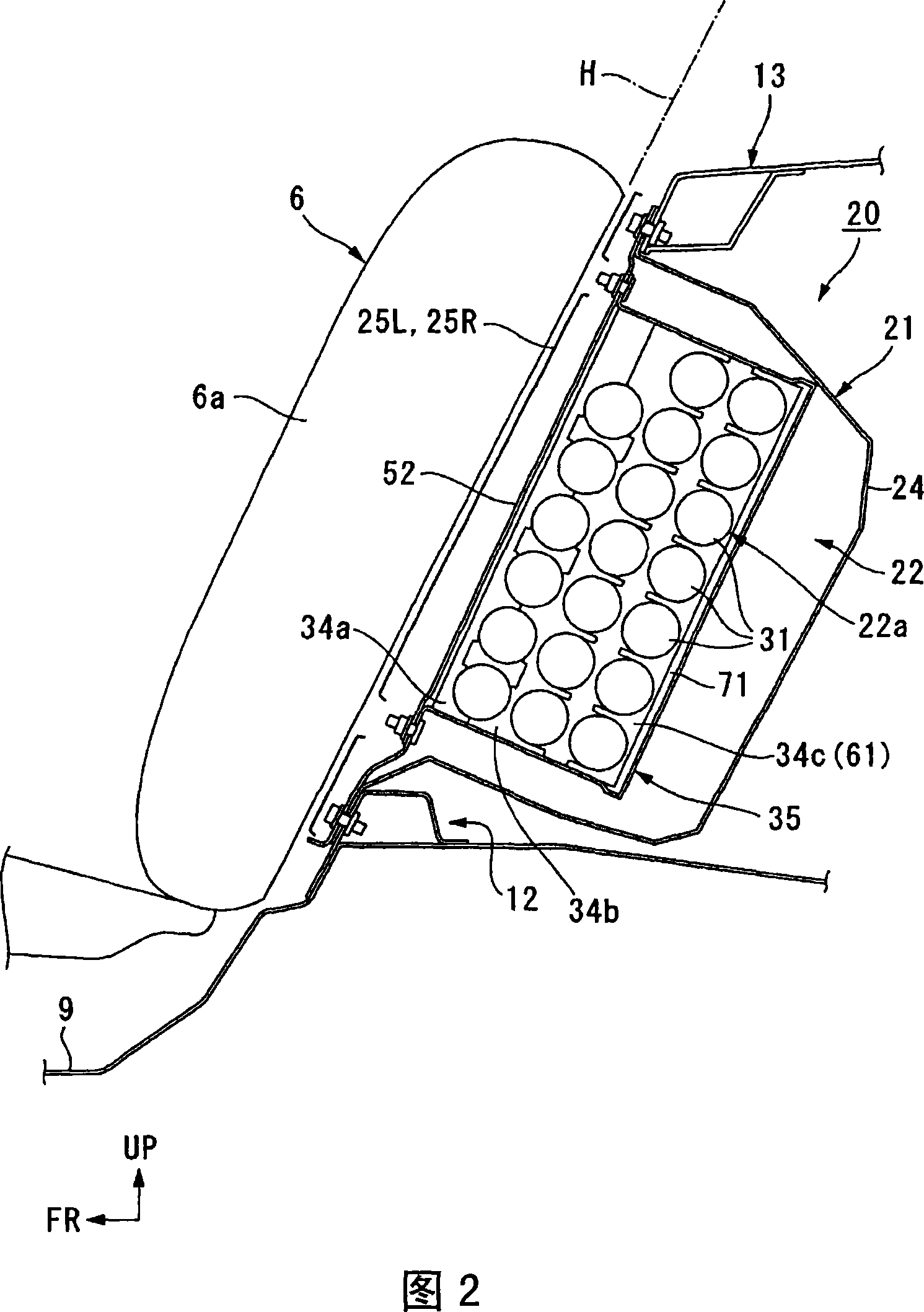

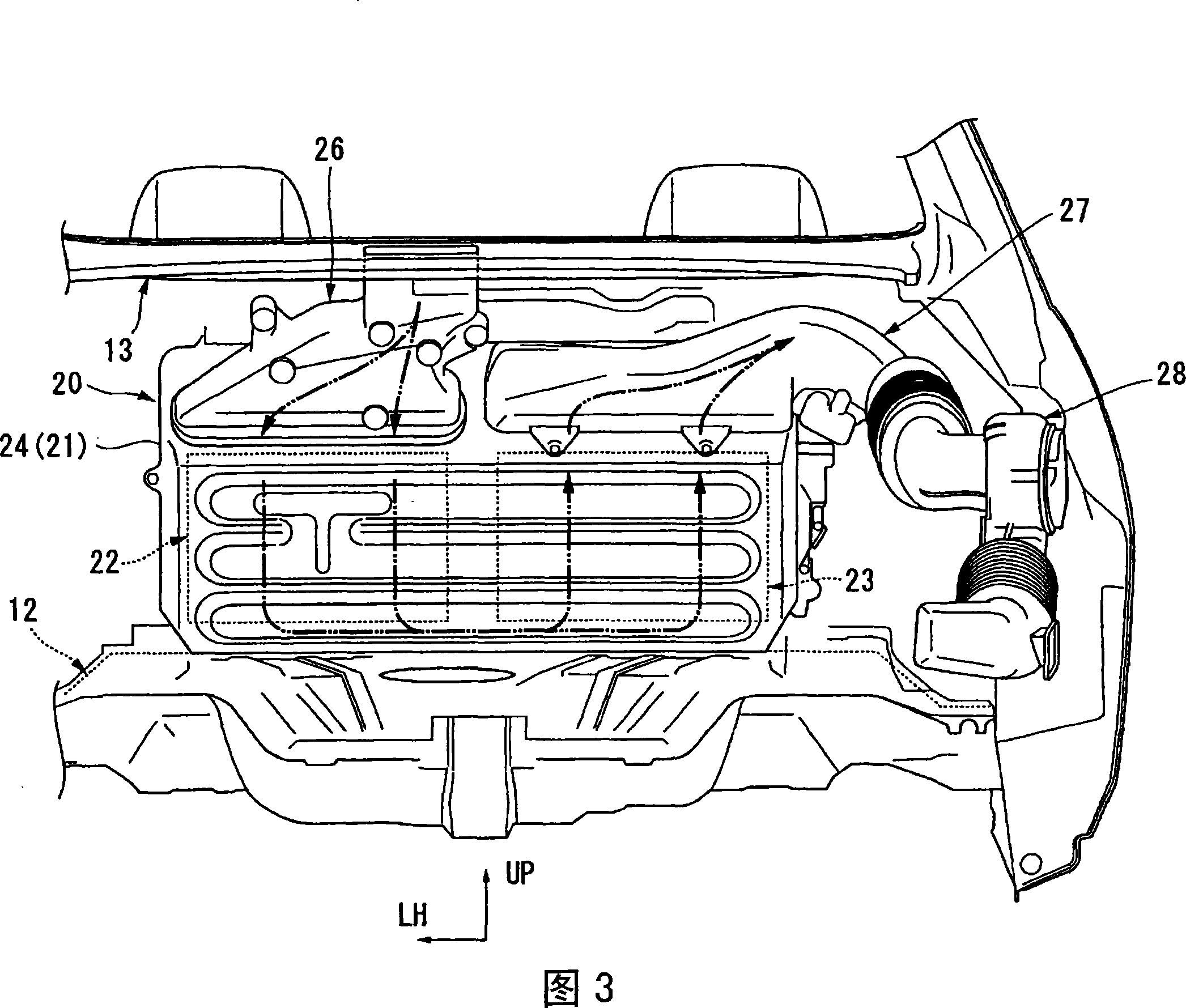

[0073] A power unit 3 in which the engine and a motor generator are arranged in series is mounted in an engine compartment 2 at the front of the vehicle body of the vehicle 1 , and driving force from the power unit 3 is transmitted to front wheels 4 . Behind the engine compartment 2 is provided a compartment 7 having a front seat 5 and a rear seat 6 , and behind the compartment 7 is provided a luggage compartment 8 divided by the compartment 7 and the seat backs 6 a of the rear seat 6 . Further, behind the seat back 6 a of the rear seat 6 (inside the luggage room 8 ), a high-voltage distribution box 20 connect...

Embodiment 2

[0125] Next, a second embodiment of this invention will be described.

[0126] This embodiment is different from the above-mentioned first embodiment in that instead of the sensor cover 80, a sensor cover 100 is used to attach the battery 31, and the same parts as those in the above-mentioned embodiment are given the same reference numerals, and the description thereof will be omitted. .

[0127] The sensor cover 100 shown in FIGS. 13 , 14 , and 15 is made of insulating resin like the sensor cover 80 described above, and is composed of a pair of semicircular bodies 101 and 102 that match the outer circumference of the battery 31 . Ends on one side of the circumferential direction of these semicircular bodies 101 and 102 are connected via, for example, a flexible thin-walled portion 103 (or via a hinge shaft), thereby constituting a hinge portion 104 .

[0128] In the state where the hinge part 104 is disposed on the longitudinal outer side of the battery 31, the semicircular ...

Embodiment 3

[0138] Next, a third embodiment of this invention will be described.

[0139] In this embodiment, the structure is that the wiring harness 128 (corresponding to the wiring 76 ) of the temperature sensor 75 installed on the battery assembly 121A is led out to the end plate 122 of the battery assembly 121A, and the The wire harness fixing device holds the wire harness 128, and the same reference numerals are assigned to the same parts as those in the above-mentioned embodiments, and the description thereof will be omitted.

[0140] As shown in FIGS. 17 and 18 , in a battery pack 121A of this embodiment, the positive and negative electrodes of a pair of batteries 31 are arranged differently from each other, and the ends thereof are connected by end plates 122 . At this time, a predetermined gap is formed between the two batteries 31 . A plurality of such battery packs 121A are arranged in a row, for example, stacked four layers up and down, and one end thereof is properly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com